ASTM C602-95a(2001)

(Specification)Standard Specification for Agricultural Liming Materials

Standard Specification for Agricultural Liming Materials

SCOPE

1.1 This specification covers agricultural liming materials, such as burnt lime (quicklime), hydrated lime, limestone, (calcitic and dolomitic), marl, shells, and byproducts including slag, and other materials.

1.2 The following precautionary caveat pertains only to the test method portion, Section 8: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information.

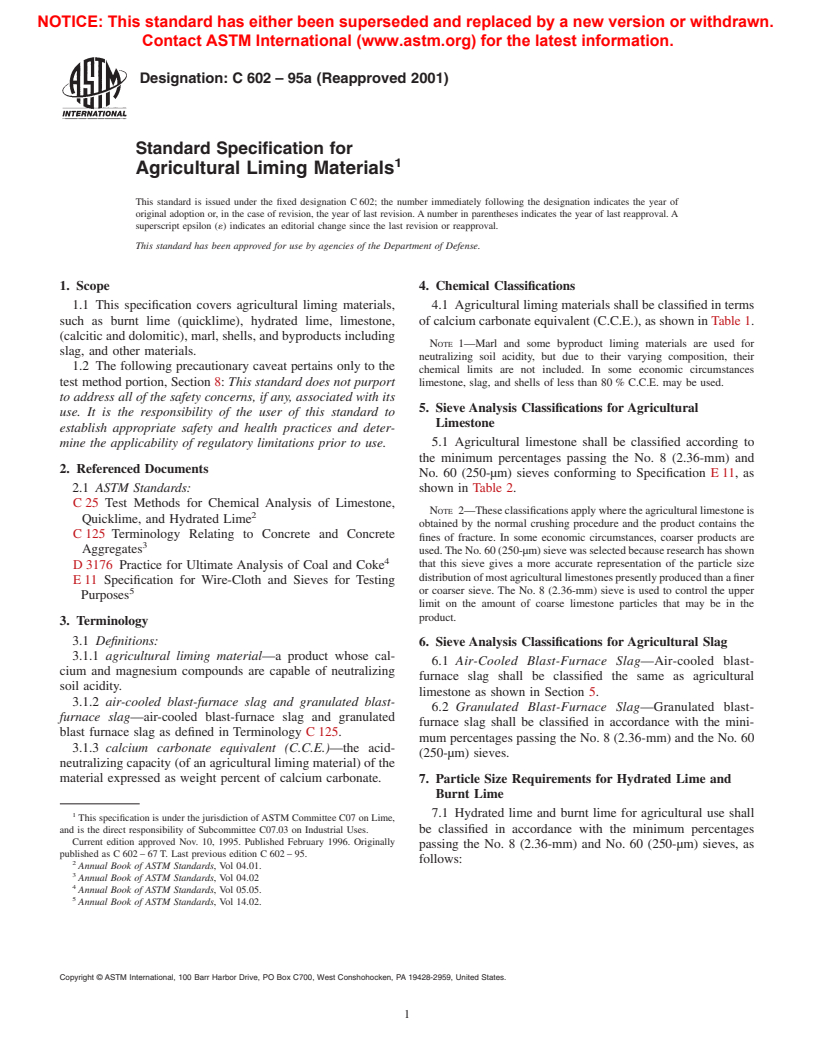

Designation: C 602 – 95a (Reapproved 2001)

Standard Specification for

Agricultural Liming Materials

This standard is issued under the fixed designation C 602; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope 4. Chemical Classifications

1.1 This specification covers agricultural liming materials, 4.1 Agricultural liming materials shall be classified in terms

such as burnt lime (quicklime), hydrated lime, limestone, of calcium carbonate equivalent (C.C.E.), as shown in Table 1.

(calcitic and dolomitic), marl, shells, and byproducts including

NOTE 1—Marl and some byproduct liming materials are used for

slag, and other materials.

neutralizing soil acidity, but due to their varying composition, their

1.2 The following precautionary caveat pertains only to the

chemical limits are not included. In some economic circumstances

test method portion, Section 8: This standard does not purport limestone, slag, and shells of less than 80 % C.C.E. may be used.

to address all of the safety concerns, if any, associated with its

5. Sieve Analysis Classifications for Agricultural

use. It is the responsibility of the user of this standard to

Limestone

establish appropriate safety and health practices and deter-

5.1 Agricultural limestone shall be classified according to

mine the applicability of regulatory limitations prior to use.

