ASTM D7272-06(2011)

(Test Method)Standard Test Method for Determining the Integrity of Seams Used in Joining Geomembranes by Pre-manufactured Taped Methods

Standard Test Method for Determining the Integrity of Seams Used in Joining Geomembranes by Pre-manufactured Taped Methods

SIGNIFICANCE AND USE

Significance—With the increased use of geomembranes as a barrier material to restrict liquid migration from one location to another, a need has been created for a standard test method to evaluate the quality of geomembrane seams produced by tape methods. In the case of geomembranes, it has become evident that geomembrane seams can exhibit separation in the field under certain conditions. This is an index type test method used for quality assurance and quality control purposes, it is also intended to provide the quality engineer with sufficient seam peel and shear data to evaluate seam quality.

Use—Recording and reporting data such as separation that occurs during the peel test and elongation during the shear test, will allow the quality assurance engineer to take measures necessary to ensure the repair of inferior seams during construction, and therefore, minimize the potential for seam separation while in service. The acceptable value of adhesion measured will, of course, vary from product to product as a result of different formulations and types of products. However, once a product is established, minimum values of separation force can be determined and agreed to by producer and consumer and both can monitor the installation to assure maintenance of the agreed-upon minimum value.

SCOPE

1.1 This test method describes destructive quality control and/or quality assurance tests to determine the integrity of seams produced using taped seaming methods. This test method presents the procedures used for determining the quality of taped seams subjected to both peel and shear tests. These test procedures are intended for non-reinforced and reinforced geomembranes.

1.2 The types of tape seaming techniques used to construct geomembrane seams include the following.

1.2.1 Inseam Tape—This technique requires the membrane to be overlapped a minimum distance. The top sheet is folded back and both the bottom sheet and the top sheet are primed with an adhesive primer. The primer is allowed to flash-off. The tape adhesive is applied to the bottom sheet so that a minimum of the tape will extend out from under the top sheet when laid over the tape. The top sheet is allowed to lay flat over the tape and the release paper is removed by pulling it at a 45 to 90 degree angle, keeping the release paper flat to the surface of the bottom sheet. The seam area is then rolled with a silicone sleeved roller.

1.2.2 Cover Strip Tape—This technique requires the membrane to be overlapped a minimum distance. An area either side of the seam edge is primed. The primer is allowed to flash-off. The cover strip is applied with the adhesive side down centered over the top sheet edge while removing the release paper as it proceeds along centered over the edge of the top sheet. The cover strip is then rolled with a silicone sleeved roller.

1.3 For nondestructive test methods, see Practice D4437.

1.4 This test method is applicable for seaming processes that use tape adhesive as a seaming mechanism.

1.5 Subsequent decisions as to seam acceptance criteria are made according to the site-specific contract plans, specifications, and contractor quality control/contractor quality assurance (CQC/CQA) documents.

1.6 In case of a material specific test method, this test method shall take precedence.

1.7 Hazardous Materials—Always consult the proper material safety data sheets for any hazardous material used for the proper ventilation and protection. The use of the oven in these test methods, in this practice, may accelerate fume production from the test specimen.

1.8 The values stated in both inch-pound and SI units are to be regarded separately as the standard. Values in parentheses are for information only.

1.9 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and...

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D7272 − 06 (Reapproved 2011)

Standard Test Method for

Determining the Integrity of Seams Used in Joining

Geomembranes by Pre-manufactured Taped Methods

This standard is issued under the fixed designation D7272; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 1.6 In case of a material specific test method, this test

method shall take precedence.

1.1 This test method describes destructive quality control

and/or quality assurance tests to determine the integrity of 1.7 Hazardous Materials—Always consult the proper mate-

seams produced using taped seaming methods. This test rial safety data sheets for any hazardous material used for the

method presents the procedures used for determining the proper ventilation and protection. The use of the oven in these

quality of taped seams subjected to both peel and shear tests. test methods, in this practice, may accelerate fume production

These test procedures are intended for non-reinforced and from the test specimen.

reinforced geomembranes.

1.8 The values stated in both inch-pound and SI units are to

be regarded separately as the standard. Values in parentheses

1.2 The types of tape seaming techniques used to construct

geomembrane seams include the following. are for information only.

1.2.1 Inseam Tape—This technique requires the membrane

1.9 This standard does not purport to address all of the

to be overlapped a minimum distance. The top sheet is folded

safety concerns, if any, associated with its use. It is the

back and both the bottom sheet and the top sheet are primed

responsibility of the user of this standard to establish appro-

withanadhesiveprimer.Theprimerisallowedtoflash-off.The

priate safety and health practices and determine the applica-

tape adhesive is applied to the bottom sheet so that a minimum

bility of regulatory limitations prior to use.

of the tape will extend out from under the top sheet when laid

2. Referenced Documents

over the tape. The top sheet is allowed to lay flat over the tape

and the release paper is removed by pulling it at a 45 to 90

2.1 ASTM Standards:

degreeangle,keepingthereleasepaperflattothesurfaceofthe D413 TestMethodsforRubberProperty—AdhesiontoFlex-

bottom sheet. The seam area is then rolled with a silicone

ible Substrate

sleeved roller.

