ASTM F1282-00

(Specification)Standard Specification for Polyethylene/Aluminum/Polyethylene (PE-AL-PE) Composite Pressure Pipe

Standard Specification for Polyethylene/Aluminum/Polyethylene (PE-AL-PE) Composite Pressure Pipe

SCOPE

1.1 This specification covers a coextruded polyethylene composite pressure pipe with a welded aluminum tube reinforcement between the inner and outer layers. The inner and outer polyethylene layers are bonded to the aluminum tube by a melt adhesive. Included is a system of nomenclature for the polyethylene-aluminum-polyethylene (PE-AL-PE) pipes, the requirements and test methods for materials, the dimensions and strengths of the component tubes and finished pipe, adhesion tests, and the burst and sustained pressure performance. Also given are the requirements and methods of marking.

1.2 This specification relates only to metal and plastic composite pipes incorporating a welded metallic tube. The welded metallic tube of itself is capable of sustaining internal pressures. Pipes consisting of metallic layers not welded together are outside the scope of this specification.

1.3 Specifications for connectors for use with pipe meeting the requirements of this specification are given in Annex A1.

1.4 This specification excludes crosslinked polyethylene-aluminum-crosslinked polyethylene pipes (see Specification F 1281).

1.5 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.6 The following precautionary caveat pertains only to the test methods portion, Section 9, of this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: F 1282 – 00 An American National Standard

Standard Specification for

Polyethylene/Aluminum/Polyethylene (PE-AL-PE) Composite

Pressure Pipe

This standard is issued under the fixed designation F 1282; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope Extrusion Materials

D 1598 Test Method for Time-to-Failure of Plastic Pipe

1.1 This specification covers a coextruded polyethylene

Under Constant Internal Pressure

composite pressure pipe with a welded aluminum tube rein-

D 1599 Test Method for Short-Time Hydraulic Failure Pres-

forcement between the inner and outer layers. The inner and

sure of Plastic Pipe, Tubing, and Fittings

outer polyethylene layers are bonded to the aluminum tube by

D 1600 Terminology for Abbreviated Terms Relating to

a melt adhesive. Included is a system of nomenclature for the

Plastics

polyethylene-aluminum-polyethylene (PE-AL-PE) pipes, the

D 1898 Practice for Sampling of Plastics

requirements and test methods for materials, the dimensions

D 2104 Specification for Polyethylene (PE) Plastic Pipe,

and strengths of the component tubes and finished pipe,

Schedule 40

adhesion tests, and the burst and sustained pressure perfor-

D 2122 Test Method for Determining Dimensions of Ther-

mance. Also given are the requirements and methods of

moplastic Pipe and Fittings

marking.

D 2837 Test Method for Obtaining Hydrostatic Design

1.2 This specification relates only to metal and plastic

Basis for Thermoplastic Pipe Materials

composite pipes incorporating a welded metallic tube. The

D 3035 Specification for Polyethylene (PE) Plastic Pipe

welded metallic tube of itself is capable of sustaining internal

(DR-PR) Based on Controlled Outside Diameter

pressures. Pipes consisting of metallic layers not welded

D 3350 Specification for Polyethylene Plastics Pipe and

together are outside the scope of this specification.

Fittings Materials

1.3 Specifications for connectors for use with pipe meeting

E 8 Test Methods for Tension Testing of Metallic Materials

the requirements of this specification are given in Annex A1.

F 412 Terminology Relating to Plastic Piping Systems

1.4 This specification excludes crosslinked polyethylene-

F 1281 Specification for Crosslinked Polyethylene/

aluminum-crosslinked polyethylene pipes (see Specification

Aluminum/Crosslinked Polyethylene (PEX-AL-PEX)

F 1281).

Pressure Pipe

1.5 The values stated in SI units are to be regarded as the

2.2 NSF Standard:

standard. The values given in parentheses are for information

Standard No. 61 Drinking Water System Components—

only.

Health Effects

1.6 The following precautionary caveat pertains only to the

2.3 Uniform Classification Committee Standard:

test methods portion, Section 9, of this specification: This

Uniform Freight Classification

standard does not purport to address all of the safety concerns,

2.4 National Motor Freight Association Standard:

if any, associated with its use. It is the responsibility of the user

National Motor Freight Classification

of this standard to establish appropriate safety and health

2.5 Federal Standard:

practices and determine the applicability of regulatory limita-

Fed. Std. No. 123 Marking for Shipments (Civil Agencies)

tions prior to use.

2.6 Military Standard:

2. Referenced Documents

2.1 ASTM Standards:

Annual Book of ASTM Standards, Vol 08.04.

D 618 Practice for Conditioning Plastics and Electrical

Annual Book of ASTM Standards, Vol 08.02.

Insulating Materials for Testing

Annual Book of ASTM Standards, Vol 03.01.

