ASTM D3241-14a

(Test Method)Standard Test Method for Thermal Oxidation Stability of Aviation Turbine Fuels

Standard Test Method for Thermal Oxidation Stability of Aviation Turbine Fuels

SIGNIFICANCE AND USE

5.1 The test results are indicative of fuel performance during gas turbine operation and can be used to assess the level of deposits that form when liquid fuel contacts a heated surface that is at a specified temperature.

SCOPE

1.1 This test method covers the procedure for rating the tendencies of gas turbine fuels to deposit decomposition products within the fuel system.

1.2 The differential pressure values in mm Hg are defined only in terms of this test method.

1.3 The deposition values stated in SI units shall be regarded as the referee value.

1.4 The pressure values stated in SI units are to be regarded as standard. The psi comparison is included for operational safety with certain older instruments that cannot report pressure in SI units.

1.5 No other units of measurement are included in this standard.

1.6 WARNING—Mercury has been designated by many regulatory agencies as a hazardous material that can cause central nervous system, kidney and liver damage. Mercury, or its vapor, may be hazardous to health and corrosive to materials. Caution should be taken when handling mercury and mercury containing products. See the applicable product Material Safety Data Sheet (MSDS) for details and EPA’s website—http://www.epa.gov/mercury/faq.htm—for additional information. Users should be aware that selling mercury and/or mercury containing products into your state or country may be prohibited by law.

1.7 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific warning statements, see 6.1.1, 7.2, 7.2.1, 7.3, 11.1.1, and Annex A5.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D3241 − 14a AnAmerican National Standard

Designation 323/99

Standard Test Method for

Thermal Oxidation Stability of Aviation Turbine Fuels

This standard is issued under the fixed designation D3241; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope* 2. Referenced Documents

1.1 This test method covers the procedure for rating the 2.1 ASTM Standards:

tendencies of gas turbine fuels to deposit decomposition D1655Specification for Aviation Turbine Fuels

products within the fuel system. D4306Practice for Aviation Fuel Sample Containers for

Tests Affected by Trace Contamination

1.2 The differential pressure values in mm Hg are defined

E177Practice for Use of the Terms Precision and Bias in

only in terms of this test method.

ASTM Test Methods

1.3 The deposition values stated in SI units shall be re-

E691Practice for Conducting an Interlaboratory Study to

garded as the referee value.

Determine the Precision of a Test Method

1.4 The pressure values stated in SI units are to be regarded

2.2 ISO Standards:

as standard. The psi comparison is included for operational

ISO 3274 Geometrical Product Specifications (GPS)—

safety with certain older instruments that cannot report pres-

Surface Texture: Profile Method—Nominal Characteris-

sure in SI units.

tics Of Contact (Stylus) Instruments

ISO 4288 Geometrical Product Specifications (GPS)—

1.5 No other units of measurement are included in this

Surface Texture: Profile Method—Rules And Procedures

standard.

For The Assessment Of Surface Texture

1.6 WARNING—Mercury has been designated by many

2.3 ASTM Adjuncts:

regulatory agencies as a hazardous material that can cause

Color Standard for Tube Deposit Rating

central nervous system, kidney and liver damage. Mercury, or

its vapor, may be hazardous to health and corrosive to

3. Terminology

materials.Cautionshouldbetakenwhenhandlingmercuryand

mercury containing products. See the applicable product Ma-

3.1 Definitions of Terms Specific to This Standard:

terial Safety Data Sheet (MSDS) for details and EPA’s

3.1.1 deposits, n—oxidative products laid down on the test

website—http://www.epa.gov/mercury/faq.htm—for addi-

area of the heater tube or caught in the test filter, or both.

tional information. Users should be aware that selling mercury

3.1.1.1 Discussion—Fuel deposits will tend to predominate

and/or mercury containing products into your state or country

at the hottest portion of the heater tube, which is between the

may be prohibited by law.

30-mm and 50-mm position.

1.7 This standard does not purport to address all of the

3.1.2 heater tube, n—an aluminum coupon controlled at

safety concerns, if any, associated with its use. It is the

elevated temperature, over which the test fuel is pumped.

responsibility of the user of this standard to establish appro-

3.1.2.1 Discussion—The tube is resistively heated and con-

priate safety and health practices and determine the applica-

trolled in temperature by a thermocouple positioned inside.

bility of regulatory limitations prior to use. For specific

The critical test area is the thinner portion, 60 mm in length,

warning statements, see 6.1.1, 7.2, 7.2.1, 7.3, 11.1.1, and

Annex A5.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

This test method is under the jurisdiction of ASTM Committee D02 on Standards volume information, refer to the standard’s Document Summary page on

Petroleum Products, Liquid Fuels, and Lubricants and is the direct responsibility of the ASTM website.

