ASTM C1469-00(2005)

(Test Method)Standard Test Method for Shear Strength of Joints of Advanced Ceramics at Ambient Temperature

Standard Test Method for Shear Strength of Joints of Advanced Ceramics at Ambient Temperature

SIGNIFICANCE AND USE

Advanced ceramics are candidate materials for structural applications requiring high degrees of wear and corrosion resistance, often at elevated temperatures.

Joints are produced to enhance the performance and applicability of materials. While the joints between similar materials are generally made for manufacturing complex parts and repairing components, those involving dissimilar materials usually are produced to exploit the unique properties of each constituent in the new component. Depending on the joining process, the joint region may be the weakest part of the component. Since under mixed-mode and shear loading, the load transfer across the joint requires reasonable shear strength, it is important that the quality and integrity of joint under in-plane shear forces be quantified. Shear strength data are also needed to monitor the development of new and improved joining techniques.

Shear tests provide information on the strength and deformation of materials under shear stresses.

This test method may be used for material development, material comparison, quality assurance, characterization, and design data generation.

For quality control purposes, results derived from standardized shear test specimens may be considered indicative of the response of the material from which they were taken for given primary processing conditions and post-processing heat treatments.

SCOPE

1.1 This test method covers the determination of shear strength of joints in advanced ceramics at ambient temperature. Test specimen geometries, test specimen fabrication methods, testing modes (that is, force or displacement control), testing rates (that is, force or displacement rate), data collection, and reporting procedures are addressed.

1.2 This test method is used to measure shear strength of ceramic joints in test specimens extracted from larger joined pieces by machining. Test specimens fabricated in this way are not expected to warp due to the relaxation of residual stresses but are expected to be much straighter and more uniform dimensionally than butt-jointed test specimens prepared by joining two halves, which are not recommended. In addition, this test method is intended for joints, which have either low or intermediate strengths with respect to the substrate material to be joined. Joints with high strengths should not be tested by this test method because of the high probability of invalid tests resulting from fractures initiating at the reaction points rather than in the joint. Determination of the shear strength of joints using this test method is appropriate particularly for advanced ceramic matrix composite materials but also may be useful for monolithic advanced ceramic materials.

1.3 Values expressed in this test method are in accordance with the International System of Units (SI) and Practice IEEE/ASTM SI 10.

1.4 This test method does not purport to address the safety problems associated with its use. It is the responsibility of the user of this test method to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Specific precautionary statements are noted in 8.1 and 8.2.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:C1469–00(Reapproved 2005)

Standard Test Method for

Shear Strength of Joints of Advanced Ceramics at Ambient

Temperature

This standard is issued under the fixed designation C1469; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

1.1 This test method covers the determination of shear 2.1 ASTM Standards:

strengthofjointsinadvancedceramicsatambienttemperature. C1145 Terminology of Advanced Ceramics

Test specimen geometries, test specimen fabrication methods, C1161 Test Method for Flexural Strength of Advanced

testing modes (that is, force or displacement control), testing Ceramics at Ambient Temperature

rates (that is, force or displacement rate), data collection, and C1211 Test Method for Flexural Strength of Advanced

reporting procedures are addressed. Ceramics at Elevated Temperatures

1.2 This test method is used to measure shear strength of C1275 Test Method for Monotonic Tensile Behavior of

ceramic joints in test specimens extracted from larger joined Continuous Fiber-Reinforced Advanced Ceramics with

pieces by machining. Test specimens fabricated in this way are Solid Rectangular Cross-Section Test Specimens atAmbi-

not expected to warp due to the relaxation of residual stresses ent Temperature

but are expected to be much straighter and more uniform C1341 Test Method for Flexural Properties of Continuous

dimensionally than butt-jointed test specimens prepared by Fiber-Reinforced Advanced Ceramic Composites

joining two halves, which are not recommended. In addition, D3878 Terminology for Composite Materials

this test method is intended for joints, which have either low or D5379/D5379M Test Method for Shear Properties of Com-

intermediate strengths with respect to the substrate material to posite Materials by the V-Notched Beam Method

