ASTM D3967-05

(Test Method)Standard Test Method for Splitting Tensile Strength of Intact Rock Core Specimens

Standard Test Method for Splitting Tensile Strength of Intact Rock Core Specimens

SIGNIFICANCE AND USE

By definition the tensile strength is obtained by the direct uniaxial tensile test. But the tensile test is difficult and expensive for routine application. The splitting tensile test appears to offer a desirable alternative, because it is much simpler and inexpensive. Furthermore, engineers involved in rock mechanics design usually deal with complicated stress fields, including various combinations of compressive and tensile stress fields. Under such conditions, the tensile strength should be obtained with the presence of compressive stresses to be representative of the field conditions. The splitting tensile strength test is one of the simplest tests in which such stress fields occur. Since it is widely used in practice, a uniform test method is needed for data to be comparable. A uniform test is also needed to insure positively that the disk specimens break diametrally due to tensile pulling along the loading diameter.

Note 2—Notwithstanding the statements on precision and bias contained in this test method; the precision of this test method is dependent on the competence of the personnel performing it, and the suitability of the equipment and facilities used. Agencies that meet the criteria of Practice D 3740 are generally considered capable of competent and objective testing. Reliable testing depends on many factors; Practice D 3740 provides a means of evaluating some of these factors.

SCOPE

1.1 This test method covers testing apparatus, specimen preparation, and testing procedures for determining the splitting tensile strength of rock by diametral line compression of a disk.Note 1

The tensile strength of rock determined by tests other than the straight pull test is designated as the "indirect" tensile strength and, specifically, the value obtained in Section of this test is termed the "splitting" tensile strength.

1.2 The values stated in SI units are to be regarded as the standard.

1.3 All dimension and force measurements, and stress calculations shall conform to the guidelines for significant digits and rounding established in Practice D 6026.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D3967–05

Standard Test Method for

1

Splitting Tensile Strength of Intact Rock Core Specimens

This standard is issued under the fixed designation D 3967; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope* 3. Terminology

1.1 This test method covers testing apparatus, specimen 3.1 Refer to Terminology D 653 for specific definitions.

preparation, and testing procedures for determining the split-

4. Significance and Use

ting tensile strength of rock by diametral line compression of a

4.1 By definition the tensile strength is obtained by the

disk.

direct uniaxial tensile test. But the tensile test is difficult and

NOTE 1—The tensile strength of rock determined by tests other than the

expensive for routine application. The splitting tensile test

straight pull test is designated as the “indirect” tensile strength and,

appears to offer a desirable alternative, because it is much

specifically, the value obtained in Section 9 of this test is termed the

simpler and inexpensive. Furthermore, engineers involved in

“splitting” tensile strength.

rock mechanics design usually deal with complicated stress

1.2 The values stated in SI units are to be regarded as the

fields, including various combinations of compressive and

standard.

tensile stress fields. Under such conditions, the tensile strength

1.3 All dimension and force measurements, and stress

shouldbeobtainedwiththepresenceofcompressivestressesto

calculations shall conform to the guidelines for significant

be representative of the field conditions. The splitting tensile

digits and rounding established in Practice D 6026.

strength test is one of the simplest tests in which such stress

1.4 This standard does not purport to address all of the

fields occur. Since it is widely used in practice, a uniform test

safety concerns, if any, associated with its use. It is the

method is needed for data to be comparable. A uniform test is

responsibility of the user of this standard to establish appro-

also needed to insure positively that the disk specimens break

priate safety and health practices and determine the applica-

diametrally due to tensile pulling along the loading diameter.

bility of regulatory limitations prior to use.

NOTE 2—Notwithstanding the statements on precision and bias con-

2. Referenced Documents

tained in this test method; the precision of this test method is dependent

2

onthecompetenceofthepersonnelperformingit,andthesuitabilityofthe

2.1 ASTM Standards:

equipment and facilities used. Agencies that meet the criteria of Practice

D 653 Terminology Relating to Rock, Soil, and Contained

D 3740 are generally considered capable of competent and objective

Fluids

testing. Reliable testing depends on many factors; Practice D 3740

D 3740 Practice for Minimum Requirements for Agencies

provides a means of evaluating some of these factors.