Subcommittee D02.J0.03 on Combustion and Thermal Properties. Available from International Organization for Standardization (ISO), 1, ch. de

Current edition approved Oct. 1, 2014. Published December 2014. Originally la Voie-Creuse, CP 56, CH-1211 Geneva 20, Switzerland, http://www.iso.org.

approved in 1973. Last previous edition approved in 2014 as D3241–14. DOI: Available from ASTM International Headquarters. Order Adjunct No.

10.1520/D3241-14A. ADJD3241. Original adjunct produced in 1986.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D3241 − 14a

betweentheshouldersofthetube.Fuelinlettothetubeisatthe 6.1.2 Certain operational parameters used with the instru-

0-mm position, and fuel exit is at 60 mm. ment are critically important to achieve consistent and correct

results. These are listed in Table 2.

3.2 Abbreviations:

3.2.1 ∆P—differential pressure.

6.2 Heater Tube Deposit Rating Apparatus:

6.2.1 Visual Tube Rater (VTR), the tuberator described in

4. Summary of Test Method

Annex A1.

4.1 This test method for measuring the high temperature 6.2.2 Interferometric Tube Rater (ITR)—the tuberator de-

scribed in Annex A2.

stability of gas turbine fuels uses an instrument that subjects

thetestfueltoconditionsthatcanberelatedtothoseoccurring

6.2.3 Ellipsometric Tube Rater (ETR)—the tuberator de-

in gas turbine engine fuel systems. The fuel is pumped at a scribed in Annex A3.

fixed volumetric flow rate through a heater, after which it

6.3 Because jet fuel thermal oxidation stability is defined

enters a precision stainless steel filter where fuel degradation

only in terms of this test method, which depends upon, and is

products may become trapped.

inseparable from, the specific equipment used, the test method

4.1.1 The apparatus uses 450 mLof test fuel ideally during

shall be conducted with the equipment used to develop the test

a 2.5-h test. The essential data derived are the amount of

method or equivalent equipment.

deposits on an aluminum heater tube, and the rate of plugging

of a 17 µm nominal porosity precision filter located just

7. Reagents and Materials

downstream of the heater tube.

7.1 Use distilled (preferred) or deionized water in the spent

5. Significance and Use sample reservoir as required for Model 230 and 240 instru-

ments.

5.1 The test results are indicative of fuel performance

duringgasturbineoperationandcanbeusedtoassessthelevel

7.2 Use methyl pentane, 2,2,4-trimethylpentane, or

ofdepositsthatformwhenliquidfuelcontactsaheatedsurface

n-heptane (technical grade, 95 mol % minimum purity) as

that is at a specified temperature. general cleaning solvent. This solvent will effectively clean

internal metal surfaces of apparatus before a test, especially

6. Apparatus

those surfaces (before the test section) that contact fresh

sample.(Warning—Extremelyflammable.Harmfulifinhaled

6.1 Aviation Fuel Thermal Oxidation Stability Tester —

(see Annex A5).)

Eight models of suitable equipment may be used as indicated

7.2.1 Use trisolvent (equal mix of acetone (1), toluene (2),

in Table 1.

and isopropanol (3)) as a specific solvent to clean internal

6.1.1 Portions of this test may be automated. Refer to the

(working) surface of test section only. (Warning—(1) Ex-

appropriate user manual for the instrument model to be used

tremely flammable, vapors may cause flash fire; (2) and (3)

for a description of detailed procedure. A manual is provided

Flammable.Vaporsofallthreeharmful.Irritatingtoskin,eyes,

with each test rig. (Warning—No attempt should be made to

and mucous membranes.)

operate the instrument without first becoming acquainted with

all components and the function of each.)

7.3 Usedrycalciumsulfate+cobaltchloridegranules(97+

3 mix) in the aeration dryer. This granular material changes

gradually from blue to pink color indicating absorption of

water. (Warning—Do not inhale dust or ingest. May cause

5 stomach disorder.)

