ASTM D4860-91(2005)

(Test Method)Standard Test Method for Free Water and Particulate Contamination in Mid-Distillate Fuels (Clear and Bright Numerical Rating)

Standard Test Method for Free Water and Particulate Contamination in Mid-Distillate Fuels (Clear and Bright Numerical Rating)

SCOPE

1.1 This test method provides a rapid, portable means for field and laboratory use to visually inspect for particulate matter and numerically rate free water in aviation turbine and distillate fuels.

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific hazard statements, see 11.2.3.1 and Annex A1.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation:D4860–91(Reapproved 2005)

Standard Test Method for

Free Water and Particulate Contamination in Mid-Distillate

Fuels (Clear and Bright Numerical Rating)

This standard is issued under the fixed designation D 4860; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 3.1.1 clear-and-bright (also termed clean-and-bright)—a

condition in which the fuel contains no visible water drops or

1.1 This test method covers a rapid, portable means for field

particulates and is free of haze or cloudiness.

and laboratory use to inspect visually for particulate matter and

3.1.2 free water—water in excess of that soluble in the fuel

numerically rate free water in aviation turbine and distillate

atthetemperatureofthetestandappearinginthefuelasahaze

fuels.

or cloudiness, or as droplets.

1.2 The values stated in SI units are to be regarded as the

3.1.3 Micro-Separometer clear-and-bright (MSEP–C&B)—

standard. The values given in parentheses are for information

a numerical rating indicating the presence and ease of removal

only.

of free water and particulate contamination by filtration.

1.3 This standard does not purport to address all of the

3.1.4 solid particulates—small solid or semi-solid particles,

safety concerns, if any, associated with its use. It is the

sometimes referred to as silt or sediment, present in fuel as a

responsibility of the user of this standard to establish appro-

result of contamination by air-blown dusts, corrosion by-

priate safety and health practices and determine the applica-

products, fuel instability, or protective-coating deterioration.

bility of regulatory limitations prior to use. For specific

warning statements, see 11.2.3 and Annex A1.

4. Summary of Test Method

2. Referenced Documents 4.1 Visual inspection of the fuel sample for free water and

particulate matter is performed immediately when the sample

2.1 ASTM Standards:

is taken. A glass container is used to view for water haze, and

D 1500 Test Method for ASTM Color of Petroleum Prod-

the fuel sample is swirled to create a vortex to detect the

ucts (ASTM Color Scale)

presence of particulate matter.

D 1744 Test Method for Determination of Water in Liquid

4.2 Anumerical rating for free water is obtained by filtering

Petroleum Products by Karl Fischer Reagent

a portion of the fuel sample at a programmed rate (50 mL/45

D 2276 Test Method for Particulate Contaminant in Avia-

s)throughastandardfiberglasscoalescer/filter.Aportionofthe

tion Fuel by Line Sampling

effluent is used to establish a reference (100) level by a light

D 2709 Test Method for Water and Sediment in Middle

transmittance measurement. Another portion of the unproc-

Distillate Fuels by Centrifuge

essed (unfiltered) fuel sample is then compared to the 100

D 4057 Practice for Manual Sampling of Petroleum and

reference level. The results are reported on a 50 to 100 scale to

Petroleum Products

the nearest whole number. A test can be performed in 5 to 10

D 4176 Test Method for Free Water and Particulate Con-

min.

tamination in Distillate Fuels (Visual Inspection Proce-

dures)

NOTE 1—Thestandardfiberglasscoalescer/filterconsistsofaprecision-

machined aluminum housing containing fiber-glass material that has been

3. Terminology

selected to specific air flow characteristics. These criteria have a direct

bearing on the test results.

3.1 Definitions of Terms Specific to This Standard:

5. Significance and Use

This test method is under the jurisdiction of ASTM Committee D02 on

5.1 The test provides a field test to evaluate visually a fuel

Petroleum Products and Lubricants and is the direct responsibility of Subcommittee

sample for particulate matter and free water similar to Test

D02.14 on Stability and Cleanliness of Liquid Fuels.

Method D 4176 plus a numerical rating for free water. High

Current edition approved Nov. 1, 2005. Published November 2005. Originally

e1

numerical ratings indicate that the fuel is relatively free of free

approved in 1988. Last previous edition approved in 2000 as D 4860 – 91 (2000) .

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

water. The degree of water and particulate contamination can

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

be measured using other methods such as Test Methods

Standards volume information, refer to the standard’s Document Summary page on

D 1744, D 2276, and D 2709.

the ASTM website.

