ASTM B121/B121M-95

(Specification)Standard Specification for Leaded Brass Plate, Sheet, Strip, and Rolled Bar

Standard Specification for Leaded Brass Plate, Sheet, Strip, and Rolled Bar

SCOPE

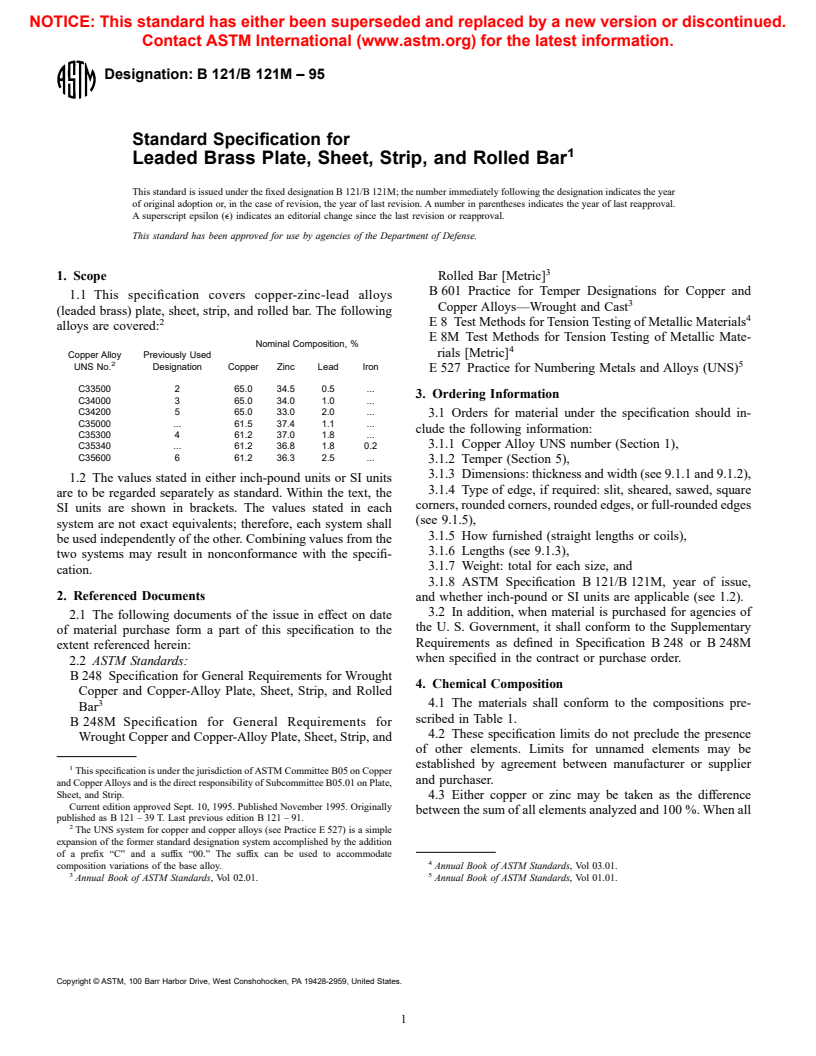

1.1 This specification establishes the requirements for copper-zinc-lead alloys (leaded brass) plate, sheet, strip, and rolled bar. The following alloys are covered:Nominal Composition, %Copper AlloyPreviously UsedUNS No.DesignationCopperZincLead IronC33500265.034.5 0.5...C34000365.034.0 1.0...C34200565.033.0 2.0...C35000...61.537.4 1.1...C35300461.237.0 1.8...C35600661.236.3 2.5...

1.2 The values stated in either inch-pound units or SI units are to be regarded separately as standard. Within the text, the SI units are shown in brackets. The values stated in each system are not exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in nonconformance with the specification.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: B 121/B 121M – 95

Standard Specification for

Leaded Brass Plate, Sheet, Strip, and Rolled Bar

This standard is issued under the fixed designation B 121/B 121M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope Rolled Bar [Metric]

B 601 Practice for Temper Designations for Copper and

1.1 This specification covers copper-zinc-lead alloys

Copper Alloys—Wrought and Cast

(leaded brass) plate, sheet, strip, and rolled bar. The following

E 8 Test Methods for Tension Testing of Metallic Materials

alloys are covered:

E 8M Test Methods for Tension Testing of Metallic Mate-

Nominal Composition, %

rials [Metric]

Copper Alloy Previously Used

UNS No. Designation Copper Zinc Lead Iron

E 527 Practice for Numbering Metals and Alloys (UNS)

C33500 2 65.0 34.5 0.5 .

3. Ordering Information

C34000 3 65.0 34.0 1.0 .

C34200 5 65.0 33.0 2.0 .

3.1 Orders for material under the specification should in-

C35000 . 61.5 37.4 1.1 .

clude the following information:

C35300 4 61.2 37.0 1.8 .

3.1.1 Copper Alloy UNS number (Section 1),

C35340 . 61.2 36.8 1.8 0.2

C35600 6 61.2 36.3 2.5 .

