ASTM C1072-00a

(Test Method)Standard Test Method for Measurement of Masonry Flexural Bond Strength

Standard Test Method for Measurement of Masonry Flexural Bond Strength

SCOPE

1.1 This test method covers the determination of flexural bond strength of nonreinforced masonry by physical testing of each joint of masonry prisms.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:C1072–00a

Standard Test Method for

Measurement of Masonry Flexural Bond Strength

This standard is issued under the fixed designation C 1072; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope * unit and mortar properties, workmanship, curing conditions,

coatings on masonry units, or any other factors that may be of

1.1 This test method covers the determination of flexural

concern.

bond strength of nonreinforced masonry by physical testing of

3.3 Flexural bond strength determined by this test method

each joint of masonry prisms.

should not be interpreted as the flexural bond strength of a wall

1.2 This standard does not purport to address all of the

constructed of the same material. However, results may be

safety concerns, if any, associated with its use. It is the

used to predict the flexural strength of a wall. Nor should it be

responsibility of the user of this standard to establish appro-

interpreted as an indication of extent of bond for purposes of

priate safety and health practices and determine the applica-

water permeance evaluation.

bility of regulatory limitations prior to use.

4. Apparatus

2. Referenced Documents

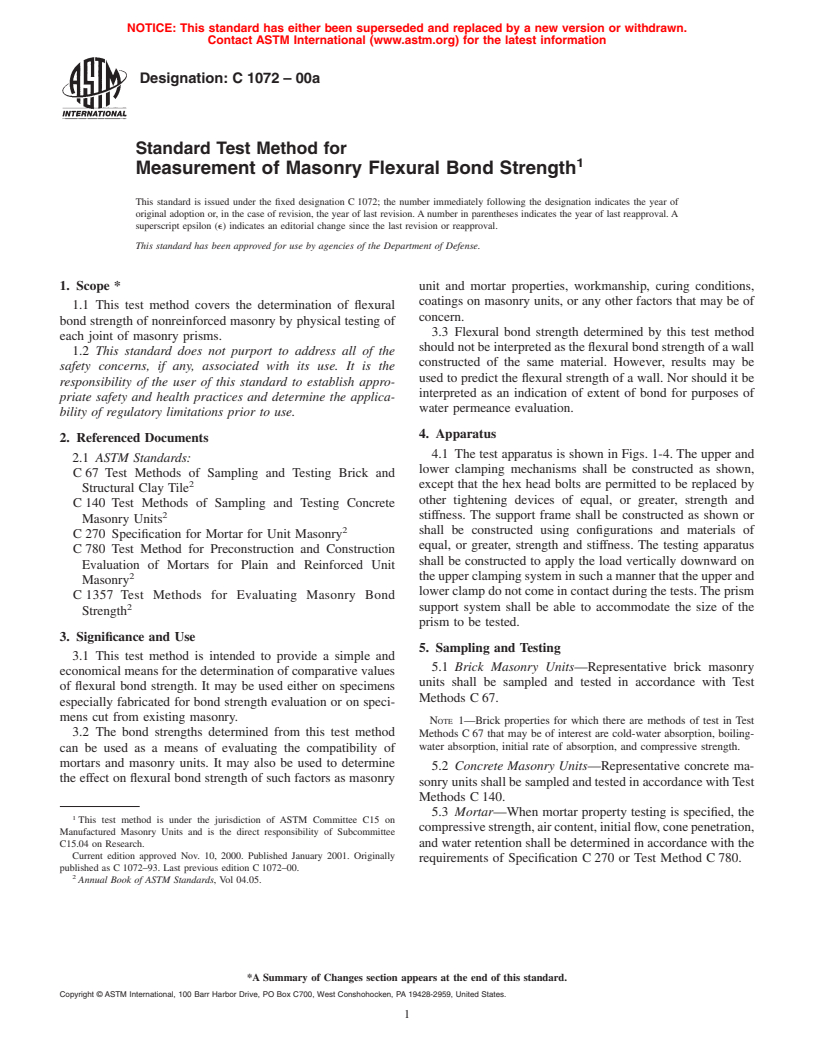

4.1 The test apparatus is shown in Figs. 1-4. The upper and

2.1 ASTM Standards:

lower clamping mechanisms shall be constructed as shown,

C 67 Test Methods of Sampling and Testing Brick and

except that the hex head bolts are permitted to be replaced by

Structural Clay Tile

other tightening devices of equal, or greater, strength and

C 140 Test Methods of Sampling and Testing Concrete

stiffness. The support frame shall be constructed as shown or

Masonry Units

shall be constructed using configurations and materials of

C 270 Specification for Mortar for Unit Masonry

equal, or greater, strength and stiffness. The testing apparatus

C 780 Test Method for Preconstruction and Construction

shall be constructed to apply the load vertically downward on

Evaluation of Mortars for Plain and Reinforced Unit

the upper clamping system in such a manner that the upper and

Masonry

lower clamp do not come in contact during the tests.The prism

C 1357 Test Methods for Evaluating Masonry Bond

2 support system shall be able to accommodate the size of the

Strength

prism to be tested.