Engaged in the Testing and/or Inspection of Soil and Rock

5. Apparatus

as Used in Engineering Design and Construction

D 6026 Practice for Using Significant Digits in Geotechni-

5.1 Loading Device, to apply and measure axial load on the

cal Data

specimen, of sufficient capacity to apply the load at a rate

E4 Practices for Force Verification of Testing Machines

conforming to the requirements in 8.3. It shall be verified at

E 691 Practice for Conducting an Interlaboratory Study to

suitable time intervals in accordance with Practices E4 and

Determine the Precision of a Test Method

shall comply with the requirements prescribed therein.

5.2 Bearing Surfaces—The testing machine shall be

equipped with two steel bearing blocks having a Rockwell

1

ThistestmethodisunderthejurisdictionofASTMCommitteeD18onSoiland

hardness of not less than 58 HRC (see Note 3).

Rock and is the direct responsibility of Subcommittee D18.12 on Rock Mechanics.

Current edition approved Aug. 15, 2005. Published September 2005. Originally

NOTE 3—False platens, with bearing faces conforming to the require-

approved in 1981. Last previous edition approved in 2004 as D 3967 – 95a (2004).

2 ments of this standard, may be used. These shall be oil hardened to more

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

than 58 HRC, and surface ground. With abrasive rocks these platens tend

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

to roughen after a number of specimens have been tested, and hence need

Standardsvolume information, refer to the standard’s Document Summary page on

the ASTM website. to be surfaced from time to time.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM Interna

...

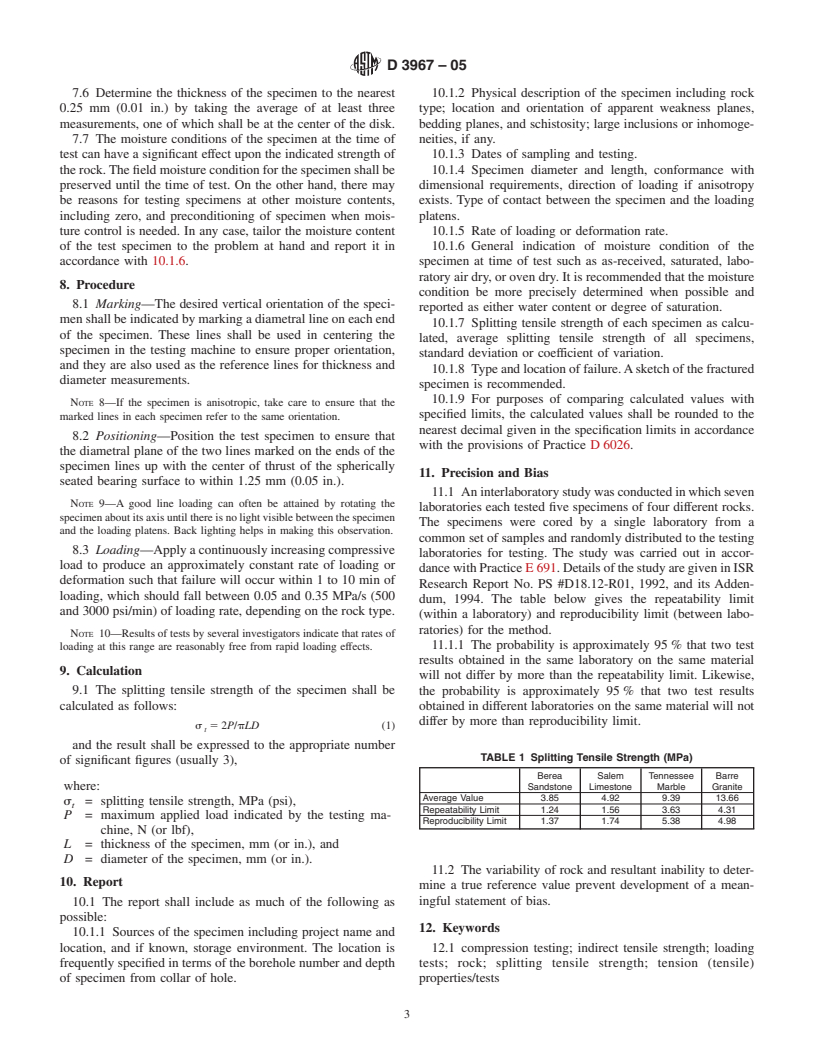

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.