ASTM F683-99

(Practice)Standard Practice for Selection and Application of Thermal Insulation for Piping and Machinery

Standard Practice for Selection and Application of Thermal Insulation for Piping and Machinery

SCOPE

1.1 This practice provides guidance in the selection of types and thicknesses of thermal insulation materials for piping, machinery, and equipment for nonnuclear shipboard applications. Methods and materials for installation, including lagging, are also detailed.

1.2 Supplemental requirements and exceptions to the requirements discussed herein for ships of the U.S. Navy are included in Supplementary Requirements S1.

1.3 Asbestos or asbestos-containing materials shall not be used.

1.4 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information only.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: F 683 – 99 An American National Standard

Standard Practice for

Selection and Application of Thermal Insulation for Piping

and Machinery

This standard is issued under the fixed designation F 683; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope Setting Thermal Insulating and Finishing Cement

C 533 Specification for Calcium Silicate Block and Pipe

1.1 This practice provides guidance in the selection of types

Thermal Insulation

and thicknesses of thermal insulation materials for piping,

C 547 Specification for Mineral Fiber Preformed Pipe Insu-

machinery, and equipment for nonnuclear shipboard applica-

lation

tions. Methods and materials for installation, including lag-

C 552 Specification for Cellular Glass Thermal Insulation

ging, are also detailed.

C 553 Specification for Mineral Fiber Blanket Thermal

1.2 Supplemental requirements and exceptions to the re-

Insulation for Commercial and Industrial Applications

quirements discussed herein for vessels of the U.S. Navy are

C 610 Specification for Molded Expanded Perlite Block and

included in Annex A1.

Pipe Thermal Insulation

1.3 Asbestos or asbestos containing materials shall not be

C 612 Specification for Mineral Fiber Block and Board

used.

Thermal Insulation

1.4 The values stated in inch-pound units are to be regarded

C 680 Practice for Determination of Heat Gain or Loss and

as the standard. The values given in parentheses are for

the Surface Temperatures of Insulated Pipe and Equipment

information only.

Systems by the Use of a Computer Program

1.5 This standard does not purport to address all of the

C 892 Specification for High-Temperature Fiber Blanket

safety concerns, if any, associated with its use. It is the

Thermal Insulation

responsibility of the user of this standard to establish appro-

2.2 Federal Specification:

priate safety and health practices and determine the applica-

DOD-I-24688 Insulation, polyimide pipe, anti-sweat and

bility of regulatory limitations prior to use.

thermal sheet and tube

2. Referenced Documents

HH-P-31 Packing and Lagging Material, Fibrous Glass

Metallic and Plain Cloth and Tape

2.1 ASTM Standards:

2.3 Military Specifications:

A 167 Specification for Stainless and Heat-Resisting

MIL-A-3316 Adhesive, Fire-Resistant, Thermal Insulation

Chromium-Nickel Steel Plate, Sheet, and Strip

MIL-A-24179 Adhesive, Flexible, Unicellular-Plastic,

A 526/A526M Specification for Steel Sheet, Zinc-Coated

Thermal Insulation

(Galvanized) by the Hot-Dip Process, Commercial Qual-

MIL-C-19565 Coating Compounds, Thermal Insulation

ity

Pipe Covering—Fire and Water-Resistant Vapor Barrier

B 209 Specification for Aluminum and Aluminum-Alloy

and Weather Resistant

Sheet and Plate

MIL-C-20079 Cloth, Glass, Tape, Textile Glass and Thread,

C 168 Terminology Relating to Thermal Insulating Materi-

Glass

als

MIL-C-22395 Compound, End Sealing, Thermal Insulation

C 195 Specification for Mineral Fiber Thermal Insulating

Pipe Covering—Fire, Water, and Weather Resistant

Cement

MIL-I-2781 Insulation, Pipe, Thermal

C 449/C449M Specification for Mineral Fiber Hydraulic-

MIL-I-2818 Insulation Blanket, Thermal, Fibrous Material

MIL-I-2819 Insulation, Block, Thermal

This practice is under the jurisdiction of ASTM Committee F-25 on Ships and MIL-I-16411 Insulation, Felt, Thermal, Glass Fiber

Marine Technology and is the direct responsibility of Subcommittee F25.02 on

MIL-I-22344 Insulation, Pipe, Thermal, Fibrous Glass

Insulation/Processes.

MIL-P-15280 Plastic Material, Unicellular (Sheets and

Current edition approved April 10, 1999. Published August 1999. Originally

Tubes)

published as F 683 – 80. Last previous edition F 683 – 97.

Annual Book of ASTM Standards, Vol 01.03.

