ASTM D5439-95(2012)

(Test Method)Standard Test Method for Determination of Sediment in Moellon

Standard Test Method for Determination of Sediment in Moellon

SIGNIFICANCE AND USE

This test method is intended for use in determining the toluene insoluble sediment contained in Moellon.

SCOPE

1.1 This test method covers the determination of the toluene insoluble sediment contained in Moellon. This test method was derived from Test Method D473.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D5439 − 95 (Reapproved 2012)

Standard Test Method for

Determination of Sediment in Moellon

This standard is issued under the fixed designation D5439; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 4.1.1 ExtractionFlask,awide-neckErlenmeyerflaskof1-L

capacity.

1.1 This test method covers the determination of the toluene

4.1.2 Condenser, a condenser in the form of a metal coil

insolublesedimentcontainedinMoellon.Thistestmethodwas

approximately 25 mm in diameter and 50 mm in length

derived from Test Method D473.

attached to, and with the ends projecting through a lid of

1.2 The values stated in SI units are to be regarded as

sufficient diameter to cover the neck of the flask as shown in

standard. No other units of measurement are included in this

Fig. 1. The coil should be made from stainless steel, tin,

standard.

tin-plated copper, or tin-plated brass tubing having an outside

1.3 This standard does not purport to address all of the

diameter of 5 to 8 mm and a wall thickness of 1.5 mm. If

safety concerns, if any, associated with its use. It is the

constructed of tin-plated copper or brass, the tin coating shall

responsibility of the user of this standard to establish appro-

have a minimum thickness of 0.075 mm. The exposed surface

priate safety and health practices and determine the applica-

of the coil for cooling purposes is about 115 cm .

bility of regulatory limitations prior to use.

4.1.3 ExtractionThimble—Theextractionthimbleshouldbe

2. Referenced Documents of a refractory porous material, pore size index P15, 25 mm in

2 diameter by 70 mm in height, weighing not less than 15 g and

2.1 ASTM Standards:

not more than 17 g. The thimble shall be suspended from the

D473 Test Method for Sediment in Crude Oils and Fuel Oils

condenser coil by means of a basket so that it hangs approxi-

by the Extraction Method

mately midway between the surface of the extracting solvent

D4057 Practice for Manual Sampling of Petroleum and

and the bottom of the condenser coil.

