ASTM D2789-95(2011)

(Test Method)Standard Test Method for Hydrocarbon Types in Low Olefinic Gasoline by Mass Spectrometry

Standard Test Method for Hydrocarbon Types in Low Olefinic Gasoline by Mass Spectrometry

SIGNIFICANCE AND USE

A knowledge of the hydrocarbon composition of gasoline process streams, blending stocks and finished motor fuels is useful in following the effect of changes in plant operating conditions, diagnosing process upsets, blending finished products and in evaluating the relationship between composition and performance properties.

SCOPE

1.1 This test method covers the determination by mass spectrometry of the total paraffins, monocycloparaffins, dicycloparaffins, alkylbenzenes, indans or tetralins or both, and naphthalenes in gasoline having an olefin content of less than 3 volume % and a 95 % distillation point of less than 210°C (411°F) as determined in accordance with Test Method D86. Olefins are determined by Test Method D1319, or by Test Method D875.

1.2 It has not been determined whether this test method is applicable to gasoline containing oxygenated compounds (for example, alcohols and ethers).

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D2789 −95(Reapproved 2011)

Standard Test Method for

Hydrocarbon Types in Low Olefinic Gasoline by Mass

Spectrometry

This standard is issued under the fixed designation D2789; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope D2001 Test Method for Depentanization of Gasoline and

Naphthas

1.1 This test method covers the determination by mass

D2002 Practice for Isolation of Representative Saturates

spectrometry of the total paraffins, monocycloparaffins,

Fraction from Low-Olefinic Petroleum Naphthas (With-

dicycloparaffins, alkylbenzenes, indans or tetralins or both, and

drawn 1998)

naphthalenes in gasoline having an olefin content of less than

3 volume % and a 95 % distillation point of less than 210°C

3. Terminology

(411°F) as determined in accordance with Test Method D86.

Olefins are determined by Test Method D1319,orbyTest 3.1 Definitions of Terms Specific to This Standard:

3.1.1 The summations of characteristic mass fragments are

Method D875.

defined as follows (equations are identical to those in 11.1):

1.2 It has not been determined whether this test method is

applicable to gasoline containing oxygenated compounds (for 43 paraffins 5 total peak height of m/e 43157171185199.

~ !

(

example, alcohols and ethers).

(1)

1.3 The values stated in SI units are to be regarded as 1

41 ~monocycloparaffins! 5 total peak height of m/e 41155169183

(

standard. No other units of measurement are included in this

197. (2)

standard.

67 ~dicycloparaffins! 5 total peak height of m/e 67168181182

(

1.4 This standard does not purport to address all of the

195196. (3)

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro- 1

77 alkylbenzenes 5 total peak height of m/e 77178179191192

~ !

(

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

11611162. (4)

2. Referenced Documents 1

103 ~indans and tetralins! 5 total peak height of m/e 10311041117

(

2.1 ASTM Standards:

1118113111321145114611591160.

D86 Test Method for Distillation of Petroleum Products at

(5)

Atmospheric Pressure

128 naphthalenes 5 total peak height of m/e 128114161421155

~ !

(

D875 Method for Calculating of Olefins and Aromatics in

1156. (6)

Petroleum Distillates from Bromine Number and Acid

Absorption (Withdrawn 1984)

T 5 total ion intensity 5 411 431 671 771 1031 128.

( ( ( ( ( (

D1319 Test Method for Hydrocarbon Types in Liquid Petro-

(7)

leum Products by Fluorescent Indicator Adsorption

3.1.2 carbon number—by definition, is the average number

of carbon atoms in the sample.

This test method is under the jurisdiction of ASTM Committee D02 on

3.1.3 mass number—with a plus sign as superscript, is

Petroleum Products and Lubricants and is the direct responsibility of Subcommittee

defined as the peak height associated with the same mass

D02.04.0M on Mass Spectroscopy.

Current edition approved May 1, 2011. Published August 2011. Originally number.

approved in 1969. Last previous edition approved in 2005 as D2789–95(2005).

DOI: 10.1520/D2789-05R11.

