ASTM D1105-96

(Test Method)Standard Test Method for Preparation of Extractive-Free Wood

Standard Test Method for Preparation of Extractive-Free Wood

SCOPE

1.1 This method covers the preparation of extractive-free wood and is applicable to all North American woods. Extractives in wood consist of materials that are soluble in neutral solvents and that are not a part of the wood.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Specific precautionary statements are given in Section 4.2.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

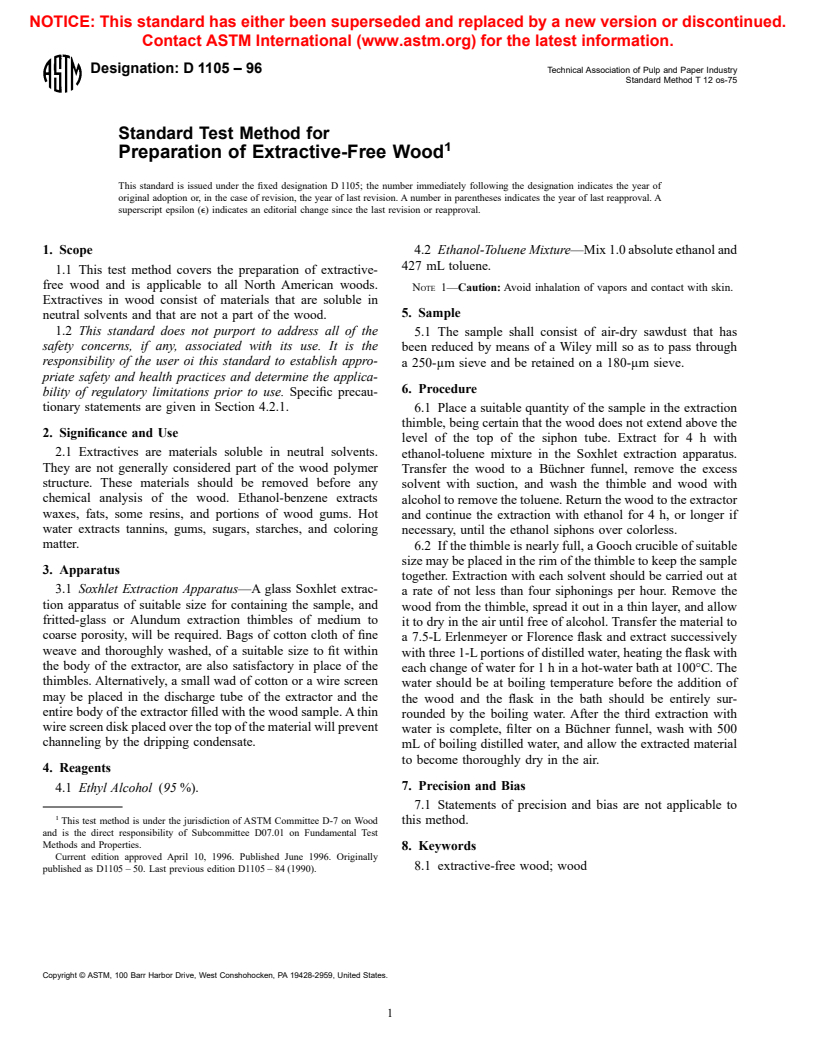

Designation: D 1105 – 96 Technical Association of Pulp and Paper Industry

Standard Method T 12 os-75

Standard Test Method for

Preparation of Extractive-Free Wood

This standard is issued under the fixed designation D 1105; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 4.2 Ethanol-Toluene Mixture—Mix 1.0 absolute ethanol and

427 mL toluene.

1.1 This test method covers the preparation of extractive-

free wood and is applicable to all North American woods.

NOTE 1—Caution: Avoid inhalation of vapors and contact with skin.

Extractives in wood consist of materials that are soluble in

5. Sample

neutral solvents and that are not a part of the wood.