D638 Test Method for Tensile Properties of Plastics

1.2.2 Cover Strip Tape—This technique requires the mem-

D653 Terminology Relating to Soil, Rock, and Contained

branetobeoverlappedaminimumdistance.Anareaeitherside

Fluids

of the seam edge is primed. The primer is allowed to flash-off.

D882 Test Method for Tensile Properties of Thin Plastic

Thecoverstripisappliedwiththeadhesivesidedowncentered

Sheeting

over the top sheet edge while removing the release paper as it D4437 Practice for Non-destructive Testing (NDT) for De-

proceeds along centered over the edge of the top sheet. The

termining the Integrity of Seams Used in Joining Flexible

cover strip is then rolled with a silicone sleeved roller. Polymeric Sheet Geomembranes

D4439 Terminology for Geosynthetics

1.3 For nondestructive test methods, see Practice D4437.

D5199 Test Method for Measuring the Nominal Thickness

1.4 This test method is applicable for seaming processes

of Geosynthetics

that use tape adhesive as a seaming mechanism.

D5994 Test Method for Measuring Core Thickness of Tex-

1.5 Subsequent decisions as to seam acceptance criteria are tured Geomembranes

made according to the site-specific contract plans,

3. Terminology

specifications, and contractor quality control/contractor quality

3.1 Definitions—For definitions of other geosynthetic terms

assurance (CQC/CQA) documents.

used in this method, refer to Terminology D4439. For defini-

tions of soil terms, refer to Terminology D653.

This test method is under the jurisdiction of ASTM Committee D35 on

GeosyntheticsandisthedirectresponsibilityofSubcommitteeD35.10onGeomem-

branes. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

CurrenteditionapprovedJune1,2011.PublishedJuly2011.Originallyapproved contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

2006. Last previous version approved 2006 as D7272–06.DOI: 10.1520/D7272- Standards volume information, refer to the standard’s Document Summary page on

06R11. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D7272 − 06 (2011)

3.2 Definitions of Terms Specific to This Standard: minimum of 25 mm (1 in.) in length. Smooth surfaces, fine

3.2.1 tape adhesive, n—solid strip of prefabricated or manu- serrated or coarse serrated grip faces, use the grips that have all

factured adhesive factory laminated to a release paper used to been found to be suitable for testing, depending on type of

join two polymer sheets. geomembrane seams that are being tested.

3.2.2 tape adhesive seam, n—adhesive-based tape placed

NOTE1—Gripslinedwiththinrubber,crocus-clothorpressuresensitive

between two polymer sheet materials forming a surface bond. tape as well as file-faced or serrated grips have been successfully used for

many materials. The choice of grip surface will depend on the material

3.2.3 cover strip adhesive, n—solid strip of prefabricated or

tested, thickness, etc.

manufactured adhesive factory laminated to layer of polymer

5.2.4 Drive Mechanism—A drive mechanism for imparting

sheet material factory laminated to a release paper used to join

to the movable member in uniform, controlled velocity with

two polymer sheets.

respect to the stationary member. Unless otherwise specified in

3.2.4 cover strip adhesive seam, n—adhesive-based lami-

the material specification, the mechanism shall be capable of

nated tape placed over two overlapping polymer sheet materi-

and adjusted so that the movable member shall have a uniform

als forming a surface bond.

speed of 50 mm/min, (2 in./min), 300 mm/min (12 in./min),

and 500 mm/min (20 in./min).

4. Significance and Use

5.2.5 Load Indicator—A suitable load-indicating mecha-

4.1 Significance—With the increased use of geomembranes

nism capable of showing the total tensile load carried by the

as a barrier material to restrict liquid migration from one

test specimen when held by the grips.This mechanism shall be

location to another, a need has been created for a standard test

essentially free of inertia lag at the specified rate of testing and

method to evaluate the quality of geomembrane seams pro-

shall indicate the load with an accuracy of 61 % of the

duced by tape methods. In the case of geomembranes, it has

indicated value or better.

become evident that geomembrane seams can exhibit separa-

5.2.6 Extension Indicator (Extensometer) (If Employed)—A

tion in the field under certain conditions. This is an index type

suitable instrument shall be used for determining the distance

test method used for quality assurance and quality control

between two designated points within the gage length of the

purposes, it is also intended to provide the quality engineer

test specimen as the specimen is stretched and shall conform to

with sufficient seam peel and shear data to evaluate seam

requirements specified in Test Method D638.

quality.