4. Summary of Test Method

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

4.1 Samples are analyzed by mass spectrometry, based on

Standards volume information, refer to the standard’s Document Summary page on

the summation of characteristic mass fragments, to determine

the ASTM website.

the concentration of the hydrocarbon types. The average

The last approved version of this historical standard is referenced on

www.astm.org. number of carbon atoms of the sample is estimated from

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D2789−95 (2011)

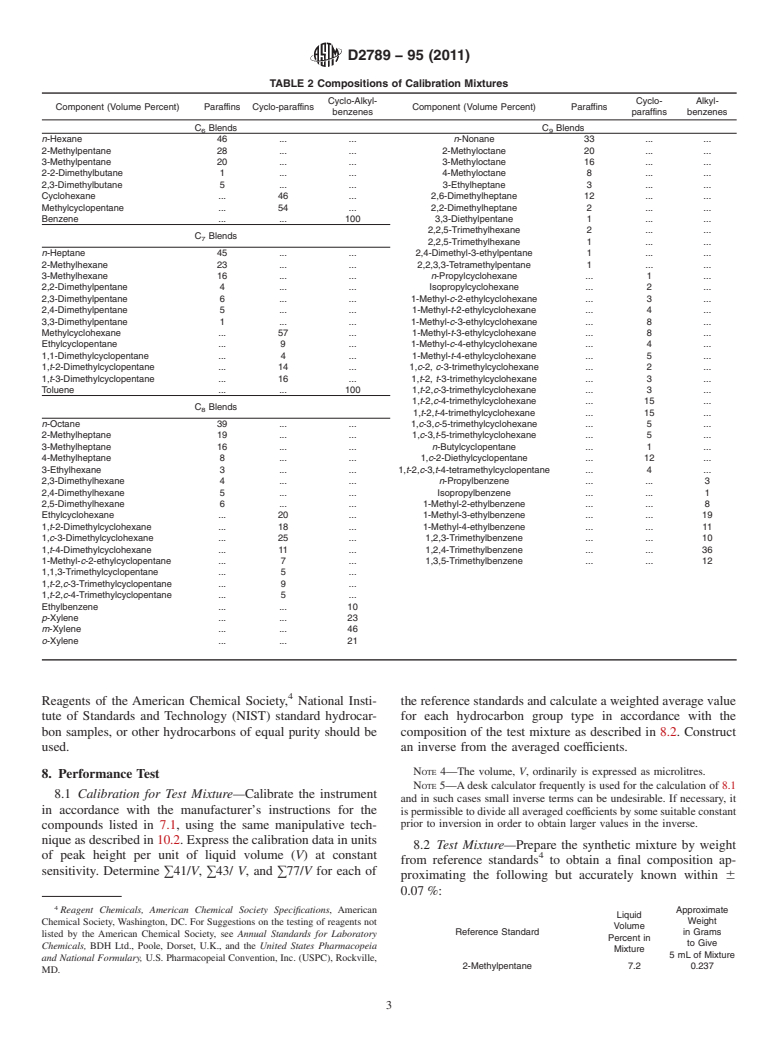

develop their own calibration data using the blends described in Table 2.

spectral data. Calculations are made from calibration data

whicharedependentupontheaveragenumberofcarbonatoms

6.2 Sample Inlet System—Any sample inlet system that

of the sample. Results are expressed in liquid volume percent.

allows the introduction of the text mixture (8.2) without loss,

contamination, or change of composition.

5. Significance and Use

NOTE 2—Laboratory testing has shown that, unless a special sampling

5.1 A knowledge of the hydrocarbon composition of gaso-

techniqueoraheatedinletsystemisused,relativelylargeerrorswilloccur

line process streams, blending stocks and finished motor fuels

in the determination of small quantities of indans, tetralins, and naphtha-

lenes.

is useful in following the effect of changes in plant operating

conditions, diagnosing process upsets, blending finished prod-

6.3 Manometer—Amanometer suitable for direct reading in

ucts and in evaluating the relationship between composition

the 0 to 100-mtorr (0 to 13-Pa) range is optional.

and performance properties.

