ASTM G97-18

(Test Method)Standard Test Method for Laboratory Evaluation of Magnesium Sacrificial Anode Test Specimens for Underground Applications

Standard Test Method for Laboratory Evaluation of Magnesium Sacrificial Anode Test Specimens for Underground Applications

SIGNIFICANCE AND USE

5.1 This test is a guide for evaluating magnesium anodes. The degree of correlation between this test and service performance has not been fully determined.

5.2 Test specimens from the same casting may not be identical because of inhomogeneities in the casting. A method of ensuring that identical test specimens are being evaluated is to retest a test specimen. The surface of the test specimen should be smoothed by machining before retesting. The new diameter should be measured and the test current adjusted so that the retest current density is 0.039 mA/cm2 (0.25 mA/in.2).

5.3 The values of potential and Ah per unit mass consumed as measured by this test method, may not agree with those found in field applications. It is unlikely that field results of Ah per unit mass consumed would ever be greater than those measured in this test. However, actual test comparisons are not sufficient to allow precise correlation of laboratory and field results.

SCOPE

1.1 This test method covers a laboratory procedure that measures the two fundamental performance properties of magnesium sacrificial anode test specimens operating in a saturated calcium sulfate, saturated magnesium hydroxide environment. The two fundamental properties are electrode (oxidation) potential and ampere hours (Ah) obtained per unit mass of specimen consumed. Magnesium anodes installed underground are usually surrounded by a backfill material that typically consists of 75 % gypsum (CaSO4·2H2O), 20 % bentonite clay, and 5 % sodium sulfate (Na2SO4). The calcium sulfate, magnesium hydroxide test electrolyte simulates the long term environment around an anode installed in the gypsum-bentonite-sodium sulfate backfill.

1.2 This test method is intended to be used for quality assurance by anode manufacturers or anode users. However, long term field performance properties may not be identical to property measurements obtained using this laboratory test.

Note 1: Refer to Terminology G193 for terms used in this test method.

1.3 The values stated in SI units are to be regarded as standard. The values given in parentheses after SI units are provided for information only and are not considered standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use. For specific precautions, See Section 8 and Paragraph 9.1.1.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:G97 −18

Standard Test Method for

Laboratory Evaluation of Magnesium Sacrificial Anode Test

1

Specimens for Underground Applications

ThisstandardisissuedunderthefixeddesignationG97;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginal

adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.Asuperscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

2

1.1 This test method covers a laboratory procedure that 2.1 ASTM Standards:

measures the two fundamental performance properties of D1193 Specification for Reagent Water

magnesium sacrificial anode test specimens operating in a E691 Practice for Conducting an Interlaboratory Study to

saturated calcium sulfate, saturated magnesium hydroxide Determine the Precision of a Test Method

environment. The two fundamental properties are electrode G3 Practice for Conventions Applicable to Electrochemical

(oxidation) potential and ampere hours (Ah) obtained per unit Measurements in Corrosion Testing

mass of specimen consumed. Magnesium anodes installed G16 Guide for Applying Statistics to Analysis of Corrosion

underground are usually surrounded by a backfill material that Data

typically consists of 75 % gypsum (CaSO ·2H O), 20 % ben- G193 Terminology and Acronyms Relating to Corrosion

4 2

tonite clay, and 5 % sodium sulfate (Na SO ). The calcium G215 Guide for Electrode Potential Measurement

2 4

sulfate, magnesium hydroxide test electrolyte simulates the

2.2 American National Standard:

long term environment around an anode installed in the

ANSI/NFPA 480 Storage,Handling,andProcessingofMag-

gypsum-bentonite-sodium sulfate backfill. 3

nesium Solids and Powders, 1998 Edition

1.2 This test method is intended to be used for quality

assurance by anode manufacturers or anode users. However, 3. Terminology

long term field performance properties may not be identical to

3.1 Definitions—The terminology used herein shall be in

property measurements obtained using this laboratory test.

accordance with Terminology G193.

NOTE1—RefertoTerminologyG193fortermsusedinthistestmethod.

