ASTM E1696-95b(2001)

(Test Method)Standard Test Method for Field Measurement of Raised Retroreflective Pavement Markers Using a Portable Retroreflectometer

Standard Test Method for Field Measurement of Raised Retroreflective Pavement Markers Using a Portable Retroreflectometer

SCOPE

1.1 This test method covers the measurement of the retroreflective properties of raised retroreflective pavement markers at a prescribed geometry, by means of a portable retroreflectometer that can be used in the field. The measurements can be compared to minimum requirements to determine the need for replacement.

1.2 The observation angle specified for retroreflectometers in this test method is that currently specified for raised pavement markers in the United States and may differ from the angles used elsewhere. For other jurisdictions, replace the observations angle specified herein with the observation angle specified by the pertinent agency.

1.3 This test method is intended to be used for field measurement of raised retroreflective pavement markers but may also be used to measure the performance of new markers before they are placed in the field.

1.4 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.5 The standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

Designation: E 1696 – 95b (Reapproved 2001)

Standard Test Method for

Field Measurement of Raised Retroreflective Pavement

Markers Using a Portable Retroreflectometer

This standard is issued under the fixed designation E 1696; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 3.2.1 coeffıcient of luminous intensity, R , n—of a retrore-

I

flector, ratio of the luminous intensity (I) of the retroreflector in

1.1 This test method covers the measurement of the retrore-

the direction of observation to the illuminance (E|nt) at the

flective properties of raised retroreflective pavement markers at

retroreflector on a plane perpendicular to the direction of

a prescribed geometry, by means of a portable retroreflecto-

−1

incident light, expressed in candelas per lux (cd·lx ).

meter that can be used in the field. The measurements can be

3.2.1.1 Discussion—When values are low, the coefficient of

compared to minimum requirements to determine the need for

(retroreflected) luminous intensity may be given in millican-

replacement.

−1

delas per lux (mcd·lx ). R =(I/E|nt).

1.2 The observation angle specified for retroreflectometers I

3.2.2 entrance angle, n—angle between the illumination

in this test method is that currently specified for raised

axis and the retroreflector axis.

pavement markers in the United States and may differ from the

3.2.3 illumination axis, n—line from the effective center of

angles used elsewhere. For other jurisdictions, replace the

the source aperture to the retroreflector center.

observations angle specified herein with the observation angle

3.2.4 observation angle, a, n—the angle between the illu-

specified by the pertinent agency.

mination axis and the observation axis.

1.3 This test method is intended to be used for field

3.2.5 portable retroreflectometer—a hand-held instrument

measurement of raised retroreflective pavement markers but

that can be used in the field or in the laboratory for measure-

may also be used to measure the performance of new markers

ment of retroreflectance.

before they are placed in the field.

3.2.5.1 Discussion—In this test method, “portable retrore-

1.4 The values stated in SI units are to be regarded as the

flectometer” refers to a hand-held instrument that can be placed

standard. The values given in parentheses are for information

over a raised retroreflective pavement marker to measure the

only.

coefficient of luminous intensity with a prescribed geometry.

1.5 The standard does not purport to address all of the

3.2.6 instrument standard, n—a working standard used to

safety concerns, if any, associated with its use. It is the

standardize the portable retroreflectometer.

responsibility of the user of this standard to establish appro-

3.2.7 retroreflection, n—reflection in which the reflected

priate safety and health practices and determine the applica-

rays are preferentially returned in directions close to the

bility of regulatory limitations prior to use

opposite of the direction of the incident rays, this property

2. Referenced Documents being maintained over wide variations of the direction of the

incident rays.

2.1 ASTM Standards:

3.2.8 retroreflective element, n—one optical unit which by

E 284 Terminology of Appearance

refraction or reflection or both produces the phenomenon of

E 809 Practice for Measuring Photometric Characteristics

retroreflection.

of Retroreflectors

4. Summary of Test Method

3. Terminology

4.1 This test method involves the use of commercial por-

3.1 The terms and definitions in Terminology E 284 are

table retroreflectometers for determining the coefficient of

applicable to this test method.

luminous intensity of pavement markers.

3.2 Definitions—The delimiting phrase “in retroreflection”

4.2 Entrance angle b shall be between 0 and 2°, entrance

applies to each of the following definitions when used outside 1

angle b shall be 0 6 2°.

the context of this or other retroreflection standards:

4.3 Unless otherwise specified by the user, the observation

angle shall be 0.2° 6 0.01°.

