ASTM B388-06

(Specification)Standard Specification for Thermostat Metal Sheet and Strip

Standard Specification for Thermostat Metal Sheet and Strip

ABSTRACT

This specification covers the standard for thermostat metals in the form of sheet or strip proposed for use as temperature-sensitive elements of devices for controlling, compensating, or indicating temperature. Metals shall adhere to physical requirements such as maximum sensitivity range, maximum recommended temperature, flexibility, electrical resistivity, modulus of elasticity, specific heat, density, and hardness.

SCOPE

1.1 This specification covers thermostat metals in the form of sheet or strip that are used for the temperature-sensitive elements of devices for controlling, compensating, or indicating temperature and is intended to supply acceptance requirements to purchasers ordering this material by type designation.

1.2 The values in inch-pound units are to be regarded as the standard. The metric equivalent to inch-pound units may be approximate.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to become familiar with all hazards including those identified in the appropriate Material Safety Data Sheet (MSDS) for this product/material as provided by the manufacturer, to establish appropriate safety and health practices, and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: B388 – 06

Standard Specification for

1

Thermostat Metal Sheet and Strip

This standard is issued under the fixed designation B388; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope C351 Test Method for Mean Specific Heat of Thermal

3

Insulation

1.1 This specification covers thermostat metals in the form

E92 Test Method for Vickers Hardness of Metallic Materi-

of sheet or strip that are used for the temperature-sensitive

als

elements of devices for controlling, compensating, or indicat-

E384 Test Method for Knoop and Vickers Hardness of

ing temperature and is intended to supply acceptance require-

Materials

ments to purchasers ordering this material by type designation.

1.2 The values in inch-pound units are to be regarded as the

3. Terminology

standard. The metric equivalent to inch-pound units may be

3.1 Definition:

approximate.

3.1.1 thermostat metal, n—acompositematerialcomprising

1.3 This standard does not purport to address all of the

two or more metallic layers of differing coefficients of thermal

safety concerns, if any, associated with its use. It is the

expansion such that the radius of curvature of the composite

responsibility of the user of this standard to become familiar

changes with temperature change.

with all hazards including those identified in the appropriate

Material Safety Data Sheet (MSDS) for this product/material

4. Ordering Information

as provided by the manufacturer, to establish appropriate

4.1 Orders for material under this specification shall include

safety and health practices, and determine the applicability of

the following information:

regulatory limitations prior to use.