4. Summary of Test Method

1.3 The values stated in SI units are to be regarded as

standard. The values given in parentheses after SI units are 4.1 A known direct current is passed through test cells

provided for information only and are not considered standard. connected in series. Each test cell consists of a pre-weighed

test magnesium alloy anode specimen, a steel pot container

1.4 This standard does not purport to address all of the

cathode, and a known electrolyte. Test specimen oxidation

safety concerns, if any, associated with its use. It is the

potential is measured several times during the 14-day test and

responsibility of the user of this standard to establish appro-

1 h after the current is turned off at the end of the test.The total

priate safety, health, and environmental practices and deter-

Ah passed through the cells are measured.At the conclusion of

mine the applicability of regulatory limitations prior to use.

the test, each test specimen is cleaned and weighed. The Ah

For specific precautions, See Section 8 and Paragraph 9.1.1.

obtained per unit mass of specimen lost is calculated.

1.5 This international standard was developed in accor-

dance with internationally recognized principles on standard-

5. Significance and Use

ization established in the Decision on Principles for the

Development of International Standards, Guides and Recom-

5.1 This test is a guide for evaluating magnesium anodes.

mendations issued by the World Trade Organization Technical

The degree of correlation between this test and service perfor-

Barriers to Trade (TBT) Committee. mance has not been fully determined.

1 2

This test method is under the jurisdiction of ASTM Committee G01 on For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Corrosion of Metals and is the direct responsibility of Subcommittee G01.10 on contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Corrosion in Soils. Standards volume information, refer to the standard’s Document Summary page on

Current edition approved Nov. 1, 2018. Published December 2018. Originally the ASTM website.

3

approved in 1989. Last previous edition approved in 2013 as G97 – 97 (2013). DOI: Available from National Fire Protection Association (NFPA), 1 Batterymarch

10.1520/G0097-18. Park, Quincy, MA 02169-7471, http://www.nfpa.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