NOTE 3—The expression mtorr as used in this procedure replaces the

older µ (micron) unit of pressure.

6. Apparatus

6.4 Microburet or Constant-Volume Pipet.

6.1 Mass Spectrometer—Any mass spectrometer that passes

7. Reference Standards

the performance test described in Section 8.

7.1 Samplesofthefollowinghydrocarbonswillberequired:

NOTE 1—Calibration and precision data for this method were obtained

2-methylpentane, 2,4-dimethylpentane, n-octane, methylcyclo-

on Consolidated Electrodynamics Corp.Type 21-101, 21-102, and 21-103

mass spectrometers. These instruments operated with an ion source

pentane, methylcyclohexane, cis-1,2-dimethylcyclohexane,

temperature at or near 250°C and at a constant magnetic field of about

benzene, toluene, and p-xylene (Warning—Extremely flam-

3100 to 3500 gauss. Laboratories using either Consolidated Electrody-

mable liquids. Benzene is a poison, carcinogen, and is harmful

namics Corp. mass spectrometers that operate with different parameters or

or fatal if swallowed.). Only reagent grade chemicals conform-

instruments other than this design should check the applicability of the

calibration data in Table 1. If necessary, individual laboratories should ing to the specifications of the Committee on Analytical

TABLE 1 Calibration Data

A

^43/T ^41/T ^67/T ^77/T ^103/T ^128/T Reference

Paraffins:

C 0.6949 0.3025 0.0019 0.0006 . . (1)

C 0.7379 0.2583 0.0027 0.0010 . . (3)

C 0.7592 0.2362 0.0032 0.0014 . . (3)

C 0.7462 0.2350 0.0052 0.0021 . 0.0113 (12)

C 0.7772 0.2007 0.0056 0.0014 . 0.0151 (13)

Monocycloparaffins:

C 0.1234 0.8218 0.0460 0.0086 . . (1)

C 0.0731 0.8213 0.0952 0.0104 . . (3)

C 0.0737 0.8279 0.0866 0.0117 . . (3)

C 0.0884 0.8029 0.0942 0.0140 0.0003 0.0003 (12)

C 0.1471 0.6272 0.2176 0.0080 . . (13)

Dicycloparaffins:

C 0.0057 0.1848 0.7843 0.0246 0.0004 . (4)

C 0.0171 0.2270 0.7070 0.0483 0.0005 . (5)

C 0.0114 0.2973 0.6582 0.0324 0.0006 . (6)

Alkylbenzenes:

C 0.0004 0.0004 . 0.9992 . . (2)

C 0.0146 0.0120 0.0007 0.9726 . . (3)

C 0.0033 0.0112 0.0007 0.9488 0.0359 . (3)

C 0.0061 0.0218 0.0020 0.9103 0.0598 . (12)

C 0.0095 0.0350 0.0025 0.8656 0.0839 0.0034 (13)

Indans and tetralins:

C 0.0144 0.0101 0.0002 0.1600 0.8154 . (7)

C 0.0062 0.0123 0.0044 0.2314 0.7236 0.0222 (8)

C 0.0231 0.0199 0.0017 0.1619 0.7456 0.0477 (9)

Naphthalenes:

C 0.0121 0.0037 0.0008 0.0581 0.0065 0.9188 (10)

C 0.0702 0.0140 0.0011 0.0172 0.0018 0.8957 (11)

A

References to source of calibration data:

(1) National cooperative by letter of Nov. 22, 1965.

(2) Local task group cooperative by meeting of March 1966.

(3) National cooperative by letter of Aug. 6, 1962.

(4) API No. 448, 100 %, bicyclo-(3.3.0)-octane.

(5) Shell data, 100 %, for 1-methyl-cis-(3.3.0)-bicyclooctane.

(6) API No. 412, 100 %, trans-decalin.

(7) Unweighted API No. 413 and No. 1214 spectra of indan.

(8) API No. 1103, 13 %; API No. 1104, 13 %; API No. 941, 37 %; API No. 539, 37 %.

(9) Unweighted averages of API Nos. 1216, 1106, 1107, 1108, 1109.

