ASTM F683-00

(Practice)Standard Practice for Selection and Application of Thermal Insulation for Piping and Machinery

Standard Practice for Selection and Application of Thermal Insulation for Piping and Machinery

SCOPE

1.1 This practice provides guidance in the selection of types and thicknesses of thermal insulation materials for piping, machinery, and equipment for nonnuclear shipboard applications. Methods and materials for installation, including lagging, are also detailed.

1.2 Supplemental requirements and exceptions to the requirements discussed herein for ships of the U.S. Navy are included in Supplementary Requirements S1.

1.3 Asbestos or asbestos-containing materials shall not be used.

1.4 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information only.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: F 683 – 00 An American National Standard

Standard Practice for

Selection and Application of Thermal Insulation for Piping

1

and Machinery

This standard is issued under the fixed designation F 683; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope C 195 Specification for Mineral Fiber Thermal Insulating

6

Cement

1.1 This practice provides guidance in the selection of types

C 449/C449M Specification for Mineral Fiber Hydraulic-

and thicknesses of thermal insulation materials for piping,

6

Setting Thermal Insulating and Finishing Cement

machinery, and equipment for nonnuclear shipboard applica-

C 533 Specification for Calcium Silicate Block and Pipe

tions. Methods and materials for installation, including lag-

6

Thermal Insulation

ging, are also detailed.

C 534 Specification for Preformed Flexible Elastomeric

1.2 Supplemental requirements and exceptions to the re-

6

Cellular Thermal Insulation in Sheet and Tubular Form

quirements discussed herein for ships of the U.S. Navy are

6

C 547 Specification for Mineral Fiber Pipe Insulation

included in Supplementary Requirements S1.

6

C 552 Specification for Cellular Glass Thermal Insulation

1.3 Asbestos or asbestos-containing materials shall not be

C 553 Specification for Mineral Fiber Blanket Thermal

used.

6

Insulation for Commercial and Industrial Applications

1.4 The values stated in inch-pound units are to be regarded

C 610 Specification for Molded Expanded Perlite Block and

as the standard. The values given in parentheses are for

6

Pipe Thermal Insulation

information only.

C 612 Specification for Mineral Fiber Block and Board

1.5 This standard does not purport to address all of the

6

Thermal Insulation

safety concerns, if any, associated with its use. It is the

C 680 Practice for Determination of Heat Gain or Loss and

responsibility of the user of this standard to establish appro-

the Surface Temperatures of Insulated Pipe and Equipment

priate safety and health practices and determine the applica-

6

Systems by the Use of a Computer Program

bility of regulatory limitations prior to use.

C 892 Specification for High-Temperature Fiber Blanket

2 6

2. Referenced Documents Thermal Insulation

D 962 Specification for Aluminum Powder and Paste Pig-

2.1 ASTM Standards:

7

ments for Paints

A 167 Specification for Stainless and Heat-Resisting

8

3

D 3400 Specification for Liquid Sodium Silicates

Chromium-Nickel Steel Plate, Sheet, and Strip

F 1138 Specification for Spray Shields for Mechanical

A 653/A 653M Specification for Steel Sheet, Zinc-Coated

9

Joints

(Galvanized) or Zinc-Iron Alloy-Coated (Galvannealed)

10

4

2.2 Federal Specifications:

by the Hot Dip Process

HH-P-31 Packing and Lagging Material, Fibrous Glass

B 209 Specification for Aluminum and Aluminum-Alloy

5

Metallic and Plain Cloth and Tape

Sheet and Plate

TT-P-28 Paint, Aluminum, Heat Resisting (1200°F)

B 209M Specification for Aluminum and Aluminum-Alloy

10

5

2.3 Military Specifications:

Sheet and Plate [Metric]

DoD-C-15328 Primer (Wash), Pretreatment (Formula No.

C 168 Terminology Relating to Thermal Insulating Materi-

6

117 for Metals) Metric

als

DoD-C-24596 Coating Compounds, Nonflaming, Fire-

Protective (Metric)

1 DoD-E-24607 Enamel, Interior, Nonflaming (Dry), Chlori-

This practice is under the jurisdiction of ASTM Committee F25 on Ships and

Marine Technology and is the direct responsibility of Subcommittee F25.02 on nated Alkyd Resin, Semigloss (Metric)

Insulation/Processes.