1.2 This standard does not purport to address all of the

5.1 The sample shall consist of air-dry sawdust that has

safety concerns, if any, associated with its use. It is the

been reduced by means of a Wiley mill so as to pass through

responsibility of the user oi this standard to establish appro-

a 250-μm sieve and be retained on a 180-μm sieve.

priate safety and health practices and determine the applica-

6. Procedure

bility of regulatory limitations prior to use. Specific precau-

tionary statements are given in Section 4.2.1. 6.1 Place a suitable quantity of the sample in the extraction

thimble, being certain that the wood does not extend above the

2. Significance and Use

level of the top of the siphon tube. Extract for 4 h with

2.1 Extractives are materials soluble in neutral solvents.

ethanol-toluene mixture in the Soxhlet extraction apparatus.

They are not generally considered part of the wood polymer

Transfer the wood to a Büchner funnel, remove the excess

structure. These materials should be removed before any

solvent with suction, and wash the thimble and wood with

chemical analysis of the wood. Ethanol-benzene extracts

alcohol to remove the toluene. Return the wood to the extractor

waxes, fats, some resins, and portions of wood gums. Hot

and continue the extraction with ethanol for 4 h, or longer if

water extracts tannins, gums, sugars, starches, and coloring

necessary, until the ethanol siphons over colorless.

matter.

6.2 If the thimble is nearly full, a Gooch crucible of suitable

size may be placed in the rim of the thimble to keep the sample

3. Apparatus

together. Extraction with each solvent should be carried out at

3.1 Soxhlet Extraction Apparatus—A glass Soxhlet extrac-

a rate of not less than four siphonings per hour. Remove the

tion apparatus of suitable size for containing the sample, and

wood from the thimble, spread it out in a thin layer, and allow

fritted-glass or Alundum extraction thimbles of medium to

it to dry in the air until free of alcohol. Tra

...

This May Also Interest You

ABSTRACT

This specification covers three types of aluminum-pigmented asphalt roof coatings suitable for application to roofing or masonry surfaces by brush or spray. Type I is nonfibered, Type II is fibered with asbestos, and Type III is fibered other than asbestos. The coatings shall adhere to chemical requirements such as composition limits for water, nonvolatile matter, metallic aluminum, and insolubility in CS2. They shall also meet physical requirements as to uniformity, consistency, and luminous reflectance.

SCOPE

1.1 This specification covers asphalt-based, aluminum-pigmented roof coatings suitable for application to roofing or masonry surfaces by brush or spray.

1.2 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system are not necessarily exact equivalents; therefore, to ensure conformance with the standard, each system shall be used independently of the other, and values from the two systems shall not be combined.

1.3 The following precautionary caveat pertains only to the test method portion, Section 8, of this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Technical specification2 pagesEnglish languagesale 15% off

SIGNIFICANCE AND USE

5.1 This test method simulates the hydrostatic loading conditions which are often present in actual sandwich structures, such as marine hulls. This test method can be used to compare the two-dimensional flexural stiffness of a sandwich composite made with different combinations of materials or with different fabrication processes. Since it is based on distributed loading rather than concentrated loading, it may also provide more realistic information on the failure mechanisms of sandwich structures loaded in a similar manner. Test data should be useful for design and engineering, material specification, quality assurance, and process development. In addition, data from this test method would be useful in refining predictive mathematical models or computer code for use as structural design tools. Properties that may be obtained from this test method include:

5.1.1 Panel surface deflection at load,

5.1.2 Panel face-sheet strain at load,

5.1.3 Panel bending stiffness,

5.1.4 Panel shear stiffness,

5.1.5 Panel strength, and

5.1.6 Panel failure modes.

SCOPE

1.1 This test method determines the two-dimensional flexural properties of sandwich composite plates subjected to a distributed load. The test fixture uses a relatively large square panel sample which is simply supported all around and has the distributed load provided by a water-filled bladder. This type of loading differs from the procedure of Test Method C393, where concentrated loads induce one-dimensional, simple bending in beam specimens.

1.2 This test method is applicable to composite structures of the sandwich type which involve a relatively thick layer of core material bonded on both faces with an adhesive to thin-face sheets composed of a denser, higher-modulus material, typically, a polymer matrix reinforced with high-modulus fibers.

