ASTM D4520-03(2008)

(Practice)Standard Practice for Determining Water Injectivity Through the Use of On-Site Floods

Standard Practice for Determining Water Injectivity Through the Use of On-Site Floods

SIGNIFICANCE AND USE

The injectivity of a water is best determined by measurements as near to the well as possible to minimize changes in water properties due to air contact and time. This practice describes how core flow tests are carried out near the well.

This practice permits the differentiation of permeability losses from the effects of chemical interaction of water and rock and from the effects of plugging by suspended solids. The procedure can be utilized to estimate the chemical and filtration requirements for the full-scale injection project.

Application of the test results to injection wells requires consideration of test core selection and geometry effects.

This practice as described assumes that the water does not contain free oil or other immiscible hydrocarbons. The presence of free oil would require the method to be modified to account for the effect of oil saturation in the test cores on the water permeability.

SCOPE

1.1 This practice covers a procedure for conducting on-site core flood tests to determine the filtration and chemical treatment requirements for subsurface injection of water. ,

1.2 This practice applies to water disposal, secondary recovery, and enhanced oil recovery projects and is applicable to injection waters with all ranges of total dissolved solids contents.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D4520 − 03(Reapproved 2008)

Standard Practice for

Determining Water Injectivity Through the Use of On-Site

Floods

This standard is issued under the fixed designation D4520; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2.2 American Petroleum Institute Standards:

API RP27 Recommended Practice for Determining Perme-

1.1 This practice covers a procedure for conducting on-site

ability of Porous Media

core flood tests to determine the filtration and chemical

API RP40 Recommended Practice for Core-Analysis Pro-

2, 3

treatment requirements for subsurface injection of water.

cedure

1.2 This practice applies to water disposal, secondary

recovery, and enhanced oil recovery projects and is applicable

3. Terminology

to injection waters with all ranges of total dissolved solids

3.1 Definitions:

contents.

3.1.1 For definitions of terms relating to water and water

1.3 This standard does not purport to address all of the

chemistry, refer to Terminology D1129. Refer to Terminology

safety concerns, if any, associated with its use. It is the

D653 for definitions relating to soil and rock

responsibility of the user of this standard to establish appro-

3.2 Definitions of Terms Specific to This Standard:

priate safety and health practices and determine the applica-

3.2.1 filtration requirement—the maximum suspended sol-

bility of regulatory limitations prior to use.

ids size (in micrometres) allowed in an injection water to

minimize formation plugging.

2. Referenced Documents

3.2.2 test core—a sample cut from a full core that has been

2.1 ASTM Standards:

recovered from the formation into which water is injected.

D420 Guide to Site Characterization for Engineering Design

3.2.3 permeability—the capacity of a rock (or other porous

and Construction Purposes (Withdrawn 2011)

medium) to conduct liquid or gas. It is measured as the

D653 Terminology Relating to Soil, Rock, and Contained

proportionality constant between flow velocity and hydraulic

Fluids

gradient.

D1129 Terminology Relating to Water

3.2.4 pore volume—the volid volume of a porous medium

D2434 Test Method for Permeability of Granular Soils

that can be saturated with the transmitted fluid.

(Constant Head)

D4404 Test Method for Determination of Pore Volume and

3.2.5 porosity—the ratio, usually expressed as a percentage

Pore Volume Distribution of Soil and Rock by Mercury

of the volume of voids of a given soil, rock mass, or other

Intrusion Porosimetry

porous medium to the total volume of the soil, rock mass, or

other porous medium.

3.2.6 rock-water interaction—a reaction between a porous

This practice is under the jurisdiction of ASTM Committee D19 on Water and

rock and the injected water causing precipitation or swelling or

is the direct responsibility of Subcommittee D19.05 on Inorganic Constituents in

release of fines (clays) within the rock.

Water.

Current edition approved May 1, 2008. Published May 2008. Originally

approved in 1986. Last previous edition approved in 2003 as D4520 – 03. DOI: 4. Summary of Practice

10.1520/D4520-03R08.

