ASTM D807-05(2009)

(Practice)Standard Practice for Assessing the Tendency of Industrial Boiler Waters to Cause Embrittlement (USBM Embrittlement Detector Method)

Standard Practice for Assessing the Tendency of Industrial Boiler Waters to Cause Embrittlement (USBM Embrittlement Detector Method)

SIGNIFICANCE AND USE

Embrittlement is a form of intercrystalline cracking that is associated with the exposure of boiler steel to a combination of physical and chemical factors. For embrittlement of boiler metal to occur, the metal must be under stress, it must be at the site of a leak, and it must be exposed to the concentrated boiler water. In addition, the boiler water must be embrittling in nature. The precise chemical causes of the embrittling nature of some waters is not well understood. Experience has shown that certain waters exhibit an embrittling characteristic while others do not.

Because embrittlement is a form of cracking, it is nearly impossible to detect in an operating boiler until a failure has occured. In general, cracking failures tend to be sudden, and often with serious consequences. This practice offers a way to determine whether a particular water is embrittling or not. It also makes it possible to determine if specific treatment actions have rendered the water nonembrittling.

SCOPE

1.1 This practice, known as the embrittlement-detector method, covers the apparatus and procedure for determining the embrittling or nonembrittling characteristics of the water in an operating boiler. The interpretation of the results shall be restricted to the limits set forth in Section 8.6.

Note 1—The embrittlement detector was designed to reproduce closely the conditions existing in an actual boiler seam. It is considered probable that the individual conditions of leakage, concentration, and stress in the boiler seam can equal those in the detector. The essential difference between the detector and the boiler is that the former is so constructed and operated that these three major factors act simultaneously, continuously, and under the most favorable circumstances to produce cracking; whereas, in the boiler the three factors are brought together only under unique circumstances. Furthermore, in the detector any cracking is produced in a small test surface that can be inspected thoroughly, while the susceptible areas in a boiler are large and can be inspected only with difficulty. In these respects the embrittlement detector provides an accelerated test of the fourth condition necessary for embrittlement, the embrittling nature of the boiler water.

Note 2—Cracks in a specimen after being subjected to this test indicate that the boiler water can cause embrittlement cracking, but not that the boiler in question necessarily has cracked or will crack.

1.2 The effectiveness of treatment to prevent cracking, as well as an indication of whether an unsafe condition exists, are shown by this practice. Such treatments are evaluated in terms of method specimen resistance to failure.

1.3 The practice may be applied to embrittlement resistance testing of steels other than boiler plate, provided that a duplicate, unexposed specimen does not crack when bent 90° on a 2-in. (51-mm) radius.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D807 − 05(Reapproved 2009)

Standard Practice for

Assessing the Tendency of Industrial Boiler Waters to

Cause Embrittlement (USBM Embrittlement Detector

Method)

This standard is issued under the fixed designation D807; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 1.2 The effectiveness of treatment to prevent cracking, as

3 well as an indication of whether an unsafe condition exists, are

1.1 This practice, known as the embrittlement-detector

shown by this practice. Such treatments are evaluated in terms

method, covers the apparatus and procedure for determining

of method specimen resistance to failure.

the embrittling or nonembrittling characteristics of the water in

an operating boiler. The interpretation of the results shall be 1.3 The practice may be applied to embrittlement resistance

restricted to the limits set forth in Section 8.6. testing of steels other than boiler plate, provided that a

duplicate, unexposed specimen does not crack when bent 90°

NOTE1—Theembrittlementdetectorwasdesignedtoreproduceclosely

on a 2-in. (51-mm) radius.

the conditions existing in an actual boiler seam. It is considered probable

that the individual conditions of leakage, concentration, and stress in the

1.4 This standard does not purport to address all of the

boiler seam can equal those in the detector. The essential difference

safety concerns, if any, associated with its use. It is the

between the detector and the boiler is that the former is so constructed and

responsibility of the user of this standard to establish appro-

operated that these three major factors act simultaneously, continuously,

priate safety and health practices and determine the applica-

andunderthemostfavorablecircumstancestoproducecracking;whereas,

in the boiler the three factors are brought together only under unique

bility of regulatory limitations prior to use.

circumstances. Furthermore, in the detector any cracking is produced in a

small test surface that can be inspected thoroughly, while the susceptible

2. Referenced Documents

areas in a boiler are large and can be inspected only with difficulty. In

these respects the embrittlement detector provides an accelerated test of 2.1 ASTM Standards:

the fourth condition necessary for embrittlement, the embrittling nature of

A108 Specification for Steel Bar, Carbon and Alloy, Cold-

the boiler water.

Finished

NOTE2—Cracksinaspecimenafterbeingsubjectedtothistestindicate

A515/A515M Specification for Pressure Vessel Plates, Car-

that the boiler water can cause embrittlement cracking, but not that the

bon Steel, for Intermediate- and Higher-Temperature Ser-

boiler in question necessarily has cracked or will crack.

vice

D1129 Terminology Relating to Water

United States Bureau of Mines.

