ASTM B774-00(2005)

(Specification)Standard Specification for Low Melting Point Alloys

Standard Specification for Low Melting Point Alloys

ABSTRACT

This specification covers low-melting point metal alloys and soldiers, including bismuth-tin, bismuth-lead, bismuth-tin-lead, bismuth-tin-lead-cadmium, bismuth-tin-lead-indium-cadmium, bismuth-tin-lead-indium, indium-lead, indium-lead-silver, and indium-tin joining together two or more metals at temperatures below their melting points; blocking for support and removable borders; radiation shielding; fusible plugs; fuses; tube bending; and punch setting. This specification shall include those alloys having liquidus temperature not exceeding the melting point of the tin lead eutectic, and alloys in the form of solid bars, ingots, powder and special forms, and in the form of solid ribbon and wire. The composition of the alloys shall conform to the chemical requirements for bismuth, lead, tin, cadmium, indium, silver, copper, antimony, and zinc. Alloys shall be tested and shall conform to specified values for alloy freezing point, and powder mesh size.

SCOPE

1.1 This specification covers low-melting point metal alloys and soldiers, including bismuth-tin, bismuth-lead, bismuth-tin-lead, bismuth-tin-lead-cadmium, bismuth-tin-lead-indium-cadmium, bismuth-tin-lead-indium, indium-lead, and indium-lead-silver, and indium-tin joining together two or more metals at temperatures below their melting points; blocking for support and removable borders; radiation shielding; fusible plugs; fuses; tube bending; and punch setting.

1.1.1 This specification shall include those alloys having a liquidus temperature not exceeding 361oF (183oC), the melting point of the tin lead eutectic.

1.1.2 This specification includes low-melting point alloys in the form of solid bars, ingots, powder and special forms, and in the form of solid ribbon and wire.

1.2 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: B 774 – 00 (Reapproved 2005)

Standard Specification for

Low Melting Point Alloys

This standard is issued under the fixed designation B 774; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope MIL-STD 129 Marking for Shipment and Storage

2.3 Federal Standard:

1.1 This specification covers low-melting point metal alloys

Fed. Std. No. 123 Marking for Shipment (Civil Agencies)

and soldiers, including bismuth–tin, bismuth–lead, bismuth-

–tin–lead, bismuth–tin–lead–cadmium, bismuth–tin–lead–indi-

3. Terminology

um–cadmium, bismuth–tin–lead–indium, indium–lead, and in-

3.1 Definition:

dium–lead–silver, and indium–tin joining together two or more

3.1.1 producer, n— the primary manufacturer of the mate-

metals at temperatures below their melting points; blocking for

rial.

support and removable borders; radiation shielding; fusible

3.2 Definitions of Terms Specific to This Standard:

plugs; fuses; tube bending; and punch setting.

3.2.1 liquidus, n—the lowest temperature at which an alloy

1.1.1 This specification shall include those alloys having a

is fully transformed from a solid to a liquid.

liquidus temperature not exceeding 361°F (183°C), the melting

3.2.2 lot, n—theterm“lot”asusedinthisspecificationshall

point of the tin lead eutectic.

be defined as follows: for solid alloy metal, a lot shall consist

1.1.2 This specification includes low-melting point alloys in

of all the metal of the same time designation, produced from

the form of solid bars, ingots, powder and special forms, and in

the same batch of raw materials under essentially the same

the form of solid ribbon and wire.

conditions, and offered for inspection at one time.

1.2 The values stated in inch-pound units are to be regarded

3.2.3 lot number, n— the term “lot number” as used in this

as the standard. The values given in parentheses are for

specification refers to a numerical designation for a lot that is

information only.

traceable to a date of manufacture.

1.3 This standard does not purport to address all of the

3.2.4 solidus, n—The highest temperature at which an alloy

safety concerns, if any, associated with its use. It is the

is fully transformed from a liquid to a solid.

responsibility of the user of this standard to become familiar

with all hazards including those identified in the appropriate

4. Classification

Material Safety Data Sheet (MSDS) for this product/material

4.1 Type Designation—The type designation shall use the

as provided by the manufacturer, to establish appropriate

following symbols to properly identify the material:

safety and health practices, and determine the applicability of

4.1.1 Alloy Composition—The composition is identified by

regulatory limitations prior to use.

three numbers that relate to the melting point in degrees

2. Referenced Documents Fahrenheit where it is eutectic or six numbers where it is a

2 range alloy.