1.3 The values stated in either SI units or inch-pound units are to be regarded separately as standard. Within the text the inch-pound units are shown in brackets. The values stated in each system are not exact equivalents; therefore, each system must be used independently of the other. Combining values from the two systems may result in nonconformance with the standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Standard12 pagesEnglish languagesale 15% off

SIGNIFICANCE AND USE

4.1 Different electroplating systems can be corroded under the same conditions for the same length of time. Differences in the average values of the radius or half-width or of penetration into an underlying metal layer are significant measures of the relative corrosion resistance of the systems. Thus, if the pit radii are substantially higher on samples with a given electroplating system, when compared to other systems, a tendency for earlier failure of the former by formation of visible pits is indicated. If penetration into the semi-bright nickel layer is substantially higher, a tendency for earlier failure by corrosion of basis metal is evident.

SCOPE

1.1 This test method provides a means for measuring the average dimensions and number of corrosion sites in an electroplated decorative nickel plus chromium or copper plus nickel plus chromium coating on steel after the coating has been subjected to corrosion tests. This test method is useful for comparing the relative corrosion resistances of different electroplating systems and for comparing the relative corrosivities of different corrosive environments. The numbers and sizes of corrosion sites are related to deterioration of appearance. Penetration of the electroplated coatings leads to appearance of basis metal corrosion products.

1.2 The values stated in SI units are to be regarded as the standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Standard3 pagesEnglish languagesale 15% off

SIGNIFICANCE AND USE

4.1 This practice shall be used when ultrasonic inspection is required by the order or specification for inspection purposes where the acceptance of the forging is based on limitations of the number, amplitude, or location of discontinuities, or a combination thereof, which give rise to ultrasonic indications.

4.2 The acceptance criteria shall be clearly stated as order requirements.

SCOPE

1.1 This practice for ultrasonic examination covers turbine and generator steel rotor forgings covered by Specifications A469/A469M, A470/A470M, A768/A768M, and A940/A940M. This practice shall be used for contact testing only.

1.2 This practice describes a basic procedure of ultrasonically inspecting turbine and generator rotor forgings. It does not restrict the use of other ultrasonic methods such as reference block calibrations when required by the applicable procurement documents nor is it intended to restrict the use of new and improved ultrasonic test equipment and methods as they are developed.

1.3 This practice is intended to provide a means of inspecting cylindrical forgings so that the inspection sensitivity at the forging center line or bore surface is constant, independent of the forging or bore diameter. To this end, inspection sensitivity multiplication factors have been computed from theoretical analysis, with experimental verification. These are plotted in Fig. 1 (bored rotors) and Fig. 2 (solid rotors), for a true inspection frequency of 2.25 MHz, and an acoustic velocity of 2.30 in./s × 105 in./s [5.85 cm/s × 105 cm/s]. Means of converting to other sensitivity levels are provided in Fig. 3. (Sensitivity multiplication factors for other frequencies may be derived in accordance with X1.1 and X1.2 of Appendix X1.)

FIG. 1 Bored Forgings

Note 1: Sensitivity multiplication factor such that a 10 % indication at the forging bore surface will be equivalent to a 1/8 in. [3 mm] diameter flat bottom hole. Inspection frequency: 2.0 MHz or 2.25 MHz. Material velocity: 2.30 in./s × 105 in./s [5.85 cm/s × 105 cm/s].

FIG. 2 Solid Forgings

Note 1: Sensitivity multiplication factor such that a 10 % indication at the forging centerline surface will be equivalent to a 1/8 in. [3 mm] diameter flat bottom hole. Inspection frequency: 2.0 MHz or 2.25 MHz. Material velocity: 2.30 in./s × 105 in./s [5.85 cm/s × 105 cm/s].

FIG. 3 Conversion Factors to Be Used in Conjunction with Fig. 1 and Fig. 2 if a Change in the Reference Reflector Diameter is Required

1.4 Considerable verification data for this method have been generated which indicate that even under controlled conditions very significant uncertainties may exist in estimating natural discontinuities in terms of minimum equivalent size flat-bottom holes. The possibility exists that the estimated minimum areas of natural discontinuities in terms of minimum areas of the comparison flat-bottom holes may differ by 20 dB (factor of 10) in terms of actual areas of natural discontinuities. This magnitude of inaccuracy does not apply to all results but should be recognized as a possibility. Rigid control of the actual frequency used, the coil bandpass width if tuned instruments are used, and so forth, tend to reduce the overall inaccuracy which is apt to develop.