The following equipment, as described in Table 1 and RR:D02-1309, was used

to develop this test method. The following equipment, as described in Table 1 and

determinedasequivalentintestingasdetailedinRR:D02-1631,isprovidedbyPAC,

8. Standard Operating Conditions

8824 Fallbrook Drive, Houston, TX 77064. The following equipment, as described

in Table 1 and determined as equivalent in testing as detailed in RR:D02-1728, is

8.1 Standard conditions of the test method are as follows:

provided by Falex Corporation, 1020 Airpark Dr., Sugar Grove, IL, 60554-9585.

This is not an endorsement or certification by ASTM International.

TABLE 1 Instrument Models

Instrument Model Pressurize With Principle Differential Pressure by

A

202 nitrogen gear Hg Manometer; No Record

A

203 nitrogen gear Manometer + Graphical Record

A

215 nitrogen gear Transducer + Printed Record

A

230 hydraulic syringe Transducer + Printout

A

240 hydraulic syringe Transducer + Printout

B

230 Mk III hydraulic dual piston (HPLC Type) Transducer + Printout

C

F400 hydraulic dual piston (HPLC Type) Transducer + Printout

D

230 Mk IV hydraulic single piston (HPLC Type) Transducer + Printout

A

See RR:D02-1309.

B

See RR:D02-1631.

C

See RR:D02-1728.

D

See RR:D02-1757.

D3241 − 14a

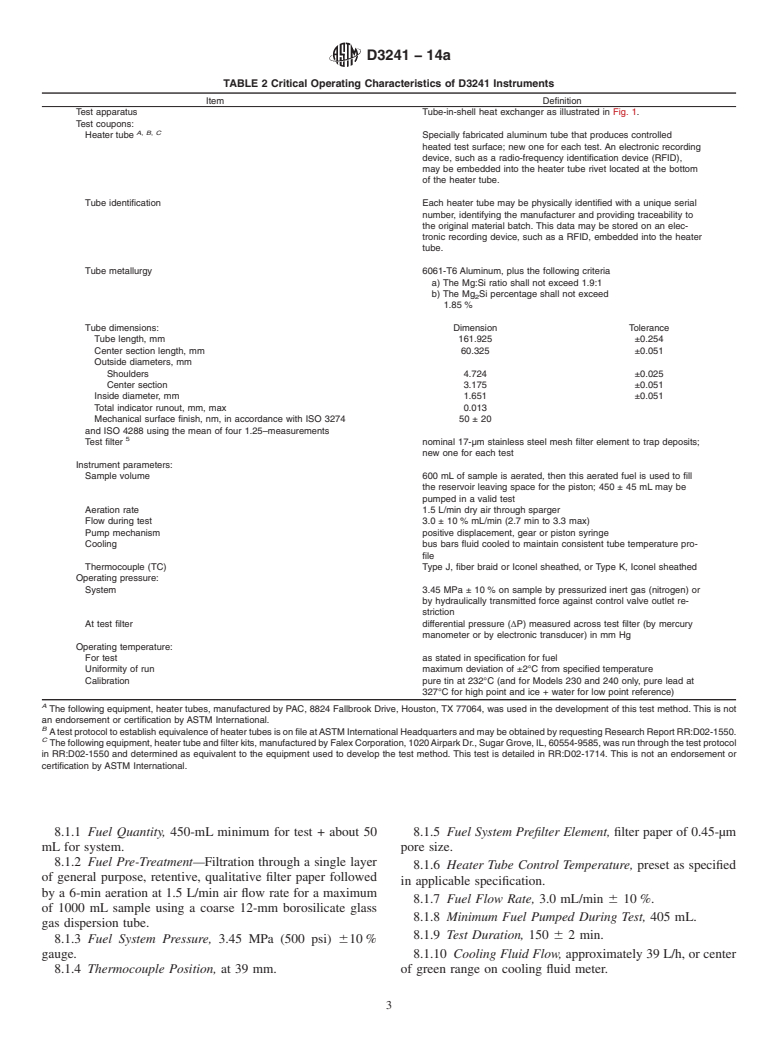

TABLE 2 Critical Operating Characteristics of D3241 Instruments

Item Definition

Test apparatus Tube-in-shell heat exchanger as illustrated in Fig. 1.

Test coupons:

A, B, C

Heater tube Specially fabricated aluminum tube that produces controlled

heated test surface; new one for each test. An electronic recording

device, such as a radio-frequency identification device (RFID),

may be embedded into the heater tube rivet located at the bottom

of the heater tube.