D 1248 Specification for Polyethylene Plastics Molding and

Available from the National Sanitation Foundation, P.O. Box 1468, Ann Arbor,

MI 48106.

Available from the Uniform Classification Committee, Suite 1106, 222 South

This specification is under the jurisdiction of ASTM Committee F-17 on Plastic Riverside Plaza, Chicago, IL 60606.

Piping Systems and is the direct responsibility of Subcommittee F17.11 on Available from the National Motor Freight Traffic Association, Inc., National

Composite. Motor Freight Classification, American Tracking Associations, Inc., Traffic Dept.,

Current edition approved April 10, 2000. Published June 2000. Originally 1616 P St., NW, Washington, DC 20036.

published as F 1282 – 90. Last previous edition F 1282 – 99. Available from Standardization Documents Order Desk, Bldg. 4 Section D, 700

Annual Book of ASTM Standards, Vol 08.01. Robbins Ave., Philadelphia, PA 19111-5094, Attn: NPODS.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

F 1282

MIL-STD-129 Marking for Shipment and Storage two criteria, namely, (1) short-term strength tests and (2)

long-term strength tests.

3. Terminology

NOTE 1—Pipe that is intended for use in the transport of potable water

3.1 Definitions—Definitions are in accordance with Termi-

should be evaluated, and certified safe for this purpose, by a testing agency

nology F 412, and abbreviations are in accordance with Ter-

acceptable to the local health authority. The evaluation should be in

minology D 1600, unless otherwise specified.

accordance with requirements that are no less restrictive than those in

3.2 Definitions of Terms Specific to This Standard: National Sanitation Foundation (NSF) Standard 61. The seal or mark of

the laboratory making the evaluation and the standard tested against

3.2.1 assembly—the joint between a fitting and a length of

should be included in the marking on the pipe.

pipe.

3.2.2 pipe— the complete structure, consisting of the alu- 5.3.2 This specification covers pipe made from PE plastics

minum, melt adhesive, and polyethylene layers intimately as defined by three hydrostatic design stresses developed on the

bonded together. The pipe for this specification is termed a

basis of long-term tests (see Appendix X1).

PE-AL-PE composite pipe. 5.3.3 Polyethylene plastics used to make pipe meeting the

3.2.3 pipe hoop stress—for simplicity the value of the hoop

requirements of this specification shall be virgin resin meeting

stress quoted assumes a homogeneous wall. Local values of the requirements of either Grade PE20A, B, or C; Grade

stress will vary with the different layers (see 3.2.3.1).

PE23A, B, or C; Grade PE30A, B, or C; or Grade PE33A, B,

3.2.3.1 Discussion—Thick walled plastic pipes produced or C in accordance with Specification D 3350.

from one material have hoop stresses that vary through the

5.3.3.1 Class B compounds shall have sufficient ultraviolet

wall, and are usually described by the Lame Theory. The (UV) stabilizers to protect the pipe from deleterious effects due

composite nature of the PE-AL-PE pipe, composed of materi- to continuous outdoor exposure during storage and shipping.

als with very different Young’s Modulus values, will, on Pipe produced from Class B compounds is not suitable for

pressurization, not have a uniform stress distribution through exposed outdoor application. Class A, B, and C compounds

the thickness of the wall of the pipe. The PE-AL-PE pipes have shall have sufficient antioxidants to meet the requirements in

a hoop stress distribution that differs substantially from both Specification D 3350.

the thick and thin walled pipe cases. 5.3.4 The polyethylene compound used shall meet the

minimum 80°C (176°F) temperature stress rupture lifetimes for

4. Pipe Classification

pipe as specified in Specifications D 2104 and D 3035.

4.1 Pipe Diameter—The PE-AL-PE composite pipes are

5.4 Melt Adhesive—The material shall have a density cell of

classified by outside diameter.

1, 2, or 3; a melt index cell of 1, 2, or 3; and a color code of

4.2 Pipe Dimension Ratio—The concept of dimension ratio

A or B, in accordance with Specification D 3350.

is not relevant to PE-AL-PE laminated pipes, and cannot be

5.5 Rework Material—Clean rework material, generated

used to relate pressure rating with total wall thickness.

from the manufacturer’s own production, may be used by the

same manufacturer, as long as the pipe produced meets all of

5. Materials

the requirements of this specification. Rework material con-

5.1 General—The PE-AL-PE pipe is composed of one

taining aluminum or reprocessed or recycled plastics shall not

metallic layer, two layers of the same polymeric adhesive and

be used for the production of pipe.

two layers of the same polyethylene. For pipe made to this

6. Requirements

specification the constituent materials must meet the following

requirements: 6.1 General—The requirements and test methods in this

5.2 Aluminum—The aluminum shall have a thickness as specification cover PE-AL-PE pipes. Tests on the individual

specified in Table 1. The material shall have minimum elon- layers that comprise this composite pipe are outside the scope

gations and ultimate tensile strengths of 20 % and 100 MPa of this specification. The raw materials used, however, must

(14 600 psi), respectively. The tests shall be conducted accord- conform to the requirements in Section 5.

ing to Test Methods E 8. 6.2 Dimensions and Tolerances of Pipe:

5.3 Polyethylene: 6.2.1 Pipe Diameter—The minimum outside diameter and

5.3.1 Polyethylene plastics used to make pipe meeting the tolerances of the pipe shall meet the requirements given in

requirements of this specification are categorized by means of Table 1, when measured in accordance with 9.1 and 9.1.2.