4.1 This practice assumes that the injection water has been

Farley,J.T.,andRedline,D.G.,“EvaluationofFloodWaterQualityintheWest

Montalvo Field,” Journal Petroleum Technology, July 1968, pp. 683–687.

characterized in terms of dissolved and suspended solids

McCune, C. C., “On-Site Testing to Define Injection Water Quality

contents (including hydrocarbons and other organics as appli-

Requirements,” Journal Petroleum Technology, January 1977, pp. 17–24.

cable) by established standard practices and methods.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

5 6

The last approved version of this historical standard is referenced on Available from American Petroleum Institute (API), 1220 L. St., NW,

www.astm.org. Washington, DC 20005-4070, http://www.api.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D4520 − 03 (2008)

4.2 Test core material is selected by consultation between 6.2 Rock-water interactions are more common in sand-

geologists and engineers and prepared for the tests by standard stones than in carbonate rocks. However, within carbonate

practices. rocks dissolved iron in the injection water may precipitate

especially in the presence of dissolved oxygen. Alkaline

4.3 In the on-site core flood the permeability of the test core

precipitates(CaCO andMg(OH) )mayalsoformincarbonate

3 2

is monitored to detect interactions between the formation rock

rocks.

and the injection water.The water is filtered at various levels to

6.2.1 Dissolved hydrogen sulfide in the presence of dis-

determine the filtration required (in micrometres) to minimize

solved iron and oxygen can also be a problem in waters

permeability loss (damage) from suspended solids. Backflow-

injected into carbonate and sandstones resulting in precipita-

ing injection wells are simulated by reversing the flow direc-

tion of sulfides and hydroxides of iron.

tion through the cores.

6.3 The iron and alkaline precipitates described in 6.2 can

5. Significance and Use

also form from waters injected into sandstones. Swelling type

5.1 The injectivity of a water is best determined by mea-

clays (montmorillonite and mixed layer clays) and dispersible

surements as near to the well as possible to minimize changes

clays (kaolinite and chlorite) are potential sources of perme-

in water properties due to air contact and time. This practice

ability losses due to changes in salinity or ionic content of the

describes how core flow tests are carried out near the well.

injected water compared to the natural waters in the formation.

5.2 This practice permits the differentiation of permeability

In some sandstones fine mica particles have been caused to

losses from the effects of chemical interaction of water and

migrate by the injection of a potassium ion deficient water.

rock and from the effects of plugging by suspended solids. The

6.4 In some instances in both sandstones and carbonates

procedurecanbeutilizedtoestimatethechemicalandfiltration

some fine particles are released to migrate as a result of water

requirements for the full-scale injection project.

saturating the cleaned and dried test cores.

5.3 Application of the test results to injection wells requires

consideration of test core selection and geometry effects.

7. Apparatus

5.4 This practice as described assumes that the water does

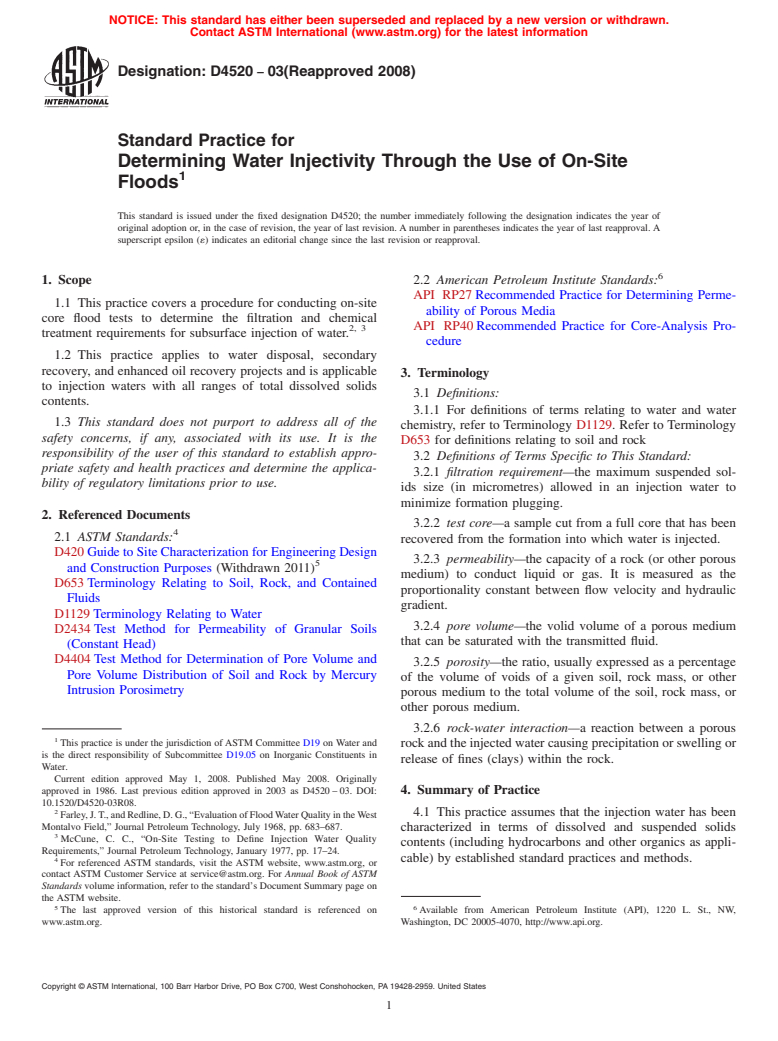

7.1 A schematic diagram of the test apparatus is shown in

not contain free oil or other immiscible hydrocarbons. The

Fig. 1. The component parts are assembled from commercially

presence of free oil would require the method to be modified to

available laboratory apparatus with the exception of the core

account for the effect of oil saturation in the test cores on the

holders (Fig. 2). While four cores are shown in Fig. 1 the

water permeability.