D1193 Specification for Reagent Water

This test method is under the jurisdiction of ASTM Committee D19 on Water

E3 Guide for Preparation of Metallographic Specimens

and is the direct responsibility of Subcommittee D19.03 on Sampling Water and

E883 Guide for Reflected–Light Photomicrography

Water-Formed Deposits, Analysis of Water for Power Generation and Process Use,

On-Line Water Analysis, and Surveillance of Water.

E1351 Practice for Production and Evaluation of Field

Current edition approved Oct. 1, 2009. Published November 2009. Originally

Metallographic Replicas

approved in 1944. Last previous edition approved in 2005 as D807 – 05. DOI:

10.1520/D0807-05R09.

This test method was developed during an investigation conducted under a 3. Terminology

cooperative agreement between the Joint Research Committee on Boiler Feedwater

3.1 Definitions:

Studies and the United States Bureau of Mines.

For information on the development of this test method reference may be made 3.1.1 The term embrittlement cracking in this test method is

to the following:

defined in accordance with Terminology D1129 as follows:

Schroeder, W. C. and Berk, A. A. “Intercrystalline Cracking of Boiler Steel and

3.1.1.1 embrittlement cracking—aformofmetalfailurethat

Its Prevention,” Bulletin 443, U.S. Bureau of Mines, 1941.

occurs in steam boilers at riveted joints and at tube ends, the

Schroeder, W. C., Berk, A. A. and Stoddard, C. K. “Embrittlement Detector

Testing on Boilers,” Power Plant Engineering, Vol 45, August, 1941, pp. 69–76.

cracking being predominantly intercrystalline.

“Embrittlement Symposium,” Transactions of the Am. Soc. Mech. Engrs., Vol

64, 1942, pp. 393–444.

Whirl, S. F. and Purcell, T. E. “Protection Against Caustic Embrittlement by

Coordinated Phosphate-pH Control,” Proceedings,ThirdAnnualWater Conference, For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Engrs. Soc. of Western Penna., 1942, pp. 45–60. contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Berk, A. A. and Schroeder, W. C. “A Practical Way to Prevent Embrittlement Standards volume information, refer to the standard’s Document Summary page on

Cracking,” Transactions, Am. Soc. Mech. Engr., Vol 65, 1943, pp. 701–711. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D807 − 05 (2009)

NOTE 3—This form of cracking, which has been known as “caustic

embrittlement,”isbelievedtoresultfromtheactionofcertainconstituents

of concentrated boiler water upon steel under stress.

NOTE 4—For a detailed discussion as to what cracking should be

considered significant for the purpose of this practice, see Section 8.6.

3.1.2 For definitions of other terms used in this practice,

refer to Terminology D1129.

4. Summary of Practice

4.1 For embrittlement cracking of the boiler metal to be

possible, the boiler water must concentrate a thousand times or

more in contact with the metal under high residual or applied

tensile stress. In a boiler such concentration may take place in

riveted seams or in annular spaces at tube ends, and the steel at

such locations may be highly stressed when the boiler is

constructedormaybecomehighlystressedwhenitisoperated.

If the chemicals in the boiler water concentrate in the seams to

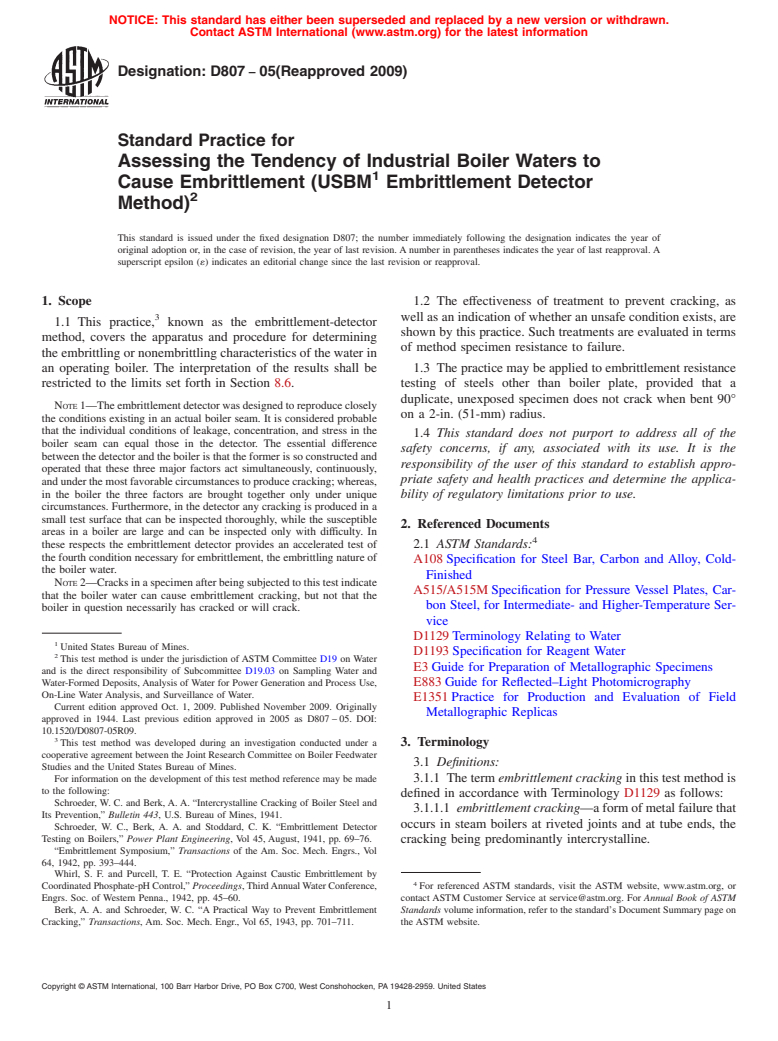

FIG. 2 Embrittlement Detector Installed

develop an embrittling solution, cracking may occur.

