ASTM B469-94

(Specification)Standard Specification for Seamless Copper-Alloy Tubes for Pressure Applications (Withdrawn 2000)

Standard Specification for Seamless Copper-Alloy Tubes for Pressure Applications (Withdrawn 2000)

SCOPE

1.1 This specification establishes the requirements for seamless tubes produced from Copper Alloy UNS Nos. C19200 and C70600 for general engineering applications. Note 1-This tube is particularly suitable for automobile hydraulic brake lines exposed to a corrosive salt environment.

1.2 The values stated in inch-pound units are the standard. SI values given in parentheses are for information only.

1.3 The following hazard statement pertains only to the test method described in Sections 15.3.3, 15.3.4, and 15.3.5 of this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Standards Content (Sample)

Designation: B 469 – 94

AMERICAN SOCIETY FOR TESTING AND MATERIALS

100 Barr Harbor Dr., West Conshohocken, PA 19428

Reprinted from the Annual Book of ASTM Standards. Copyright ASTM

Standard Specification for

1

Seamless Copper-Alloy Tubes for Pressure Applications

This standard is issued under the fixed designation B 469; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope * 2.2 SAE Handbook Vol. 2 Standard J 533 Flares for Tubing

[6-92]

1.1 This specification establishes the requirements for seam-

2

less tubes produced from Copper Alloy UNS Nos. C19200

and C70600 for general engineering applications.

3. Terminology

NOTE 1—This tube is particularly suitable for automobile hydraulic

3.1 Description of terms specific to this specification:

brake lines exposed to a corrosive salt environment.

3.2 flattening—a condition resulting from a test procedure

1.2 The values stated in inch-pound units are the standard.

in which different elements of a tube specimen are compressed

SI values given in parentheses are for information only.

slowly by one stroke of a press whereby a micrometer caliper

1.3 The following hazard statement pertains only to the test

set at three times the wall thickness shall pass freely over the

method described in Sections 15.3.3, 15.3.4, and 15.3.5 of this

tube throughout the flattened part except at the points where the

specification: This standard does not purport to address all of

change in the element of compression takes place.

the safety concerns, if any, associated with its use. It is the

3.3 unaided eye—without visual enhancement. However

responsibility of the user of this standard to establish appro-

corrective spectacles necessary for normal vision shall be

priate safety and health practices and determine the applica-

allowed.

bility of regulatory limitations prior to use.

4. Ordering Information

2. Referenced Documents

4.1 The contract or purchase order for product under this

2.1 ASTM Standards:

specification should include the following information:

B 153 Test Method for Expansion (Pin Test) of Copper and

4.1.1 ASTM designation and year of issue (for example,

3

Copper-Alloy Pipe and Tubing

B469 – XX),

B 251 Specification for General Requirements for Wrought

4.1.2 Copper Alloy UNS No. (Section 1 and Table 1),

3

Seamless Copper and Copper-Alloy Tubes

4.1.3 Temper (Section 8),

B 601 Practice for Temper Designations for Copper and

4.1.4 Size (Section 11 and Table 2),

3

Copper Alloys-Wrought and Cast

4.1.5 How furnished; straight lengths or coiled lengths

4

E 8 Test Methods for Tension Testing of Metallic Material

(Section 11),

E 29 Practice for Using Significant Digits in Test Data to

4.1.5.1 Length; when straight,

5

Determine Conformance with Specifications

4.1.6 Total length; each size and alloy,

E 62 Methods for Chemical Analysis of Copper and Copper

4.1.7 Total weight, and

6

Alloys (Photometric Methods)

4.1.8 When product is to be subsequently welded (Note B

E 255 Practice for Sampling Copper and Copper Alloys for

Table 1).

6

the Determination of Chemical Composition

4.2 The following options are available and should be

E 478 Test Methods for Chemical Analysis of Copper

specified in the contract or purchase order when required:

6

Alloys

4.2.1 Heat identification or traceability details,

7

E 527 Practice for Numbering Metals and Alloys (UNS)

4.2.2 Flaring test (Section 10.1.1),

4.2.3 Expansion test (Section 15.3 & 15.3.2),

4.2.4 Flattening test (Section 15.3 & 15.3.3),

1

This specification is under the jurisdiction of ASTM Committee B-5 on Copper

4.2.5 Bend test (Section 15.3 & 15.3.4),

and Copper Alloys and is the direct responsibility of Subcommittee B05.04 on Pipe

and Tube. 4.2.6 Hydrostatic test (Section 15.3 & 15.3.4),

Current edition approved July 15, 1994. Published September 1994. Originally

4.2.7 Certification (Specification B 251), and

published as B 469 – 68. Last previous edition B 469 – 88.

