ASTM D5121-22

(Practice)Standard Practice for Preparation of Rock Slabs for Durability Testing

Standard Practice for Preparation of Rock Slabs for Durability Testing

SIGNIFICANCE AND USE

4.1 This practice is used to prepare rock specimens for durability testing and to evaluate any internal defects, such as cracks, that may not be apparent on the surfaces of broken blocks of rock. Such evaluation can also aid in the selection and location of slabs for testing as outlined in Practice D4992. In some cases, the need for further testing or evaluation may be eliminated.

4.2 The sawing of rock samples will reduce them to a suitable specimen size and quantity for testing and, in many cases, preserve the natural structure of the internal defects so the samples can be evaluated by the various durability tests.

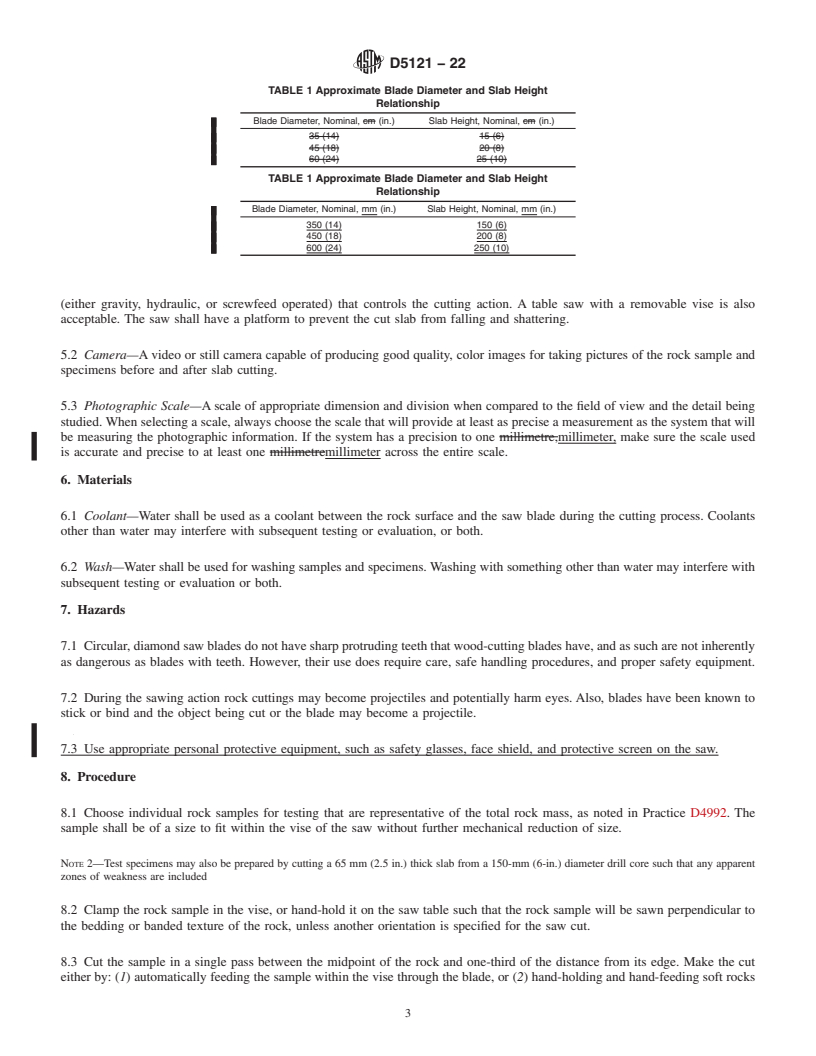

4.3 Durability tests specimens should be 65 ± 5 mm (2.5 ± 0.25 in) thick normal to bedding or any potential planes of weakness which may be observed in the samples. In no case will the size of the slab be less than 125 mm (5 in.) on a side, excluding the thickness Ideally, a test specimen size equal to the proposed design size would provide the ultimate in correlation between laboratory tests and actual field performance. However, in most cases, this is neither practical nor economically feasible.