2.1 ASTM Standards:

4.1.2 Form—The form is indicated by a single letter in

E55 PracticeforSamplingWroughtNonferrousMetalsand

accordance with Table 1.

Alloys for Determination of Chemical Composition

4.1.3 Powder Mesh Size—The powder mesh size is identi-

E88 Practice for Sampling Nonferrous Metals and Alloys

fied by a size symbol number (Table 2).

in Cast Form for Determination of Chemical Composition

2.2 Military Standard:

5. Ordering Information

5.1 Orders for material under this specification shall indi-

This specification is under the jurisdiction of ASTM Committee B02 on

cate the following information, as required, to adequately

Nonferrous Metals and Alloys and is the direct responsibility of Subcommittee

describe the desired material:

B02.02 on Refined Lead, Tin, Antimony, and Their Alloys.

5.1.1 Type designation (see 4.1),

Current edition approved Nov. 1, 2005. Published February 2006. Originally

5.1.2 Detailed requirements for special forms,

approved in 1987. Last previous edition approved in 2000 as B 774 - 00.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on Available from Standardization Documents Order Desk, DODSSP, Bldg. 4,

the ASTM website. Section D, 700 Robbins Ave., Philadelphia, PA 19111-5098.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

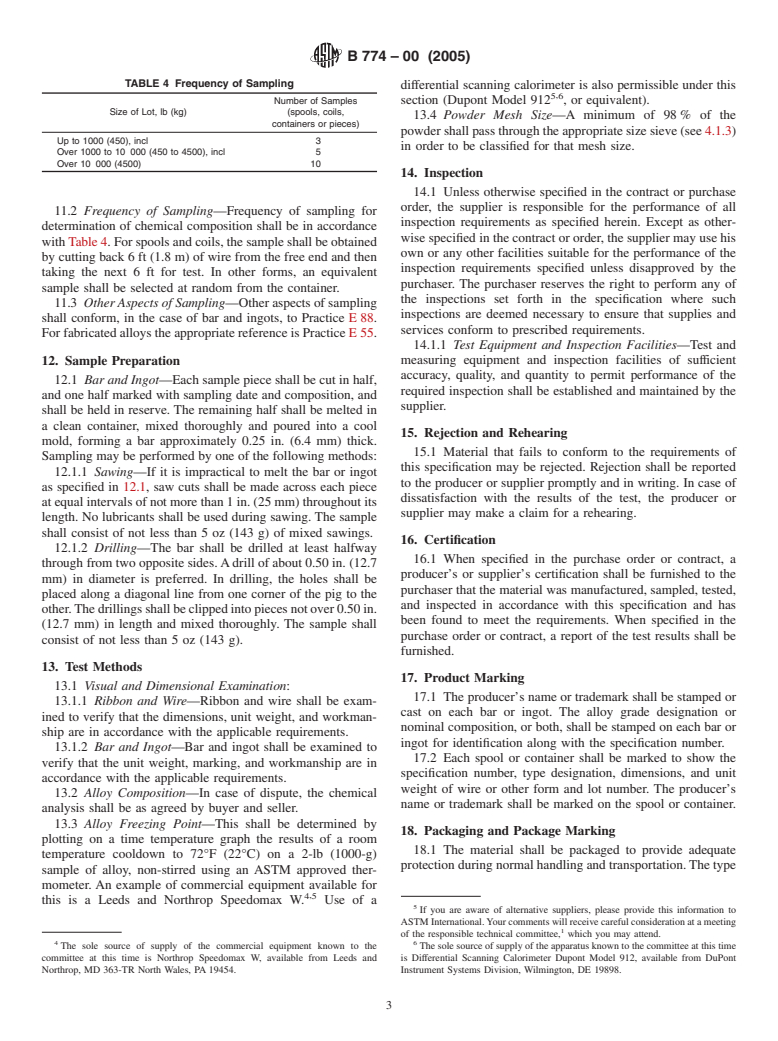

B 774 – 00 (2005)

TABLE 1 Form NOTE 1—By mutual agreement between the supplier and the purchaser,

analysis may be required and limits established for elements or com-

Symbol Form

pounds not specified in Table 3.

B bar

I ingot

8. Physical and Performance Requirements

P powder

R ribbon 8.1 Alloy must freeze within 2°F of its solidus.

S special (includes pellets, preforms, shot, etc.