Tube identification Each heater tube may be physically identified with a unique serial

number, identifying the manufacturer and providing traceability to

the original material batch. This data may be stored on an elec-

tronic recording device, such as a RFID, embedded into the heater

tube.

Tube metallurgy 6061-T6 Aluminum, plus the following criteria

a) The Mg:Si ratio shall not exceed 1.9:1

b) The Mg Si percentage shall not exceed

1.85 %

Tube dimensions: Dimension Tolerance

Tube length, mm 161.925 ±0.254

Center section length, mm 60.325 ±0.051

Outside diameters, mm

Shoulders 4.724 ±0.025

Center section 3.175 ±0.051

Inside diameter, mm 1.651 ±0.051

Total indicator runout, mm, max 0.013

Mechanical surface finish, nm, in accordance with ISO 3274 50±20

and ISO 4288 using the mean of four 1.25–measurements

Test filter nominal 17-µm stainless steel mesh filter element to trap deposits;

new one for each test

Instrument parameters:

Sample volume 600 mL of sample is aerated, then this aerated fuel is used to fill

the reservoir leaving space for the piston; 450 ± 45 mL may be

pumped in a valid test

Aeration rate 1.5 L/min dry air through sparger

Flow during test 3.0 ± 10 % mL/min (2.7 min to 3.3 max)

Pump mechanism positive displacement, gear or piston syringe

Cooling bus bars fluid cooled to maintain consistent tube temperature pro-

file

Thermocouple (TC) Type J, fiber braid or Iconel sheathed, or Type K, Iconel sheathed

Operating pressure:

System 3.45 MPa ± 10 % on sample by pressurized inert gas (nitrogen) or

by hydraulically transmitted force against control valve outlet re-

striction

At test filter differential pressure (∆P) measured across test filter (by mercury

manometer or by electronic transducer) in mm Hg

Operating temperature:

For test as stated in specification for fuel

Uniformity of run maximum deviation of ±2°C from specified temperature

Calibration pure tin at 232°C (and for Models 230 and 240 only, pure lead at

327°C for high point and ice + water for low point reference)

A

The following equipment, heater tubes, manufactured by PAC, 8824 Fallbrook Drive, Houston, TX 77064, was used in the development of this test method. This is not

an endorsement or certification by ASTM International.

B

AtestprotocoltoestablishequivalenceofheatertubesisonfileatASTMInternationalHeadquartersandmaybeobtainedbyrequestingResearchReportRR:D02-1550.

C

Thefollowingequipment,heatertubeandfilterkits,manufacturedbyFalexCorporation,1020AirparkDr.,SugarGrove,IL,60554-9585,wasrunthroughthetestprotocol

in RR:D02-1550 and determined as equivalent to the equipment used to develop the test method. This test is detailed in RR:D02-1714. This is not an endorsement or

certification by ASTM International.

8.1.1 Fuel Quantity, 450-mL minimum for test + about 50 8.1.5 Fuel System Prefilter Element, filter paper of 0.45-µm

mL for system.

pore size.

8.1.2 Fuel Pre-Treatment—Filtration through a single layer

8.1.6 Heater Tube Control Temperature, preset as specified

of general purpose, retentive, qualitative filter paper followed

in applicable specification.

by a 6-min aeration at 1.5 L/min air flow rate for a maximum

8.1.7 Fuel Flow Rate, 3.0 mL/min 6 10%.

of 1000 mL sample using a coarse 12-mm borosilicate glass

8.1.8 Minimum Fuel Pumped During Test, 405 mL.

gas dispersion tube.

8.1.9 Test Duration, 150 6 2 min.

8.1.3 Fuel System Pressure, 3.45 MPa (500 psi) 610%

8.1.10 Cooling Fluid Flow, approximately 39 L/h, or center

gauge.

8.1.4 Thermocouple Position, at 39 mm. of green range on cooling fluid meter.

D3241 − 14a

10. Calibration and Standardization Procedure

10.1 Perform checks of key components at the frequency

indicated in the following (see Annexes or user manual for

details).

10.1.1 Thermocouple—Calibrate a thermocouple when first

installed and then normally every 30 to 50 tests thereafter, but

at least every 6 months (see A4.2.8).