TABLE 1 Outside Diameters, Aluminum Thickness, and Tolerances for PE-AL-PE

Nominal Pipe Size, Minimum Outside Tolerance on Minimum, Maximum Out-of- Minimum Aluminum Tolerance on Thickness,

A

mm (in.) Diameter, mm (in.) mm (in.) Roundness, mm (in.) Thickness, mm (in.) mm (in.)

0912 ( ⁄8) 12.00 (0.472) +0.30 (0.012) 0.3 (0.012) 0.18 (0.007) +0.09 (+0.0035)

1216 ( ⁄2) 16.00 (0.630) +0.30 (0.012) 0.4 (0.016) 0.18 (0.007) +0.09 (+0.0035)

1620 ( ⁄8) 20.00 (0.787) +0.30 (0.012) 0.5 (0.020) 0.23 (0.009) +0.09 (+0.0035)

2025 ( ⁄4) 25.00 (0.984) +0.30 (0.012) 0.5 (0.020) 0.23 (0.009) +0.09 (+0.0035)

2532 (1) 32.00 (1.260) +0.30 (0.012) 0.5 (0.020) 0.28 (0.011) +0.09 (+0.0035)

3240 ( ⁄4) 40.10 (1.579) +0.30 (0.012) 0.5 (0.020) 0.33 (0.014)

4150 ( ⁄2) 50.10 (1.972) +0.30 (0.012) 0.5 (0.020) 0.47 (0.020)

5163 (2) 63.10 (2.484) +0.40 (0.016) 0.5 (0.020) 0.57 (0.024)

6075 ( ⁄2) 75.10 (2.957) +0.60 (0.024) 1.0 (0.039) 0.67 (0.028)

A

The out-of-roundness specification applies only to tubing prior to coiling.

F 1282

Maximum and minimum (out-of-roundness) tolerances apply cient to determine conformance with this specification. The

only to measurements made on pipe prior to coiling. number of specimens designated for each test shall be taken