8.2 Powder Mesh Size—The powder mesh size shall be as

W wire

specified in 5.1.1 and 4.1.3.

9. Dimensions and Unit Weight

TABLE 2 Powder Mesh Size

9.1 Bar and Ingot—The dimensions and unit weight of bar

Size Symbol Powder Mesh Size

and ingot shall be agreed between the supplier and purchaser.

3 325

9.2 Wire (Solid)—The dimensions and unit weight of wire

2 200

alloys shall be as specified in 5.1.3 and 5.1.4. The tolerance on

1 100

the specified outside diameter shall be 65% or 60.002 in.

(0.05 mm), whichever is greater.

9.3 Other Forms:

5.1.3 Dimensions of ribbon and wire solder (see 9.2), 9.3.1 Dimensions for ribbon and special forms shall be as

5.1.4 Unit weight, agreed between the supplier and purchaser.

5.1.5 Packaging (see Section 18), 9.3.2 The unit weight of alloy powder shall be as specified

5.1.6 Marking (see Section 17), in 5.1.4.

5.1.7 ASTM specification designation and year of issue,

10. Workmanship, Finish, and Appearance

marked on the purchase order and on the package or spool, and

10.1 All forms of the alloys shall be processed in such a

5.1.8 Special requirements, as agreed upon between sup-

manner as to be uniform in quality and free of defects that will

plier and purchaser.

affect life, serviceability, or appearance.

6. Materials and Manufacture

11. Sampling for Chemical Analysis

6.1 The producer shall use care to have each lot of alloy as

11.1 Care must be taken to ensure that the sample selected

uniforminqualityaspracticableandofsatisfactoryappearance

for testing is representative of the material. The method of

in accordance with the best industrial practices. Each bar,

sampling shall consist of one of the following methods:

ingot, or other form in which the alloy is sold shall be uniform

11.1.1 Samplesmaybetakenfromthefinalsolidifiedcastor

in composition within the entire lot.

fabricated product.

11.1.2 Representative samples may be obtained from the lot

7. Chemical Composition

of molten metal during casting. The molten sample shall be

7.1 The composition of the alloys covered by this specifi- poured into a cool mold, forming a bar approximately 0.25 in.

cation shall be as shown in Table 3. (6.4 mm) thick.

TABLE 3 Chemical Requirements Composition, wt. %

(range or maximum rules)

Alloy Constituents — wt % Melting Points

Designation

Solidus Liquidus

Bi Pb Sn Cd In Ag Cu Sb Zn °F °C °F °C

117 44.2–45.2 22.1–23.1 7.8–8.8 4.8–5.8 18.6–19.6 0.001 0.08 0.1 0.08 117 47 117 47

129–133 48.14–50.14 16.92–18.92 10.55–12.55 129 54 133 56

136 48.5–49.5 17.5–18.5 11.5–12.5 0.005 20.5–21.5 0.001 0.08 0.1 0.08 136 58 136 58

158 49.5–50.5 26.2–27.2 12.8–13.8 9.5–10.5 0.008 0.001 0.08 0.1 0.08 158 70 158 70

158–165 49.5–50.5 24.45–25.45 12.0–13.0 12.0–13.0 0.10 158 70 165 74

158–190 42.0–43.0 37.2–38.2 10.8–11.8 8.0–9.0 0.008 0.001 0.08 0.1 0.08 158 70 190 88

174 56.5–57.5 0.05 16.5–17.5 0.005 25.5–26.5 0.001 0.08 0.1 0.08 174 79 174 79

203 52.0–53.0 31.5–32.5 15.0–16.0 0.005 0.008 0.001 0.08 0.1 0.08 203 95 203 95

203–239 49.5–50.5 24.5–25.5 24.5–25.5 203 95 239 115

216–217 53.5–54.5 25.5–26.5 19.5–20.5 216 102 217 103

255 55.0–56.0 44.0–45.0 0.01 0.005 0.008 0.001 0.08 0.1 0.08 255 124 255 124

281 57.5–58.5 0.05 41.5–42.5 0.005 0.008 0.01 0.08 0.1 0.08 281 138 281 138

281–338 39.5–40.5 0.05 59.5–60.5 0.005 0.008 0.01 0.08 0.1 0.08 281 138 338 170

291–325 13.5–14.5 42.5–43.5 42.5–43.5 0.005 0.008 0.01 0.08 0.1 0.08 291 144 325 163

244 0.01 0.05 47.5–48.5 0.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.