This test method is under the jurisdiction of ASTM Committee E12 on Color

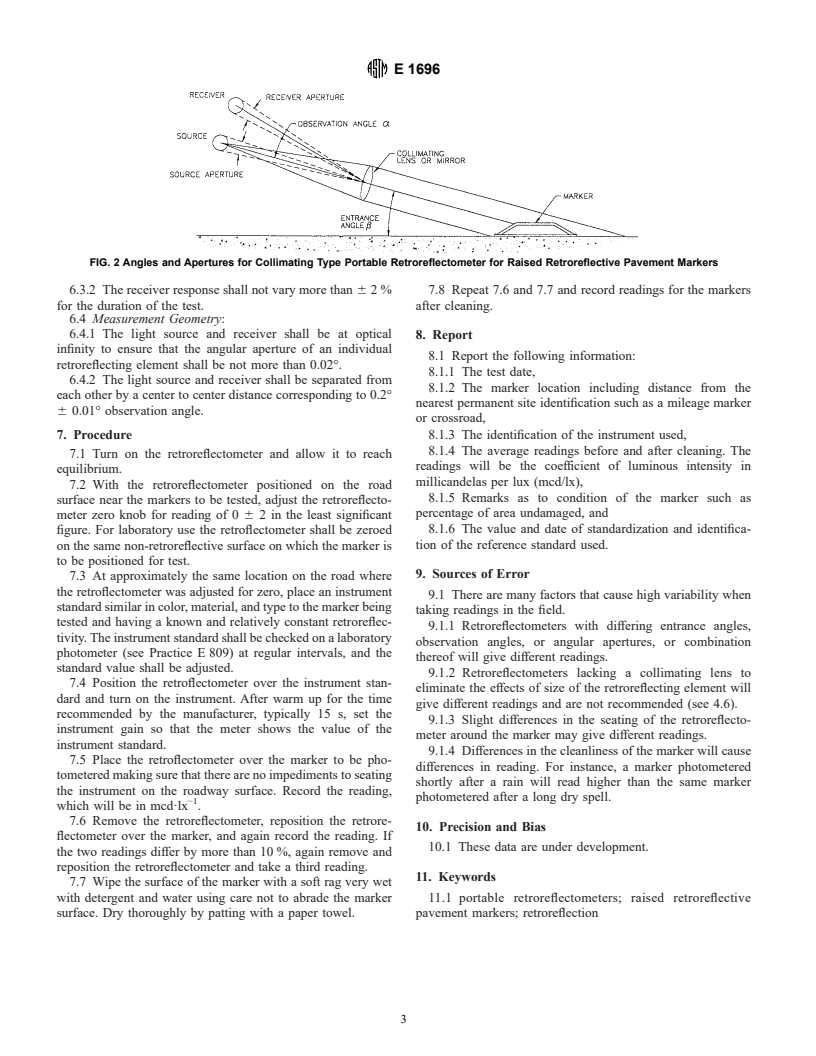

4.4 The observation half plane shall be vertical. Rotation

and Appearance and is the direct responsibility of Subcommittee E12.10 on

angle shall be 0° (see Fig. 1 and Fig. 2).

Retroreflection.

Current edition approved Oct. 10, 1995. Published December 1995. Originally

4.5 The sum of the aperture angles of source plus receiver

published as E 1696 – 95. Last previous edition E 1696 – 95a.

shall be 0.2° 6 0.04° (see Table 1 of Practice E 809).

Annual Book of ASTM Standards, Vol 06.01.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

E 1696

coefficient of (retroreflected) luminous intensity. These condi-

tions need to be observed and noted by the user.

6. Apparatus

6.1 Portable Retroreflectometer:

6.1.1 The retroreflectometer shall be portable with the

capability of being positioned over markers installed on the

roadway surface.

6.1.2 The retroreflectometer shall be constructed so that

placement on the road will preclude any stray light from

entering the area being tested under daylight conditions.

6.1.3 The retroreflectometer shall be constructed so that it

can be placed over the marker with the illumination axis

parallel to the road surface.