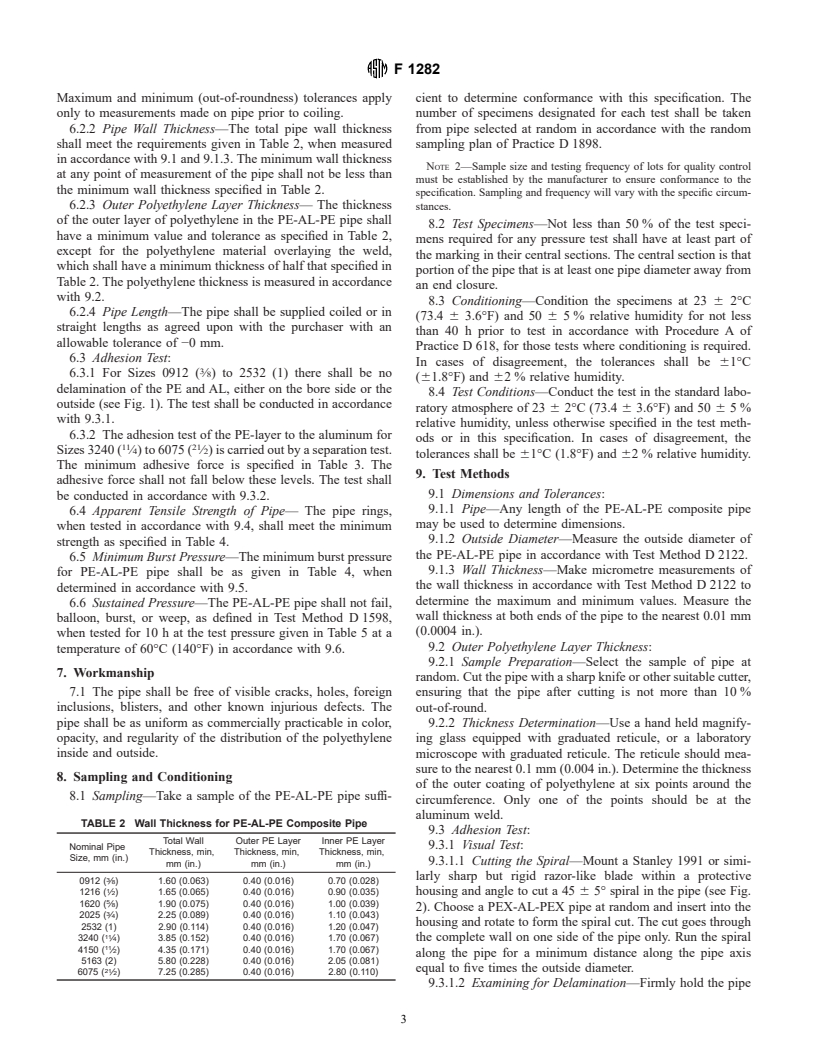

6.2.2 Pipe Wall Thickness—The total pipe wall thickness from pipe selected at random in accordance with the random

shall meet the requirements given in Table 2, when measured sampling plan of Practice D 1898.

in accordance with 9.1 and 9.1.3. The minimum wall thickness

NOTE 2—Sample size and testing frequency of lots for quality control

at any point of measurement of the pipe shall not be less than

must be established by the manufacturer to ensure conformance to the

the minimum wall thickness specified in Table 2.

specification. Sampling and frequency will vary with the specific circum-

6.2.3 Outer Polyethylene Layer Thickness— The thickness

stances.

of the outer layer of polyethylene in the PE-AL-PE pipe shall

8.2 Test Specimens—Not less than 50 % of the test speci-

have a minimum value and tolerance as specified in Table 2,

mens required for any pressure test shall have at least part of

except for the polyethylene material overlaying the weld,

the marking in their central sections. The central section is that

which shall have a minimum thickness of half that specified in

portion of the pipe that is at least one pipe diameter away from

Table 2. The polyethylene thickness is measured in accordance

an end closure.

with 9.2.

8.3 Conditioning—Condition the specimens at 23 6 2°C

6.2.4 Pipe Length—The pipe shall be supplied coiled or in

(73.4 6 3.6°F) and 50 6 5 % relative humidity for not less

straight lengths as agreed upon with the purchaser with an

than 40 h prior to test in accordance with Procedure A of

allowable tolerance of −0 mm.

Practice D 618, for those tests where conditioning is required.

6.3 Adhesion Test:

In cases of disagreement, the tolerances shall be 61°C

6.3.1 For Sizes 0912 ( ⁄8) to 2532 (1) there shall be no

(61.8°F) and 62 % relative humidity.

delamination of the PE and AL, either on the bore side or the

8.4 Test Conditions—Conduct the test in the standard labo-

outside (see Fig. 1). The test shall be conducted in accordance

ratory atmosphere of 23 6 2°C (73.4 6 3.6°F) and 50 6 5%

with 9.3.1.

relative humidity, unless otherwise specified in the test meth-

6.3.2 The adhesion test of the PE-layer to the aluminum for

ods or in this specification. In cases of disagreement, the

11 21

Sizes 3240 ( ⁄4) to 6075 ( ⁄2) is carried out by a separation test.

tolerances shall be 61°C (1.8°F) and 62 % relative humidity.

The minimum adhesive force is specified in Table 3. The

9. Test Methods

adhesive force shall not fall below these levels. The test shall

9.1 Dimensions and Tolerances:

be conducted in accordance with 9.3.2.

9.1.1 Pipe—Any length of the PE-AL-PE composite pipe

6.4 Apparent Tensile Strength of Pipe— The pipe rings,

may be used to determine dimensions.

when tested in accordance with 9.4, shall meet the minimum

9.1.2 Outside Diameter—Measure the outside diameter of

strength as specified in Table 4.

the PE-AL-PE pipe in accordance with Test Method D 2122.

6.5 Minimum Burst Pressure—The minimum burst pressure

9.1.3 Wall Thickness—Make micrometre measurements of

for PE-AL-PE pipe shall be as given in Table 4, when

the wall thickness in accordance with Test Method D 2122 to

determined in accordance with 9.5.

determine the maximum and minimum values. Measure the

6.6 Sustained Pressure—The PE-AL-PE pipe shall not fail,

wall thickness at both ends of the pipe to the nearest 0.01 mm

balloon, burst, or weep, as defined in Test Method D 1598,

(0.0004 in.).

when tested for 10 h at the test pressure given in Table 5 at a

9.2 Outer Polyethylene Layer Thickness:

temperature of 60°C (140°F) in accordance with 9.6.

9.2.1 Sample Preparation—Select the sample of pipe at

7. Workmanship

random. Cut the pipe with a sharp knife or other suitable cutter,

7.1 The pipe shall be free of visible cracks, holes, foreign

ensuring that the pipe after cutting is not more than 10 %

inclusions, blisters, and other known injurious defects. The out-of-round.

pipe shall be as

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.