10.1.2 Differential Pressure Cell—Standardize once a year

or when installing a new cell (see A4.2.6).

10.1.3 Aeration Dryer—Check at least monthly and change

if color indicates significant absorption of water (see 7.3).

10.1.4 Metering Pump—Performtwochecksofflowratefor

FIG. 1 Standard Heater Section, Essential to All D3241 Test In-

each test as described in Section 11.

struments

10.1.5 Filter Bypass Valve—For Models 202, 203, and 215,

check for leakage at least once a year (see X1.6).

8.1.11 Power Setting, approximately 75 to 100 on non-

computer models; internally set for computer models.

11. Procedure

9. Preparation of Apparatus

11.1 Preparation of Fuel Test Sample:

11.1.1 Filter and aerate sample using standard operating

9.1 Cleaning and Assembly of Heater Test Section:

conditions (see A4.2.9). (Warning —All jet fuels must be

9.1.1 Cleantheinsidesurfaceoftheheatertestsectionusing

considered flammable except JP5 and JP7. Vapors are harmful

a nylon brush saturated with trisolvent material to remove all

(see A5.3, A5.6, and A5.7).)

deposits.

9.1.2 Checktheheatertubetobeusedinthetestforsurface

NOTE 3—Before operating, see Warning in 6.1.1.

defectsandstraightne

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

´1

Designation: D3241 − 14 D3241 − 14a An American National Standard

Designation 323/99

Standard Test Method for

Thermal Oxidation Stability of Aviation Turbine Fuels

This standard is issued under the fixed designation D3241; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

ε NOTE—A Research Report was added editorially to Annex A3 in August 2014.

1. Scope*

1.1 This test method covers the procedure for rating the tendencies of gas turbine fuels to deposit decomposition products within

the fuel system.

1.2 The differential pressure values in mm Hg are defined only in terms of this test method.

1.3 The deposition values stated in SI units shall be regarded as the referee value.

1.4 The pressure values stated in SI units are to be regarded as standard. The psi comparison is included for operational safety

with certain older instruments that cannot report pressure in SI units.

1.5 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.6 WARNING—Mercury has been designated by many regulatory agencies as a hazardous material that can cause central

nervous system, kidney and liver damage. Mercury, or its vapor, may be hazardous to health and corrosive to materials. Caution

should be taken when handling mercury and mercury containing products. See the applicable product Material Safety Data Sheet

(MSDS) for details and EPA’s website—http://www.epa.gov/mercury/faq.htm—for additional information. Users should be aware

that selling mercury and/or mercury containing products into your state or country may be prohibited by law.

1.7 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use. For specific warning statements, see 6.1.1, 7.2, 7.2.1, 7.3, 11.1.1, and Annex A5.

2. Referenced Documents

2.1 ASTM Standards:

D1655 Specification for Aviation Turbine Fuels

D4306 Practice for Aviation Fuel Sample Containers for Tests Affected by Trace Contamination

E177 Practice for Use of the Terms Precision and Bias in ASTM Test Methods

E691 Practice for Conducting an Interlaboratory Study to Determine the Precision of a Test Method

2.2 ISO Standards:

ISO 3274 Geometrical Product Specifications (GPS)—Surface Texture: Profile Method—Nominal Characteristics Of Contact

(Stylus) Instruments

ISO 4288 Geometrical Product Specifications (GPS)—Surface Texture: Profile Method—Rules And Procedures For The

Assessment Of Surface Texture

2.3 ASTM Adjuncts:

Color Standard for Tube Deposit Rating

This test method is under the jurisdiction of ASTM Committee D02 on Petroleum Products, Liquid Fuels, and Lubricants and is the direct responsibility of Subcommittee

D02.J0.03 on Combustion and Thermal Properties.

Current edition approved May 1, 2014Oct. 1, 2014. Published July 2014December 2014. Originally approved in 1973. Last previous edition approved in 20132014 as

D3241 – 13.D3241 – 14. DOI: 10.1520/D3241-14E01.10.1520/D3241-14A.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Available from International Organization for Standardization (ISO), 1, ch. de la Voie-Creuse, CP 56, CH-1211 Geneva 20, Switzerland, http://www.iso.org.

Available from ASTM International Headquarters. Order Adjunct No. ADJD3241. Original adjunct produced in 1986.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D3241 − 14a

3. Terminology

3.1 Definitions of Terms Specific to This Standard:

3.1.1 deposits, n—oxidative products laid down on the test area of the heater tube or caught in the test filter, or both.