Withdrawn.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D4860–91 (2005)

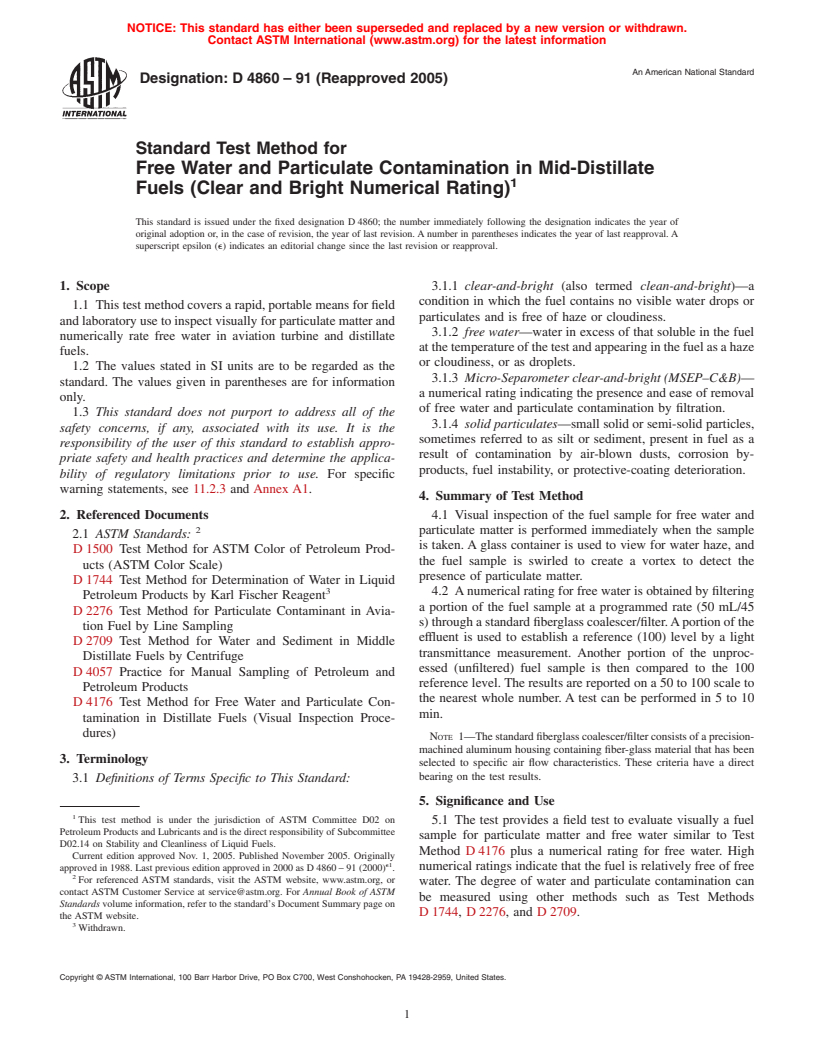

FIG. 1 Micro-Separometer Mark V Deluxe and Control Panel

5.2 The color of the sample does not affect the measure- 7. Apparatus

ment. Limited laboratory evaluations of samples have deter-

7.1 Micro-Separometer, Mark V Deluxe

mined the degree of free water can be rated in fuels with dark

7.1.1 The Micro-Separometer is a completely portable and

opaque color having a darker rating than five in Test Method

self contained unit capable of operating on an internal re-

D 1500.

chargeable battery pack or being connected to an a-c power

source using power cords that are furnished for various

6. Interferences

voltages. Connection to an a-c power source provides power to

6.1 When a fuel is visually inspected at or below the cloud the unit and effects battery recharge.The accessories as well as

the expendable materials for six tests can be packed in the

point temperature of the fuel, small amounts of solid wax

particles can be confused with a water-induced haze or cover of the lockable case.

cloudiness.

6.2 The presence of free water or particulate can be ob-

scured and missed during visual inspection of the fuel, if the 4

A registered trademark of and available from EMCEE Electronics, Inc., 520

ASTM color rating is greater than five. Cypress Ave., Venice, FL 34292.

D4860–91 (2005)

7.1.2 The Micro-Separometer Mark V Deluxe model and

the associated control panel is shown in Fig. 1. The emulsifier

is on the right side of the raised panel and the syringe drive

mechanism is on the left side. The control panel containing the

operating controls is mounted on the fixed panel in the left side

of the case.

7.1.3 All of the controls are located in a push-button array

on the control panel. The push buttons illuminate when

depressed, thus indicating operational status. A circuit breaker

located on the control panel provides protection for the a-c

power circuit.

7.1.4 By depressing the ON push button, the electronic

circuits are energized. The ON push button light pulses on and

off when the instrument is being operated by an a-c source and

constantly remains on when the battery (d-c) pack is used. The

A-G lettered push buttons sequentially illuminate on and off

indicating ready operational status.

NOTE 2—Of the lettered (A-G) push buttons, only the C push button is

applicable to this test method.