1.5 This practice for inspection applies to solid cylindrical forgings having outer diameters of not less than 2.5 in. [64 mm] nor greater than 100 in. [2540 mm]. It also applies to cylindrical forgings with concentric cylindrical bores having wall thicknesses of 2.5 [64 mm] in. or greater, within the same outer diameter limits as for solid cylinders. For solid sections less than 15 in. [380 mm] in diameter and for bored cylinders of less than 7.5 in. [190 mm] wall thickness the transducer used for the inspection will be different than the transducer used for larger sections.

1.6 Supplementary requirements of an optional nature are provided for use at the option of the...

- Standard8 pagesEnglish languagesale 15% off

- Standard8 pagesEnglish languagesale 15% off

SIGNIFICANCE AND USE

5.1 Often the most critical stress to which a sandwich panel core is subjected is shear. The effect of repeated shear stresses on the core material can be very important, particularly in terms of durability under various environmental conditions.

5.2 This test method provides a standard method of obtaining the sandwich core shear fatigue response. Uses include screening candidate core materials for a specific application, developing a design-specific core shear cyclic stress limit, and core material research and development.

Note 3: This test method may be used as a guide to conduct spectrum loading. This information can be useful in the understanding of fatigue behavior of core under spectrum loading conditions, but is not covered in this standard.

5.3 Factors that influence core fatigue response and shall therefore be reported include the following: core material, core geometry (density, cell size, orientation, etc.), specimen geometry and associated measurement accuracy, specimen preparation, specimen conditioning, environment of testing, specimen alignment, loading procedure, loading frequency, force (stress) ratio and speed of testing (for residual strength tests).

Note 4: If a sandwich panel is tested using the guidance of this standard, the following may also influence the fatigue response and should be reported: facing material, adhesive material, methods of material fabrication, adhesive thickness and adhesive void content. Further, core-to-facing strength may be different between precured/bonded and co-cured facings in sandwich panels with the same core and facing materials.

SCOPE

1.1 This test method determines the effect of repeated shear forces on core material used in sandwich panels. Permissible core material forms include those with continuous bonding surfaces (such as balsa wood and foams) as well as those with discontinuous bonding surfaces (such as honeycomb).

1.2 This test method is limited to test specimens subjected to constant amplitude uniaxial loading, where the machine is controlled so that the test specimen is subjected to repetitive constant amplitude force (stress) cycles. Either shear stress or applied force may be used as a constant amplitude fatigue variable.

1.3 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system are not necessarily exact equivalents; therefore, to ensure conformance with the standard, each system shall be used independently of the other, and values from the two systems shall not be combined. Within the text, the inch-pound units are shown in brackets.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Standard6 pagesEnglish languagesale 15% off

ABSTRACT

This specification covers coal tar primer suitable for use with coal tar pitch in roofing, dampproofing, and waterproofing below or above ground level, for application to concrete, masonry, and coal tar surfaces. Different tests shall be conducted in order to determine the following physical properties of coal tar primer: water content, consistency, specific gravity, matter insoluble in benzene, distillation, and coke residue content.

SCOPE

1.1 This specification covers coal tar primer suitable for use with coal tar pitch in roofing, dampproofing, and waterproofing below or above ground level, for application to concrete, masonry, and coal tar surfaces.

1.2 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in nonconformance with the standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Technical specification2 pagesEnglish languagesale 15% off

ABSTRACT

This test method deals with the acceptance criteria for the magnetic particle examination of forged steel crankshafts and forgings having large main bearing journal or crankpin diameters. Covered here are three classes of forgings, which shall be evaluated under two areas of inspection, namely: major critical areas, and minor critical areas. During inspection, magnetic particle indications shall be classified as: surface indications, which include nonmetallic inclusions or stringers, open or twist cracks, flakes, or pipes; open or pinpoint indications; and non-open indications. Procedures for dimpling, depressing, inspection, and product marking are also mentioned.