3.1.1.1 Discussion—

Fuel deposits will tend to predominate at the hottest portion of the heater tube, which is between the 30-mm and 50-mm position.

3.1.2 heater tube, n—an aluminum coupon controlled at elevated temperature, over which the test fuel is pumped.

3.1.2.1 Discussion—

The tube is resistively heated and controlled in temperature by a thermocouple positioned inside. The critical test area is the thinner

portion, 60 mm in length, between the shoulders of the tube. Fuel inlet to the tube is at the 0-mm position, and fuel exit is at 60

mm.

3.2 Abbreviations:

3.2.1 ΔP—differential pressure.

4. Summary of Test Method

4.1 This test method for measuring the high temperature stability of gas turbine fuels uses an instrument that subjects the test

fuel to conditions that can be related to those occurring in gas turbine engine fuel systems. The fuel is pumped at a fixed volumetric

flow rate through a heater, after which it enters a precision stainless steel filter where fuel degradation products may become

trapped.

4.1.1 The apparatus uses 450 mL of test fuel ideally during a 2.5-h test. The essential data derived are the amount of deposits

on an aluminum heater tube, and the rate of plugging of a 17 μm nominal porosity precision filter located just downstream of the

heater tube.

5. Significance and Use

5.1 The test results are indicative of fuel performance during gas turbine operation and can be used to assess the level of deposits

that form when liquid fuel contacts a heated surface that is at a specified temperature.

6. Apparatus

6.1 Aviation Fuel Thermal Oxidation Stability Tester —Eight models of suitable equipment may be used as indicated in Table

1.

6.1.1 Portions of this test may be automated. Refer to the appropriate user manual for the instrument model to be used for a

description of detailed procedure. A manual is provided with each test rig. (Warning—No attempt should be made to operate the

instrument without first becoming acquainted with all components and the function of each.)

6.1.2 Certain operational parameters used with the instrument are critically important to achieve consistent and correct results.

These are listed in Table 2.

The following equipment, as described in Table 1 and RR:D02-1309, was used to develop this test method. The following equipment, as described in Table 1 and

determined as equivalent in testing as detailed in RR:D02-1631, is provided by PAC, 8824 Fallbrook Drive, Houston, TX 77064. The following equipment, as described in

Table 1 and determined as equivalent in testing as detailed in RR:D02-1728, is provided by Falex Corporation, 1020 Airpark Dr., Sugar Grove, IL, 60554-9585. This is not

an endorsement or certification by ASTM International.

TABLE 1 Instrument Models

Instrument Model Pressurize With Principle Differential Pressure by

A

202 nitrogen gear Hg Manometer; No Record

A

203 nitrogen gear Manometer + Graphical Record

A

215 nitrogen gear Transducer + Printed Record

A

230 hydraulic syringe Transducer + Printout

A

240 hydraulic syringe Transducer + Printout

B

230 Mk III hydraulic dual piston (HPLC Type) Transducer + Printout

C

F400 hydraulic dual piston (HPLC Type) Transducer + Printout

D

230 Mk IV hydraulic single piston (HPLC Type) Transducer + Printout

A

See RR:D02-1309.

B

See RR:D02-1631.

C

See RR:D02-1728.

D

See RR:D02-1757.

