ASTM D4535-85(2004)

(Test Method)Standard Test Methods for Measurement of Thermal Expansion of Rock Using a Dilatometer

Standard Test Methods for Measurement of Thermal Expansion of Rock Using a Dilatometer

SCOPE

1.1 These test methods cover the laboratory measurement of the linear (one-dimensional) thermal expansion of rocks using a dilatometer.

1.2 These test methods are applicable between temperatures of 25oC to 300oC. Both bench top and confined measurement techniques are presented. Rocks of varying moisture content can be tested.

1.3 For satisfactory results in conformance with these test methods, the principles governing the size, construction, and use of the apparatus described in these methods should be followed. If the results are to be reported as having been obtained by this method, then all pertinent requirements prescribed in this method shall be met.

1.4 These test methods do not establish details of construction and procedure to cover all test situations that might offer difficulties to a person without technical knowledge concerning the theory of heat flow, temperature measurement, and general testing practices. Standardization of these test methods does not reduce the need for such technical knowledge. It is recognized also that it would be unwise, because of the standardization of this method, to resist in any way the further development of improved or new methods or procedures by research workers.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D 4535 – 85 (Reapproved 2004)

Standard Test Methods for

Measurement of Thermal Expansion of Rock Using a

Dilatometer

This standard is issued under the fixed designation D4535; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope E228 Test Method for Linear Thermal Expansion of Solid

Materials with Vitreous a Silica Dilatometer

1.1 Thesetestmethodscoverthelaboratorymeasurementof

the linear (one-dimensional) thermal expansion of rocks using

3. Terminology

a dilatometer.

3.1 Definitions of Terms Specific to This Standard:

1.2 Thesetestmethodsareapplicablebetweentemperatures

3.1.1 sample thermal strain, e— change in length of a unit

t

of 25°C to 300°C. Both bench top and confined measurement

length of sample when the sample is subjected to heat. The

techniques are presented. Rocks of varying moisture content

mathematical expression is:

can be tested.

1.3 For satisfactory results in conformance with these test e 5 ~L 2 L !/L (1)

t 2 1 0

methods, the principles governing the size, construction, and

where:

use of the apparatus described in these methods should be

L and L = specimen lengths corresponding to tempera-

1 2

followed. If the results are to be reported as having been

tures T and T , and

1 2

obtained by this method, then all pertinent requirements

L = the original specimen length at some refer-

prescribed in this method shall be met.

ence temperature T .

1.4 These test methods do not establish details of construc-

Thermal strain is also equal to the specimen thermal dis-

tion and procedure to cover all test situations that might offer

placement, d, divided by the original sample length:

t

difficultiestoapersonwithouttechnicalknowledgeconcerning

e 5d/L (2)

the theory of heat flow, temperature measurement, and general t t 0

testing practices. Standardization of these test methods does

3.1.2 mean coeffıcient of linear expression, a —between

m

not reduce the need for such technical knowledge. It is

two temperatures, T and T , is defined as follows:

1 2

recognized also that it would be unwise, because of the

a 5 ~L 2 L !/[L ~T 2 T !# (3)

m 2 1 0 2 1

standardization of this method, to resist in any way the further

development of improved or new methods or procedures by

where:

research workers. L and L = specimen lengths at temperatures T and T ,

1 2 1 2

1.5 This standard does not purport to address all of the respectively. Therefore, a is obtained by

m

safety concerns, if any, associated with its use. It is the dividing the linear thermal strain, (L − L )/

1 2

responsibility of the user of this standard to establish appro- L , by the change in temperature units are

inch/inch or centimetre/centimetre per tem-

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use. perature change in °F or °C, respectively. a

m

is often expressed in parts per million per

2. Referenced Documents

degree.