3.1.2 Temper (Section 5),

3.1.3 Dimensions: thickness and width (see 9.1.1 and 9.1.2),

1.2 The values stated in either inch-pound units or SI units

3.1.4 Type of edge, if required: slit, sheared, sawed, square

are to be regarded separately as standard. Within the text, the

corners, rounded corners, rounded edges, or full-rounded edges

SI units are shown in brackets. The values stated in each

(see 9.1.5),

system are not exact equivalents; therefore, each system shall

3.1.5 How furnished (straight lengths or coils),

be used independently of the other. Combining values from the

3.1.6 Lengths (see 9.1.3),

two systems may result in nonconformance with the specifi-

3.1.7 Weight: total for each size, and

cation.

3.1.8 ASTM Specification B 121/B 121M, year of issue,

2. Referenced Documents

and whether inch-pound or SI units are applicable (see 1.2).

3.2 In addition, when material is purchased for agencies of

2.1 The following documents of the issue in effect on date

the U. S. Government, it shall conform to the Supplementary

of material purchase form a part of this specification to the

Requirements as defined in Specification B 248 or B 248M

extent referenced herein:

when specified in the contract or purchase order.

2.2 ASTM Standards:

B 248 Specification for General Requirements for Wrought

4. Chemical Composition

Copper and Copper-Alloy Plate, Sheet, Strip, and Rolled

4.1 The materials shall conform to the compositions pre-

Bar

scribed in Table 1.

B 248M Specification for General Requirements for

4.2 These specification limits do not preclude the presence

Wrought Copper and Copper-Alloy Plate, Sheet, Strip, and

of other elements. Limits for unnamed elements may be

established by agreement between manufacturer or supplier

This specification is under the jurisdiction of ASTM Committee B05 on Copper

and purchaser.

and Copper Alloys and is the direct responsibility of Subcommittee B05.01 on Plate,

Sheet, and Strip.

4.3 Either copper or zinc may be taken as the difference

Current edition approved Sept. 10, 1995. Published November 1995. Originally

between the sum of all elements analyzed and 100 %. When all

published as B 121 – 39 T. Last previous edition B 121 – 91.

The UNS system for copper and copper alloys (see Practice E 527) is a simple

expansion of the former standard designation system accomplished by the addition

of a prefix “C” and a suffix “00.” The suffix can be used to accommodate

Annual Book of ASTM Standards, Vol 03.01.

composition variations of the base alloy.

Annual Book of ASTM Standards, Vol 01.01.

Annual Book of ASTM Standards, Vol 02.01.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

B 121/B 121M

TABLE 1 Chemical Requirements TABLE 3 Grain Size Requirements for Annealed Material

Composition Standard

Grain Size, mm

Copper Alloy

Copper Alloy UNS No. Temper

UNS No.

Copper Lead Iron Zinc

Nominal Min Max

Designation

C33500 62.0–65.0 0.25–0.7 0.10 max remainder

OS070 0.070 0.050 0.100

C33500, C34000,

C34000 62.0–65.0 0.8–1.5 0.10 max remainder

OS050 0.050 0.035 0.070

C34200, C35000,

C34200 62.0–65.0 1.5–2.5 0.10 max remainder

OS035 0.035 0.025 0.050

C34300, C34340,

C35000 60.0–63.0 0.8–2.0 0.10 max remainder

and C35600

OS025 0.025 0.015 0.035

C35300 60.0–63.0 1.5–2.5 0.10 max remainder

C35340 60.0–63.0 1.5–2.5 0.10–0.30 remainder

C35600 60.0–63.0 2.0–3.0 0.10 max remainder

6.1.2 Products ordered to this specification in SI units shall

be tested in accordance with Test Methods E 8M, and shall

elements in Table 1 are analyzed, their sum shall be as shown

conform to tensile strength requirements prescribed in MPa

in the table below.

units in Table 2.

Copper Plus Named 6.1.3 Acceptance or rejection based on mechanical proper-

Copper Alloy UNS No. Elements, % min.

ties shall depend only on the tensile strength.

C33500 99.6

7. Grain Size Requirements of Annealed Tempers

C34000 99.6

C34200 99.6

7.1 Grain size shall be the standard test for material of all

C35000 99.6

thicknesses in annealed tempers, and acceptance or rejection

C35300 99.5

shall depend only on the grain size. The average grain size of

C35340 99.5

C35600 99.5

each of two samples of annealed material as determined on a

plane parallel to the surface of the material shall be within the

5. Temper

limits prescribed in Table 3.

5.1 Rolled Material—The standard tempers of rolled mate-

8. Rockwell Hardness

rial are as designated in Table 2 in the column entitled “Temper

Standard.” Special or nonstandard tempers are subject to

8.1 Rockwell hardness tests offer a quick and convenient

negotiation between manufacturer or supplier and purchaser

method of checking leaded brass of any temper for general

(see 3.1.2).

conformity

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.