the minimum percentages passing the No. 8 (2.36-mm) and

2. Referenced Documents

No. 60 (250-µm) sieves conforming to Specification E11,as

2.1 ASTM Standards: shown in Table 2.

C25 Test Methods for Chemical Analysis of Limestone,

NOTE 2—Theseclassificationsapplywheretheagriculturallimestoneis

Quicklime, and Hydrated Lime

obtained by the normal crushing procedure and the product contains the

C 125 Terminology Relating to Concrete and Concrete

fines of fracture. In some economic circumstances, coarser products are

Aggregates used.TheNo.60(250-µm)sievewasselectedbecauseresearchhasshown

that this sieve gives a more accurate representation of the particle size

D 3176 Practice for Ultimate Analysis of Coal and Coke

distributionofmostagriculturallimestonespresentlyproducedthanafiner

E11 Specification for Wire-Cloth and Sieves for Testing

5 or coarser sieve. The No. 8 (2.36-mm) sieve is used to control the upper

Purposes

limit on the amount of coarse limestone particles that may be in the

product.

3. Terminology

3.1 Definitions:

6. Sieve Analysis Classifications for Agricultural Slag

3.1.1 agricultural liming material—a product whose cal-

6.1 Air-Cooled Blast-Furnace Slag—Air-cooled blast-

cium and magnesium compounds are capable of neutralizing

furnace slag shall be classified the same as agricultural

soil acidity.

limestone as shown in Section 5.

3.1.2 air-cooled blast-furnace slag and granulated blast-

6.2 Granulated Blast-Furnace Slag—Granulated blast-

furnace slag—air-cooled blast-furnace slag and granulated

furnace slag shall be classified in accordance with the mini-

blast furnace slag as defined in Terminology C 125.

mum percentages passing the No. 8 (2.36-mm) and the No. 60

3.1.3 calcium carbonate equivalent (C.C.E.)—the acid-

(250-µm) sieves.

neutralizing capacity (of an agricultural liming material) of the

material expressed as weight percent of calcium carbonate.

7. Particle Size Requirements for Hydrated Lime and

Burnt Lime

7.1 Hydrated lime and burnt lime for agricultural use shall

This specification is under the jurisdiction ofASTM Committee C07 on Lime,

and is the direct responsibility of Subcommittee C07.03 on Industrial Uses. be classified in accordance with the minimum percentages

Current edition approved Nov. 10, 1995. Published February 1996. Originally

passing the No. 8 (2.36-mm) and No. 60 (250-µm) sieves, as

published as C 602 – 67 T. Last previous edition C 602 – 95.

follows:

Annual Book of ASTM Standards, Vol 04.01.

Annual Book of ASTM Standards, Vol 04.02

Annual Book of ASTM Standards, Vol 05.05.

Annual Book of ASTM Standards, Vol 14.02.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

C 602 – 95a (2001)

TABLE 1 Agricultural Liming Materials

tube, place these subsamples in a pail and then mix them by

Calcium Carbonate passing through the riffle three times, recombining the splits

Material Equivalent (C.C.E.),

between each pass. After the third pass, by means of the riffle,

percent

reduce the sample to 2 lb (0.92 kg) and place in a labeled, dry

Burnt lime not less than 140

samplecontainer.Mixandreducethesamplerapidlytoprevent

Hydrated lime not less than 110

Limestone not less than 80 either loss or absorption of moisture.

Slag not less than 80

8.1.2.3 Ground Limestone, Slag, Shells, and Marl, in

Shells not less than 80

Bags—Proceed as in 8.1.2.2.

8.1.2.4 Ground Limestone, Ground Burnt Lime, Hydrated

TABLE 2 Classification for Agricultural Limestone

Lime, Slag, Shells, and Marl, in Bulk—Take at least ten

Passing No. 8 Passing No. 60 subsamples,representativeofthelot,fromthelot(car,truck,or

Class (2.36-mm) (250-µm)

stockpile), using the sampling tube. If possible, the tube should

Designation Sieve, min, Sieve, min,

be inserted to its full length, given a one-half turn and then

percent percent

removed. If the material is too hard for use of the probe, dig

S 100 100

T99 75 holes distributed over the entire surface of the mass, to a depth

O95 55

of about 2 ft (610 mm) and from the sides of the hole take

N90 40

approximately 1-pt (473-cm ) subsamples. Collect the sub-

E80 25

samples in a pail and mix the sample by passing through the

riffle three times, recombining the splits between passes. After

the third pass, by means of the riffle, reduce the sample to 2 lb

Min. %

(0.92 kg) and place immediately in a labeled, dry sample

Passing Sieve No. Hydrated Lime Burnt Lime

container. Mix and reduce the sample rapidly to prevent loss or

8 (2.36 mm) 100 95

absorption of moisture. When the sample is too wet for

60 (250 µm) 97 35

adequate field mixing and reduction, the entire sample is dried

8. Sampli

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.