D3241 − 14a

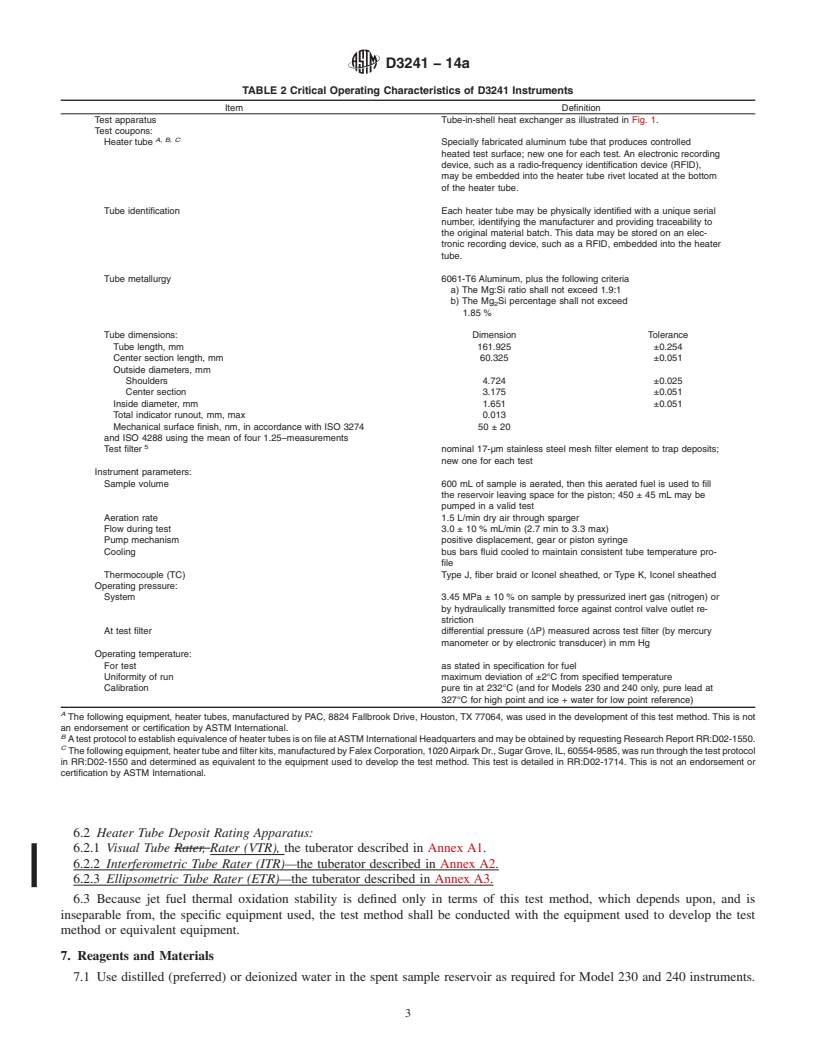

TABLE 2 Critical Operating Characteristics of D3241 Instruments

Item Definition

Test apparatus Tube-in-shell heat exchanger as illustrated in Fig. 1.

Test coupons:

A, B, C

Heater tube Specially fabricated aluminum tube that produces controlled

heated test surface; new one for each test. An electronic recording

device, such as a radio-frequency identification device (RFID),

may be embedded into the heater tube rivet located at the bottom

of the heater tube.

Tube identification Each heater tube may be physically identified with a unique serial

number, identifying the manufacturer and providing traceability to

the original material batch. This data may be stored on an elec-

tronic recording device, such as a RFID, embedded into the heater

tube.

Tube metallurgy 6061-T6 Aluminum, plus the following criteria

a) The Mg:Si ratio shall not exceed 1.9:1

b) The Mg Si percentage shall not exceed

1.85 %

Tube dimensions: Dimension Tolerance

Tube length, mm 161.925 ±0.254

Center section length, mm 60.325 ±0.051

Outside diameters, mm

Shoulders 4.724 ±0.025

Center section 3.175 ±0.051

Inside diameter, mm 1.651 ±0.051

Total indicator runout, mm, max 0.013

Mechanical surface finish, nm, in accordance with ISO 3274 50 ± 20

and ISO 4288 using the mean of four 1.25–measurements

Test filter nominal 17-μm stainless steel mesh filter element to trap deposits;

new one for each test

Instrument parameters:

Sample volume 600 mL of sample is aerated, then this aerated fuel is used to fill

the reservoir leaving space for the piston; 450 ± 45 mL may be

pumped in a valid test

Aeration rate 1.5 L/min dry air through sparger

Flow during test 3.0 ± 10 % mL/min (2.7 min to 3.3 max)

Pump mechanism positive displacement, gear or piston syringe

Cooling bus bars fluid cooled to maintain consistent tube temperature pro-

file

Thermocouple (TC) Type J, fiber braid or Iconel sheathed, or Type K, Iconel sheathed

Operating pressure:

System 3.45 MPa ± 10 % on sample by pressurized inert gas (nitrogen) or

by hydraulically transmitted force against control valve outlet re-

striction

At test filter differential pressure (ΔP) measured across test filter (by mercury

manometer or by electronic transducer) in mm Hg

Operating temperature:

For test as stated in specification for fuel

Uniformity of run maximum deviation of ±2°C from specified temperature

Calibration pure tin at 232°C (and for Models 230 and 240 only, pure lead at

327°C for high point and ice + water for low point reference)

A

The following equipment, heater tubes, manufactured by PAC, 8824 Fallbrook Drive, Houston, TX 77064, was used in the development of this test method. This is not

an endorsement or certification by ASTM International.