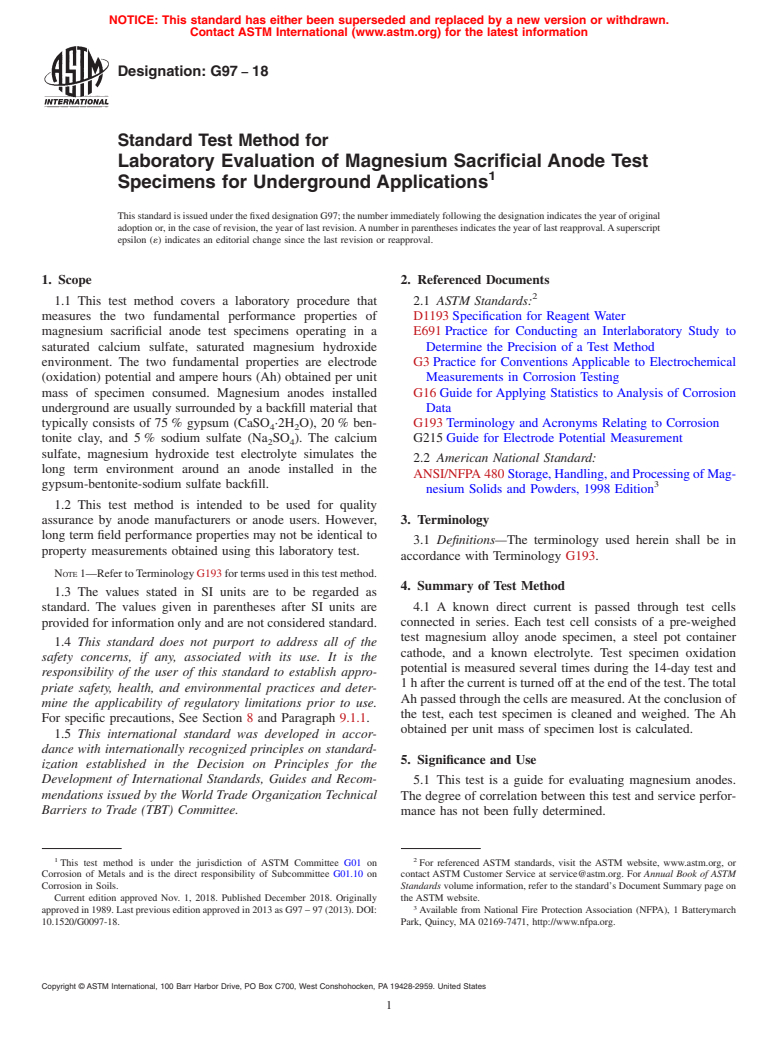

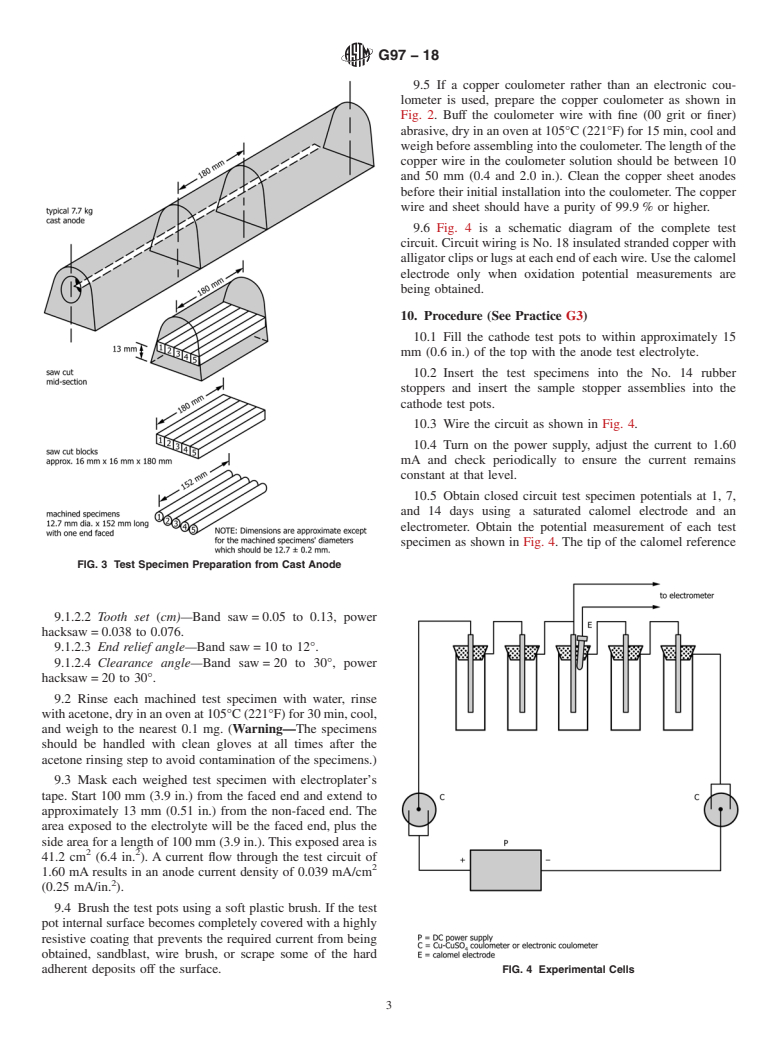

G97−18

5.2 Test specimens from the same casting may not be

identical because of inhomogeneities in the casting. A method

of ensuri

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: G97 − 97 (Reapproved 2013) G97 − 18

Standard Test Method for

Laboratory Evaluation of Magnesium Sacrificial Anode Test

1

Specimens for Underground Applications

This standard is issued under the fixed designation G97; the number immediately following the designation indicates the year of original

adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A superscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method covers a laboratory procedure that measures the two fundamental performance properties of magnesium

sacrificial anode test specimens operating in a saturated calcium sulfate, saturated magnesium hydroxide environment. The two

fundamental properties are electrode (oxidation potential)(oxidation) potential and ampere hours (Ah) obtained per unit mass of

specimen consumed. Magnesium anodes installed underground are usually surrounded by a backfill material that typically consists

of 75 % gypsum (CaSO ·2H O), 20 % bentonite clay, and 5 % sodium sulfate (Na SO ). The calcium sulfate, magnesium

4 2 2 4

hydroxide test electrolyte simulates the long term environment around an anode installed in the gypsum-bentonite-sodium sulfate

backfill.

1.2 This test method is intended to be used for quality assurance by anode manufacturers or anode users. However, long term

field performance properties may not be identical to property measurements obtained using this laboratory test.

NOTE 1—Refer to Terminology G15G193 for terms used in this test method.

