ASTM D5265-03(2009)

(Test Method)Standard Test Method for Bridge Impact Testing

Standard Test Method for Bridge Impact Testing

SIGNIFICANCE AND USE

Materials shipped in long, narrow packages, with lengths at least three times their width or height, are liable to damage as a result of impact near their midpoint when only the ends are supported. This type of damage can occur during the shipment of packaging of mixed dimensions. It is particularly prevalent during conveyer line transport and sortation. This test method provides a means of determining resistance to such damage.

SCOPE

1.1 This test method is intended to determine the capability of a long package with a narrow cross-section to resist impact near its center when the package is supported only at its ends. This test method allows the user to select from two test options: Option A employs the use of a free-fall drop tester (see Exhibit B), and Option B employs the use of simulated mechanical impact testing equipment (SMITE; see Exhibit A). The two optional procedures are designed to impart the same amount of kinetic energy at impact; therefore, each procedure yields equal damage-producing potential.

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information.

Designation:D5265–03 (Reapproved 2009)

Standard Test Method for

Bridge Impact Testing

This standard is issued under the fixed designation D5265; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3. Terminology

1.1 This test method is intended to determine the capability 3.1 Definitions—The terms and definitions used in this test

of a long package with a narrow cross-section to resist impact method may be found in Terminology D996.

near its center when the package is supported only at its ends. 3.2 Definitions of Terms Specific to This Standard:

Thistestmethodallowstheusertoselectfromtwotestoptions: 3.2.1 elongate package—a package that is long in propor-

OptionAemploys the use of a free-fall drop tester (see Exhibit tion to width and thickness, with lengths at least three times

B), and Option B employs the use of simulated mechanical their width or height.

impact testing equipment (SMITE; see Exhibit A). The two

4. Significance and Use

optional procedures are designed to impart the same amount of

kineticenergyatimpact;therefore,eachprocedureyieldsequal 4.1 Materials shipped in long, narrow packages, with

lengths at least three times their width or height, are liable to

damage-producing potential.

1.2 The values stated in SI units are to be regarded as the damage as a result of impact near their midpoint when only the

ends are supported. This type of damage can occur during the

standard. The values given in parentheses are for information

only. shipment of packaging of mixed dimensions. It is particularly

prevalentduringconveyerlinetransportandsortation.Thistest

1.3 This standard does not purport to address all of the

safety problems, if any, associated with its use. It is the method provides a means of determining resistance to such

damage.

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

5. Apparatus

bility of regulatory limitations prior to use.

5.1 Option A—Free-Fall Drop Tester, conforming to the

2. Referenced Documents

conditions specified in 10.2.1 (see Fig. 1).

2.1 ASTM Standards: 5.1.1 Impactor,composedofadensehardwood,withamass

of 5.7 6 0.2 kg (12.546 0.4 lb), length of approximately 610

D644 Test Method for Moisture Content of Paper and

w

Paperboard by Oven Drying mm (24 in.), and width of 178 mm (7 in.). The depth can be

adjusted to obtain the desired weight as stated above. The long

D685 Practice for Conditioning Paper and Paper Products

for Testing edges of the impactor shall be rounded to a radius of 6 62mm

1 1

( ⁄4 6 ⁄16 in.).

D996 Terminology of Packaging and Distribution Environ-

ments

NOTE 1—If a lighter wood is used, the depth can be adjusted to achieve

D4332 Practice for Conditioning Containers, Packages, or

the correct mass.