4.2 In the embrittlement detector (Fig. 1), the conditions of

water. In addition, the boiler water must be embrittling in

concentration and stress are provided by the design of the unit.

nature.Theprecisechemicalcausesoftheembrittlingnatureof

Boiler water is permitted to seep slowly from the small hole

some waters is not well understood. Experience has shown that

through the restricted space between the contact surfaces of the

certain waters exhibit an embrittling characteristic while others

test specimen and the groove in the block. As this extremely

do not.

slow flow takes place toward atmospheric pressure, the heat in

the metal and in the liquid causes progressive evaporation to

5.2 Because embrittlement is a form of cracking, it is nearly

produce an increasingly concentrated solution. When the

impossible to detect in an operating boiler until a failure has

detector is properly adjusted, concentrated boiler water is in

occured. In general, cracking failures tend to be sudden, and

contact with the stressed test surface of the specimen, thus

often with serious consequences. This practice offers a way to

providing the necessary factor to determine whether the boiler

determine whether a particular water is embrittling or not. It

water can cause embrittlement cracking.

also makes it possible to determine if specific treatment actions

have rendered the water nonembrittling.

5. Significance and Use

6. Apparatus

5.1 Embrittlement is a form of intercrystalline cracking that

is associated with the exposure of boiler steel to a combination

6.1 Embrittlement Detector—The embrittlement detector

of physical and chemical factors. For embrittlement of boiler

shall consist of the unit, complete with steel specimen, as

metal to occur, the metal must be under stress, it must be at the

shown assembled in cross section in Fig. 1 and as the installed

site of a leak, and it must be exposed to the concentrated boiler

unit in Fig. 2.The principal parts consist of a rectangular block

base through which the water circulates and in which a groove

has been machined to receive the test specimen, a test

specimen, and a clamping plate which fits over four stud bolts

in the block. When the nuts on the stud bolts are tightened, the

pressure of the clamping plate molds the test specimen to the

contour of the groove, thus stressing in tension the surface of

the specimen. Working drawings (Note 4) showing the dimen-

sionsofallthemachinedpartsareshowninFigs.3-5.Accurate

machining of the groove with respect to the small hole through

which the boiler water is brought to the test surface of the

specimen is especially important.

6.2 Wrenches—An extra-heavy box-type wrench of 27-mm

(1 ⁄16-in.) opening is recommended for assembling and adjust-

ing the unit. A lighter box-type wrench of 19-mm ( ⁄4-in.)

opening is recommended for the hexagonal head of the

adjusting screw in the end of the specimen.

