ASTM F2633-13

(Specification)Standard Specification for Wrought Seamless Nickel-Titanium Shape Memory Alloy Tube for Medical Devices and Surgical Implants

Standard Specification for Wrought Seamless Nickel-Titanium Shape Memory Alloy Tube for Medical Devices and Surgical Implants

ABSTRACT

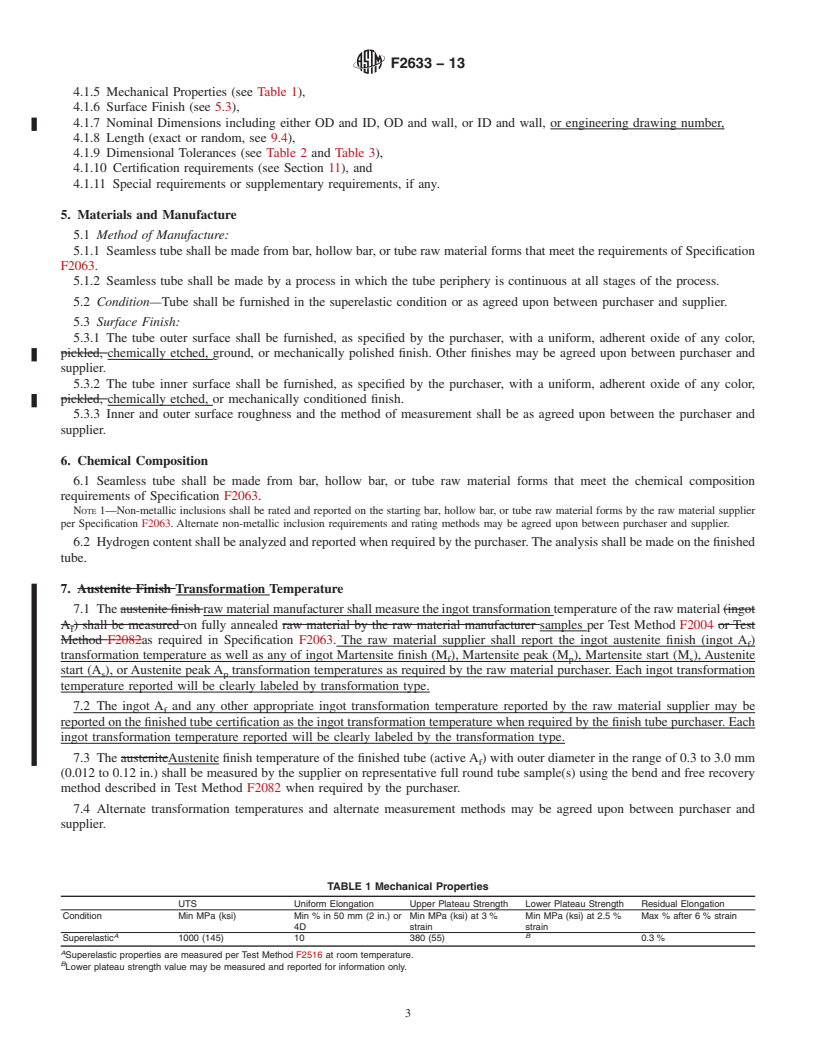

This specification covers the chemical, mechanical, and dimensional requirements for wrought seamless nickel-titanium shape memory alloy tubes used for the manufacture of medical devices and surgical implants. Tubes shall be furnished in the superelastic condition, and the outer surface shall have a pickled, ground, or mechanically polished finish, or as agreed upon between purchaser and supplier. This specification addresses those product variables that differentiate drawn medical grade tube from the raw material and mill product forms. This specification applies precisely to tube with 10 mm (0.4 in.) and smaller nominal outside diameter and 2 mm (0.08 in.) and thinner nominal wall thickness. The mechanical properties to which the tubes shall conform are ultimate tensile strength (UTS), uniform elongation, upper plateau strength, lower plateau strength, and residual elongation.