Packaging Components for Testing

5.1.2 Support Blocks, made from hardwood, nominal 150

E122 Practice for Calculating Sample Size to Estimate,

by 150 mm (6 by 6 in.), long enough to support the full width

With Specified Precision, the Average for a Characteristic

of the largest package to be tested.

of a Lot or Process

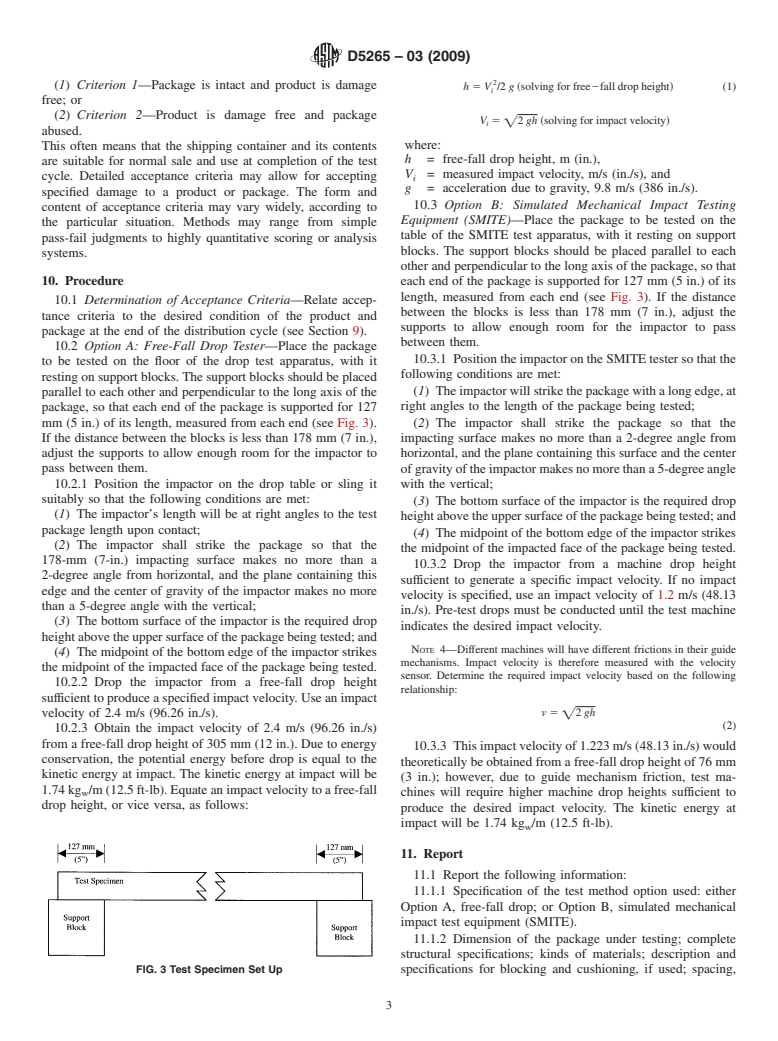

5.2 Option B—Commercial SMITE Tester, using a guided

impactor and velocity meter to calculate the theoretical free-

1 fall drop of the missile (see Fig. 2).

This test method is under the jurisdiction of ASTM Committee D10 on

Packaging and is the direct responsibility of Subcommittee D10.22 on Physical Test 5.2.1 SMITE Tester Impactor (missile), fabricated in a

Methods.

U-shape cross-section from a steel flat plate, with a mass of

Current edition approved March 1, 2009. Published March 2009. Originally

22.68 60.2kg (50 60.4lb)andlengthofapproximately760

w

approved in 1992. Last previous edition approved in 2003 as D5265 – 03 DOI:

mm (30 in.). The long edges of the missile shall be rounded to

10.1520/D5265-03R09.

1 1

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

a radius of 6 62mm( ⁄4 6 ⁄16 in.).

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

NOTE 2—The standard SMITE tester is equipped with a variety of

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. interchangeable missiles, providing impact options ranging from flat drop,

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D5265–03 (2009)

5.2.2 Support Blocks, made from dense hardwood, nominal

150 by 150 mm (6 by 6 in.), long enough to support the full

width of the largest package to be tested.

6. Sampling

6.1 The test specimens and number of samples shall be

chosen to permit an adequate determination of representative

performance. For large production runs, lot sampling for

quality control in accordance with Practice E122 is advised.

6.2 In the absence of any sampling plan, at least three

representative specimens should be selected for performance

evaluation.