6. Sampling and Specimen Preparation

4.2 Use—Recording and reporting data such as separation

that occurs during the peel test and elongation during the shear

6.1 Trial Seam Sample—A representative seam from each

test, will allow the quality assurance engineer to take measures

seaming crew, fabricated from the same sheet material, and

necessary to ensure the repair of inferior seams during

using the seaming methods as those recommended by the

construction, and therefore, minimize the potential for seam

geomembrane fabricator manufacturer, shall be used for this

separation while in service. The acceptable value of adhesion

method.

measured will, of course, vary from product to product as a

6.1.1 Destructive Seam Sample—Alternatively,cutaportion

result of different formulations and types of products.

of the fabricated seam from the installed liner or a daily test

However, once a product is established, minimum values of

seam sample in accordance with the project specifications. It is

separation force can be determined and agreed to by producer

recommended that the cutout sample be 0.3 m (1 ft) wide and

and consumer and both can monitor the installation to assure

0.45 m (1.5 ft) in length with the seam centered in the middle

maintenance of the agreed-upon minimum value.

of the seam.

6.1.2 Specimen Preparation—Five specimens shall be cut

5. Apparatus

from the submittal sample for each the Peel and Shear test.The

specimens for the Peel test shall be cut using a calibrated die,

5.1 Tensile instrumentation shall meet the requirements

25 6 3 mm (nominal 1 6 0.125 in.) wide by 150 63mm

outlined in Test Method D638 or D882.

(nominal 6 6 0.125 in.) long die. The Specimens for the Shear

5.2 A testing machine of the constant-rate-of-cross head

testshallbediecutusingacalibrateddie,25 63mm(nominal

movement type comprising essentially of the following:

1 6 0.125 in.) wide by 2 inches greater than the width of the

5.2.1 Fixed Member—A fixed or essentially stationary

seam. Specimens shall be such that the die is centered over the

member carrying one grip.

sample seam, perpendicular to the centerline of the seam. Peel

5.2.2 Movable Member—A movable member carrying a

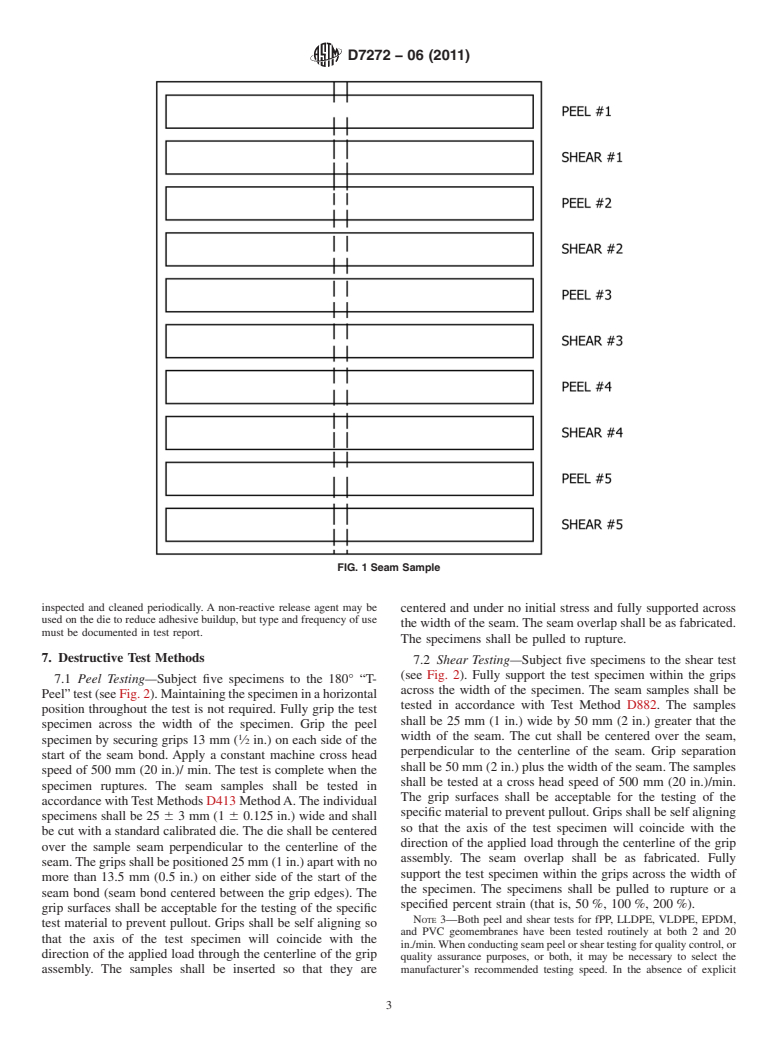

and shear specimens shall be cut as shown in Fig. 1.

second grip.

6.1.3 Conditioning—Samples should be conditioned for 24

5.2.3 Grips—Grips for holding the test specimen between

hours in a standard laboratory environment that conforms to

the fixed member and the movable member and minimizes

the requirements for testing geosynthetics as stated in Termi-

both slippage and uneven stress distribution. The grips shall be

nology D4439.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.