Note 1: The quality of the result produced by this standard is dependent upon the competence of the personnel performing it, and the suitability of the equipment and facilities used. Agencies that meet the criteria of Practice D3740 are generally considered capable of competent and objective testing/sampling/inspection/etc. Users of this standard are cautioned that compliance with Practice D3740 does not in itself assure reliable results. Reliable results depend on many factors; Practice D3740 provides a means of evaluation some of those factors.

SCOPE

1.1 This practice covers the preparation of rock slabs for various tests and any visual inspections used to evaluate the durability of rock for erosion control. These tests include, but are not limited to, Test Methods D5240/D5240M, D5312/D5312M, and D5313/D5313M. This practice is appropriate for the assessment of breakwater stone, armor stone, riprap, and gabion sized rock materials.

1.2 Units—The values stated in SI units are to be regarded as standard. The inch-pound units given in parentheses are for information only.

1.3 All observed and measured values shall conform to the guidelines for significant digits and rounding established in Practice D6026, unless superseded by this standard.

1.4 This practice offers a set of instructions for performing one or more specific operations. This document cannot replace education or experience and should be used in conjunction with professional judgment. Not all aspects of this practice may be applicable in all circumstances. This ASTM standard is not intended to represent or replace the standard of care by which the adequacy of a given professional service must be judged, nor should this document be applied without consideration of a project's many unique aspects. The word “Standard” in the title of this document means only that the document has been approved through the ASTM consensus process.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use. For a specific hazards statement, see Section 7.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D5121 − 22

Standard Practice for

1

Preparation of Rock Slabs for Durability Testing

This standard is issued under the fixed designation D5121; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* mendations issued by the World Trade Organization Technical

Barriers to Trade (TBT) Committee.

1.1 This practice covers the preparation of rock slabs for

various tests and any visual inspections used to evaluate the

2. Referenced Documents

durability of rock for erosion control. These tests include, but

2

2.1 ASTM Standards:

are not limited to, Test Methods D5240/D5240M, D5312/

D653 Terminology Relating to Soil, Rock, and Contained

D5312M, and D5313/D5313M.This practice is appropriate for

Fluids

the assessment of breakwater stone, armor stone, riprap, and

D3740 Practice for Minimum Requirements for Agencies

gabion sized rock materials.

Engaged in Testing and/or Inspection of Soil and Rock as

1.2 Units—The values stated in SI units are to be regarded

Used in Engineering Design and Construction

as standard. The inch-pound units given in parentheses are for

D4992 Practice for Evaluation of Rock to be Used for

information only.

Erosion Control

1.3 All observed and measured values shall conform to the D5240/D5240M Test Method for Evaluation of the Durabil-

guidelines for significant digits and rounding established in ity of Rock for Erosion Control Using Sodium Sulfate or

Practice D6026, unless superseded by this standard. Magnesium Sulfate

D5312/D5312M TestMethodforEvaluationofDurabilityof

1.4 This practice offers a set of instructions for performing

Rock for Erosion Control Under Freezing and Thawing

one or more specific operations. This document cannot replace

Conditions

education or experience and should be used in conjunction

D5313/D5313M TestMethodforEvaluationofDurabilityof

with professional judgment. Not all aspects of this practice may

Rock for Erosion Control Under Wetting and Drying

be applicable in all circumstances. This ASTM standard is not

Conditions

intended to represent or replace the standard of care by which

D6026 Practice for Using Significant Digits and Data Re-

the adequacy of a given professional service must be judged,

cords in Geotechnical Data

nor should this document be applied without consideration of

a project’s many unique aspects. The word “Standard” in the

3. Terminology

title of this document means only that the document has been

3.1 Definitions—For definitions of common technical terms

approved through the ASTM consensus process.

used in this standard, refer to Terminology D653.