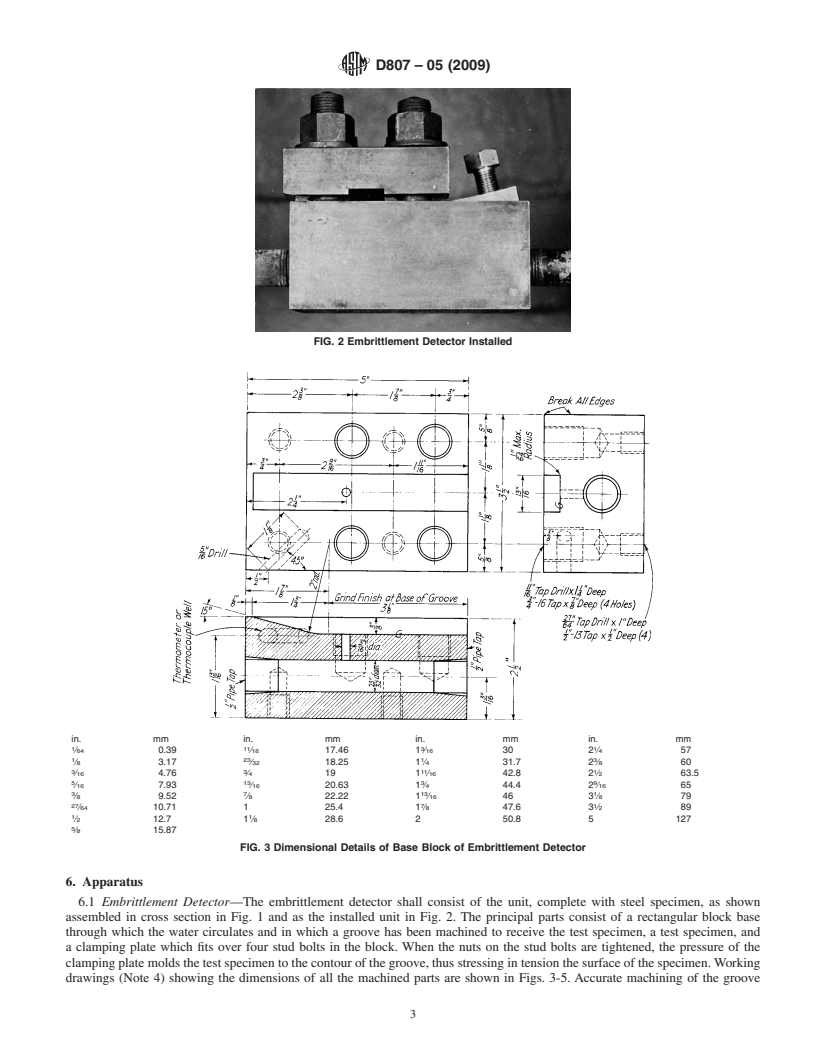

6.3 Jig for Bending Specimen—A jig as shown in Fig. 6,or

its equivalent, is recommended for bending the specimen with

ahydraulicpressattheendofthetesttorevealcracksthatmay

have been formed but are too fine to be visible without

FIG. 1 Cross-Section of Embrittlement Detector additional stressing of the steel surface. Other devices may be

D807 − 05 (2009)