be joined. Joints with high strengths should not be tested by E4 Practices for Force Verification of Testing Machines

this test method because of the high probability of invalid tests E6 TerminologyRelatingtoMethodsofMechanicalTesting

resulting from fractures initiating at the reaction points rather E122 Practice for Calculating Sample Size to Estimate,

than in the joint. Determination of the shear strength of joints With Specified Precision, the Average for a Characteristic

using this test method is appropriate particularly for advanced of a Lot or Process

ceramic matrix composite materials but also may be useful for E337 Test Method for Measuring Humidity with a Psy-

monolithic advanced ceramic materials. chrometer (the Measurement of Wet- and Dry-Bulb Tem-

1.3 Values expressed in this test method are in accordance peratures)

with the International System of Units (SI) and Practice IEEE/ASTM SI 10 American National Standard for Use of

IEEE/ASTM SI 10 . the International System of Units (SI): The Modern Metric

1.4 This test method does not purport to address the safety System

problems associated with its use. It is the responsibility of the

3. Terminology

user of this test method to establish appropriate safety and

3.1 Definitions—The definitions of terms relating to shear

health practices and determine the applicability of regulatory

limitations prior to use. Specific precautionary statements are strength testing appearing in Terminology E6, to advanced

ceramics appearing in Terminologies C1145 and D3878 apply

noted in 8.1 and 8.2.

to the terms used in this test method.Additional terms used in

conjunction with this test method are defined as follows.

3.1.1 advanced ceramic, n—highly-engineered, high-

performance predominately nonmetallic, inorganic, ceramic

material having specific functional attributes. C1145

This test method is under the jurisdiction of ASTM Committee C28 on

Advanced Ceramics and is the direct responsibility of Subcommittee C28.07 on

Ceramic Matrix Composites. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved June 1, 2005. Published June 2005. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 2000. Last previous edition approved in 2000 as C1469 – 00. DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/C1469-00R05. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

C1469–00 (2005)

3.1.2 breaking force [F], n—force at which fracture occurs. 4. Summary of Test Method

3.1.3 ceramic matrix composite, n—material consisting of

4.1 This test method describes an asymmetrical four-point

two or more materials (insoluble in one another), in which the

flexure test method to determine shear strengths of advanced

major, continuous component (matrix component) is a ceramic

ceramic joints. Test specimens and test setup are shown

while the secondary component(s) may be ceramic, glass-

schematicallyinFig.1andFig.2,respectively.Selectionofthe

ceramic, glass, metal, or organic in nature. These components

test specimen geometry depends on the bond strength of the

are combined on macroscale to form a useful engineering

joint, which may be determined by preparing longer test

material possessing certain properties or behavior not pos-

specimens of the same cross-section and using a standard

sessed by the individual constituents. C1275

four-point flexural strength test, for example, Test Method

3.1.4 joining, n—controlled formation of chemical, or me-

C1161 for monolithic advanced ceramic base material andTest

chanical bond, or both, between similar or dissimilar materials.

Method C1341 for composite advanced ceramic base material.

3.1.5 shear strength [F/L ], n—maximum shear stress

If the joint flexural strength is low (that is, <25 % of the

which a material is capable of sustaining. Shear strength is

flexural strength of the base material), the recommended test

calculated from the shear fracture force and the shear stressed

area. specimen geometry for shear strength testing of the joint is the

NOTE 1—The width of the joint, which varies between 0.05 and 0.20 mm, based on the joining method used, is smaller than that of the notch in b).

All dimensions are given in mm.