6.1.4 The combined spectral distribution of the light source

and the spectral responsivity of the receiver shall match the

combined spectral distribution of CIE Illuminant A and the V

(l) spectral luminosity function according to the following

criterion: for any choice of plano parallel colored absorptive

filter mounted in front of a white retroreflective sample, the

ratio of the R measured with the filter to the R measured

I I

without the filter shall be within 10 % of the Illuminant A

luminous transmittance of an air-spaced pair of two such filters.

NOTE 1—In the retroreflectometer the filter should be mounted with a

downward tilt (for example, 1.0°) for avoiding specular reflection into the

receiver.

6.1.5 When using a standard similar in color, material, and

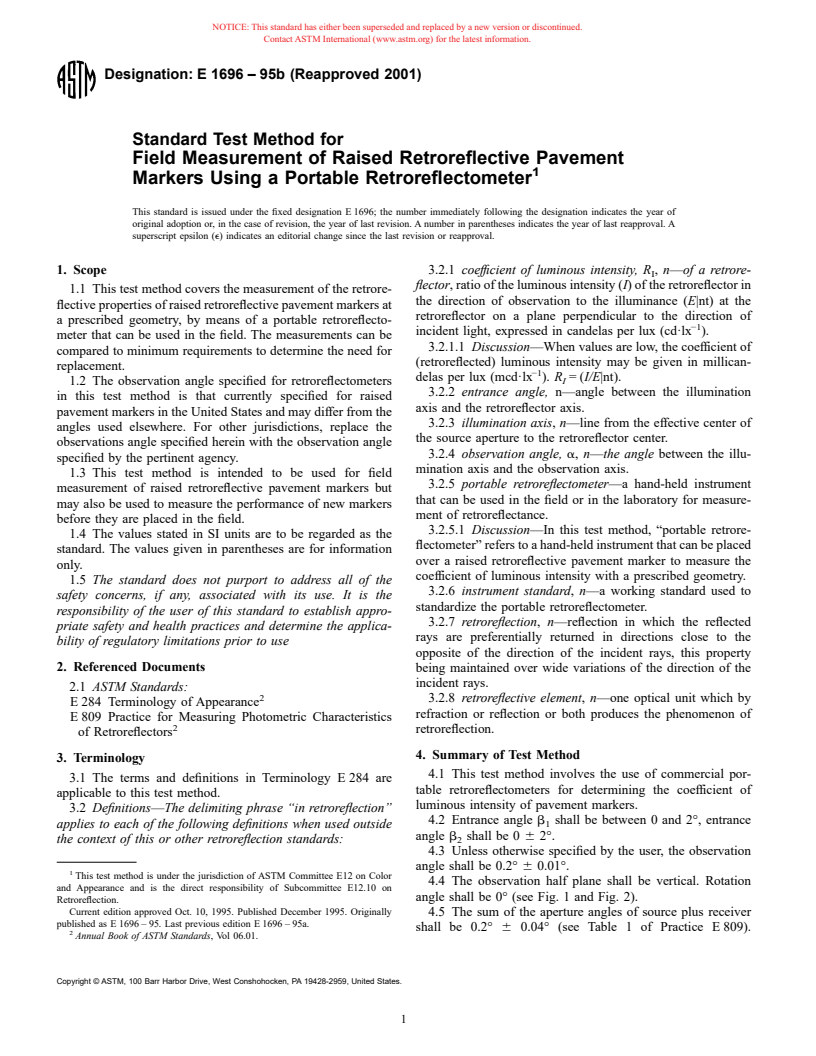

FIG. 1 Position of Marker for Photometry

type to the sample, measured R shall not deviate by more than

I

10 % from measurements made on a laboratory photometer

Maximum system sensitivity is obtained when aperture angles

conforming to Practice E 809 with observation angle, a,as

of source and receiver are equal.

specified and b = b = e = 0°.

1 2

4.6 The aperture angle of an individual retroreflective ele-

6.1.6 If, for convenience, the user chooses to use a white

ment shall be 0.02° max (see Practice E 809). For a portable

standard for all markers, a correction factor shall be applied to

photometer this aperture angle can be achieved by interposing

the readings obtained with the white standard. To determine the

a collimating lens in the illumination and observation axes.

correction factor, (1) standardize the instrument using a white

4.7 A portable standard shall be used for standardization.

standard; (2) without changing the instrument settings, note the

4.8 After standardization place the retroreflectometer di-

reading for a selected prephotometered standar

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.