B

A test protocol to establish equivalence of heater tubes is on file at ASTM International Headquarters and may be obtained by requesting Research Report RR:D02-1550.

C

The following equipment, heater tube and filter kits, manufactured by Falex Corporation, 1020 Airpark Dr., Sugar Grove, IL, 60554-9585, was run through the test protocol

in RR:D02-1550 and determined as equivalent to the equipment used to develop the test method. This test is detailed in RR:D02-1714. This is not an endorsement or

certification by ASTM International.

6.2 Heater Tube Deposit Rating Apparatus:

6.2.1 Visual Tube Rater, Rater (VTR), the tuberator described in Annex A1.

6.2.2 Interferometric Tube Rater (ITR)—the tuberator described in Annex A2.

6.2.3 Ellipsometric Tube Rater (ETR)—the tuberator described in Annex A3.

6.3 Because jet fuel thermal oxidation stability is defined only in terms of this test method, which depends upon, and is

inseparable from, the specific equipment used, the test method shall be conducted with the equipment used to develop the test

method or equivalent equipment.

7. Reagents and Materials

7.1 Use distilled (preferred) or deionized water in the spent sample reservoir as required for Model 230 and 240 instruments.

D3241 − 14a

FIG. 1 Standard Heater Section, Essential to All D3241 Test Instruments

7.2 Use methyl pentane, 2,2,4-trimethylpentane, or n-heptane (technical grade, 95 mol % minimum purity) as general cleaning

solvent. This solvent will effectively clean internal metal surfaces of apparatus before a test, especially those surfaces (before the

test section) that contact fresh sample. (Warning —Extremely flammable. Harmful if inhaled (see Annex A5).)

7.2.1 Use trisolvent (equal mix of acetone (1), toluene (2), and isopropanol (3)) as a specific solvent to clean internal (working)

surface of test section only. (Warning—(1) Extremely flammable, vapors may cause flash fire; (2) and (3) Flammable. Vapors of

all three harmful. Irritating to skin, eyes, and mucous membranes.)

7.3 Use dry calcium sulfate + cobalt chloride granules (97 + 3 mix) in the aeration dryer. This granular material changes

gradually from blue to pink color indicating absorption of water. (Warning—Do not inhale dust or ingest. May cause stomach

disorder.)

8. Standard Operating Conditions

8.1 Standard conditions of the test method are as follows:

8.1.1 Fuel Quantity, 450-mL minimum for test + about 50 mL for system.

8.1.2 Fuel Pre-Treatment—Filtration through a single layer of general purpose, retentive, qualitative filter paper followed by a

6-min aeration at 1.5 L/min air flow rate for a maximum of 1000 mL sample using a coarse 12-mm borosilicate glass gas dispersion

tube.

8.1.3 Fuel System Pressure, 3.45 MPa (500 psi) 610 % gauge.

8.1.4 Thermocouple Position, at 39 mm.

8.1.5 Fuel System Prefilter Element, filter paper of 0.45-μm pore size.

8.1.6 Heater Tube Control Temperature, preset as specified in applicable specification.

8.1.7 Fuel Flow Rate, 3.0 mL/min 6 10 %.

8.1.8 Minimum Fuel Pumped During Test, 405 mL.

8.1.9 Test Duration, 150 6 2 min.

8.1.10 Cooling Fluid Flow, approximately 39 L/h, or center of green range on cooling fluid meter.

8.1.11 Power Setting, approximately 75 to 100 on non-computer models; internally set for computer models.

9. Preparation of Apparatus

9.1 Cleaning and Assembly of Heater Test Section:

9.1.1 Clean the inside surface of the heater test section using a nylon brush saturated with trisolvent material to remove all

deposits.

9.1.2 Check the heater tube to be used in the test for surface defects and straightness by referring to the procedure in Annex

A1.10. Be careful, also, to avoid scratching tube shoulder during the examination, since the tube shoulder must be smooth to ensure

a seal under the flow conditions of the test.

9.1.3 Assemble the heater section using new items: (1) visually checked heater tube, (2) test filter, and (3) three O-rings. Inspect

insulators to be sure they are undamaged.

NOTE 1—Heater

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.