number used in a test is optional. The apparatus essentially

consists of a filtration section and a core flood section. The

6. Sources of Rock-Water Interactions

various components are connected with plastic or stainless

6.1 Water injected into a porous rock may interact with the

steel flow lines with required valves and gauges as illustrated.

rock to reduce the permeability as a result of the formation of

precipitates, clay swelling, clay dispersion, or the migration of 7.2 The filtration section is assembled from four cartridge

filter holders mounted two each in series. Valves are installed

other fine solids.

FIG. 1 Schematic of Test Equipment

D4520 − 03 (2008)

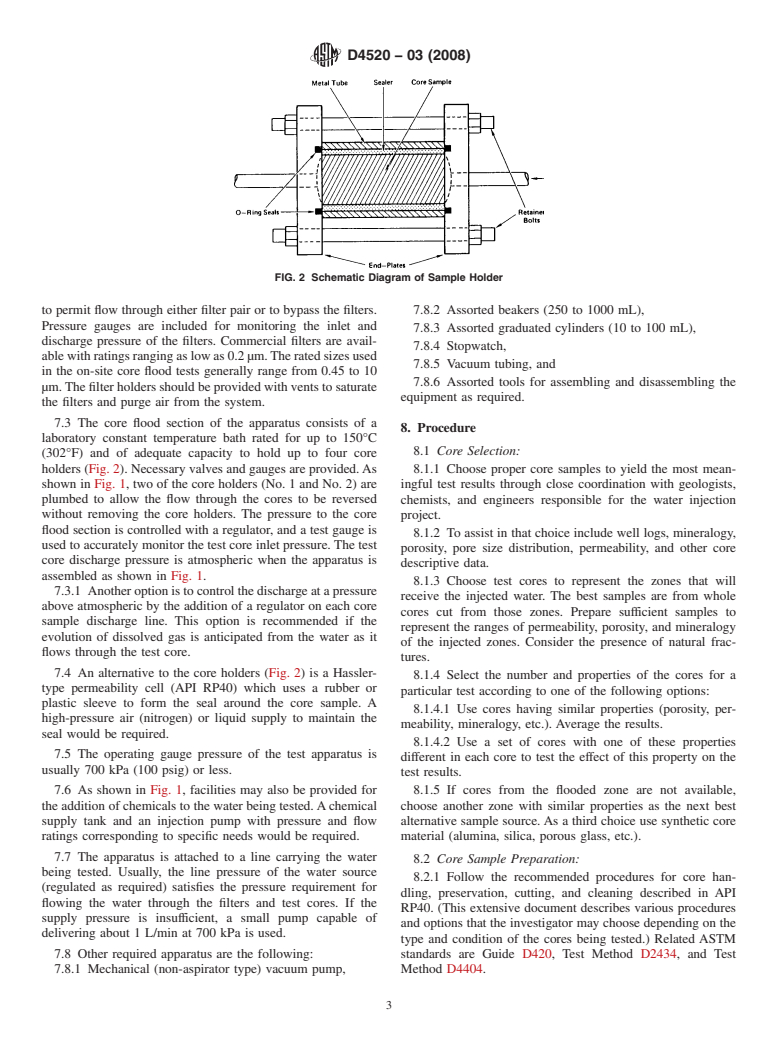

FIG. 2 Schematic Diagram of Sample Holder

to permit flow through either filter pair or to bypass the filters. 7.8.2 Assorted beakers (250 to 1000 mL),

Pressure gauges are included for monitoring the inlet and

7.8.3 Assorted graduated cylinders (10 to 100 mL),

discharge pressure of the filters. Commercial filters are avail-

7.8.4 Stopwatch,

ablewithratingsrangingaslowas0.2µm.Theratedsizesused

7.8.5 Vacuum tubing, and

in the on-site core flood tests generally range from 0.45 to 10

7.8.6 Assorted tools for assembling and disassembling the

µm.The filter holders should be provided with vents to saturate

equipment as required.

the filters and purge air from the system.