4.2.8 Test report (Specification B 251).

2

Refer to Practice E 527 for an explanation of the unified numbering system

(UNS).

3

5. General Requirements

Annual Book of ASTM Standards, Vol 02.01.

4

Annual Book of ASTM Standards, Vol 03.01.

5.1 The following sections of Specification B 251 are a part

5

Annual Book of ASTM Standards, Vol 14.02.

6

of this specification:

Annual Book of ASTM Standards, Vol 03.05.

7

Annual Book of ASTM Standards, Vol 01.01. 5.1.1 Terminology,

*A Summary of Changes section appears at the end of this standard.

1

---------------------- Page: 1 ----------------------

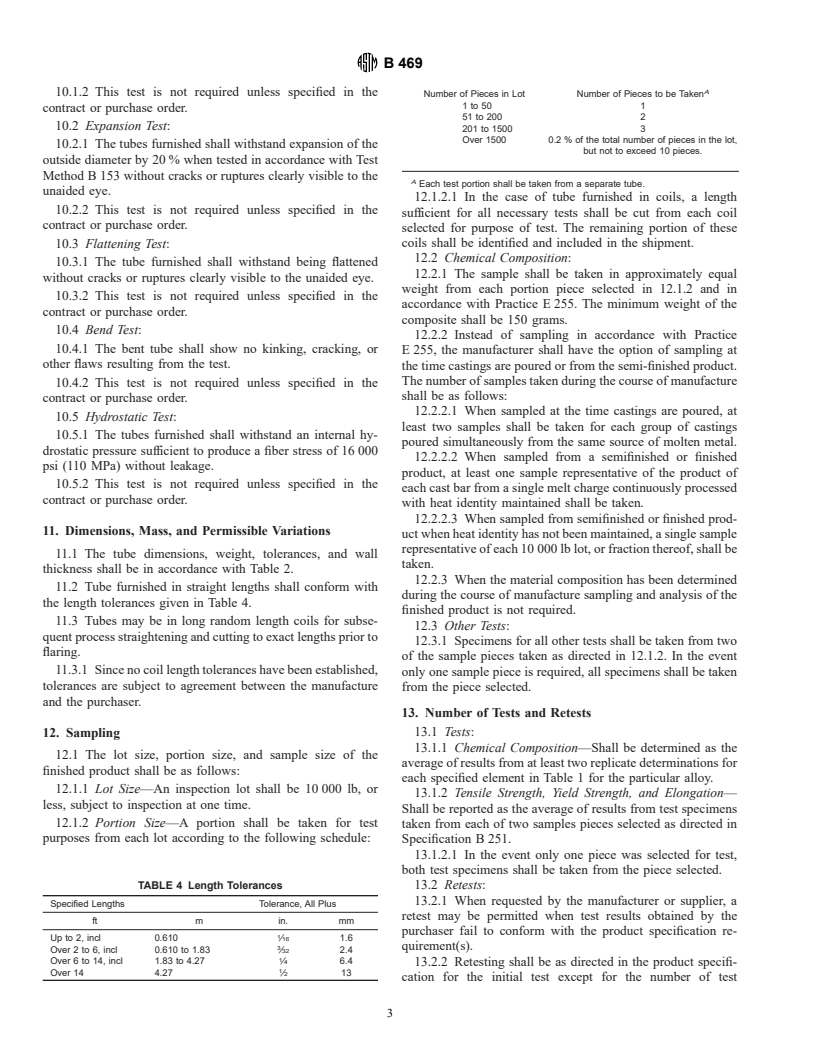

B 469

TABLE 1 Chemical Requirements TABLE 3 Mechanical Requirements

A C

Composition, % Tensile, ksi Yield, ksi Elongation,

Alloy Temper

B

(MPa) (MPa) %

Element

Copper Alloy Copper Alloy

UNS No. C19200 UNS No. C70600 C19200 H55 40 (275) 35 (240) 10

O61 38 (260) 12

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.