2.1 ASTM Standards:

3.1.3 Uponheating( T > T ),anincreaseinthelengthofthe

2 1

E83 Practice for Verification and Classification of Exten- rock sample will give a positive value of a . If a decrease in

m

someters

length (contraction) is observed, a will become negative.

m

4. Summary of Test Methods

ThesetestmethodsareunderthejurisdictionofASTMCommitteeD18onSoil

4.1 The application of heat to a rock causes it to expand.

and Rock and are the direct responsibility of Subcommittee D18.12 on Rock

This expansion divided by the original length of the rock

Mechanics.

Current edition approved Nov. 1, 2004. Published December 2004. Originally

specimens is the thermal strain from which coefficients of

approved in 1985. Last previous edition approved in 2000 as D4535–85(2000)

expansioncanbecalculated.Thisstandardcoverstwomethods

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standardsvolume information, refer to the standard’s Document Summary page on

the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D 4535 – 85 (2004)

formeasuringrockexpansion.Theprimarydifferencebetween 5.3 Rocks are also often anisotropic, thus displaying differ-

the two methods is in the type of dilatometer used. ent thermal strains depending on the orientation of strain

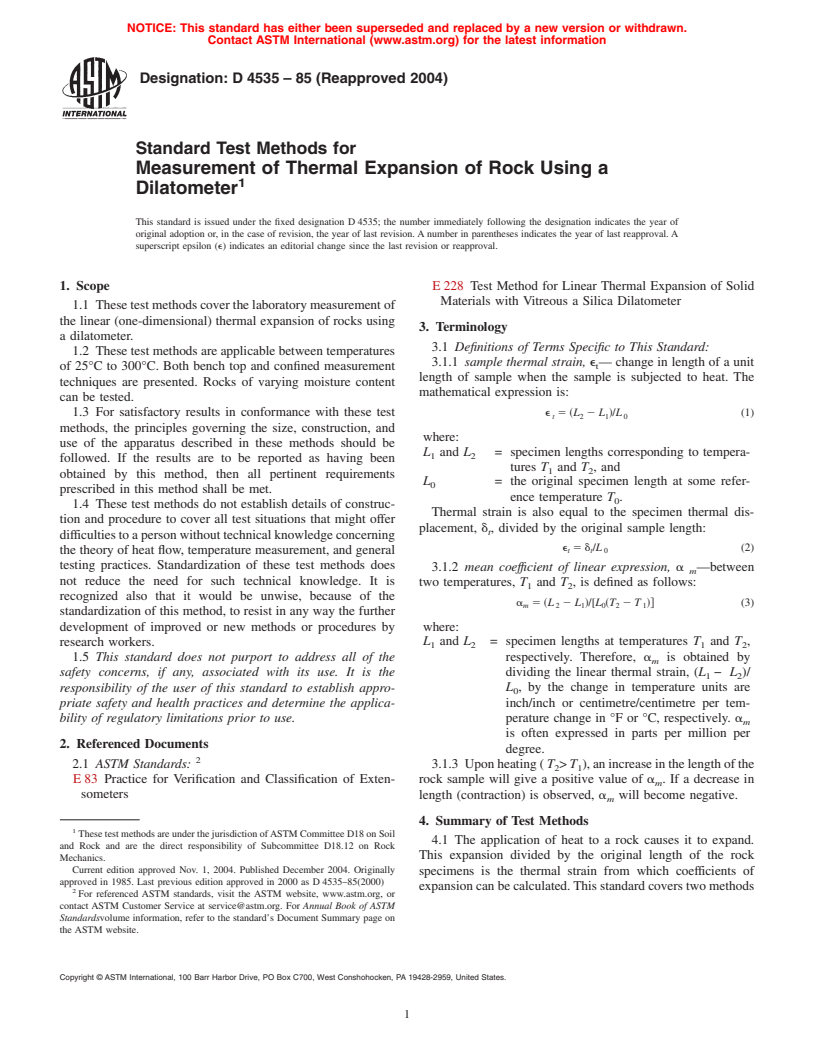

4.1.1 Test Method I—Test Method I is the procedure used measurement.Thesemethodsallowformeasuringstraininone

when making unconfined or bench top measurements. The directiononly.Ifanisotropyisexpected,sampleswithdifferent

method and apparatus are similar to that described in Test orientations should be prepared and tested.