7.3 The core flood section of the apparatus consists of a

8. Procedure

laboratory constant temperature bath rated for up to 150°C

8.1 Core Selection:

(302°F) and of adequate capacity to hold up to four core

holders (Fig. 2). Necessary valves and gauges are provided.As

8.1.1 Choose proper core samples to yield the most mean-

shown in Fig. 1, two of the core holders (No. 1 and No. 2) are ingful test results through close coordination with geologists,

plumbed to allow the flow through the cores to be reversed

chemists, and engineers responsible for the water injection

without removing the core holders. The pressure to the core project.

flood section is controlled with a regulator, and a test gauge is

8.1.2 To assist in that choice include well logs, mineralogy,

used to accurately monitor the test core inlet pressure. The test

porosity, pore size distribution, permeability, and other core

core discharge pressure is atmospheric when the apparatus is

descriptive data.

assembled as shown in Fig. 1.

8.1.3 Choose test cores to represent the zones that will

7.3.1 Another option is to control the discharge at a pressure

receive the injected water. The best samples are from whole

above atmospheric by the addition of a regulator on each core

cores cut from those zones. Prepare sufficient samples to

sample discharge line. This option is recommended if the

represent the ranges of permeability, porosity, and mineralogy

evolution of dissolved gas is anticipated from the water as it

of the injected zones. Consider the presence of natural frac-

flows through the test core.

tures.

7.4 An alternative to the core holders (Fig. 2) is a Hassler-

8.1.4 Select the number and properties of the cores for a

type permeability cell (API RP40) which uses a rubber or

particular test according to one of the following options:

plastic sleeve to form the seal around the core sample. A

8.1.4.1 Use cores having similar properties (porosity, per-

high-pressure air (nitrogen) or liquid supply to maintain the

meability, mineralogy, etc.). Average the results.

seal would be required.

8.1.4.2 Use a set of cores with one of these properties

7.5 The operating gauge pressure of the test apparatus is

different in each core to test the effect of this property on the

usually 700 kPa (100 psig) or less.

test results.

7.6 As shown in Fig. 1, facilities may also be provided for 8.1.5 If cores from the flooded zone are not available,

the addition of chemicals to the water being tested.Achemical choose another zone with similar properties as the next best

supply tank and an injection pump with pressure and flow alternative sample source. As a third choice use synthetic core

ratings corresponding to specific needs would be required. material (alumina, silica, porous glass, etc.).

7.7 The apparatus is attached to a line carrying the water

8.2 Core Sample Preparation:

being tested. Usually, the line pressure of the water source

8.2.1 Follow the recommended procedures for core han-

(regulated as required) satisfies the pressure requirement for

dling, preservation, cutting, and cleaning described in API

flowing the water through the filters and test cores. If the

RP40. (This extensive document describes various procedures

supply pressure is insufficient, a small pump capable of

and options that the investigator may choose depending on the

delivering about 1 L/min at 700 kPa is used.

type and condition of the cores being tested.) Related ASTM

7.8 Other required apparatus are the following: standards are Guide D420, Test Method D2434, and Test

7.8.1 Mechanical (non-aspirator type) vacuum pump, Method D4404.

D4520 − 03 (2008)

8.2.2 The preferred sample dimensions for the core flood 8.3.9 This procedure assumes sample cores are to be

test are 19 mm (0.75 in.) to 38 mm (1.5 in.) outside diameter vacuum saturated with the same water used in the core flood

with a minimum length to diameter ratio of 1:0. test. If a special water or brine is to be used as the saturating

fluid, the procedure is the same, except a valving arrangement

8.2.3 Carry out the following procedure for each core

is needed near the water supply valve to allow for flow of the

sample in the set to be tested:

requiredfluids.Inallcasesfilterthesaturatingfluidto0.45µm.

8.2.3.1 Cut the core sample parallel to the formation bed-

ding plane and then clean by solvent-extraction to remove

8.4 Initial Permeability Measurement :

residual hydrocarbons and water from the pore space. Dry the

8.4.1 The initial permeability of the test core with 0.45-µm

sample and determine the porosity according to the recom-

filtered water is the base value to which permeability changes

mended procedures in API RP40.

are compared.

8.2.3.2 Use the air permeability of the core sample as a

8.4.2 Followtheproceduresin8.1-8.3sothatthecoreshave

guide for choosing representative samples of the formation

been mounted, vacuum saturated, and under pressure and

being tested. The procedure for measuring air permeabilities is

0.45-µm filtered water is available upstream of the test cores.

described in API RP27.

Set and allow the constant temperature bath to become

8.2.3.3 Seal the core sample with an epoxy resin or other

stabilized at the test temperature. (Use water in the bath if the

suitable sealant in a metal (stainless steel, aluminum, brass)

test temperature is less than 80°C (176°F). Use another heating

tube having an inside diameter about 6.4 mm (0.25 in.) larger

medium such as silicone oil at higher temperatures.)

than the outside diameter of the sample.