7.1.5 The RESET push button can be depressed at any time

A B CDEF

to cancel the test in progress and restore the program to the

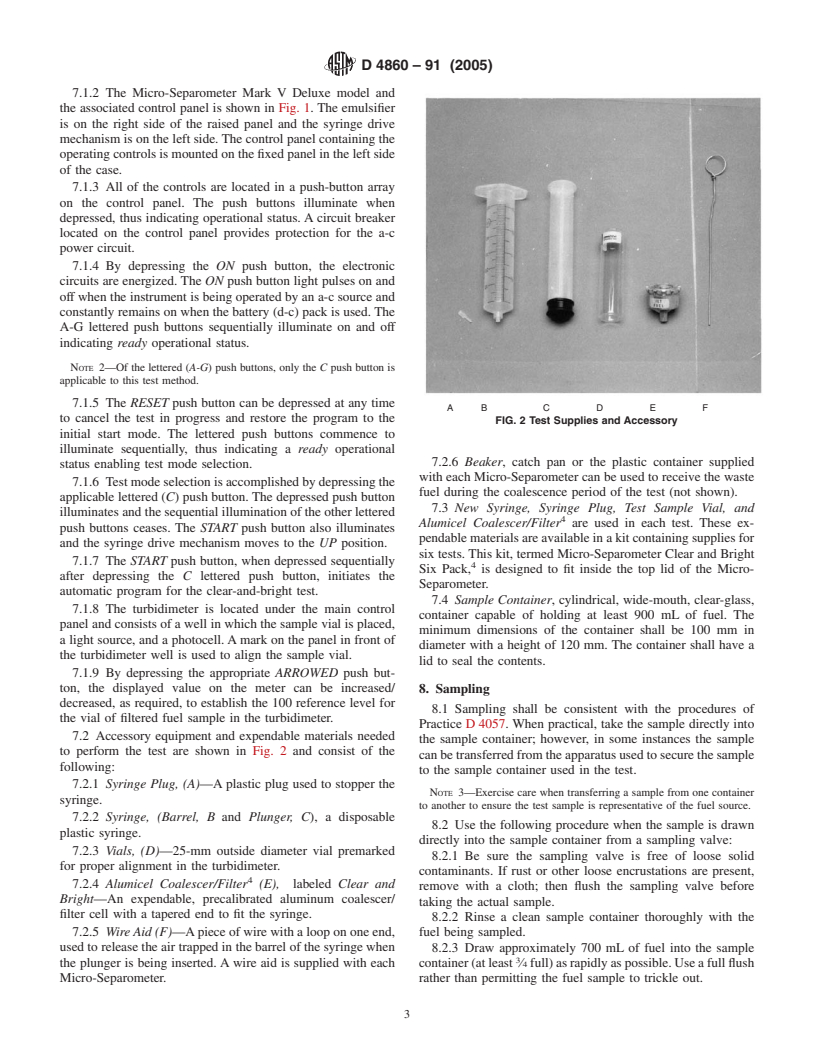

FIG. 2 Test Supplies and Accessory

initial start mode. The lettered push buttons commence to

illuminate sequentially, thus indicating a ready operational

7.2.6 Beaker, catch pan or the plastic container supplied

status enabling test mode selection.

with each Micro-Separometer can be used to receive the waste

7.1.6 Test mode selection is accomplished by depressing the

fuel during the coalescence period of the test (not shown).

applicable lettered (C) push button. The depressed push button

7.3 New Syringe, Syringe Plug, Test Sample Vial, and

illuminates and the sequential illumination of the other lettered

Alumicel Coalescer/Filter are used in each test. These ex-

push buttons ceases. The START push button also illuminates

pendable materials are available in a kit containing supplies for

and the syringe drive mechanism moves to the UP position.

six tests. This kit, termed Micro-Separometer Clear and Bright

7.1.7 The START push button, when depressed sequentially

Six Pack, is designed to fit inside the top lid of the Micro-

after depressing the C lettered push button, initiates the

Separometer.

automatic program for the clear-and-bright test.

7.4 Sample Container, cylindrical, wide-mouth, clear-glass,

7.1.8 The turbidimeter is located under the main control

container capable of holding at least 900 mL of fuel. The

panel and consists of a well in which the sample vial is placed,

minimum dimensions of the container shall be 100 mm in

a light source, and a photocell.Amark on the panel in front of

diameter with a height of 120 mm. The container shall have a

the turbidimeter well is used to align the sample vial.

lid to seal the contents.

7.1.9 By depressing the appropriate ARROWED push but-

ton, the displayed value on the meter can be increased/

8. Sampling

decreased, as required, to establish the 100 reference level for

8.1 Sampling shall be consistent with the procedures of

the vial of filtered fuel sample in the turbidimeter.

Practice D 4057. When practical, take the sample directly into

7.2 Accessory equipment and expendable materials needed

the sample container; however, in some instances the sample

to perform the test are shown in Fig. 2 and consist of the

canbetransferredfromtheapparatususedtosecurethesample

following:

to the sample container used in the test.

