ASTM D5167-91(1997)

(Practice)Standard Practice for Melting of Hot-Applied Joint and Crack Sealant and Filler for Evaluation

Standard Practice for Melting of Hot-Applied Joint and Crack Sealant and Filler for Evaluation

SCOPE

1.1 This standard establishes the procedure for melting or heating, or both, of hot-applied joint and crack sealants and fillers in preparation for the making of test specimens used in the laboratory evaluations of the sealants and fillers. Refer to the specific standard material specification for sampling requirements, test sample quantity, temperatures and times for melting and heating, and the number of specimens required for testing.

1.2 This procedure is applicable to the hot-applied joint and crack sealants and fillers used in both portland cement and asphaltic-concrete pavements.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific precautions see Section 7.

1.4 The values stated in inch-pound units are to be regarded as the standard. The values in parentheses are provided for information purposes only.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: D 5167 – 91 (Reapproved 1997)

Standard Practice for

Melting of Hot-Applied Joint and Crack Sealant and Filler for

Evaluation

This standard is issued under the fixed designation D 5167; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope or filler to which the sealant or filler can be heated and still

conform to the particular specification requirements.

1.1 This standard establishes the procedure for melting or

3.1.3 recommended application temperature—any tempera-

heating, or both, of hot-applied joint and crack sealants and

ture between the recommended safe heating temperature and

fillers in preparation for the making of test specimens used in

the recommended pouring temperature.

the laboratory evaluations of the sealants and fillers. Refer to

the specific standard material specification for sampling re-

4. Significance and Use

quirements, test sample quantity, temperatures and times for

4.1 It is intended that this practice be used by manufactur-

melting and heating, and the number of specimens required for

ers, users and testing agencies. The use of this practice

testing.

establishes a uniform procedure for the melting or heating of

1.2 This procedure is applicable to the hot-applied joint and

hot-applied sealants and fillers. It is not intended to establish

crack sealants and fillers used in both portland cement and

test procedures or conditions of test which are associated with

asphaltic-concrete pavements.

each of the joint sealants and fillers.

1.3 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

5. Standard Conditions

responsibility of the user of this standard to establish appro-

5.1 The laboratory atmospheric conditions, hereinafter re-

priate safety and health practices and determine the applica-

ferred to as standard conditions, shall be as detailed in

bility of regulatory limitations prior to use. For specific

Specification E 171, 73.4 6 3.6°F (23 6 2°C) and 50 %

precautions see Section 7.

relative humidity 65 %. The material shall be conditioned for

1.4 The values stated in inch-pound units are to be regarded

24 h at standard conditions before melting or heating.

as the standard. The values in parentheses are provided for

information purposes only.

6. Apparatus

6.1 Laboratory Melter:

2. Referenced Documents

6.1.1 The equipment for melting of the joint sealant or filler

2.1 ASTM Standards:

2 shall be an oil jacketed melter equipped with a mechanical

E 1 Specification for ASTM Thermometers

agitator and thermometers for the oil bath and material in the

E 77 Test Method for the Inspection and Verification of

2 melting vat.

Thermometers

6.1.2 The heat transfer oil shall be a high flash point oil, that

E 171 Specification for Standard Atmospheres for Condi-

3 is, in excess of 600°F (315°C).

tioning and Testing Materials

6.1.3 The heat source shall be thermostatically controlled

3. Terminology and capable of maintaining the heat transfer oil temperature

within a tolerance of 65°F (63°C) and capable of heating the

3.1 Definitions of Terms Specific to This Standard:

oil to a maximum of 550°F (288°C).

3.1.1 recommended safe heating temperature—The maxi-

6.1.4 The mechanical agitator speed for the material shall be

mum temperature recommended by the manufacturer of the

30 6 5 rpm when fully loaded and the agitator speed for the oil

sealant or filler to which the sealant or filler can be heated and

bath shall be such to allow continuous circulation of the oil.

still conform to the particular specification requirements.