8.4.3 Open the valve-to-waste downstream of the regulator

8.2.3.4 Machine the ends of the core sample and metal tube

momentarily to check flow.

flat and perpendicular to the tube axis. Generally a stream of

8.4.4 Open the valves to the test cores. Place a 500-mL

compressed air on the core ends during machining will prevent

beaker under the discharge tube from each core holder. Open

the intrusion of fines into the rock pores. the valves at the effluent end of each test core.

8.2.3.5 Mount the metal tube (containing the

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:D 4520–95 (Reapproved 1999) Designation:D4520–03 (Reapproved 2008)

Standard Practice for

Determining Water Injectivity Through the Use of On-Site

Floods

This standard is issued under the fixed designation D 4520; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This practice covers a procedure for conducting on-site core flood tests to determine the filtration and chemical treatment

2, 3

requirements for subsurface injection of water.

1.2 This practice applies to water disposal, secondary recovery, and enhanced oil recovery projects and is applicable to injection

waters with all ranges of total dissolved solids contents.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2.1 ASTM Standards:

D 420 Guide to Site Characterization for Engineering, Design, and Construction Purposes

D 653 Terminology Relating to Soil, Rock, and Contained Fluids

D 1129 Terminology Relating to Water

D 2434Test Method for Permeability of Granular Soils (Constant Head)

D3370Practices for Sampling Water from Closed Conduits Test Method for Permeability of Granular Soils (Constant Head)

D 4404 Test Method for Determination of Pore Volume and Pore Volume Distribution of Soil and Rock by Mercury Intrusion

Porosimetry

2.2 American Petroleum Institute Standards:

API RP27 Recommended Practice for Determining Permeability of Porous Media

API RP40 Recommended Practice for Core-Analysis Procedure

3. Terminology

3.1 Definitions:

3.1.1 For definitions of terms relating to water and water chemistry, refer to Terminology D 1129. Refer to Terminology D 653

for definitions relating to soil and rock.

3.2 Definitions of Terms Specific to This Standard:

3.2.1 filtration requirement—the maximum suspended solids size (in micrometres) allowed in an injection water to minimize

formation plugging.

3.2.2 test core—a sample cut from a full core that has been recovered from the formation into which water is injected.

3.2.3 permeability—the capacity of a rock (or other porous medium) to conduct liquid or gas. It is measured as the

proportionality constant between flow velocity and hydraulic gradient.

3.2.4 pore volume—the volid volume of a porous medium that can be saturated with the transmitted fluid.

3.2.5 porosity—the ratio, usually expressed as a percentage of the volume of voids of a given soil, rock mass, or other porous

medium to the total volume of the soil, rock mass, or other porous medium.

This practice is under the jurisdiction of ASTM Committee D-19D19 on Water and is the direct responsibility of Subcommittee D19.05 on Inorganic Constituents in

Water.

Current edition approved Sept. 10, 1995.May 1, 2008. Published November 1995.May 2008. Originally published as D4520–86.approved in 1986. Last previous edition

D4520–86(1991). approved in 2003 as D 4520 – 03.

Farley, J. T., and Redline, D. G., “Evaluation of Flood Water Quality in the West Montalvo Field,” Journal Petroleum Technology, July 1968, pp. 683–687.

McCune, C. C., “On-Site Testing to Define Injection Water Quality Requirements,” Journal Petroleum Technology, January 1977, pp. 17–24.

Annual Book of ASTM Standards, Vol 04.08.

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Annual Book of ASTM Standards, Vol 11.01.

Available from American Petroleum Institute (API), 1220 L. St., NW, Washington, DC 20005-4070, http://www.api.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D4520–03 (2008)

3.2.6 rock-water interaction—a reaction between a porous rock and the injected water causing precipitation or swelling or

release of fines (clays) within the rock.

4. Summary of Practice

4.1 This practice assumes that the injection water has been characterized in terms of dissolved and suspended solids contents

(including hydrocarbons and other organics as applicable) by established standard practices and methods.

4.2 Test core material is selected by consultation between geologists and engineers and prepared for the tests by standard

practices.

4.3 In the on-site core flood the permeability of the test core is monitored to detect interactions between the formation rock and

the injection water. The water is filtered at various levels to determine the filtration required (in micrometres) to minimize

permeability loss (damage) from suspended solids. Backflowing injection wells are simulated by reversing the flow direction

through the cores.

5. Significance and Use

5.1 The injectivity of a water is best determined by measurements as near to the well as possible to minimize changes in water

properties due to air contact and time. This practice describes how core flow tests are carried out near the well.