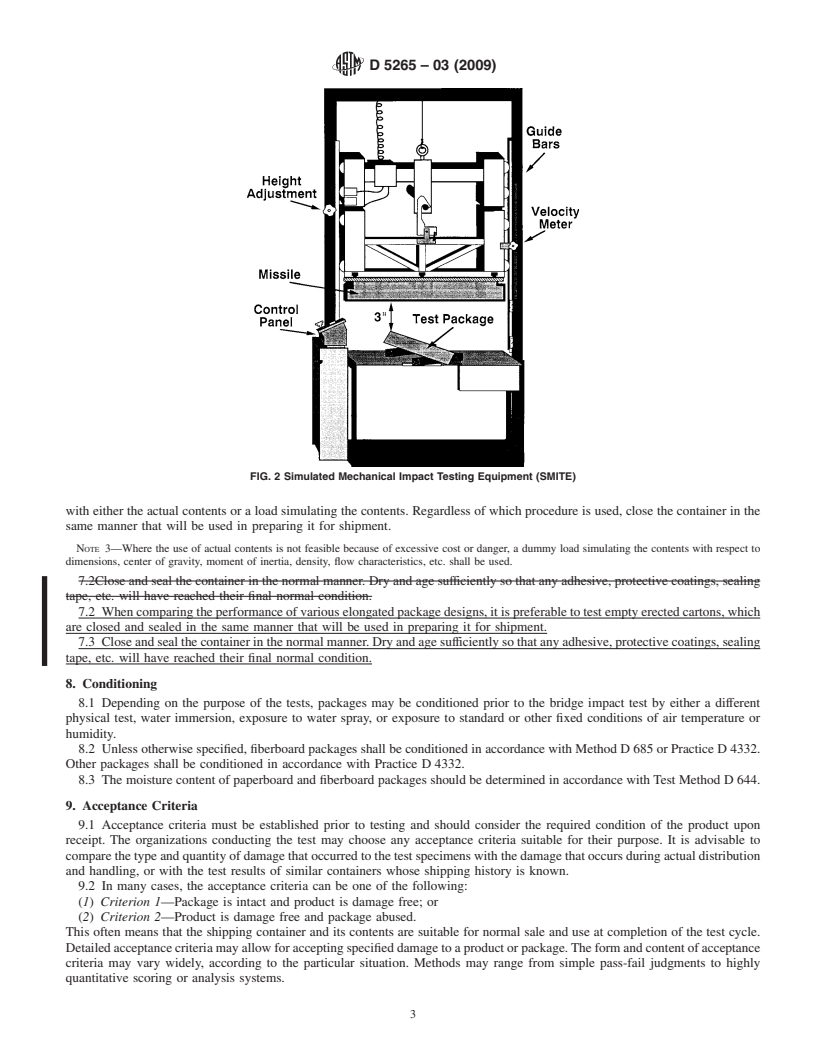

7. Test Specimens

7.1 When the protective capability of a package is to be

evaluated, it is preferable to pack the package with the actual

contents for which it was designed (Note 3). When the

capability of a box to withstand rough handling is to be

evaluated, pack the container with either the actual contents or

a load simulating the contents. Regardless of which procedure

is used, close the container in the same manner that will be

used in preparing it for shipment.

NOTE 3—Where the use of actual contents is not feasible because of

excessive cost or danger, a dummy load simulating the contents with

respect to dimensions, center of gravity, moment of inertia, density, flow

characteristics, etc. shall be used.

7.2 When comparing the performance of various elongated

FIG. 1 Vertical Drop Tester

package designs, it is preferable to test empty erected cartons,

which are closed and sealed in the same manner that will be

used in preparing it for shipment.

7.3 Close and seal the container in the normal manner. Dry

and age sufficiently so that any adhesive, protective coatings,

sealingtape,etc.willhavereachedtheirfinalnormalcondition.

8. Conditioning

8.1 Depending on the purpose of the tests, packages may be

conditioned prior to the bridge impact test by either a different

physical test, water immersion, exposure to water spray, or

exposure to standard or other fixed conditions of air tempera-

ture or humidity.

