ASTM E1535-93(2006)

(Test Method)Standard Test Method for Performance Evaluation of Anaerobic Digestion Systems (Withdrawn 2011)

Standard Test Method for Performance Evaluation of Anaerobic Digestion Systems (Withdrawn 2011)

SIGNIFICANCE AND USE

This test method will yield data that will form a performance profile for an anaerobic digester facility. The significance of this profile is that it can be compared directly to another facility’ performance profile and yield a measurement of expected facility performance under field conditions.

This test method will also yield data that can be used to verify the operation of a system to a regulatory agency.

The single black box technique applied to performance evaluation examines only the overall input/output relationship. This implies that the operation of the facility during the tests will be conducted to achieve design conditions in accordance with established procedures.

SCOPE

1.1 This test method is applicable to all anaerobic digestion systems.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

WITHDRAWN RATIONALE

This test method is applicable to all anaerobic digestion systems.

Formerly under the jurisdiction of Committee E48 on Biotechnology, this test method was withdrawn in May 2011 with no replacement because it evaluates the performance of process and is no longer relevant.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:E1535–93 (Reapproved 2006)

Standard Test Method for

Performance Evaluation of Anaerobic Digestion Systems

This standard is issued under the fixed designation E1535; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope duction, and waste biomass, to provide a methodology for

evaluation of the operation of an aerobic digester.

1.1 This test method is applicable to all anaerobic digestion

systems.

5. Significance and Use

1.2 This standard does not purport to address all of the

5.1 This test method will yield data that will form a

safety concerns, if any, associated with its use. It is the

performance profile for an anaerobic digester facility. The

responsibility of the user of this standard to establish appro-

significance of this profile is that it can be compared directly to

priate safety and health practices and determine the applica-

another facility’s performance profile and yield a measurement

bility of regulatory limitations prior to use.

of expected facility performance under field conditions.

2. Referenced Documents 5.2 This test method will also yield data that can be used to

verify the operation of a system to a regulatory agency.

2.1 ASTM Standards:

5.3 The single black box technique applied to performance

E1126 Terminology Relating to Biomass Fuels

evaluation examines only the overall input/output relationship.

2.2 Standard Methods (SM) for Analysis of Water and

This implies that the operation of the facility during the tests

Wastewater:

will be conducted to achieve design conditions in accordance

2540 D Total Suspended Solids

with established procedures.

2720 B Sludge Digester Gas (Volume)

+

4500 FNH Nitrogen (Ammonia)

6. Procedure

4500 B Nitrogen (Organic), Total Kjeldahl Nitrogen

6.1 Conduct the test for a predetermined period mutually

5210 B Biochemical Oxygen Demand

agreed upon by all parties participating in the testing program.

5220 B Chemical Oxygen Demand

Start the test period when the system manufacturer determines

5520 D Oil and Grease

that the system has reached normal operating conditions.

3. Terminology Record the time period between the initial loading of the

system with waste and the start of the test period. A minimum

3.1 Definition—see Terminology E1126.

test period of 90 days is suggested.

3.1.1 biogas—a composition of methane and carbon diox-

6.2 Determine the influent and effluent concentrations of the

ide and minor constituents produced by the digestion of

following, using the methods recommended, total suspended

organic substrates in the absence of oxygen.

+

solids (TSS) SM 2540 D, NH nitrogen (ammonia) (AN) SM

4. Summary of Test Method

4500 F, nitrogen (organic)-total kjeldahl nitrogen (TKN) SM

4500 B, biochemical oxygen demand (BOD) SM 5210 B,

4.1 This test method measures the concentration and mass

chemical oxygen demand (COD) SM 5220 B, and oil and

oftheinfluentandeffluentwastes,respectively,aswellasother

grease (OG) SM 5520 D.The sampling frequency and location

operational parameters such as input energy, output gas pro-

of sampling shall be mutually agreed upon by all parties

involved in the project. As a minimum, weekly sampling of a

This test method is under the jurisdiction of ASTM Committee E48 on

composite sample of 24 h of influent and effluent is suggested.

Biotechnology and is the direct responsibility of Subcommittee E48.05 on Biomass

6.3 Measure the gas production continuously, using SM

Conversion.

2720 B, or equivalent. Analyze the gas compositions using a

Current edition approved Nov. 1, 2006. Published December 2006. Originally

approved in 1993. Last previous edition approved in 1998 as E1535 – 93 (1998).

gas chromatograph (GC) to determine the composition of CH .

DOI: 10.1520/E1535-93R06.