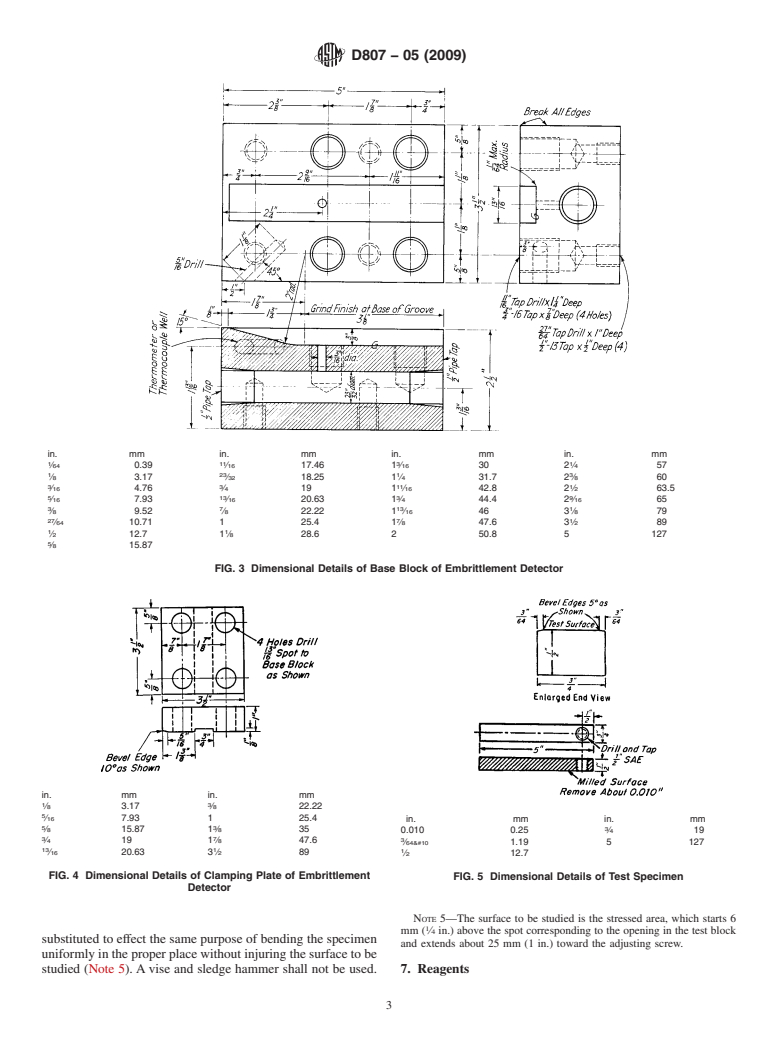

in. mm in. mm in. mm in. mm

1 11 3 1

⁄64 0.39 ⁄16 17.46 1 ⁄16 30 2 ⁄4 57

1 23 1 3

⁄8 3.17 ⁄32 18.25 1 ⁄4 31.7 2 ⁄8 60

3 3 11 1

⁄16 4.76 ⁄4 19 1 ⁄16 42.8 2 ⁄2 63.5

5 13 3 9

⁄16 7.93 ⁄16 20.63 1 ⁄4 44.4 2 ⁄16 65

3 7 13 1

⁄8 9.52 ⁄8 22.22 1 ⁄16 46 3 ⁄8 79

27 7 1

⁄64 10.71 1 25.4 1 ⁄8 47.6 3 ⁄2 89

1 1

⁄2 12.7 1 ⁄8 28.6 2 50.8 5 127

⁄8 15.87

FIG. 3 Dimensional Details of Base Block of Embrittlement Detector

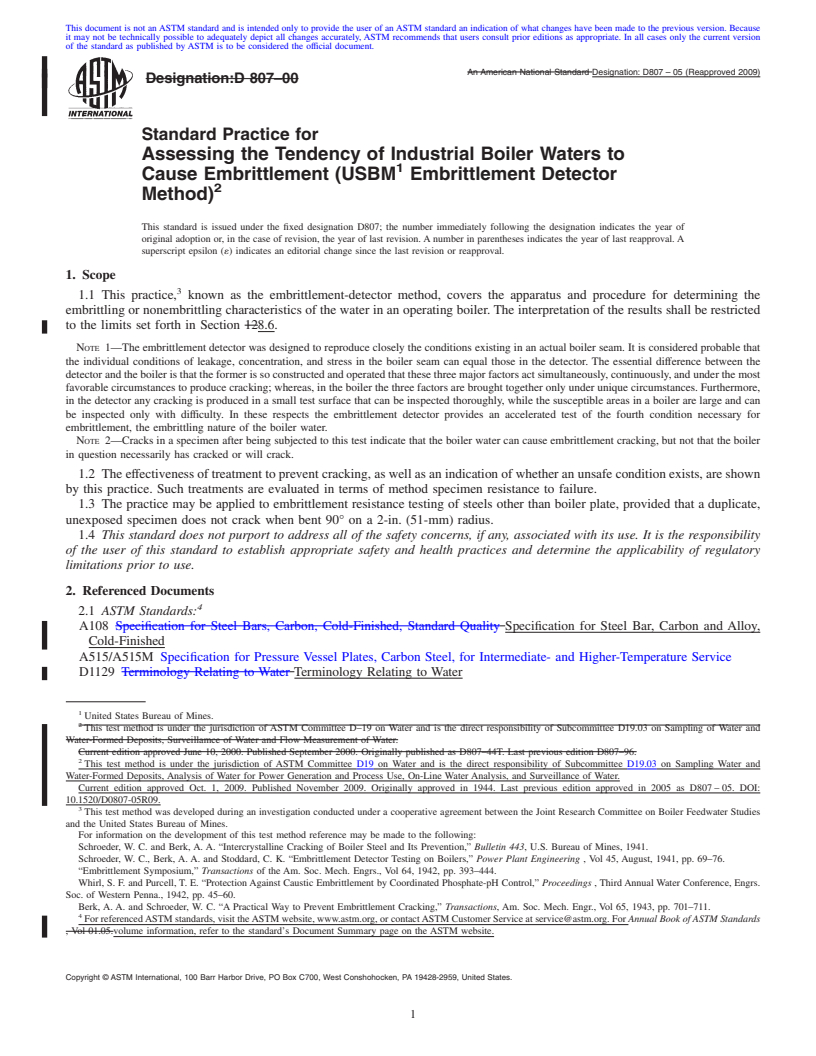

in. mm in. mm

1 3

⁄8 3.17 ⁄8 22.22

⁄16 7.93 1 25.4

in. mm in. mm

5 3

⁄8 15.87 1 ⁄8 35

0.010 0.25 ⁄4 19

3 7

⁄4 19 1 ⁄8 47.6

⁄64

1.19 5 127

13 1

⁄16 20.63 3 ⁄2 89

⁄2 12.7

FIG. 4 Dimensional Details of Clamping Plate of Embrittlement

FIG. 5 Dimensional Details of Test Specimen

Detector

NOTE 5—The surface to be studied is the stressed area, which starts 6

mm ( ⁄4 in.) above the spot corresponding to the opening in the test block

substituted to effect the same purpose of bending the specimen

and extends about 25 mm (1 in.) toward the adjusting screw.

uniformly in the proper place without injuring the surface to be

studied (Note 5). A vise and sledge hammer shall not be used. 7. Reagents

D807 − 05 (2009)

remove less soluble incrustations. Polish the groove with fine

emery cloth. Finally open the inlet valve for an instant to make

sure that the small leakage hole is cleaned out, then wipe the

groove clean.Treat the stud threads with graphite suspended in

oil (Note 10).

NOTE 9—When received from the manufacturer the detector is already

assembled with the specimen in position and should be steam tight. It is

recommended that the specimen not be removed from the detector until

after the first test is completed.

NOTE10—Alittlegraphitesuspendedinoilappliedtothethreadsofthe

studs and the adjusting screw will minimize seizing. Use kerosine instead

of oil if the pressure is greater than 3.5 MPa (500 psi).

NOTE 1—Rectangular Bars of 1-in. (25 mm) Cold-Rolled Plate Held

1 8.2.2 To assemble the specimen and the detector, center the

Togetherby1-in.Bolts.DistanceBetweenBars3 ⁄4 in.(82mm).Pressure

Transmitted by a 1 ⁄2 in. (38 mm) Round Bar. specimen with the smoothed surface facing the groove of the

FIG. 6 Jig for Bending Specimen After Test

blocksothattheendwiththeadjustingscrewholeisflushwith

theendoftheblocknotgrooved.Placetheclampingplateover

the studs, with the beveled edge inward and toward the end of

7.1 Purity of Reagents—Unless otherwise indicated, refer-

the specimen containing the adjusting screw. Place the washers

ences to water shall be understood to mean reagent water

and nuts on the studs. Tighten alternately and evenly first the

conforming to Type IV of Specification D1193.

nuts on the top pairs of studs (Note 10) in the center of the

8. Procedure detector block, thus forcing the surface of the test specimen to

conform to the curvature of the groove. Then tighten the nuts

8.1 Test Specimens

on the bottom pair of studs. Finally tighten the nuts on the top

1 3

8.1.1 Cut test specimens 13 by 19 by 127 mm ( ⁄2 by ⁄4 by

pair of studs to bring the surfaces close enough together so that

1 3

5 in.) from 13 by 19-mm ( ⁄2 by ⁄4-in.) cold-finished bar stock

the small hole in the detector block groove is sealed.