8.2 Unless otherwise specified, fiberboard packages shall be

conditioned in accordance with Method D685 or Practice

D4332. Other packages shall be conditioned in accordance

with Practice D4332.

8.3 The moisture content of paperboard and fiberboard

packages should be determined in accordance with Test

Method D644.

9. Acceptance Criteria

9.1 Acceptance criteria must be established prior to testing

and should consider the required condition of the product upon

receipt. The organizations conducting the test may choose any

acceptance criteria suitable for their purpose. It is advisable to

compare the type and quantity of damage that occurred to the

test specimens with the damage that occurs during actual

FIG. 2 Simulated Mechanical Impact Testing Equipment (SMITE)

distribution and handling, or with the test results of similar

containers whose shipping history is known.

angle edge drop, half round, half ball, and corner. The total missile

9.2 In many cases, the acceptance criteria can be one of the

assembly, regardless of which face is used, will weigh 22.68 kg (50 lb).

Knowing this, the mass of a SMITE tester is always 22.68 kg. following:

D5265–03 (2009)

(1) Criterion 1—Package is intact and product is damage

h 5 V /2 g ~solving for free2fall

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

´1

Designation:D5265–92 (Reapproved 1998) Designation: D 5265 – 03 (Reapproved

2009)

Standard Test Method for

Bridge Impact Testing

This standard is issued under the fixed designation D 5265; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

´ NOTE—Editorial changes were made in October 1998.

1. Scope

1.1 This test method is intended to determine the capability of a long package with a narrow cross-section to resist impact near

its center when the package is supported only at its ends. This test method allows the user to select from two test options: Option

Aemploys the use of a free-fall drop tester (see Exhibit B), and Option B employs the use of simulated mechanical impact testing

equipment (SMITE; see Exhibit A). The two optional procedures are designed to impart the same amount of kinetic energy at

impact; therefore, each procedure yields equal damage-producing potential.

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2.1 ASTM Standards:

D 644 Test Method for Moisture Content of Paper and Paperboard by Oven Drying

D 685 Practice for Conditioning Paper and Paper Products for Testing

D775Method for Drop Test for Loaded Boxes Practice for Conditioning Paper and Paper Products for Testing

D 996 Terminology of Packaging and Distribution Environments

D 4332 Practice for Conditioning Containers, Packages, or Packaging Components for Testing

E 122 PracticeforChoiceofSampleSizetoEstimateaMeasureofQualityforaLotorProcessPracticeforCalculatingSample

Size to Estimate, With Specified Precision, the Average for a Characteristic of a Lot or Process

3. Terminology

3.1 Definitions—The terms and definitions used in this test method may be found in Terminology D 996.

3.2 Definitions of Terms Specific to This Standard:

3.2.1 elongate package—apackagethatislonginproportiontowidthandthickness,withlengthsatleastthreetimestheirwidth

or height.

4. Significance and Use

4.1 Materials shipped in long, narrow packages, with lengths at least three times their width or height, are liable to damage as

a result of impact near their midpoint when only the ends are supported. This type of damage can occur during the shipment of

packaging of mixed dimensions. It is particularly prevalent during conveyer line transport and sortation.This test method provides

a means of determining resistance to such damage.

This test method is under the jurisdiction of ASTM Committee D-10 on Packaging and is the direct responsibility of Subcommittee D10.22 on Handling and

Transportation .

Current edition approved July 15, 1992. Published October 1992.

This test method is under the jurisdiction of ASTM Committee D10 on Packaging and is the direct responsibility of Subcommittee D10.22 on Physical Test Methods

.

Current edition approved March 1, 2009. Published March 2009. Originally approved in 1992. Last previous edition approved in 2003 as D 5265 – 03

Annual Book of ASTM Standards, Vol 15.09.

ForreferencedASTMstandards,visittheASTMwebsite,www.astm.org,orcontactASTMCustomerServiceatservice@astm.org.ForAnnualBookofASTMStandards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D 5265 – 03 (2009)

5. Apparatus

5.1 Option A—Free-Fall Drop Tester, conforming to Method D775 , conforming to the conditions specified in 10.2.1 (see Fig.