Method E228. The rock specimen thermal displacement is 5.4 Careshouldbeexercisedintheinterpretationofthermal

measured using a dilatometer as shown in Fig. 1. The sample

strain data of rocks with significant moisture content. Under

displacement is measured by a transducer located outside the certain temperature and pressure conditions, steam may be

heated area of the sample; therefore, apparent strain due to

producedintheporespace.Steammaycauseerrorsbecauseof

apparatus expansion and contraction is minimized. microcrack production or changes in the pore pressure. The

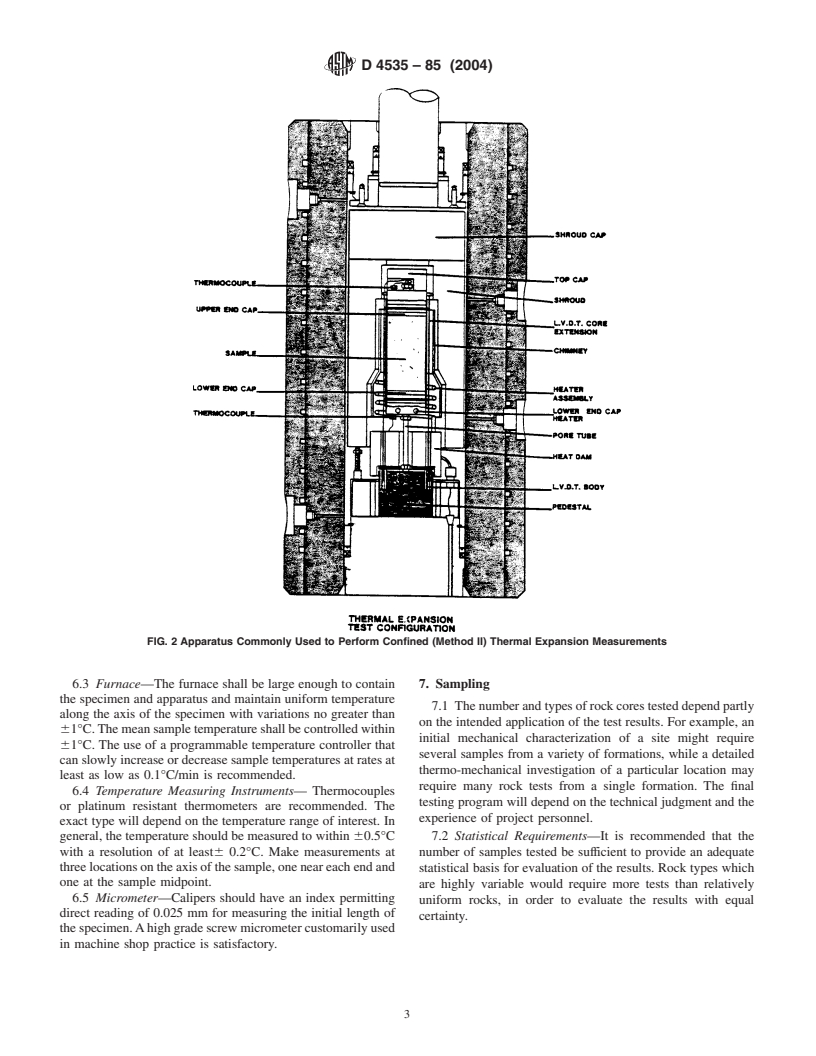

4.1.2 Test Method II—Test Method II employs a dilatomet- phase change from water to steam in the pore space can result

ric device which is located inside the heated zone, as shown in in several phenomena which complicate data analysis, as

Fig. 2. This test method is most suited for the measurement of follows:

rock thermal strain under confined conditions. 5.4.1 Evolved steam may change the pore pressure and thus

4.2 In both test methods, sample expansion is measured

the effective stress in the rock, resulting in anomalous strain

continuously as temperature is gradually increased or allowed

readings.

to stabilize at discrete temperature points.