SCOPE

1.1 This is an acceptance specification for the magnetic particle inspection of forged steel crankshafts having main bearing journals or crankpins 4 in. [200 mm] or larger in diameter.

1.2 There are three classes, with acceptance standards of increasing severity:

1.2.1 Class 1.

1.2.2 Class 2 (originally the sole acceptance standard of this specification).

1.2.3 Class 3 (formerly covered in Supplementary Requirement S1 of Specification A456 – 64 (1970)).

1.3 This specification is not intended to cover continuous grain flow crankshafts (see Specification A983/A983M); however, Specification A986/A986M may be used for this purpose.

Note 1: Specification A668/A668M is a product specification which may be used for slab-forged crankshaft forgings that are usually twisted in order to set the crankpin angles, or for barrel forged crankshafts where the crankpins are machined in the appropriate configuration from a cylindrical forging.

1.4 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard.

1.5 Unless the order specifies the applicable “M” specification designation, the material shall be furnished to the inch units.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Technical specification5 pagesEnglish languagesale 15% off

- Technical specification5 pagesEnglish languagesale 15% off

ABSTRACT

This specification covers coated glass mat water-resistant gypsum backing panel designed for use on ceilings and walls in bath and shower areas as a base for the application of ceramic or plastic tile. Coated glass mat water-resistant gypsum backing panel shall consist of a noncombustible water-resistant gypsum core, surfaced with glass mat, partially or completely embedded in the core, and with a water-resistant coating on one surface. The specimens shall be tested for flexural strength, humidified deflection, core hardness, end hardness, edge hardness, nail pull resistance, water resistance, and surface water absorption. Coated glass mat water-resistant gypsum backing panel shall have surfaces true and free of imperfections that render the panel unfit for its designed use.

SCOPE

1.1 This specification covers coated glass mat water-resistant gypsum backing panel designed for use on ceilings and walls in bath and shower areas as a base for the application of ceramic or plastic tile.

1.2 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard. Within the text, the SI units are shown in brackets.

1.3 The text of this standard references notes and footnotes that provide explanatory material. These notes and footnotes (excluding those in tables and figures) shall not be considered as requirements of the standard.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Technical specification3 pagesEnglish languagesale 15% off

- Technical specification3 pagesEnglish languagesale 15% off

SIGNIFICANCE AND USE

5.1 The honeycomb tensile-node bond strength is a fundamental property than can be used in determining whether honeycomb cores can be handled during cutting, machining and forming without the nodes breaking. The tensile-node bond strength is the tensile stress that causes failure of the honeycomb by rupture of the bond between the nodes. It is usually a peeling-type failure.

5.2 This test method provides a standard method of obtaining tensile-node bond strength data for quality control, acceptance specification testing, and research and development.

SCOPE

1.1 This test method covers the determination of the tensile-node bond strength of honeycomb core materials.

1.2 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Standard4 pagesEnglish languagesale 15% off

ABSTRACT

This specification covers emulsified asphalt suitable for use as a protective coating for built-up roofs and other exposed surfaces with specified inclines. The emulsified asphalts are grouped into three types, as follows: Type I, which contains fillers or fibers including asbestos; Type II, which contains fillers or fibers other than asbestos; and Type III, which do not contain any form of fibrous reinforcement. These types are further subdivided into two classes, as follows: Class 1, which is prepared with mineral colloid emulsifying agents; and Class 2, which is prepared with chemical emulsifying agents. Other than consistency and homogeneity of the final products, they shall also conform to specified physical property requirements such as weight, residue by evaporation, ash content of residue, water content flammability, firm set, flexibility, resistance to water, and behavior during heat and direct flame tests.

SCOPE

1.1 This specification covers emulsified asphalt suitable for use as a protective coating for built-up roofs and other exposed surfaces with inclines of not less than 4 % or 42 mm/m [1/2 in./ft].

1.2 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system are not necessarily exact equivalents; therefore, to ensure conformance with the standard, each system shall be used independently of the other, and values from the two systems shall not be combined.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Technical specification2 pagesEnglish languagesale 15% off

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.