SCOPE

1.1 This specification covers the requirements for wrought nickel-titanium shape memory alloy tube, nominally 54.5 to 57.0 mass/mass (weight) % nickel, in the superelastic condition, used for the manufacture of medical devices and surgical implants. Material shall conform to the applicable requirements of Specification F2063. This specification addresses those product variables that differentiate drawn medical grade tube from the raw material and mill product forms covered in Specification F2063.

1.2 This specification applies to tube with 10 mm (0.4 in.) and smaller nominal outside diameter and 2 mm (0.08 in.) and thinner nominal wall thickness.

1.3 The values stated in SI units are to be regarded as the standard. The values given in parentheses (inch-pound units) are for information only.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:F2633 −13

Standard Specification for

Wrought Seamless Nickel-Titanium Shape Memory Alloy

1

Tube for Medical Devices and Surgical Implants

This standard is issued under the fixed designation F2633; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* F2516 Test Method for Tension Testing of Nickel-Titanium

Superelastic Materials

1.1 This specification covers the requirements for wrought

3

nickel-titanium shape memory alloy tube, nominally 54.5 to 2.2 ISO Standard:

57.0 mass/mass (weight) % nickel, in the superelastic ISO 9001 Quality Management Systems—Requirements

condition, used for the manufacture of medical devices and ISO 13485 Quality Management Standard for Medical De-

surgical implants. Material shall conform to the applicable vices

requirements of Specification F2063. This specification ad-

dressesthoseproductvariablesthatdifferentiatedrawnmedical

3. Terminology

grade tube from the raw material and mill product forms

3.1 Definitions of Terms Specific to This Standard:

covered in Specification F2063.

3.2 See Terminology F2005 for the definition of terms used

1.2 This specification applies to tube with 10 mm (0.4 in.) in this specification that are specific to nickel-titanium alloys.

and smaller nominal outside diameter and 2 mm (0.08 in.) and

3.3 individual wall thickness measurement, n—any one of

thinner nominal wall thickness.

the wall thickness measurements taken around the circumfer-

1.3 The values stated in SI units are to be regarded as the ence on any one transverse cross-section of a single sample of

the tube.

standard. The values given in parentheses (inch-pound units)

are for information only.

3.4 lot, n—the total quantity of product produced from the

same melt heat under the same conditions, at essentially the

2. Referenced Documents

same time.

2

2.1 ASTM Standards:

3.4.1 Discussion—For purposes of this specification, con-

A632 Specification for Seamless and Welded Austenitic

version from bar to tubular form by extrusion, gundrilling, or

Stainless Steel Tubing (Small-Diameter) for General Ser-

other method is included within the scope of this definition.

vice

3.5 lot average concentricity, n—the arithmetic average of

F2004 Test Method for Transformation Temperature of

the sample concentricities measured on a statistically represen-

Nickel-Titanium Alloys by Thermal Analysis

tative number of samples from the lot.

F2005 Terminology for Nickel-Titanium Shape Memory

3.6 lot average wall thickness, n—the grand average of the

Alloys

sample average wall thicknesses measured on a statistically

F2063 Specification for Wrought Nickel-Titanium Shape

representative number of samples from the lot.

Memory Alloys for Medical Devices and Surgical Im-

plants 3.7 nominal outside diameter (OD), n—theoutsidediameter

specified on the purchaser’s order or engineering drawing

F2082 Test Method for Determination of Transformation

Temperature of Nickel-Titanium Shape Memory Alloys without regard to tolerance.

by Bend and Free Recovery

3.8 nominal wall thickness, n—the wall thickness specified

bythepurchaser’sorderorengineeringdrawingwithoutregard

to tolerance.

1

This specification is under the jurisdiction of ASTM Committee F04 on

Medical and Surgical Materials and Devices and is the direct responsibility of

3.9 sample average wall thickness, n—the arithmetic aver-

Subcommittee F04.12 on Metallurgical Materials.

age of all individual wall thickness measurements measured on

Current edition approved Oct. 1, 2013. Published November 2013. Originally

a single sample.

approved in 2007. Last previous edition approved in 2007 as F2633–07. DOI:

10.1520/F2633-13.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3

Standards volume information, refer to the standard’s Document Summary page on Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

the ASTM website. 4th Floor, New York, NY 10036, http://www.ansi.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

F2633−13

TABLE 2 Permissible Variation in OD or ID Dimensions

3.10 sample concentricity, n—two times the offset between

the centers of the two circles representing the outside diameter Nominal OD or ID in mm (in.) Permissible Variation

from Nominal in mm (in.)