5.4.2 Losing all the moisture may dehydrate clays in the

pore space and thus change expansion characteristics, espe-

5. Significance and Use

cially in layered rocks.

5.1 Information concerning the thermal expansion charac-

5.5 The researcher using this standard must use best judg-

teristics of rocks is important in the design of any underground

mentastohowtomakethethermalexpansionmeasurementso

excavation where the surrounding rock may be heated. Ther-

that it accurately represents the conditions in the field.

mal strain causes thermal stresses which ultimately affect

5.6 Method II is amenable to confined thermal strain deter-

excavation stability. Examples of applications where rock

minations. Confined tests may be most appropriate when:

thermal strain is important include: nuclear waste repositories,

5.6.1 Pore pressure must be imposed in the pore space to

underground power stations, compressed air energy storage

maintain the liquid phase of water through the desired tem-

facilities, and geothermal energy facilities.

perature range.

5.2 The coefficient of thermal expansion or “alpha” or rock

5.6.2 The thermal strain of the rock is sensitive to confining

is known to vary as the temperature changes. These methods

stress.

provide continuous thermal strain values as a function of

5.6.3 Thesampleisfragileorfriable,orboth,andcannotbe

temperature, and therefore provide information on how alpha

machined into the shapes required for Method I.

changes with temperature.

6. Apparatus

6.1 Dilatometer:

6.1.1 Method I—The dilatometer used for bench measure-

mentsmaybeofthetubeorrodtype,asshowninFig.1.Those

components of the dilatometer exposed to elevated tempera-

tures should be fabricated of materials with coefficients of

linear expansion that are as small as practicable.

6.1.2 Method II—In Method II the entire dilatometer is

exposed to elevated temperature. Therefore, transducers, rods,

and other components should be fabricated of materials with

low thermal expansions (for example, fused silica, super

invar). When the apparatus is tested with a quartz calibration

specimen, the apparatus strain should be less than 20 % of the

anticipated rock strain (refer to Fig. 2).

6.2 Extensometer—Extensometers measure length change.

In principle, any accurate length measuring device with good

long-termstabilitymaybeused;thisincludesdialgages,linear

variable differential transducers, or capacitive transducers.

Whicheverdeviceisselected,itmusthavesufficientresolution

to measure 0.01 % sample strain (Refer to PracticeE83).

6.2.1 ThosedevicesusedinMethodIImustbefabricatedof

materials that allow direct exposure of the device to the

anticipated temperature. Also, transducer bodies should be

vented for operation in a pressure environment. At least two

transducers are used, as shown in Fig. 2, and their outputs

FIG. 1 Apparatus Commonly Used to Perform Bench Top (Method

I) Thermal Expansion Measurements averaged.

D 4535 – 85 (2004)

FIG. 2 Apparatus Commonly Used to Perform Confined (Method II) Thermal Expansion Measurements

6.3 Furnace—The furnace shall be large enough to contain 7. Sampling

the specimen and apparatus and maintain uniform temperature

7.1 Thenumberandtypesofrockcorestesteddependpartly

along the axis of the specimen with variations no greater than

on the intended application of the test results. For example, an

61°C.Themeansampletemperatureshallbecontrolledwithin

initial mechanical characterization of a site might require

61°C. The use of a programmable temperature controller that

several samples from a variety of formations, while a detailed

canslowlyincreaseordecreasesampletemperaturesatratesat

thermo-mechanical investigation of a particular location may

least as low as 0.1°C/min is recommended.

require many rock tests from a single formation. The final

6.4 Temperature Measuring Instruments— Thermocouples

testing program will depend on the technical judgment and the

or platinum resistant thermometers are recommended. The

experience of project personnel.

exact type will depend on the temperature range of interest. In

general, the temperature should be measured to within 60.5°C 7.2 Statistical Requirements—It is recommended that the

with a resolution of at least6 0.2°C. Make measurements at

number of samples tested be sufficient to provide an adequate

threelocationsontheaxisofthesample,oneneareachendand

statistical basis for evaluation of the results. Rock types which

one at the sample midpoint.

are highly variable would require more tests than relatively

6.5 Micrometer—Calipers should have an index permitting

uniform rocks, in order to evaluate the results with equal

direct reading of 0.025 mm for measuring the initial length of

certainty.

thespecimen.Ahighgradescrewmicrometercustomarilyused

in machine shop practice is satisfactory.