7.2.1 Syringe Plug, (A)—A plastic plug used to stopper the

NOTE 3—Exercise care when transferring a sample from one container

syringe.

to another to ensure the test sample is representative of the fuel source.

7.2.2 Syringe, (Barrel, B and Plunger, C), a disposable

8.2 Use the following procedure when the sample is drawn

plastic syringe.

directly into the sample container from a sampling valve:

7.2.3 Vials, (D)—25-mm outside diameter vial premarked

8.2.1 Be sure the sampling valve is free of loose solid

for proper alignment in the turbidimeter.

contaminants. If rust or other loose encrustations are present,

7.2.4 Alumicel Coalescer/Filter (E), labeled Clear and

remove with a cloth; then flush the sampling valve before

Bright—An expendable, precalibrated aluminum coalescer/

taking the actual sample.

filter cell with a tapered end to fit the syringe.

8.2.2 Rinse a clean sample container thoroughly with the

7.2.5 Wire Aid (F)—Apiece of wire with a loop on one end, fuel being sampled.

used to release the air trapped in the barrel of the syringe when 8.2.3 Draw approximately 700 mL of fuel into the sample

the plunger is being inserted. A wire aid is supplied with each container(atleast ⁄4full)asrapidlyaspossible.Useafullflush

Micro-Separometer. rather than permitting the fuel sample to trickle out.

D4860–91 (2005)

8.2.4 Alid must be placed on the container to prevent water

absorptionorlossfromthesampletotheambientenvironment,

especially if the test is performed under different environmen-

tal conditions than those of the sample site or at a later time.

9. Preparation of Apparatus

9.1 Locate the Micro-Separometer on a clean workbench in

an area in which the temperature is within the operating limits

of the instrument, 0 to 50° (32 to 122°F).

9.2 Open the case and remove the six-pack box from the lid.

Raise the right panel until completely vertical and locked in

place. When a-c power is available, connect the power cord

and turn the instrument on; otherwise operate using battery

power.

9.3 Depress the switch (push button) marked ON.

NOTE 4—Flickering of the power indicator light during any portion of

a test sequence being performed when using battery power indicates that

recharging is necessary.

FIG. 3 Plunger Insertion

9.4 Have ready a supply of syringes, syringe plugs, vials,

and Alumicel coalescer/filters. In addition, have the wire aid

loop end out. (To ensure that only the entrapped air is expelled

readilyavailableandthecatchpanpositionedunderthesyringe

withoutfuelloss,thesyringebarrelshouldbecockedataslight

drive mechanism to accept the spent fuel.

angle with the wire aid held against the upper portion of the

10. Conditioning barrel—Fig. 3.) Insert the plunger to the 50-mL mark on the

syringe barrel. Remove the wire aid from the syringe. Remove

10.1 Under no circumstances is the test fuel to be prefiltered

the plug from the syringe and replace it with an Alumicel

as filter media can remove the very materials, water and

coalescer.

particulate matter, that the test is designed to detect.

11.2.3 Prepare for Coalescing/Filter Process—Place the

10.2 The sample temperature shall not be lower than the

entire syringe assembly into the syringe drive mechanism.

temperature at which the fuel will be stored and used. Too low

Electrically bond the coalescer/filter to the instrument by using

a temperature may cause a haze to form from water previously

the ground lead provided. Insert the end with the banana plug

in solution. When possible, perform the test with the fuel

into the recepticle located left of the syringe drive mechanism

sample at a temperature representing a real-use situation.

and attach the alligator clip to one of the coalescer/filter fins.

11. Procedure

PositionawastecontainerbeneaththeAlumicelcoalescer/filter

11.1 Visual inspection for water or particulate contamina- to collect the unwanted portion of the processed fuel sample

tion. during the coalescing/filtering period of the test (Fig. 4).

11.1.1 Immediately upon drawing a sample for field testing, (Warning—Alumicel coalescer/filters should be electrically

check visually for evidence of water or particulate contamina- bonded to the Micro-Separometer to prevent buildup of an

tion. Hold the sample container up to the ambient light source electrostatic charge that could result in ignition of flammable

and view the fuel through the walls of the container, visually test fluids (Fig. 4).)

examining for haze or lack of clarity. Check the same sample 11.2.4 Initiate the Coalescing/Filtering Process:

by swirling the fuel in the sample container to produce a 11.2.4.1 Depress the START push button which initiates the

automatic program (see Table 1). The automatic program is a

vortex. The bottom of the vortex is visually examined for

particulate matter. Record the visual clarity as clear-and-bright series of timed events controlled by the instrument that begins

with the syringe drive mechanism forcing the fuel through the

or not clear-and-bright. Record if particulate matter or water

was or was not viewed at the bottom of the vortex. Cap the Alumicel coalescer/filter

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.