5.2 This practice permits the differentiation of permeability losses from the effects of chemical interaction of water and rock

and from the effects of plugging by suspended solids. The procedure can be utilized to estimate the chemical and filtration

requirements for the full-scale injection project.

5.3 Application of the test results to injection wells requires consideration of test core selection and geometry effects.

5.4 This practice as described assumes that the water does not contain free oil or other immiscible hydrocarbons. The presence

of free oil would require the method to be modified to account for the effect of oil saturation in the test cores on the water

permeability.

6. Sources of Rock-Water Interactions

6.1 Water injected into a porous rock may interact with the rock to reduce the permeability as a result of the formation of

precipitates, clay swelling, clay dispersion, or the migration of other fine solids.

6.2 Rock-water interactions are more common in sandstones than in carbonate rocks. However, within carbonate rocks

dissolved iron in the injection water may precipitate especially in the presence of dissolved oxygen.Alkaline precipitates (CaCO

and Mg(OH) ) may also form in carbonate rocks.

6.2.1 Dissolved hydrogen sulfide in the presence of dissolved iron and oxygen can also be a problem in waters injected into

carbonate and sandstones resulting in precipitation of sulfides and hydroxides of iron.

6.3 The iron and alkaline precipitates described in 6.2 can also form from waters injected into sandstones. Swelling type clays

(montmorillonite and mixed layer clays) and dispersible clays (kaolinite and chlorite) are potential sources of permeability losses

duetochangesinsalinityorioniccontentoftheinjectedwatercomparedtothenaturalwatersintheformation.Insomesandstones

fine mica particles have been caused to migrate by the injection of a potassium ion deficient water.

6.4 Insomeinstancesinbothsandstonesandcarbonatessomefineparticlesarereleasedtomigrateasaresultofwatersaturating

the cleaned and dried test cores.

7. Apparatus

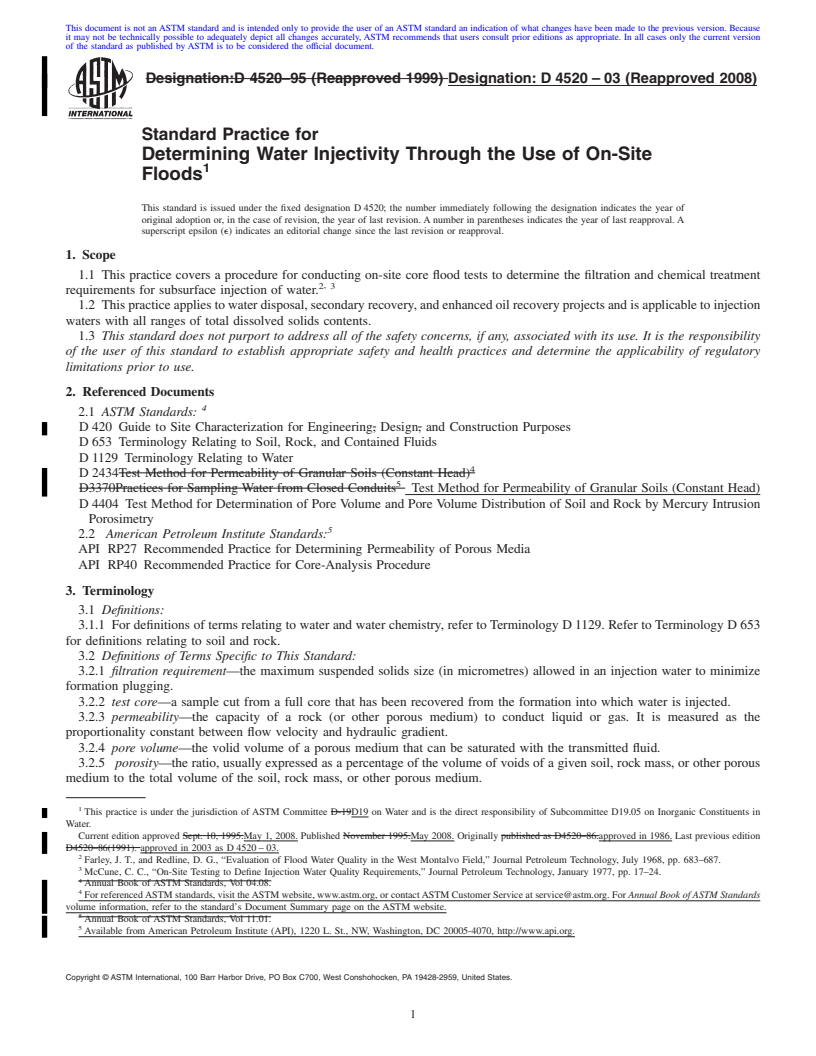

7.1 A schematic diagram of the test apparatus is shown in Fig. 1. The component parts are assembled from commercially

available laboratory apparatus with the exception of the core holders (Fig. 2). While four cores are shown in Fig. 1 the number

used in a test is optional.The apparatus essentially consists of a filtration section and a core flood section.The various components

are connected with plastic or stainless steel flow lines with required valves and gauges as illustrated.