Current edition approved Dec. 10, 2000. Published March 2001. Originally

published as F 683 – 80. Last previous edition F 683 – 99.

2 7

The latest revision of all referenced documents shall apply. Annual Book of ASTM Standards, Vol 06.03.

3 8

Annual Book of ASTM Standards, Vol 01.03. Annual Book of ASTM Standards, Vol 15.04.

4 9

Annual Book of ASTM Standards, Vol 01.06. Annual Book of ASTM Standards, Vol 01.07.

5 10

Annual Book of ASTM Standards, Vol 02.02. Available from Standardization Documents Order Desk, Bldg. 4 Section D,

6

Annual Book of ASTM Standards, Vol 04.06. 700 Robbins Ave., Philadelphia, PA 19111-5094, Attn: NPODS.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

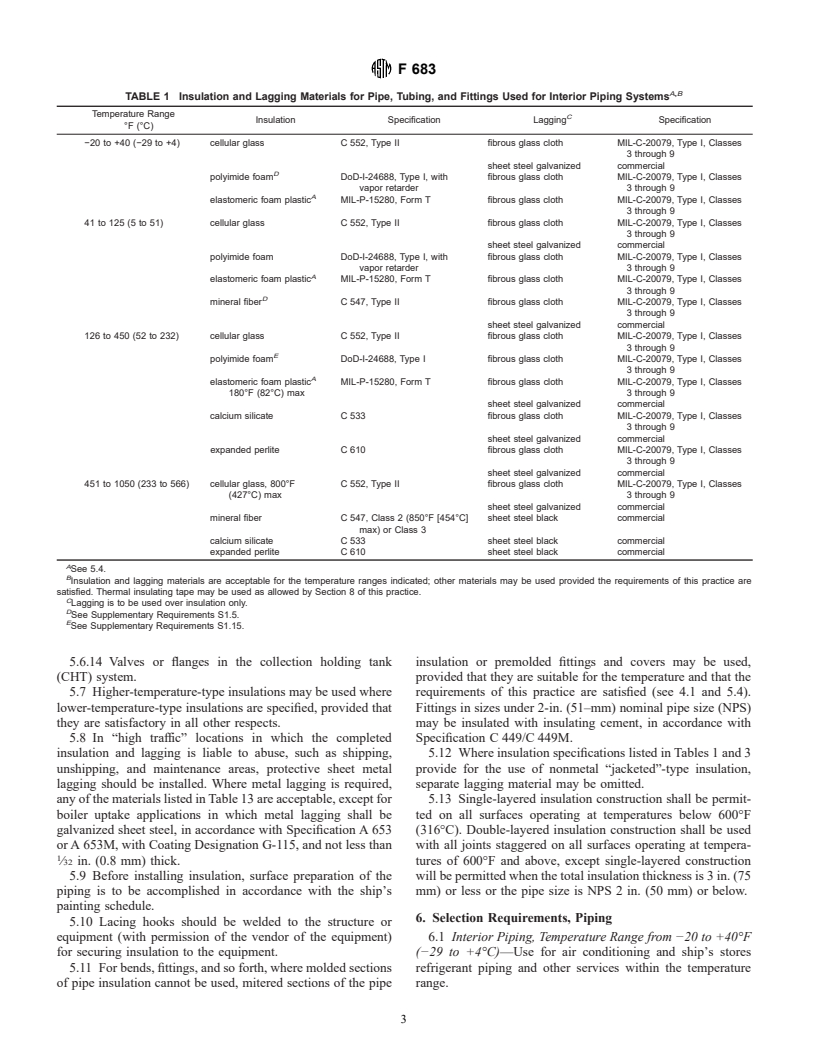

F 683

DoD-I-24688 Type I, Insulation; Polymide, Sheet and Tube range from 55 to 125°F (13 to 52°C) during normal operation,

MIL-A-3316 Adhesive, Fire-Resistant, Thermal Insulation shall be insulated except as otherwise stated herein.

MIL-A-24179 Adhesive, Flexible, Unicel

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.