1.5 This standard does not purport to address all of the

3.2 Definitions of Terms Specific to This Standard:

safety concerns, if any, associated with its use. It is the

3.2.1 rock saw, n—a saw capable of cutting rock. The term

responsibility of the user of this standard to establish appro-

“rock saw” shall include the blade which saws the rock, any

priate safety, health, and environmental practices and deter-

components that control or power the sawing process or both,

mine the applicability of regulatory limitations prior to use.

and framework on which the blade and any other associated

For a specific hazards statement, see Section 7.

components are mounted.

1.6 This international standard was developed in accor-

3.2.1.1 Discussion—A rock saw may be a water-cooled

dance with internationally recognized principles on standard-

diamond blade or diamond wire saw.

ization established in the Decision on Principles for the

Development of International Standards, Guides and Recom-

3.2.2 slab, n—a section of rock having two smooth, ap-

proximately parallel faces, produced by two saw cuts. The

thickness of the slab is generally less than the other dimensions

1

This practice is under the jurisdiction of ASTM Committee D18 on Soil and

Rock and is the direct responsibility of Subcommittee D18.17 on Rock for Erosion

2

Control. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved Jan. 1, 2022. Published January 2022. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1990. Last previous edition approved in 2015 as D5121–15. DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/D5121-22. the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D5121 − 15 D5121 − 22

Standard Practice for

1

Preparation of Rock Slabs for Durability Testing

This standard is issued under the fixed designation D5121; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*

1.1 This practice covers the preparation of rock slabs for various tests and any visual inspections used to evaluate the durability

of rock for erosion control. These tests include, but are not limited to, Test Methods D5240D5240/D5240M, D5312D5312/

D5312M, and D5313D5313/D5313M. This practice is appropriate for the assessment of breakwater stone, armor stone, riprap, and

gabion sized rock materials.

1.2 Units—The values stated in SI units are to be regarded as standard. The values inch-pound units given in parentheses are

mathematical conversions to inch-pound units that are provided for information only and are not considered standard.for

information only.

1.3 All observed and measured values shall conform to the guidelines for significant digits and rounding established in Practice

D6026, unless superseded by this standard.

1.4 This practice offers a set of instructions for performing one or more specific operations. This document cannot replace

education or experience and should be used in conjunction with professional judgment. Not all aspects of this practice may be

applicable in all circumstances. This ASTM standard is not intended to represent or replace the standard of care by which the

adequacy of a given professional service must be judged, nor should this document be applied without consideration of a project’s

many unique aspects. The word “Standard” in the title of this document means only that the document has been approved through

the ASTM consensus process.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the

applicability of regulatory limitations prior to use. For a specific hazards statement, see Section 7.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

D653 Terminology Relating to Soil, Rock, and Contained Fluids

D3740 Practice for Minimum Requirements for Agencies Engaged in Testing and/or Inspection of Soil and Rock as Used in

Engineering Design and Construction

1

This practice is under the jurisdiction of ASTM Committee D18 on Soil and Rock and is the direct responsibility of Subcommittee D18.17 on Rock for Erosion Control.

Current edition approved July 1, 2015Jan. 1, 2022. Published July 2015January 2022. Originally approved in 1990. Last previous edition approved in 20062015 as

D5121–10.–15. DOI: 10.1520/D5121-15.10.1520/D5121-22.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D5121 − 22

D4992 Practice for Evaluation of Rock to be Used for Erosion Control

D5240D5240/D5240M Test Method for Evaluation of the Durability of Rock for Erosion Control Using Sodium Sulfate or

Magnesium Sulfate

D5312D5312/D5312M Test Method for Evaluation of Durability of Rock for Erosion Control Under Freezing and Thawing

Conditions

D5313D5313/D5313M Test Method for Evaluation of Durability of Rock for Erosion Control Under Wetting and Drying

Conditions

D6026 Practice for Using Significant Digits and Data Records in Geotechnical Data

3. Terminology

3.1 Definitions—For definitions of common technical terms used in this standard, refer to Terminology D653.

3.2 Definitions of Terms Specific to This Standard:

3.2.1 rock saw, n—a saw capable of cutting rock. The t

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.