7.2 The filtration section is assembled from four cartridge filter holders mounted two each in series. Valves are installed to

permit flow through either filter pair or to bypass the filters. Pressure gauges are included for monitoring the inlet and discharge

pressure of the filters. Commercial filters are available with ratings ranging as low as 0.2 µm. The rated sizes used in the on-site

corefloodtestsgenerallyrangefrom0.45to10µm.Thefilterholdersshouldbeprovidedwithventstosaturatethefiltersandpurge

air from the system.

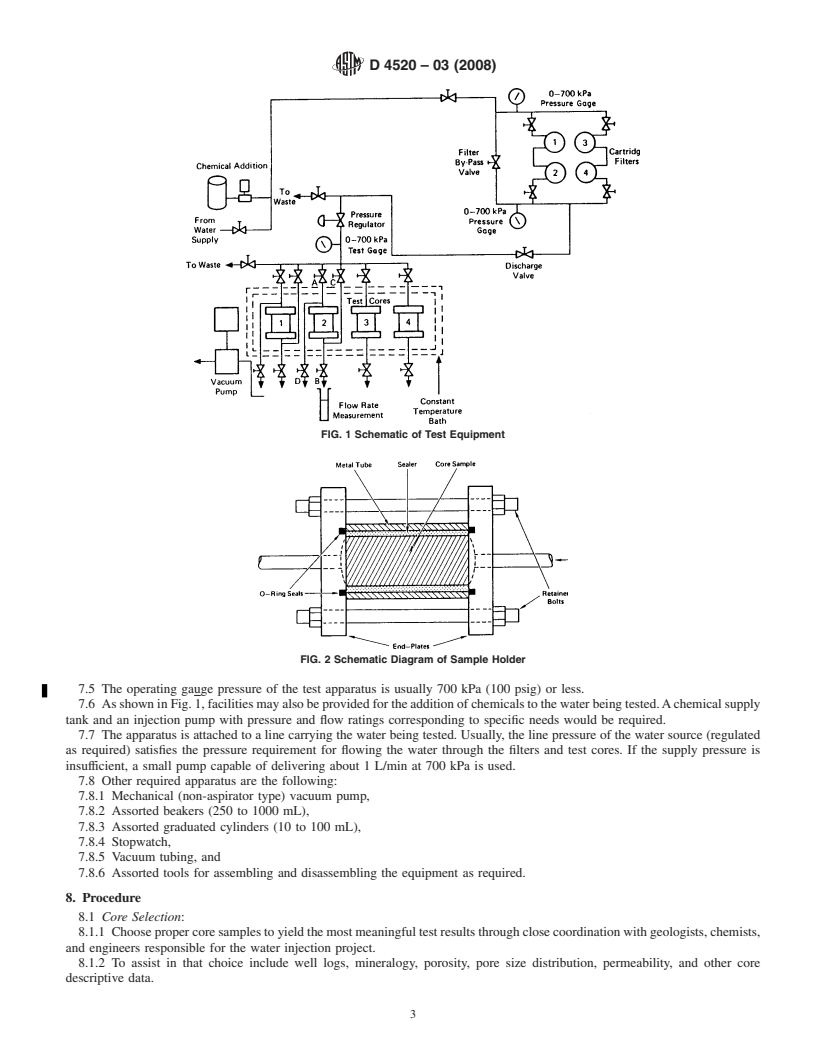

7.3 The core flood section of the apparatus consists of a laboratory constant temperature bath rated for up to 150°C (302°F) and

of adequate capacity to hold up to four core holders (Fig. 2). Necessary valves and gauges are provided.As shown in Fig. 1, two

of the core holders (No. 1 and No. 2) are plumbed to allow the flow through the cores to be reversed without removing the core

holders. The pressure to the core flood section is controlled with a regulator, and a test gauge is used to accurately monitor the test

core inlet pressure. The test core discharge pressure is atmospheric when the apparatus is assembled as shown in Fig. 1.

7.3.1 Another option is to control the discharge at a pressure above atmospheric by the addition of a regulator on each core

sample discharge line. This option is recommended if the evolution of dissolved gas is anticipated from the water as it flows

through the test core.

7.4 An alternative to the core holders (Fig. 2) is a Hassler-type permeability cell (API RP40) which uses a rubber or plastic

sleeve to form the seal around the core sample. A high-pressure air (nitrogen) or liquid supply to maintain the seal would be

required.