1).

5.1.1 Impactor, composed of a dense hardwood, with a mass of 5.7 6 0.2 kg (12.546 0.4 lb), length of approximately 610 mm

w

(24 in.), and width of 178 mm (7 in.). The depth can be adjusted to obtain the desired weight as stated above. The long edges of

1 1

the impactor shall be rounded to a radius of 6 62mm( ⁄4 6 ⁄16 in.).

NOTE 1—If a lighter wood is used, the depth can be adjusted to achieve the correct mass.

5.1.2 Support Blocks, made from hardwood, nominal 150 by 150 mm (6 by 6 in.), long enough to support the full width of the

largest package to be tested.

5.2 Option B—Commercial SMITETester, using a guided impactor and velocity meter to calculate the theoretical free-fall drop

of the missile (see Fig. 2).

5.2.1 SMITE Tester Impactor (missile) , fabricated in a U-shape cross-section from a steel flat plate, with a mass of 22.68 6

0.2 kg (50 6 0.4 lb) and length of approximately 760 mm (30 in.). The long edges of the missile shall be rounded to a radius

w

1 1

of 6 62mm( ⁄4 6 ⁄16 in.).

NOTE 2—The standard SMITE tester is equipped with a variety of interchangeable missiles, providing impact options ranging from flat drop, angle

edge drop, half round, half ball, and corner. The total missile assembly, regardless of which face is used, will weigh 22.68 kg (50 lb). Knowing this, the

mass of a SMITE tester is always 22.68 kg.

5.2.2 Support Blocks, made from dense hardwood, nominal 150 by 150 mm (6 by 6 in.), long enough to support the full width

of the largest package to be tested.

6. Sampling

6.1 The test specimens and number of samples shall be chosen to permit an adequate determination of representative

performance. For large production runs, lot sampling for quality control in accordance with Practice E 122 is advised.

6.2 In the absence of any sampling plan, at least three representative specimens should be selected for performance evaluation.

7. Test Specimens

7.1 When the protective capability of a package is to be evaluated, it is preferable to pack the package with the actual contents

for which it was designed (Note 3).When the capability of a box to withstand rough handling is to be evaluated, pack the container

FIG. 1 Vertical Drop Tester

D 5265 – 03 (2009)

FIG. 2 Simulated Mechanical Impact Testing Equipment (SMITE)

with either the actual contents or a load simulating the contents. Regardless of which procedure is used, close the container in the

same manner that will be used in preparing it for shipment.

NOTE 3—Where the use of actual contents is not feasible because of excessive cost or danger, a dummy load simulating the contents with respect to

dimensions, center of gravity, moment of inertia, density, flow characteristics, etc. shall be used.

7.2Close and seal the container in the normal manner. Dry and age sufficiently so that any adhesive, protective coatings, sealing

tape, etc. will have reached their final normal condition.

7.2 Whencomparingtheperformanceofvariouselongatedpackagedesigns,itispreferabletotestemptyerectedcartons,which

are closed and sealed in the same manner that will be used in preparing it for shipment.

7.3 Closeandsealthecontainerinthenormalmanner.Dryandagesufficientlysothatanyadhesive,protectivecoatings,sealing

tape, etc. will have reached their final normal condition.

8. Conditioning

8.1 Depending on the purpose of the tests, packages may be conditioned prior to the bridge impact test by either a different

physical test, water immersion, exposure to water spray, or exposure to standard or other fixed conditions of air temperature or

humidity.

8.2 Unless otherwise specified, fiberboard packages shall be conditioned in accordance with Method D 685 or Practice D 4332.

Other packages shall be conditioned in accordance with Practice D 4332.

8.3 The moisture content of paperboard and fiberboard packages should be determined in accordance with Test Method D 644.

9. Acceptance Criteria

9.1 Acceptance criteria must be established prior to testing and should consider the required condition of the product upon

receipt. The organizations conducting the te

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.