Discontinued 1994—Replaced by A 653/A 653M.

4 6

Annual Book of ASTM Standards, Vol 02.02. Available from Standardization Documents Order Desk, Bldg. 4 Section D, 700

Annual Book of ASTM Standards, Vol 04.06. Robbins Ave., Philadelphia, PA 19111-5094, Attn: NPODS.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

F 683

MIL-STD-769 Thermal Insulation Requirements for Ma- 5.6 Minimum insulation requirements have not been estab-

chinery and Piping lished for those surfaces or applications where insulations had

2.4 Other Documents: not been specified in past practices. In effect, the following

Title 46 Code of Federal Regulations (CFR), Shipping surfaces are excluded from insulation requirements:

(Parts 164.012 and 164.112)

5.6.1 Surfaces where application of insulation would affect

USCG Equipment List CG 190-164.012 Interior Finish proper operation.

2.5 Drawings, NAVSHIPS:

5.6.2 Equipment, components, and systems designed for the

804-5959214 Piping Insulation, Installation Details

dispersion of heat.

804-5959212 Machinery Insulation, Installation Details

5.6.3 Thermostatic steam traps and 24 in. (620 mm) of

2.6 Drawing, NAVSEA:

piping upstream of traps, which shall not be insulated. When

803-5184182 Passive Fire Protection Insulation

located in areas where personnel protection is required, ex-

panded metal shields or multilayer glass cloth shall be pro-

3. Terminology

vided.

3.1 Definitions—For definitions of terms relating to insulat-

5.6.4 Mechanical joints exposed to subatmospheric pres-

ing materials used in this practice, refer to Definitions C 168.

sures, and those included in the fuel oil service piping from

heaters to burners.

4. Materials and Manufacture

5.6.5 Fuel oil piping between headers and burners.

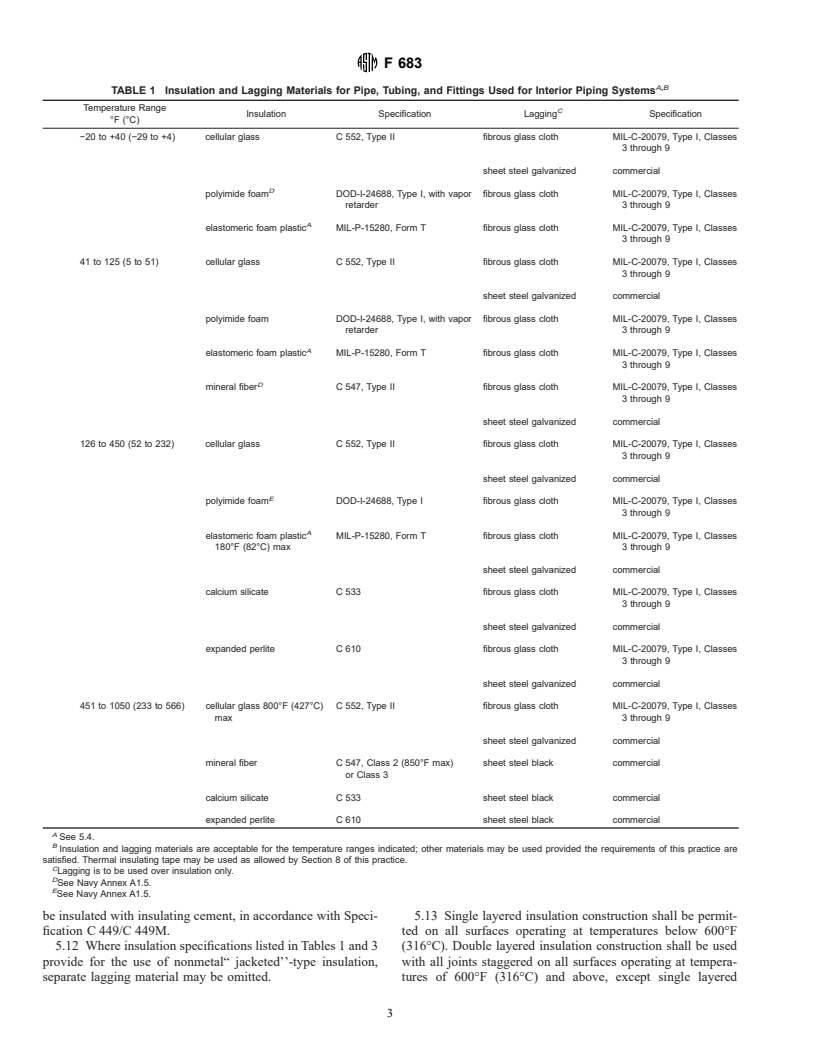

4.1 Insulation and Lagging Material Specifications,as

5.6.6 Piping above 125°F (52°C) in bilges, not within

listed in Tables 1-17, describe those materials which are

watertight enclosures.