D4520–03 (2008)

FIG. 1 Schematic of Test Equipment

FIG. 2 Schematic Diagram of Sample Holder

7.5 The operating gauge pressure of the test apparatus is usually 700 kPa (100 psig) or less.

7.6 AsshowninFig.1,facilitiesmayalsobeprovidedfortheadditionofchemicalstothewaterbeingtested.Achemicalsupply

tank and an injection pump with pressure and flow ratings corresponding to specific needs would be required.

7.7 The apparatus is attached to a line carrying the water being tested. Usually, the line pressure of the water source (regulated

as required) satisfies the pressure requirement for flowing the water through the filters and test cores. If the supply pressure is

insufficient, a small pump capable of delivering about 1 L/min at 700 kPa is used.

7.8 Other required apparatus are the following:

7.8.1 Mechanical (non-aspirator type) vacuum pump,

7.8.2 Assorted beakers (250 to 1000 mL),

7.8.3 Assorted graduated cylinders (10 to 100 mL),

7.8.4 Stopwatch,

7.8.5 Vacuum tubing, and

7.8.6 Assorted tools for assembling and disassembling the equipment as required.

8. Procedure

8.1 Core Selection:

8.1.1 Choosepropercoresamplestoyieldthemostmeaningfultestresultsthroughclosecoordinationwithgeologists,chemists,

and engineers responsible for the water injection project.

8.1.2 To assist in that choice include well logs, mineralogy, porosity, pore size distribution, permeability, and other core

descriptive data.

D4520–03 (2008)

8.1.3 Choose test cores to represent the zones that will receive the injected water. The best samples are from whole cores cut

fromthosezones.Preparesufficientsamplestorepresenttherangesofpermeability,porosity,andmineralogyoftheinjectedzones.

Consider the presence of natural fractures.

8.1.4 Select the number and properties of the cores for a particular test according to one of the following options:

8.1.4.1 Use cores having similar properties (porosity, permeability, mineralogy, etc.). Average the results.

8.1.4.2 Use a set of cores with one of these properties different in each core to test the effect of this property on the test results.

8.1.5 If cores from the flooded zone are not available, choose another zone with similar properties as the next best alternative

sample source. As a third choice use synthetic core material (alumina, silica, porous glass, etc.).

8.2 Core Sample Preparation:

8.2.1 Follow the recommended procedures for core handling, preservation, cutting, and cleaning described inAPI RP40. (This

extensivedocumentdescribesvariousproceduresandoptionsthattheinvestigatormaychoosedependingonthetypeandcondition

of the cores being tested.) Related ASTM standards are Guide D 420, Test Method D 2434, and Test Method D 4404.

8.2.2 The preferred sample dimensions for the core flood test are 19 mm (0.75 in.) to 38 mm (1.5 in.) outside diameter with

a minimum length to diameter ratio of 1:0.

8.2.3 Carry out the following procedure for each core sample in the set to be tested:

8.2.3.1 Cut the core sample parallel to the formation bedding plane and then clean by solvent-extraction to remove residual

hydrocarbonsandwaterfromtheporespace.Drythesampleanddeterminetheporosityaccordingtotherecommendedprocedures

in API RP40.

8.2.3.2 Use the air permeability of the core sample as a guide for choosing representative samples of the formation being tested.

The procedure for measuring air permeabilities is described in API RP27.

8.2.3.3 Seal the core sample with an epoxy resin or other suitable sealant in a metal (stainless steel, aluminum, brass) tube

having an inside diameter about 6.4 mm (0.25 in.) larger than the outside diameter of the sample.

8.2.3.4 Machine the ends of the core sample and metal tube flat and perpendicular to the tube axis. Generally a stream of

compressed air on the core ends during machining will prevent the intrusion of fines into the rock pores.

8.2.3.5 Mount the metal tube (containing the core sample) in a holder designed to allow water to be flowed through the sample.

An example of such a sample holder is shown schematically in Fig. 2.

8.3 Vacuum Saturation of Test Cores :

8.3.1 Install a 10-µm rated cartridge in filter No. 1 and a 0.45-µm cartridge in filter No. 2. Close valves to and from filters No.

3 and No. 4, the filter bypass valve, and valves to all core sample holders.

8.3.2 Open the valve-to-waste upstream and downstream of the regulator and the valves to and from filters No. 1 and No. 2.

Start water flow through the filters to waste.

8.3.3 Close the valve-to-waste upstream of the pressure regulator. Set the regulator at about 120 kPa (17 psi) more than the

pressure planned for the test. After about 2 min, close the valve-to-waste downstream of the regulator.

8.3.4 Mount from one to four sample cores in the holders (lines should not contain wa

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.