FIG. 1 Schematics of Test Specimen Geometries: a) Uniform, b) Straight-Notched and c) V-Notched

C1469–00 (2005)

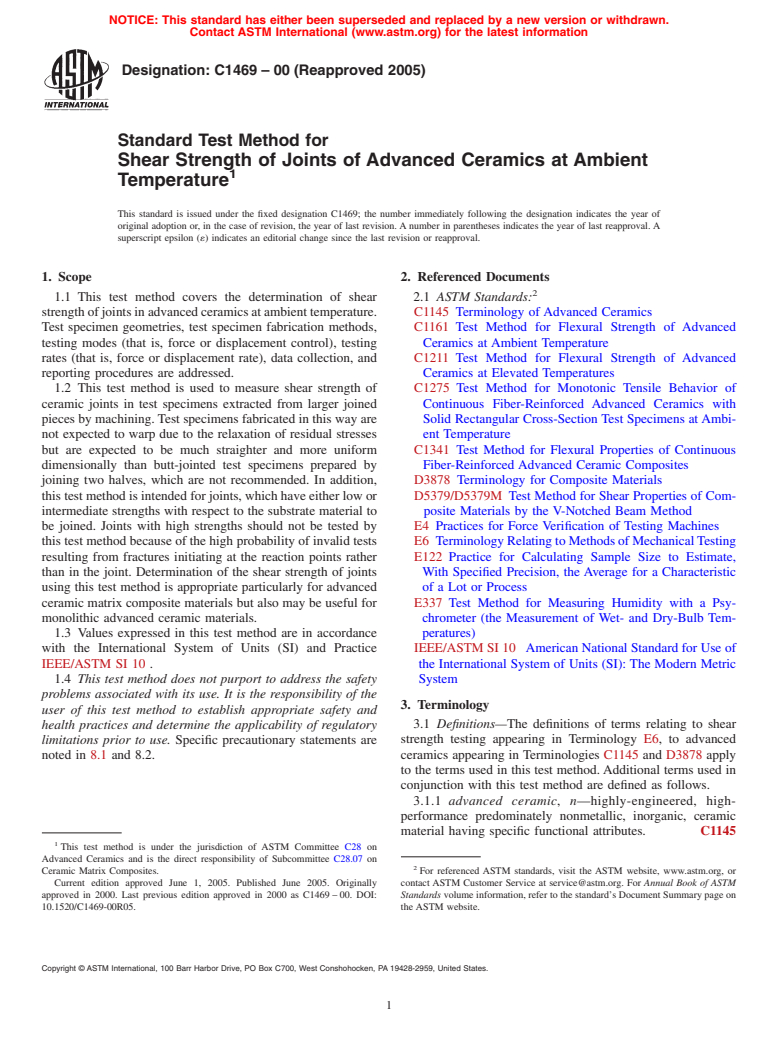

FIG. 2 Schematic of Test Fixture

uniform test specimen shown in Fig. 1a. If the joint flexural

strength is moderate (that is, 25 to 50 % of the flexural strength

of the base material), the recommended test specimen geom-

etry for shear strength testing of the joint is the straight- or

V-notched test specimen shown in Fig. 1b and Fig. 1c,

respectively. If the joint flexural strength is high (>50 % of the

flexural strength of the base material) this test method should

not be used to measure shear strength of advanced ceramic

joints because very high contact stresses at the reaction points

willprovideahighprobabilityofinvalidtests(thatis,fractures

not at the joint).