intended for use in the indicated temperature ranges. The

5.6.7 Piping in locations where sweating and possible re-

specifications and requirements outlined herein are not in-

sultant rust is not objectionable such as voids, bilges, and shaft

tended to prevent the use of new methods or materials,

alleys, plus plumbing fixtures and associated supply and drain

provided that sufficient technical data is submitted to demon-

piping immediately adjacent thereto.

strate that the proposed method or material is equivalent in

5.6.8 Dead-end hot water piping ⁄8 in. (10 mm) and smaller.

quality, effectiveness, durability, and safety to that prescribed

5.6.9 Pressure-gage piping.

by this practice.

5.6.10 Soot-blower valve units and soot-blower flanges.

5.6.11 Piping in voids and cofferdams except where omit-

5. General Requirements

ting insulation may be detrimental to system operation, such as

5.1 Piping, including valves, fittings, and flanges conveying

catapult steam.

vapors, gases, or liquids that attain temperatures outside the

5.6.12 Safety valve bodies, springs, and lifting gear.

range from 55 to 125°F (13 to 52°C) during normal operation,

5.6.13 Piping over shower stalls, behind, and under lavato-

shall be insulated except as otherwise stated herein.

ries.

5.2 The insulation thicknesses specified in this practice are

5.6.14 Valves or flanges in the collection holding tank

designed to maintain the surface temperature at or below 125°F

(CHT) System.

(52°C) for fluid temperatures up to 650°F (343°C) with an

5.7 Higher temperature-type insulations may be used where

ambient temperature of 85°F (29°C). For fluid temperatures

lower temperature-type insulations are specified, provided that

above 650°F (343°C), the surface will be maintained at a

they are satisfactory in all other respects.

maximum of 133°F (56°C).

5.8 In “high traffic’’ locations where the completed insula-

5.2.1 Insulation thicknesses have been calculated using the

tion and lagging is liable to abuse, such as shipping, unship-

computer programs in Practice C 680.

ping, and maintenance areas, protective sheet metal lagging

5.3 Piping and units of equipment with designated internal

should be installed. Where metal lagging is required, any of the

temperatures of 300°F (149°C) and over shall be insulated

materials listed in Table 13 are acceptable, except for boiler

from their supports or the supports insulated from the struc-

uptake applications in which metal lagging shall be galvanized

tures to which they are attached where the heat transmitted may

sheet steel, in accordance with Specification A 526/A 526M,

be objectionable on the opposite side of the structure.

with coating designation G-115, and not less than ⁄32 in. (0.8

5.4 Insulated piping passing through accommodation, ser-

mm) thick.

vice, and control spaces must be covered with approved

5.9 Before installing insulation, surface preparation of the

incombustible materials which meet 46 CFR, Sections 164.009

piping is to be accomplished in accordance with the ship’s

and 164.012. Elastomeric foam plastic insulation shall not be

painting schedule.

used in these spaces.

5.10 Lacing hooks should be welded to the structure or

5.5 Special consideration shall be given to the insulation of

equipment (with permission of the vendor of the equipment)

integral piping supplied with and mounted on equipment or

for securing insulation to the equipment.

machinery. In these cases, alternative materials and methods of

5.11 For bends, fittings, and so forth, in which molded

installation may be considered provided that they comply with

sections of pipe insulation cannot be used, mitered sections of

the performance requirements of this practice.

the pipe insulation or premolded fittings and covers may be

used, provided that they are suitable for the temperature and

that the requirements of this practice are satisfied (see 4.1 and

Available from U.S. Government Printing Office.

Available from U.S. Coast Guard (G-CMC/82), Washington, DC 20590. 5.4). Fittings in sizes under 2-in. nominal pipe size (NPS) may

F 683

A,B

TABLE 1 Insulation and Lagging Materials for Pipe, Tubing, and Fittings Used for Interior Piping Systems

Temperature Range

C

Insulation Specification Lagging Specification

°F (°C)

−20 to +40 (−29 to +4) cellular glass C 552, Type II fibrous glass cloth MIL-C-20079, Type I, Classes

3 through 9

sheet steel galvanized commercial

D

polyimide foam DOD-I-24688, Type I, with vapor fibrous glass cloth MIL-C-20079, Type I, Classes

retarder 3 through 9

A

elastomeric foam plastic MIL-P-15280, Form T fibrous glass cloth MIL-C-20079, Type I, Classes