(Note6andNote7)conformingtoGrade1020ofSpecification

A108.

NOTE 11—There shall be no leakage from the detector when the valves

are opened and water at full boiler pressure flows through the block.

NOTE 6—Where specimens of cold-rolled steel have been cracked,

similar specimens machined from boiler plate conforming to Specification

8.2.3 Insert the adjusting screw in the specimen and turn it

A515/A515M, or hot-rolled steel of comparable composition may be

down with the fingers until it just touches the block.

tested to determine the severity of the embrittling condition. Hot-rolled

steel has proved less susceptible to cracking than cold-rolled steel.

8.3 Installation of Detector

NOTE 7—Alloy steels are often more susceptible for cracking than the

8.3.1 Connect the assembled detector to the operating boiler

standard cold-rolled steel specified for test specimens. Where the water

so that boiler water will circulate through the block (Note 12).

tested is used in alloy-steel boilers, it is desirable that the test specimen be

Flush clean the inlet line to the detector before the detector is

prepared from the same material or from bars of similar composition and

physical properties.

attached.

8.1.2 Finish the test surface of the specimen by either

NOTE 12—The detector may be installed in a bypass to a continuous

grinding with a surface grinder to a finish comparable to that

blow-down line or in a recirculating line if one is available. The effluent

produced by No. 2 metallographic polishing paper, or milling

from the detector may be returned to the boiler or discharged to waste.

to remove surface imperfections and smoothing with No. 2

8.3.2 Maintain the temperature and pressure of the water

metallographic paper to remove the cutter marks. Grind and

circulating through the detector

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

An American National Standard Designation: D807 – 05 (Reapproved 2009)

Designation:D 807–00

Standard Practice for

Assessing the Tendency of Industrial Boiler Waters to

Cause Embrittlement (USBM Embrittlement Detector

Method)

This standard is issued under the fixed designation D807; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This practice, known as the embrittlement-detector method, covers the apparatus and procedure for determining the

embrittling or nonembrittling characteristics of the water in an operating boiler. The interpretation of the results shall be restricted

to the limits set forth in Section 128.6.

NOTE 1—The embrittlement detector was designed to reproduce closely the conditions existing in an actual boiler seam. It is considered probable that

the individual conditions of leakage, concentration, and stress in the boiler seam can equal those in the detector. The essential difference between the

detector and the boiler is that the former is so constructed and operated that these three major factors act simultaneously, continuously, and under the most

favorable circumstances to produce cracking; whereas, in the boiler the three factors are brought together only under unique circumstances. Furthermore,

in the detector any cracking is produced in a small test surface that can be inspected thoroughly, while the susceptible areas in a boiler are large and can

be inspected only with difficulty. In these respects the embrittlement detector provides an accelerated test of the fourth condition necessary for

embrittlement, the embrittling nature of the boiler water.

NOTE 2—Cracks in a specimen after being subjected to this test indicate that the boiler water can cause embrittlement cracking, but not that the boiler

in question necessarily has cracked or will crack.

1.2 The effectiveness of treatment to prevent cracking, as well as an indication of whether an unsafe condition exists, are shown

by this practice. Such treatments are evaluated in terms of method specimen resistance to failure.

1.3 The practice may be applied to embrittlement resistance testing of steels other than boiler plate, provided that a duplicate,

unexposed specimen does not crack when bent 90° on a 2-in. (51-mm) radius.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2.1 ASTM Standards:

A108 Specification for Steel Bars, Carbon, Cold-Finished, Standard Quality Specification for Steel Bar, Carbon and Alloy,

Cold-Finished

A515/A515M Specification for Pressure Vessel Plates, Carbon Steel, for Intermediate- and Higher-Temperature Service

D1129 Terminology Relating to Water Terminology Relating to Water

United States Bureau of Mines.

This test method is under the jurisdiction of ASTM Committee D–19 on Water and is the direct responsibility of Subcommittee D19.03 on Sampling of Water and

Water-Formed Deposits, Surveillamce of Water and Flow Measurement of Water.

Current edition approved June 10, 2000. Published September 2000. Originally published as D807–44T. Last previous edition D807–96.

This test method is under the jurisdiction of ASTM Committee D19 on Water and is the direct responsibility of Subcommittee D19.03 on Sampling Water and

Water-Formed Deposits, Analysis of Water for Power Generation and Process Use, On-Line Water Analysis, and Surveillance of Water.

Current edition approved Oct. 1, 2009. Published November 2009. Originally approved in 1944. Last previous edition approved in 2005 as D807 – 05. DOI:

10.1520/D0807-05R09.

This test method was developed during an investigation conducted under a cooperative agreement between the Joint Research Committee on Boiler Feedwater Studies

and the United States Bureau of Mines.