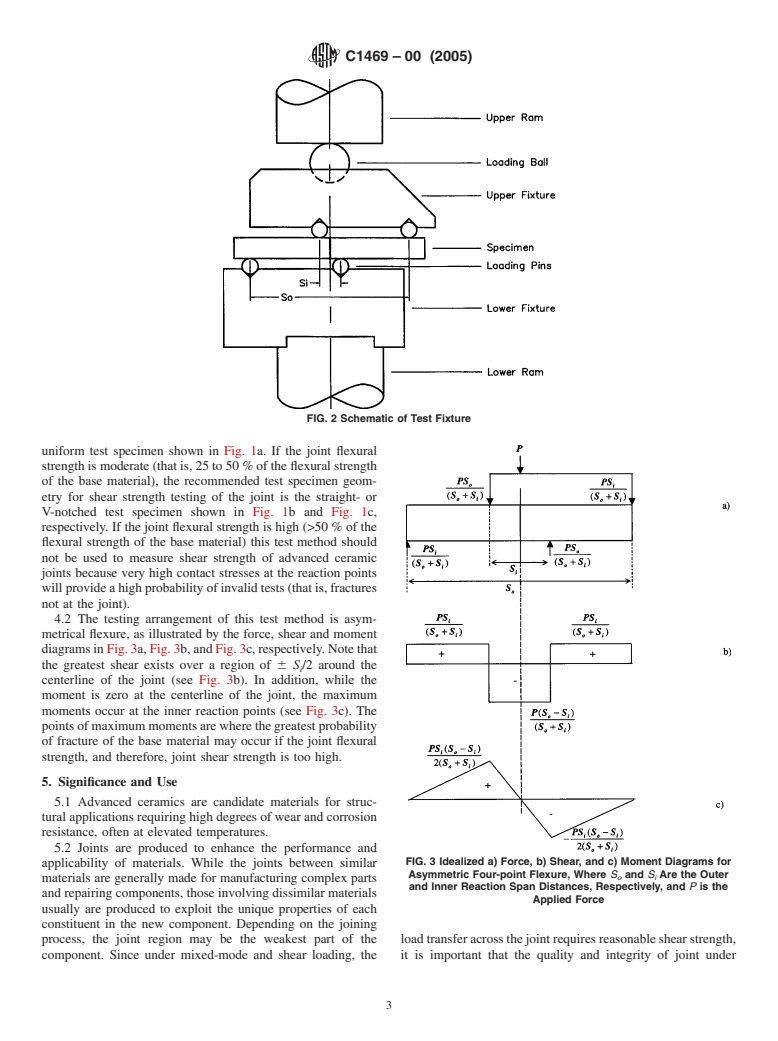

4.2 The testing arrangement of this test method is asym-

metrical flexure, as illustrated by the force, shear and moment

diagramsinFig.3a,Fig.3b,andFig.3c,respectively.Notethat

the greatest shear exists over a region of 6 S/2 around the

i

centerline of the joint (see Fig. 3b). In addition, while the

moment is zero at the centerline of the joint, the maximum

moments occur at the inner reaction points (see Fig. 3c). The

pointsofmaximummomentsarewherethegreatestprobability

of fracture of the base material may occur if the joint flexural

strength, and therefore, joint shear strength is too high.

5. Significance and Use

5.1 Advanced ceramics are candidate materials for struc-

tural applications requiring high degrees of wear and corrosion

resistance, often at elevated temperatures.

5.2 Joints are produced to enhance the performance and

FIG. 3 Idealized a) Force, b) Shear, and c) Moment Diagrams for

applicability of materials. While the joints between similar

Asymmetric Four-point Flexure, Where S and S Are the Outer

o i

materials are generally made for manufacturing complex parts

and Inner Reaction Span Distances, Respectively, and P is the

and repairing components, those involving dissimilar materials

Applied Force

usually are produced to exploit the unique properties of each

constituent in the new component. Depending on the joining

process, the joint region may be the weakest part of the loadtransferacrossthejointrequiresreasonableshearstrength,

component. Since under mixed-mode and shear loading, the it is important that the quality and integrity of joint under

C1469–00 (2005)

in-plane shear forces be quantified. Shear strength data are also and S inthefixture (seeFig.3).Theselengthsandthestrength

i

needed to monitor the development of new and improved of the joint relative to that of the base material determine

joining techniques. whether fracture takes place at the joint region or at the

5.3 Shear tests provide information on the strength and reaction points. Depending on this relative strength, it may be

deformation of materials under shear stresses. necessary to conduct preliminary tests to establish the appro-

5.4 This test method may be used for material development, priate S and S distances for the fixture to be used.

o i

material comparison, quality assurance, characterization, and 6.4 The accuracy of insertion and alignment of the test

design data generation. specimen with respect to the fixture is critical; therefore,

5.5 For quality control purposes, results derived from stan- preparations for testing should be done carefully to minimize

dardized shear test specimens may be considered indicative of thebendingmomentatthejoint,whichstronglydependsonthe

the response of the material from which they were taken for inner and outer reaction spans, as seen in Fig. 3c. See details in

given primary processing conditions and post-processing heat 10.4.

treatments. 6.5 Test environment (vacuum, inert gas, ambient air, etc.)