Petroleum Products

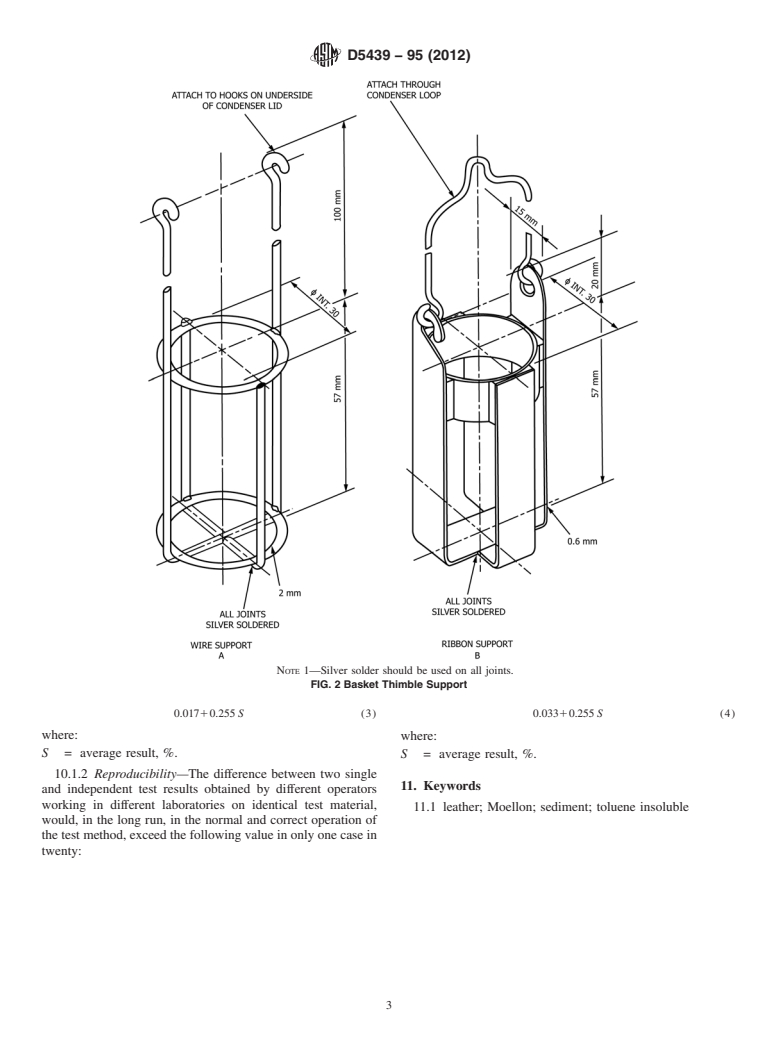

D4177 Practice for Automatic Sampling of Petroleum and 4.1.4 Thimble Basket—The thimble basket shall be

corrosion-resistant, shall be made of platinum, stainless steel,

Petroleum Products

nickel-chromium alloy, or similar material, and shall meet the

2.2 ISO Standard:

requirements of Fig. 2.

ISO 5272 Toluene for Industrial Use - Specifications

4.1.5 Water Cup—Awater cup shall be used when testing a

3. Significance and Use

samplehavingahigh-watercontent(seeFig.1b).Thecupshall

3.1 This test method is intended for use in determining the

be made of glass, shall be conical in shape, shall be approxi-

toluene insoluble sediment contained in Moellon.

mately 20 mm in diameter and 25 mm deep, and shall have a

capacity of approximately 3 mL.Aglass hook fused on the rim

4. Apparatus

at one side is so shaped that when hung on the condenser the

4.1 Extraction Apparatus (see Fig. 1 and Fig. 2), consisting

cup hangs with its rim reasonably level. In this procedure, the

of the parts described in 4.1.1 – 4.1.6.

thimble basket is suspended either as shown in Fig. 1aby

meansofthecorrosion-resistantwireloopedoverthebottomof

the condenser coil and attached to the basket supports or as in

This test method is under the jurisdiction ofASTM Committee D31 on Leather

Fig. 1b where the wire supports of the basket are attached to

and is the direct responsibility of Subcommittee D31.08 on Fats and Oils. This test

method was developed in cooperation with the American Leather Chemists Assn. hooks soldered to the underside of the condenser lid.

(Method H 23–1957).

4.1.6 SourceofHeat,asourceofheat,preferablyahotplate,

Current edition approved April 1, 2012. Published April 2012. Originally

suitable for vaporizing toluene.

approved in 1993. Last previous edition approved in 2006 as D5439 – 95(2006).

DOI: 10.1520/D5439-95R12.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

5. Solvent

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

5.1 Toluene, conforming to ISO 5272, Grade 2.

the ASTM website.

(Warning—Flammable.)

Available from American National Standards Institute, 11 West 42nd St., 13th

Floor, New York, NY 10036. 5.1.1 The typical characteristics for the reagent are:

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D5439 − 95 (2012)

7.4 When testing samples having a high water content, use

the assembly shown in Fig. 1b. In this procedure, any water in

the test portion is removed as its toluene azeotrope and is

collected in the water cup, where it separates as a bottom layer.

The toluene layer overflows into the thimble. If the cup

becomes full of water, allow the apparatus to cool and empty

the cup.

7.5 After the extraction is completed, dry the thimble for 1

h at 115 to 120°C; cool in a desiccator, without desiccant, for

1 h and weigh to the nearest 0.2 mg.

7.6 Repeat the extraction, allowing the solvent to drip from

NOTE 1—Apparatus B shows the water cup in position.

thethimbleforatleast1hbutnotlongerthan1.25h;dry,cool,

FIG. 1 Extraction Apparatus for Determination of Sediment

and weigh the thimble as described in 7.5. Repeat this

extraction for further 1-h periods, if necessary, until the masses

of the dried thimble plus sediment, after two successive

extractions, do not differ by more than 0.2 mg.

Color (APHA) 10

A

Boiling range (initial to dry point) 2.0°C

Residue after evaporation 0.001 %

8. Calculation

Substances darkened by H SO passes ACS test

2 4

Sulfur compounds (as S) 0.003 % 8.1 Calculate the mass

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.