1.3 The values stated in SI units are to be regarded as standard. The values given in parentheses after SI units are provided for

information only and are not considered standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the

applicability of regulatory limitations prior to use. For specific precautions, See Section 78 and Paragraph 8.1.19.1.1.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

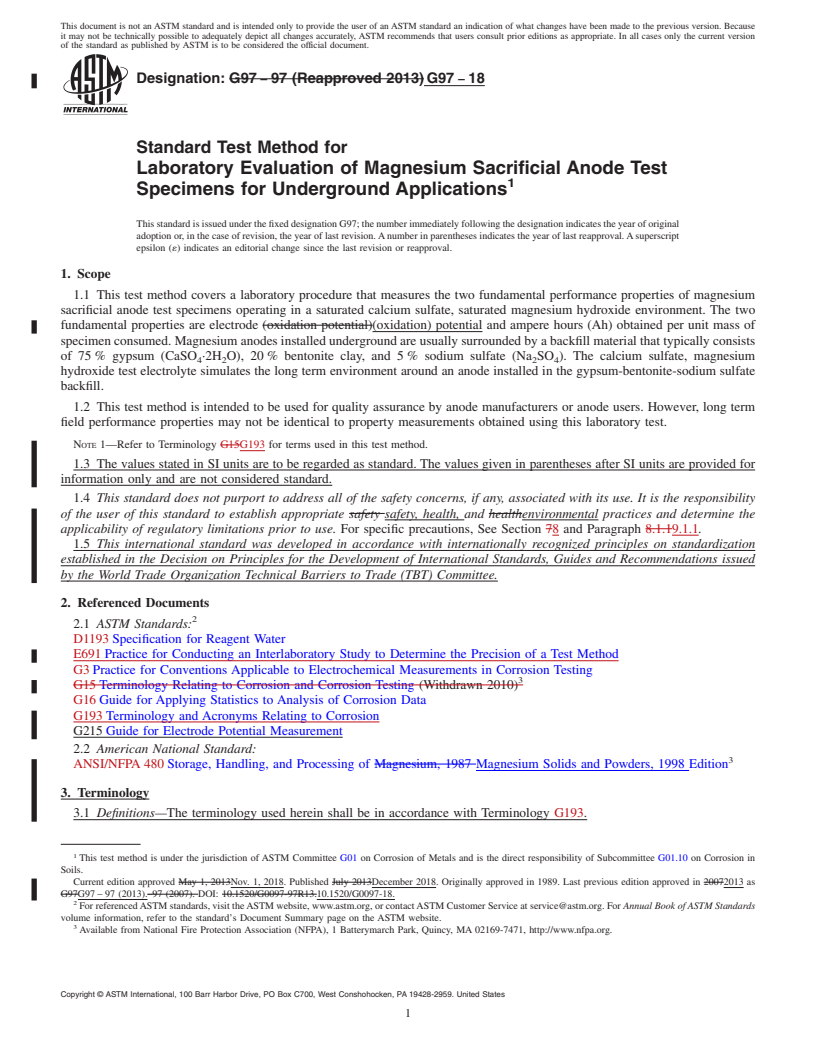

2. Referenced Documents

2

2.1 ASTM Standards:

D1193 Specification for Reagent Water

E691 Practice for Conducting an Interlaboratory Study to Determine the Precision of a Test Method

G3 Practice for Conventions Applicable to Electrochemical Measurements in Corrosion Testing

3

G15 Terminology Relating to Corrosion and Corrosion Testing (Withdrawn 2010)

G16 Guide for Applying Statistics to Analysis of Corrosion Data

G193 Terminology and Acronyms Relating to Corrosion

G215 Guide for Electrode Potential Measurement

2.2 American National Standard:

3

ANSI/NFPA 480 Storage, Handling, and Processing of Magnesium, 1987 Magnesium Solids and Powders, 1998 Edition

3. Terminology

3.1 Definitions—The terminology used herein shall be in accordance with Terminology G193.

1

This test method is under the jurisdiction of ASTM Committee G01 on Corrosion of Metals and is the direct responsibility of Subcommittee G01.10 on Corrosion in

Soils.

Current edition approved May 1, 2013Nov. 1, 2018. Published July 2013December 2018. Originally approved in 1989. Last previous edition approved in 20072013 as

G97G97 – 97 (2013).–97 (2007). DOI: 10.1520/G0097-97R13.10.1520/G0097-18.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

Available from National Fire Protection Association (NFPA), 1 Batterymarch Park, Quincy, MA 02169-7471, http://www.nfpa.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

G97 − 18

4. Summary of Test Method

4.1 A known direct current is passed through test cells connected in series. Each test cell consists of a pre-weighed test

magnesium alloy anode specimen, a steel pot container cathode, and a known electrolyte. Test specimen oxidation potential is

measured several times during the 14-day test and 1 h after the curren

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.