(OD) and the inside diameter (ID) of the tube.

Less than or equal to 1.5 (0.059) ±0.025 (0.

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: F2633 − 07 F2633 − 13

Standard Specification for

Wrought Seamless Nickel-Titanium Shape Memory Alloy

1

Tube for Medical Devices and Surgical Implants

This standard is issued under the fixed designation F2633; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope Scope*

1.1 This specification covers the requirements for wrought nickel-titanium shape memory alloy tube, nominally 54.5 %54.5 to

57.0 mass/mass (weight) % nickel, in the superelastic condition, used for the manufacture of medical devices and surgical implants.

Material shall conform to the applicable requirements of Specification F2063. This specification addresses those product variables

that differentiate drawn medical grade tube from the raw material and mill product forms covered in Specification F2063.

1.2 This specification applies to tube with 10 mm (0.4 in.) and smaller nominal outside diameter and 2 mm (0.08 in.) and thinner

nominal wall thickness.

1.3 The values stated in SI units are to be regarded as the standard. The values given in parentheses (inch-pound units) are for

information only.

2. Referenced Documents

2

2.1 ASTM Standards:

A632 Specification for Seamless and Welded Austenitic Stainless Steel Tubing (Small-Diameter) for General Service

F2004 Test Method for Transformation Temperature of Nickel-Titanium Alloys by Thermal Analysis

F2005 Terminology for Nickel-Titanium Shape Memory Alloys

F2063 Specification for Wrought Nickel-Titanium Shape Memory Alloys for Medical Devices and Surgical Implants

F2082 Test Method for Determination of Transformation Temperature of Nickel-Titanium Shape Memory Alloys by Bend and

Free Recovery

F2516 Test Method for Tension Testing of Nickel-Titanium Superelastic Materials

3

2.2 ISO Standard:

ISO 9001 Quality Management Systems—Requirements

ISO 13485 Quality Management Standard for Medical Devices

4

2.3 American Society for Quality Standards:

ASQ C1 Specification of General Requirements for a Quality Program

3. Terminology

3.1 Definitions of Terms Specific to This Standard:

3.2 See Terminology F2005 for the definition of terms used in this specification that are specific to nickel-titanium alloys.

3.3 individual wall thickness measurement, n—any one of the wall thickness measurements taken around the circumference on

any one transverse cross-section of a single sample of the tube.

3.4 lot, n—the total quantity of tubeproduct produced from the same melt heat under the same conditions, at essentially the same

time.

1

This specification is under the jurisdiction of ASTM Committee F04 on Medical and Surgical Materials and Devices and is the direct responsibility of Subcommittee

F04.12 on Metallurgical Materials.

Current edition approved April 1, 2007Oct. 1, 2013. Published May 2007November 2013. Originally approved in 2007. Last previous edition approved in 2007 as

F2633–07. DOI: 10.1520/F2633-07.10.1520/F2633-13.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

Available from American National Standards Institute (ANSI), 25 W. 43rd St., 4th Floor, New York, NY 10036, http://www.ansi.org.

3.4.1 Discussion—

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

F2633 − 13

For purposes of this specification, conversion from bar to tubular form by extrusion, gundrilling, or other method is included within

the scope of this definition.

3.5 lot average concentricity, n—the arithmetic average of the sample concentricities measured on a statistically representative

number of samples from the lot.

3.6 lot average wall thickness, n—the grand average of the sample average wall thicknesses measured on a statistically

representative number of samples from the lot.

3.7 nominal outside diameter (OD), n—the outside diameter specified by the purchaser on the purchaser’s order or engineering

drawing without regard to tolerance.

3.8 nominal wall thickness, n—the wall thickness specified by the purchaser purchaser’s order or engineering drawing without

regard to

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.