including moisture content, for example, relative humidity,

6. Interferences

may have an influence on the measured shear strength. Con-

6.1 Fractures that initiate outside of the joint region may be

versely, testing can be conducted in environments and testing

due to factors, such as localized stress concentrations, extra-

modes and rates representative of service conditions to evalu-

neous stresses introduced by improper force transfer. Such

ate material performance under those conditions. When testing

fractures will constitute invalid tests.

is conducted in uncontrolled ambient air with the objective of

6.2 Since the joint width is typically small, that is, 0.05 to

evaluating maximum strength potential, relative humidity and

0.20 mm, the proper machining of the notches at the joint

temperature must be monitored and reported. Testing at hu-

region is very critical (see Fig. 1). Improper machining of the

midity levels >65 % RH is not recommended and any devia-

notches can lead to undesired fracture at the reaction points.

tions from this recommendation shall be reported.

Furthermore, nonsymmetrical machining of the nothces can be

decisive as to how the fracture occurs between the nothces.

7. Apparatus

7.1 Testing Machines—The testing machine shall be in

NOTE 1—Finite element stress analysis of nonsymmetrical nothces

conformancewithPracticesE4.Theforcesusedindetermining

showed that when there is a misalignment between the notches and the

mid-plane of the joint, spurious normal (s ) tensile stresses are generated

shear strength shall be accurate within 61 % at any force

x

at the notches which tend to “tear” the joint and would artificially affect

within the selected force range of the testing machine as

(reduce) the magnitude of shear strength measured from the joint. The

defined in Practices E4.

magnitude of these tensile stresses could be significant depending on the

7.2 Data Acquisition—At a minimum, autographic records

material system being investigated. Based on this analysis, it is recom-

of applied force and cross-head displacement versus time shall

mended that the ratio of misalignment between the notch root and

be obtained. Either analog chart recorders or digital data

mid-plane of the joint, d, and the distance between the notches, h, should

be kept to less than 0.0125. (See Fig. 4.) acquisition systems may be used for this purpose although a

digital record is recommended for ease of later data analysis.

6.3 In this test method, the shear force required to cause

Ideally, an analog chart recorder or plotter should be used in

fracture in the joint region depends on the span lengths of S

o

conjunction with the digital data acquisition system to provide

an immediate record of the test as a supplement to the digital

record. Recording devices shall be accurate to 61 % of full

scale and shall have a minimum data acquisition rate of 10 Hz

with a response of 50 Hz deemed more than sufficient.

7.3 Dimension-Measuring Devices—Micrometers and other

devices used for measuring linear dimensions must be accurate

and precise to at least 0.01 mm.

7.4 Combination Square—Used to draw perpendicular lines

to specimen axis at the locations of inner loading points. The

tolerance must be within 0.5°.

7.5 Test Fixture—Thetestfixtureconsistsoftopandbottom

sections, reaction-pins, and a force transfer ball, as shown

schematically in Fig. 2. The bottom section is placed on a

stationary base, for example, a compression platen. The test

specimen is positioned between the top and bottom sections of

J.M. Slepetz, T.F. Zagaeski, and R.F. Novello, “In-Plane Shear Test for

Composite Materials”, AMMRC-TR-78-30, Army Materials and Mechanics Re-

NOTE 1—It is recommended that d/h ratio in both notch types is less

search Center, Watertown, MA, July 1978.

than 0.0125.

Ö. Ünal, I.E.Anderson, and S.I. Maghsoodi, “ATest Method to Measure Shear

FIG. 4 Schematic of Misalignment, d, between the Joint Line and Strength of Ceramic Joints at High Temperatures,” J. Am. Ceram. Soc., 80, 1281

Notch Root Shown for Straight—Notched Specimen (1997).

C1469–00 (2005)

TABLE 2 Recommended Dimensions for Test Specimens

thefixture.Theforceistransmittedfromthetestmachinetothe

fixture by the force transfer ball; however, a pin also can be Dimension Description Nominal Value Tolerance

used in place of the force transfer ball. Table 1 contains

L Test specimen length 36.0 mm 60.5

H Test specimen heigh

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.