D 4535 – 85 (2004)

7.3 Moisture Condition of Samples— The moisture condi- 10.3 Repeat the standardization test procedure three times,

tion of the rock can influence the measured thermal expansion. starting from the same initial condition, to verify the repeat-

Test the specimens in a manner that best simulates the in situ ability of the dilatometer. Variation from run to run should be

conditions of interest. For natural conditions, the moisture no greater than 5 %.

content of the rock core and the chemical characteristics of the 10.4 Thecalculatedexpansionofthecalibrationspecimenis

pore fluid shall be preserved between the time of recovery and subtracted from the calibration expansion results as follows:

testing; then determine the moisture content of core material

d 5d 2d ; (4)

2 1 s

contiguous to the test specimen.

where:

7.4 Anisotropy—The thermal expansion coefficient of many

d 5a·l·DT (5)

rocks is different along various axes of the rock. Measure the s

thermal expansion in several directions in order to assess the

where:

degree of anisotropy.

d = thermal expansion of the test apparatus, cm,

7.5 Documentation—Since the thermal expansion of most

d = apparent thermal expansion measured by the appa-

rock is anisotropic, it is important that the field orientation of

ratus, cm

each sample is recorded. Note the orientation of each sample

d = thermal expansion of the calibration specimen, cm

s

onthesampleandcarrysuitablemarkingsthrougheachcutting

a = coefficient of linear expansion for the calibration

until the final specimen is ready for testing. These markings

specimen,

shouldindicatecompassdirectionandup/downdirections,and

l = gage length of the calibration specimen, cm, and

other orientation with respect to geologic structures.

DT = temperaturedifferencebetweenareferencetempera-

ture (room temperature or slightly elevated above

8. Test Specimens

room temperature) and an elevated temperature, °C.

8.1 Dimension and Geometry—In general, the proper ge-

ometry is a right circular cylinder. The specific recommended

10.5 The thermal expansion of the apparatus should be less

dimensions for Method I are given in Test Method E228. For

than 20 % of the measured thermal expansion of the rock. The

Method II, the sample should be a right circular cylinder with

measured thermal expansion of the apparatus shall be reported

a length to diameter ratio of 2 to 1. For both methods the

as specified in Section 14.

minimum dimension should be 10 times the largest grain size.

11. Preconditioning

9. Preparation

11.1 Rock samples shall not be thermally cycled before the

9.1 Do not degrade the rock during machining. Prevent

actual testing unless drying is specified, in which case drying

mechanical and fracture damage to the rock fabric by appro-

shall be performed in accordance with 9.2.

priately slow machining processes and the use of proper

coolant. Select coolant fluids based upon chemical compatibil-

12. Procedure

ity with the rock; for example, tap water may be adequate for

12.1 Cleanthesamplewithanon-chemicalreactivesolvent,

granite, whereas a saturated brine or mineral oil may be best

such as acetone, and install the sample in the dilatometer.Take

for salt.

special care to ensure that the end surfaces of the specimen are

9.2 Drying—Ifthesampleistobetesteddry,dryat80°Cin

free from foreign particles. If confined experiments are to be

a vacuum oven for 24 h.At no time during the drying process

performed (Method II), jacket the specimen with an appropri-

shallthesamplebesubjectedtoheatingorcoolingratesgreater

ate heat resistant jacketing material to prevent confining fluid

than 1°C/min.

intrusion (Note 1). Install all temperature measuring instru-

9.2.1 An alternative drying schedu

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.