(10) Unweighted average of local task group (3 laboratories) data.

(11) Unweighted average of API No. 990 and No. 991.

(12) National cooperative by letter of Oct. 11, 1967.

(13) Proposed Method of Test for Hydrocarbon Types in Low Olefinic Gasoline by Mass Spectrometry; Appendix VII D2-1958.

D2789−95 (2011)

TABLE 2 Compositions of Calibration Mixtures

Cyclo-Alkyl- Cyclo- Alkyl-

Component (Volume Percent) Paraffins Cyclo-paraffins Component (Volume Percent) Paraffins

benzenes paraffins benzenes

C Blends C Blends

6 9

n-Hexane 46 . . n-Nonane 33 . .

2-Methylpentane 28 . . 2-Methyloctane 20 . .

3-Methylpentane 20 . . 3-Methyloctane 16 . .

2-2-Dimethylbutane 1 . . 4-Methyloctane 8 . .

2,3-Dimethylbutane 5 . . 3-Ethylheptane 3 . .

Cyclohexane . 46 . 2,6-Dimethylheptane 12 . .

Methylcyclopentane . 54 . 2,2-Dimethylheptane 2 . .

Benzene . . 100 3,3-Diethylpentane 1 . .

2,2,5-Trimethylhexane 2 . .

C Blends

2,2,5-Trimethylhexane 1 . .

n-Heptane 45 . . 2,4-Dimethyl-3-ethylpentane 1 . .

2-Methylhexane 23 . . 2,2,3,3-Tetramethylpentane 1 . .

3-Methylhexane 16 . . n-Propylcyclohexane . 1 .

2,2-Dimethylpentane 4 . . Isopropylcyclohexane . 2 .

2,3-Dimethylpentane 6 . . 1-Methyl-c-2-ethylcyclohexane . 3 .

2,4-Dimethylpentane 5 . . 1-Methyl-t-2-ethylcyclohexane . 4 .

3,3-Dimethylpentane 1 . . 1-Methyl-c-3-ethylcyclohexane . 8 .

Methylcyclohexane . 57 . 1-Methyl-t-3-ethylcyclohexane . 8 .

Ethylcyclopentane . 9 . 1-Methyl-c-4-ethylcyclohexane . 4 .

1,1-Dimethylcyclopentane . 4 . 1-Methyl-t-4-ethylcyclohexane . 5 .

1,t-2-Dimethylcyclopentane . 14 . 1,c-2, c-3-trimethylcyclohexane . 2 .

1,t-3-Dimethylcyclopentane . 16 . 1,t-2, t-3-trimethylcyclohexane . 3 .

Toluene . . 100 1,t-2,c-3-trimethylcyclohexane . 3 .

1,t-2,c-4-trimethylcyclohexane . 15 .

C Blends

1,t-2,t-4-trimethylcyclohexane . 15 .

n-Octane 39 . . 1,c-3,c-5-trimethylcyclohexane . 5 .

2-Methylheptane 19 . . 1,c-3,t-5-trimethylcyclohexane . 5 .

3-Methylheptane 16 . . n-Butylcyclopentane . 1 .

4-Methylheptane 8 . . 1,c-2-Diethylcyclopentane . 12 .

3-Ethylhexane 3 . . 1,t-2,c-3,t-4-tetramethylcyclopentane . 4 .

2,3-Dimethylhexane 4 . . n-Propylbenzene . . 3

2,4-Dimethylhexane 5 . . Isopropylbenzene . . 1

2,5-Dimethylhexane 6 . . 1-Methyl-2-ethylbenzene . . 8

Ethylcyclohexane . 20 . 1-Methyl-3-ethylbenzene . . 19

1,t-2-Dimethylcyclohexane . 18 . 1-Methyl-4-ethylbenzene . . 11

1,c-3-Dimethylcyclohexane . 25 . 1,2,3-Trimethylbenzene . . 10

1,t-4-Dimethylcyclohexane . 11 . 1,2,4-Trimethylbenzene . . 36

1-Methyl-c-2-ethylcyclopentane . 7 . 1,3,5-Trimethylbenzene . . 12

1,1,3-Trimethylcyclopentane . 5 .