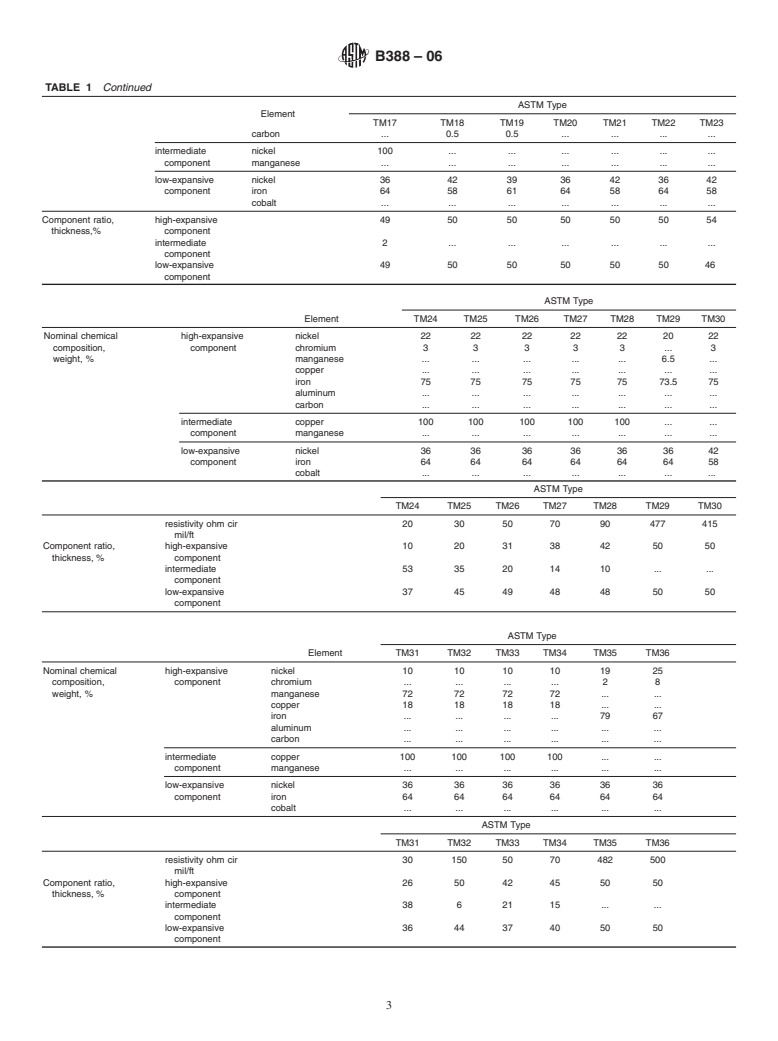

4.1.1 Type designation (Table 1 and Table 2),

2. Referenced Documents 4.1.2 Thickness (see 9.1),

2 4.1.3 Width (see 9.2),

2.1 ASTM Standards:

4.1.4 Temper (designated as percent cold reduction as

B63 Test Method for Resistivity of Metallically Conducting

needed),

Resistance and Contact Materials

4.1.5 Marking to identify vendor, type, high-expansion side

B106 Test Methods for Flexivity of Thermostat Metals

or low-expansion side,

B223 Test Method for Modulus of Elasticity of Thermostat

4.1.6 Weight.

Metals (Cantilever Beam Method)

B362 Test Method for Mechanical Torque Rate of Spiral

5. Material Segregation

Coils of Thermostat Metal

5.1 The thermostat metal shall be supplied segregated into

B389 Test Method for Thermal Deflection Rate of Spiral

two groups after slitting: (1) the burr on the low-expansive

and Helical Coils of Thermostat Metal

component, and (2) the burr on the high-expansive component.

B478 Test Method for Cross Curvature of Thermostat

These two groups shall be identified and packaged separately

Metals

or together as mutually agreed upon between the producer and

B753 Specification for Thermostat Component Alloys

the user.

6. Chemical Composition

1

This specification is under the jurisdiction of ASTM Committee B02 on

Nonferrous Metals and Alloys and is the direct responsibility of Subcommittee

6.1 The nominal composition of component materials is

B02.10 on Thermostat Metals and Electrical Resistance Heating Materials.

given in Table 1.

CurrenteditionapprovedJune1,2006.PublishedJuly2006.Originallyapproved

6.1.1 The component alloys shall be as specified in Speci-

in 1962. Last previous edition approved in 2000 as B388 – 00. DOI: 10.1520/

B0388-06. fication B753.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3

Standards volume information, refer to the standard’s Document Summary page on Withdrawn. The last approved version of this historical standard is referenced

the ASTM website. on www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

B388 – 06

7. Component Ratio 8.2 Maximum Recommended Temperature—The maximum

recommended temperatures of use of designated types of

7.1 Thetypicalthicknessratioofthecomponentmaterialsis

thermostat metals are given in Table 2 and Table 3. These

given in Table 1. The component thickness ratios are given for

values are presented to aid users in designing devices.

reference as they are lot-to-lot variable to produce required

flexivity and resistivity. Barrier(s) layer(s) for stability of

8.3 Flexivity—The flexivity of a designated thermostat

resistivity is (are) allowable. Flexivity may vary.

metal shall conform to the values in Table 2 and Table 3.

Component materials designated in Specification B753 shall,

8. Physi

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.