For information on the development of this test method reference may be made to the following:

Schroeder, W. C. and Berk, A. A. “Intercrystalline Cracking of Boiler Steel and Its Prevention,” Bulletin 443, U.S. Bureau of Mines, 1941.

Schroeder, W. C., Berk, A. A. and Stoddard, C. K. “Embrittlement Detector Testing on Boilers,” Power Plant Engineering , Vol 45, August, 1941, pp. 69–76.

“Embrittlement Symposium,” Transactions of the Am. Soc. Mech. Engrs., Vol 64, 1942, pp. 393–444.

Whirl, S. F. and Purcell, T. E. “Protection Against Caustic Embrittlement by Coordinated Phosphate-pH Control,” Proceedings , Third Annual Water Conference, Engrs.

Soc. of Western Penna., 1942, pp. 45–60.

Berk, A. A. and Schroeder, W. C. “A Practical Way to Prevent Embrittlement Cracking,” Transactions, Am. Soc. Mech. Engr., Vol 65, 1943, pp. 701–711.

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

, Vol 01.05.volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D807–05 (2009)

D1193 Specification for Reagent Water

E3 Methods of Preparation of Metallographic Specimens Guide for Preparation of Metallographic Specimens

E883 Guide for Reflected-Light Photomicrography Guide for ReflectedLight Photomicrography

E1351 Practice for Production and Evaluation of Field Metallographic Replicas

3. Terminology

3.1 Definitions:

3.1.1 The term embrittlement cracking in this test method is defined in accordance with Terminology D 1129D1129 as follows:

3.1.1.1 embrittlement cracking—a form of metal failure that occurs in steam boilers at riveted joints and at tube ends, the

cracking being predominantly intercrystalline.

NOTE 3—This form of cracking, which has been known as “caustic embrittlement,” is believed to result from the action of certain constituents of

concentrated boiler water upon steel under stress.

NOTE 4—For a detailed discussion as to what cracking should be considered significant for the purpose of this practice, see Section 128.6.

3.1.2 For definitions of other terms used in this practice, refer to Terminology D 1129D1129.

4. Summary of Practice

4.1 For embrittlement cracking of the boiler metal to be possible, the boiler water must concentrate a thousand times or more

incontactwiththemetalunderhighresidualorappliedtensilestress.Inaboilersuchconcentrationmaytakeplaceinrivetedseams

or in annular spaces at tube ends, and the steel at such locations may be highly stressed when the boiler is constructed or may

become highly stressed when it is operated. If the chemicals in the boiler water concentrate in the seams to develop an embrittling

solution, cracking may occur.

4.2 In the embrittlement detector (Fig. 1), the conditions of concentration and stress are provided by the design of the unit.

Boiler water is permitted to seep slowly from the small hole through the restricted space between the contact surfaces of the test

specimen and the groove in the block.As this extremely slow flow takes place toward atmospheric pressure, the heat in the metal

and in the liquid causes progressive evaporation to produce an increasingly concentrated solution. When the detector is properly

adjusted, concentrated boiler water is in contact with the stressed test surface of the specimen, thus providing the necessary factor

to determine whether the boiler water can cause embrittlement cracking.

5. Significance and Use

5.1 Embrittlement is a form of intercrystalline cracking that is associated with the exposure of boiler steel to a combination of

physical and chemical factors. For embrittlement of boiler metal to occur, the metal must be under stress, it must be at the site of

a leak, and it must be exposed to the concentrated boiler water. In addition, the boiler water must be embrittling in nature. The

precise chemical causes of the embrittling nature of some waters is not well understood. Experience has shown that certain waters

exhibit an embrittling characteristic while others do not.

5.2 Because embrittlement is a form of cracking, it is nearly impossible to detect in an operating boiler until a failure has

occured. In general, cracking failures tend to be sudden, and often with serious consequences. This practice offers a way to

determine whether a particular water is embrittling or not. It also makes it possible to determine if specific treatment actions have

rendered the water nonembrittling.

FIG. 1 Cross-Section of Embrittlement Detector

D807–05 (2009)

FIG. 2 Embrittlement Detector Installed

in. mm in. mm in. mm in. mm

1 11 3 1

⁄64 0.39 ⁄16 17.46 1 ⁄16 30 2 ⁄4 57

1 23 1 3

⁄8 3.17 ⁄32 18.25 1 ⁄4 31.7 2 ⁄8 60

3 3 11 1

⁄16 4.76 ⁄4 19 1 ⁄16 42.8 2 ⁄2 63.5

5 13 3 9

⁄16 7.93 ⁄16 20.63 1 ⁄4 44.4 2 ⁄16 65

3 7 13 1

⁄8 9.52 ⁄8 22.22 1 ⁄16 46 3 ⁄8 79

27 7 1

⁄64 10.71 1 25.4 1 ⁄8 47.6 3 ⁄2 89

1 1

⁄2 12.7 1 ⁄8 28.6 2 50.8 5 127

⁄8 15.87

FIG. 3 Dimensional Details of Base Block of Embrittlement Detector

6. Apparatus

6.1 Embrittlement Detector—The embrittlement detector shall consist of the unit, complete with steel specimen, as shown

assembled in cross section in Fig. 1 and as the installed unit in Fig. 2. The principal parts consist of a rectangular block base

through which the water circulates and in which a groove has been machined to receive the test specimen, a test specimen, and

a clamping plate which fits over four stud bolts in the block. When the nuts on the stud bolts are tightened, the pressure of the

clamping plate molds the test specimen to the contour of the groove, thus stressing in tension the surface of the specimen.Working

drawings (Note 4) showing the dimensions of all the machined parts are shown in Figs. 3-5. Accurate machining of the groove