1,t-2,c-3-Trimethylcyclopentane . 9 .

1,t-2,c-4-Trimethylcyclopentane . 5 .

Ethylbenzene . . 10

p-Xylene . . 23

m-Xylene . . 46

o-Xylene . . 21

Reagents of the American Chemical Society, National Insti- the reference standards and calculate a weighted average value

tute of Standards and Technology (NIST) standard hydrocar- for each hydrocarbon group type in accordance with the

bon samples, or other hydrocarbons of equal purity should be composition of the test mixture as described in 8.2. Construct

used. an inverse from the averaged coefficients.

NOTE 4—The volume, V, ordinarily is expressed as microlitres.

8. Performance Test

NOTE 5—Adesk calculator frequently is used for the calculation of 8.1

8.1 Calibration for Test Mixture—Calibrate the instrument

and in such cases small inverse terms can be undesirable. If necessary, it

in accordance with the manufacturer’s instructions for the

ispermissibletodivideallaveragedcoefficientsbysomesuitableconstant

prior to inversion in order to obtain larger values in the inverse.

compounds listed in 7.1, using the same manipulative tech-

nique as described in 10.2. Express the calibration data in units

8.2 Test Mixture—Prepare the synthetic mixture by weight

of peak height per unit of liquid volume (V) at constant

from reference standards to obtain a final composition ap-

sensitivity. Determine ∑41/V, ∑43/ V, and ∑77/V for each of

proximating the following but accurately known within 6

0.07 %:

Reagent Chemicals, American Chemical Society Specifications, American Approximate

Liquid

Weight

Chemical Society, Washington, DC. For Suggestions on the testing of reagents not

Volume

Reference Standard in Grams

listed by the American Chemical Society, see Annual Standards for Laboratory

Percent in

to Give

Chemicals, BDH Ltd., Poole, Dorset, U.K., and the United States Pharmacopeia

Mixture

5 mL of Mixture

and National Formulary, U.S. Pharmacopeial Convention, Inc. (USPC), Rockville,

2-Methylpentane 7.2 0.237

MD.

D2789−95 (2011)

obtained,admitthesampletothemassspectrometerandrecord

Approximate

Liquid

+

Weight

the mass spectrum of the sample from m/e 32 to 186.

Volume

Reference Standard in Grams

Percent in

to Give

Mixture

5 mL of Mixture 11. Calculation

2,4-Dimethylpentane 9.4 0.318

n-Octane 16.6 0.587 11.1 Peaks—Read peak heights from the record of the mass

+

Methylcyclopentane 7.1 0.267

spectrum of the sample corresponding to m/e ratios of 41, 43,

Methylcyclohexane 10.0 0.387

55, 57, 67, 68, 69, 71, 77, 78, 79, 81, 82, 83, 84, 85, 86, 91, 92,

cis-1,2-Dimethylcyclohexane 15.5 0.620

95, 96, 97, 98, 99, 100, 103, 104, 105, 106, 112, 113, 114, 117,

Benzene 7.7 0.341

Toluene 10.0 0.436

118, 119, 120, 126, 127, 128, 131, 132, 133, 134, 140, 141,

p-Xylene 16.5 0.714

142, 145, 146, 147, 148, 154, 155, 156, 159, 160, 161, 162,

100.0 3.907

168, 169, 170.

+

Record the mass spectrum of the test mixture from m/e 32

11.1.1 Calculate the following combined peak heights by

to 120 using the manipulative technique as described in 10.2.

adding together the indicated peaks:

Compute ∑41/V, ∑43/V, and ∑77/V from the spectrum of the

test mixture and calculate the composition using these values

43 5 m/e 43157171185199. (8)

(

and the inverse of 8.1. The calculated composition should

41 5 m/e 41155169183197. (9)

(

agree with known concentrations within the following limits:

67 5 m/e 67168181182195196. (10)

Percent (

Total paraffins ±0.8

77 5 m/e 77178179191192110511061119112011331134

Total cycloparaffins ±1.3 (

Total aromatics

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.