The GC analysis frequency shall be mutually agreed upon by

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

all parties participating in the testing program.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on 6.4 Measure the thermal energy input. The most common

the ASTM website.

method of thermal energy input is hot water supplied to the

Withdrawn. The last approved version of this historical standard is referenced

system using a heat exchanger. Monitor the energy input on a

on www.astm.org.

Available from American Public Health Association, 800 I Street, NW

Washington, DC 20001.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

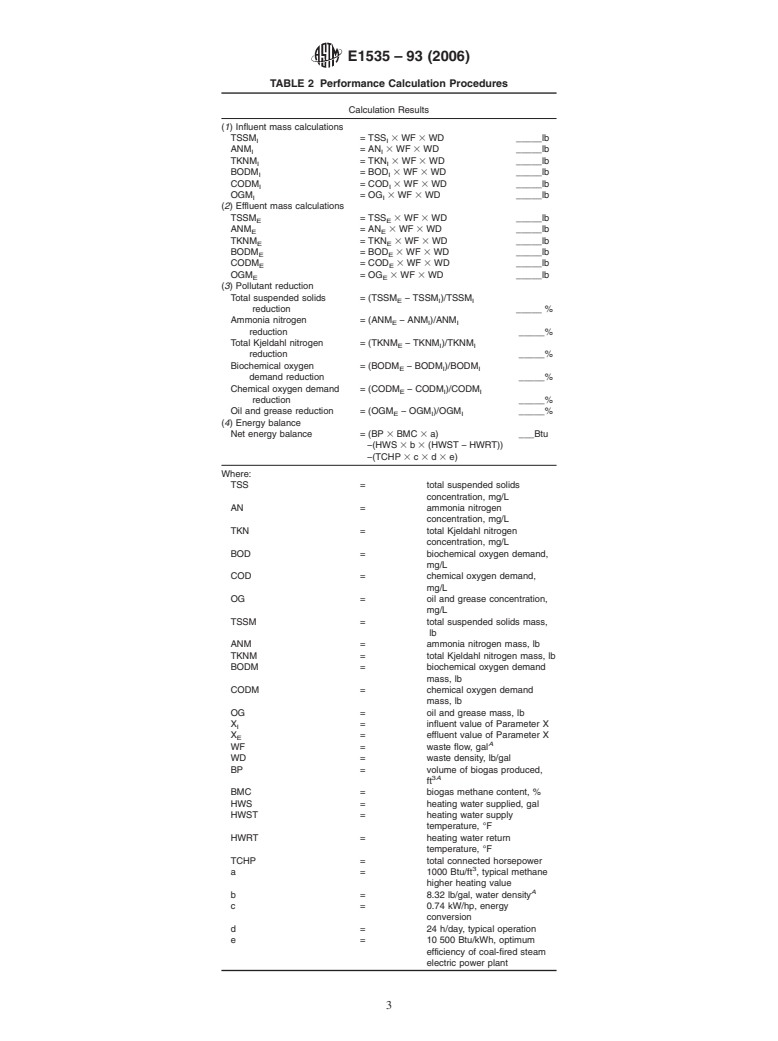

E1535–93 (2006)

TABLE 1 Data Collection Form for Anaerobic Digestion System

continuous basis by measuring the flow rate of hot water to the

Performance Evaluation

system and the influent and effluent flow temperatures, using

(1) Date:

the reference procedures and equipment.

(2) Influent concentrations, mg/L

6.5 Record the horsepower of any motors connected more

Total suspended solids (TSS)

Ammonia nitrogen (AN)

than 50 % of the time during a 24 h operation.

Total Kjeldahl nitrogen (TKN)

6.6 Record the weight of any material removed from the

Biochemical oxygen demand (BOD)

Chemical oxygen demand (COD)

system during the test period.

Oil and grease (OG)

(3) Effluent concentrations, mg/L

Total suspended solids (TSS)

7. Calculation

Ammonia nitrogen (AN)

Total Kjeldahl nitrogen (TKN)

7.1 Data Collection—See Table 1.

Biochemical oxygen demand (BOD)

7.2 Data Calculations—See Table 2.

Chemical oxygen demand (COD)

Oil and grease (OG)

7.3 Data Summary—See Table 3.

(4) Cumulative system parameters measured during test

Volume of waste processed, gal

Waste density, lb/gal

8. Precision and Bias

Volume of biogas produced, ft

Biogas methane content, weight %

8.1 The precision and bias of this test method are still under

Solids wasted from reactor, gal

evaluation.

Heating water supplied, gal

Heating water supply temperature, °F

Heating water return temperature, °F

9. Keywords

Total continuous horsepower, hp

Chemicals added, name of chemical

9.1 anaerobic digestion; biogas; biomass; waste treatment

Chemicals added, lb

Brief description of facilities inc

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.