D807–05 (2009)

in. mm in. mm

1 3

⁄8 3.17 ⁄8 22.22

⁄16 7.93 1 25.4

5 3

⁄8 15.87 1 ⁄8 35

3 7

⁄4 19 1 ⁄8 47.6

13 1

⁄16 20.63 3 ⁄2 89

FIG. 4 Dimensional Details of Clamping Plate of Embrittlement

Detector

in. mm in. mm

0.010 0.25 ⁄4 19

⁄64 1.19 5 127

⁄2 12.7

FIG. 5 Dimensional Details of Test Specimen

with respect to the small hole through which the boiler water is brought to the test surface of the specimen is especially important.

6.2 Wrenches—Anextra-heavybox-typewrenchof27-mm(1 ⁄16-in.)openingisrecommendedforassemblingandadjustingthe

unit. A lighter box-type wrench of 19-mm ( ⁄4-in.) opening is recommended for the hexagonal head of the adjusting screw in the

end of the specimen.

6.3 Jig for Bending Specimen—A jig as shown in Fig. 6, or its equivalent, is recommended for bending the specimen with a

hydraulic press at the end of the test to reveal cracks that may have been formed but are too fine to be visible without additional

stressing of the steel surface. Other devices may be substituted to effect the same purpose of bending the specimen uniformly in

the proper place without injuring the surface to be studied (Note 5). A vise and sledge hammer shall not be used.

NOTE 5—The surface to be studied is the stressed area, which starts 6 mm ( ⁄4 in.) above the spot corresponding to the opening in the test block and

extends about 25 mm (1 in.) toward the adjusting screw.

7. Test Specimens

7.1Cut test specimens 13 by 19 by 127 mm ( ⁄2 Reagents

7.1 Purity of Reagents—Unless otherwise indicated, references to water shall be understood to mean reagent water conforming

to Type IV of Specification D1193.

8. Procedure

8.1 Test Specimens

1 3 1 3

8.1.1 Cut test specimens 13 by 19 by 127 mm ( ⁄2 by ⁄4 by 5 in.) from 13 by 19-mm ( ⁄2 by ⁄4-in.) cold-finished bar stock (Note

D807–05 (2009)

NOTE—Rectangular Bars of 1-in. (25 mm) Cold-Rolled Plate Held

Togetherby1-in.Bolts.DistanceBetweenBars3 ⁄4 in.(82mm).Pressure

Transmitted by a 1 ⁄2 in. (38 mm) Round Bar.

FIG. 6 Jig for Bending Specimen After Test

6 and Note 7) conforming to Grade 1020 of Specification A 108A108.

NOTE 6—Where specimens of cold-rolled steel have been cracked, similar specimens machined from boiler plate conforming to Specification A

515A515/A515M/A515M,, or hot-rolled steel of comparable composition may be tested to determine the severity of the embrittling condition. Hot-rolled

steel has proved less susceptible to cracking than cold-rolled steel.

NOTE 7—Alloy steels are often more susceptible for cracking than the standard cold-rolled steel specified for test specimens. Where the water tested

is used in alloy-steel boilers, it is desirable that the test specimen be prepared from the same material or from bars of similar composition and physical

properties.

78.1.2 Finish the test surface of the specimen by either grinding with a surface grinder to a finish comparable to that produced

by No. 2 metallographic polishing paper, or milling to remove surface imperfections and smoothing with No. 2 metallographic

paper to remove the cutter marks. Grind and polish along the length of the specimen. If the specimen surface still shows visible

flaws, such as holes, oxide, or rolling marks, after 0.2 mm (0.01 in.) has been removed, discard the specimen and prepare another

one.

7.3Bevel8.1.3 Bevel the edges of the test surface 5°, as shown in Fig. 5.

78.1.4 Center the threaded hole in the specimen for the adjusting screw and tap as specified in Fig. 5 so that the cap screw is

perpendicular to the surface. The adjusting screw shall be sufficiently free so that it can be turned easily with the fingers.

NOTE 8—Specimens that have been prepared in accordance with the directions given in Section 7 8 may be obtained from the major water-treating

companies. 8.

8.2 Assembly of Specimen and Detector

8.2.1 When a new specimen is to be installed in the detector (Note 9), clean the block, especially the surface of the groove, with

hotwatertodissolvesolublesolids,andscrapelightlytoremovelesssolubleincrustations.Polishthegroovewithfineemerycloth.

Finally open the inlet valve for an instant to make sure that the small leakage hole is cleaned out, then wipe the groove clean.Treat

the stud threads with graphite suspended in oil (Note

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.