3 through 9

41 to 125 (5 to 51) cellular glass C 552, Type II fibrous glass cloth MIL-C-20079, Type I, Classes

3 through 9

sheet steel galvanized commercial

polyimide foam DOD-I-24688, Type I, with vapor fibrous glass cloth MIL-C-20079, Type I, Classes

retarder 3 through 9

A

elastomeric foam plastic MIL-P-15280, Form T fibrous glass cloth MIL-C-20079, Type I, Classes

3 through 9

D

mineral fiber C 547, Type II fibrous glass cloth MIL-C-20079, Type I, Classes

3 through 9

sheet steel galvanized commercial

126 to 450 (52 to 232) cellular glass C 552, Type II fibrous glass cloth MIL-C-20079, Type I, Classes

3 through 9

sheet steel galvanized commercial

E

polyimide foam DOD-I-24688, Type I fibrous glass cloth MIL-C-20079, Type I, Classes

3 through 9

A

elastomeric foam plastic MIL-P-15280, Form T fibrous glass cloth MIL-C-20079, Type I, Classes

180°F (82°C) max 3 through 9

sheet steel galvanized commercial

calcium silicate C 533 fibrous glass cloth MIL-C-20079, Type I, Classes

3 through 9

sheet steel galvanized commercial

expanded perlite C 610 fibrous glass cloth MIL-C-20079, Type I, Classes

3 through 9

sheet steel galvanized commercial

451 to 1050 (233 to 566) cellular glass 800°F (427°C) C 552, Type II fibrous glass cloth MIL-C-20079, Type I, Classes

max 3 through 9

sheet steel galvanized commercial

mineral fiber C 547, Class 2 (850°F max) sheet steel black commercial

or Class 3

calcium silicate C 533 sheet steel black commercial

expanded perlite C 610 sheet steel black commercial

A

See 5.4.

B

Insulation and lagging materials are acceptable for the temperature ranges indicated; other materials may be used provided the requirements of this practice are

satisfied. Thermal insulating tape may be used as allowed by Section 8 of this practice.

C

Lagging is to be used over insulation only.

D

See Navy Annex A1.5.

E

See Navy Annex A1.5.

be insulated with insulating cement, in accordance with Speci- 5.13 Single layered insulation construction shall be permit-

fication C 449/C 449M. ted on all surfaces operating at temperatures below 600°F

5.12 Where insulation specifications listed in Tables 1 and 3 (316°C). Double layered insulation construction shall be used

provide for the use of nonmetal“ jacketed’’-type insulation, with all joints staggered on all surfaces operating at tempera-

separate lagging material may be omitted. tures of 600°F (316°C) and above, except single layered

F 683

A

TABLE 2 Insulation and Lagging Materials for Pipe, Tubing, and Fittings Used for Weather Exposed Piping Systems

Temperature Range

Insulation Specification Lagging Specification

° F (°C)

−20 to +40 (−29 to +4) cellular glass C 552, Type II fibrous glass cloth MIL-C-20079, Type I

Class 7 (fittings)

Class 9 (piping)

polyimide foam DOD-I-24688, Type I, with fibrous glass cloth MIL-C-20079, Type I

vapor retarder Class 7 (fittings)

Class 9 (piping)

perlite C 610 fibrous glass cloth MIL-C-20079, Type I

Class 7 (fittings)

Class 9 (piping)

41 to 100 (5 to 37) cellular glass C 552, Type II corrosion resistant steel A 167, Type 304

polyimide foam DOD-I-24688, Type I, with fibrous glass cloth MIL-C-20079, Type I

vapor retarder Class 7 (fittings)

Class 9 (piping)

perlite C 610 corrosion resistant steel A 167, Type 304

calcium silicate C 533 corrosion resistant steel A 167, Type 304

B

mineral fiber C 547, Class 2 or 3 corrosion resistant steel A 167, Type 304

101 to 450 (38 to 232) cellular glass C 552, Type II corrosion resistant steel A 167, Type 304

C

polyimide foam DOD-I-24688, Type I corrosion resistant steel A 167, Type 304

perlite C 610 corrosion resistant steel A 167, Type 304

calcium silicate C 533 corrosion resistant steel A 167, Type 304

B

mineral fiber C 547, Class 2 or 3 corrosion resistant steel A 167, Type 304

A

Insulation and lagging materials listed are acceptable for the temperature ranges indicated; other materials may be used provided the requirements of this standard

are satisfied.

B

See Navy Annex A1.5.

C

See Navy Annex A1.15.

construction will be permitted when the total insulation thick-

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.