6.1.5 Except when adding the sealant or filler sample, or

3.1.2 recommended pouring temperature—The minimum

checking temperature, the melter’s pots shall be covered with

temperature recommended by the manufacturer of the sealant

close fitting lids.

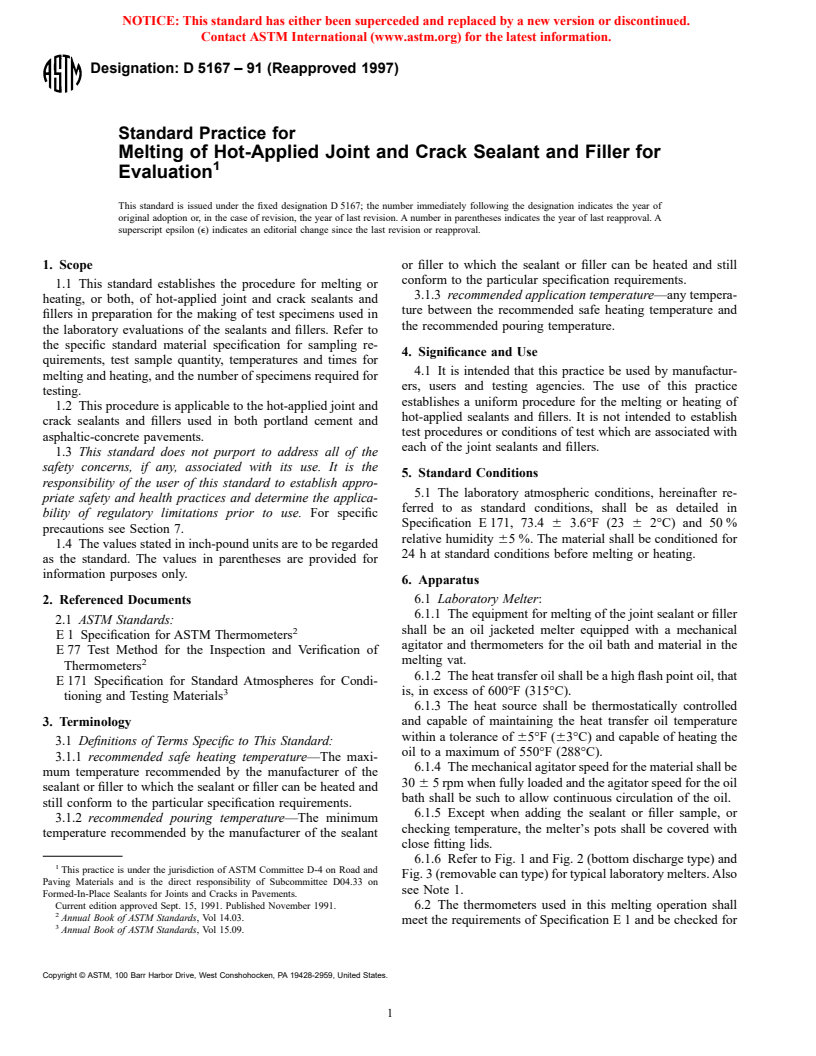

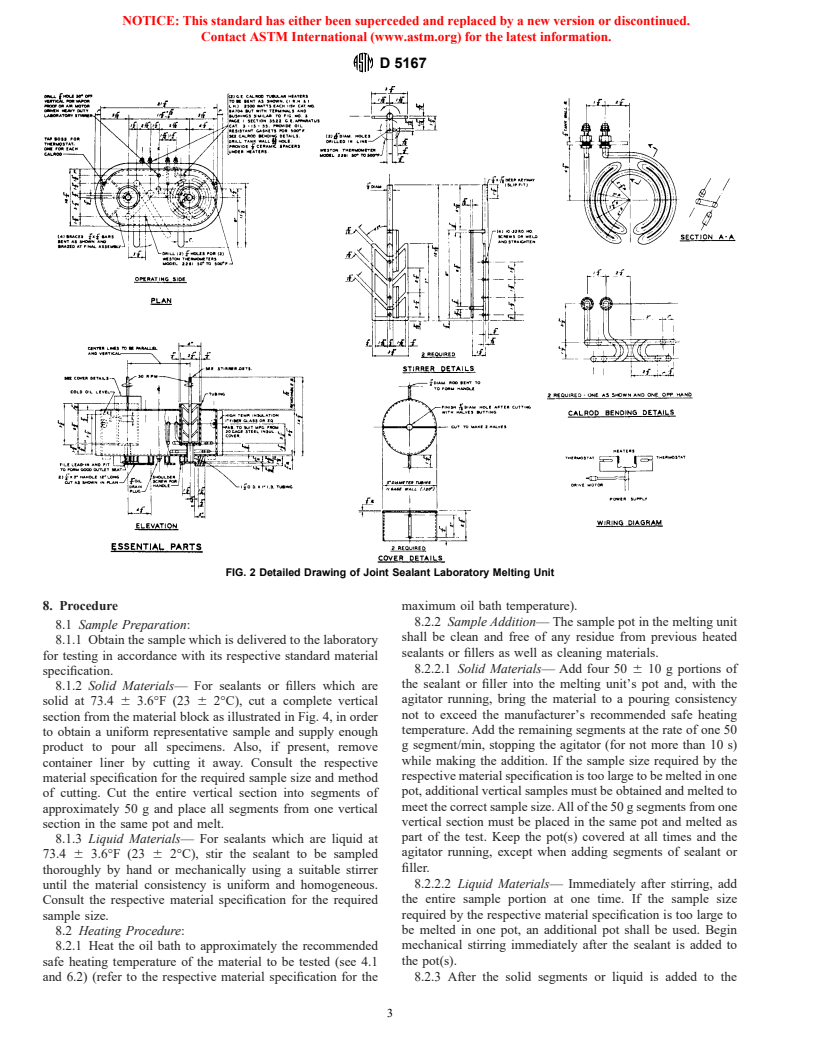

6.1.6 Refer to Fig. 1 and Fig. 2 (bottom discharge type) and

This practice is under the jurisdiction of ASTM Committee D-4 on Road and

Fig. 3 (removable can type) for typical laboratory melters. Also

Paving Materials and is the direct responsibility of Subcommittee D04.33 on

see Note 1.

Formed-In-Place Sealants for Joints and Cracks in Pavements.

Current edition approved Sept. 15, 1991. Published November 1991. 6.2 The thermometers used in this melting operation shall

Annual Book of ASTM Standards, Vol 14.03.

meet the requirements of Specification E 1 and be checked for

Annual Book of ASTM Standards, Vol 15.09.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

D 5167

FIG. 1 Detailed Drawing of Joint Sealant Laboratory Melting Unit

calibration using Test Method E 77. 7.2 Safe Heating Temperature—It is imperative that the

manufacturer’s recommended safe heating temperatures be

NOTE 1—The removable can type melter as shown in Fig. 3 is very

obtained for the material to be evaluated. The temperature of

similar in design to the melter shown in Fig. 1 and Fig. 2. Fig. 3’s pots are

designed to be removed so the melted material can be poured. Extra care the material must not exceed the safe heating temperature.

must be taken when using this type of melter. Check the manufacturer’s

7.3 The laboratory melter unit should be located under an

recommended safety procedures before use.

exhaust hood to disperse fumes.

7. Precautions

7.4 Joint/crack sealants and fillers are manufactured from a

variety of materials. To avoid compatibility problems, clean the

7.1 Prior to beginning sampling and heating of sealants or

melter so that it is free of all cleaning solvents and previously

fillers, a Material Safety Data Sheet must be obtained from the

melted material.

sealant or filler manufacturer so that proper safe handling

techniques will be used.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

D 5167

FIG. 2 Detailed Drawing of Joint Sealant Laboratory Melting Unit

8. Procedure maximum oil bath temperature).

8.2.2 Sample Addition— The sample pot in the melting unit

8.1 Sample Preparation:

shall be clean and free of any residue from previous heated

8.1.1 Obtain the sample which is delivered to the laboratory

sealants or fillers as well as cleaning materials.

for testing in accordance with

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.