3. Significance and Use

5. Sampling and Testing

3.1 This test method is intended to provide a simple and

5.1 Brick Masonry Units—Representative brick masonry

economical means for the determination of comparative values

units shall be sampled and tested in accordance with Test

of flexural bond strength. It may be used either on specimens

Methods C 67.

especially fabricated for bond strength evaluation or on speci-

mens cut from existing masonry.

NOTE 1—Brick properties for which there are methods of test in Test

3.2 The bond strengths determined from this test method Methods C 67 that may be of interest are cold-water absorption, boiling-

water absorption, initial rate of absorption, and compressive strength.

can be used as a means of evaluating the compatibility of

mortars and masonry units. It may also be used to determine

5.2 Concrete Masonry Units—Representative concrete ma-

the effect on flexural bond strength of such factors as masonry

sonry units shall be sampled and tested in accordance withTest

Methods C 140.

5.3 Mortar—When mortar property testing is specified, the

This test method is under the jurisdiction of ASTM Committee C15 on

compressivestrength,aircontent,initialflow,conepenetration,

Manufactured Masonry Units and is the direct responsibility of Subcommittee

C15.04 on Research. and water retention shall be determined in accordance with the

Current edition approved Nov. 10, 2000. Published January 2001. Originally

requirements of Specification C 270 or Test Method C 780.

published as C 1072–93. Last previous edition C 1072–00.

Annual Book of ASTM Standards, Vol 04.05.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

C1072–00a

FIG. 1 Bond Wrench Testing Apparatus

6. Test Specimen 6.3.1.6 Generally, all prisms should be cured for 28 days;

however, different periods of time may be used provided the

6.1 The test specimen shall consist of a prism, two or more

relationship between that period and 28 days strength has been

units in height, with a minimum width (b) of 4 in. (see Note 2)

established, or if the effect of age is the parameter being

as shown in Fig. X1.1. Any type of masonry unit and mortar

studied. Prisms fabricated in the laboratory shall be cured in

may be used.

laboratory air. It is recommended that the laboratory air be

NOTE 2—It is recommended that a width (b) of 1 full masonry unit be

maintained at a temperature of 75 6 15°F (24 6 8°C), with a

used. However, full widths may not be possible for samples obtained in

relative humidity between 30 and 70 %. Temperature and

accordance with 6.3.2.

humidity shall be recorded and reported. Closer controls on

6.2 A minimum of five joints shall be tested, using mortar

temperature and humidity (for example, self cure in a plastic

3 1

joints ⁄8 6 ⁄16 in. (9.5 6 1.5 mm) or as specified.

membrane) are permitted, and may result in less variation of

6.3 Prisms may be constructed in a laboratory or in the field

test results.

or may be removed from existing masonry.

NOTE 4—Workmanshipduringfabrication,temperatureofthematerials

6.3.1 Prisms Fabricated in Laboratory or Field:

during fabrication, curing conditions, time between removal from moist

6.3.1.1 Set the first unit of each prism on a firm, horizontal

curing to test, and other factors may affect the bond strengths measured by

surface without the use of mortar.

this test. Standardized specimen fabrication and curing procedures that

NOTE 3—An alignment device may be used to ensure plumbness and attempt to control these variables are prescribed in Test Methods C 1357.

joint thickness uniformity.

6.3.1.7 Whenprismsaremadeduringconstructionatthejob

6.3.1.2 Place a full or face shell mortar bed on all units

site, they shall be constructed in a location where they will not

without furrowing unless the effect of furrowing is being

be disturbed, but will be subjected to atmospheric conditions

studied.

similar to those in the masonry structure whose properties they

6.3.1.3 Immediately place the next course on the mortar bed

are intended to represent.

and tap it to proper level and joint thickness. One face of each

6.3.2 Prisms Obtained from Existing Masonry:

prism shall be in a nearly true plane.

6.3.2.1 Using a portable hand held masonry saw, cut all

6.3.1.4 Repeat 6.3.1.2 and 6.3.1.3 until the prisms are the

edges adjacent to the prism being removed. If embedments are

desired height.Then 1 6 ⁄4 h after completion of construction,

embedded in the intended sample, cut and remove sufficient

place two of the masonry units of the type used to construct the

adjacent masonry to permit cutting the embedments.

prism upon the top course. Identify all specimens using a

6.3.2.2 Identify all samples with a water-resistant marker.

water-resistant marker.

6.3.1.5 Jointsmaybetooledorstruckflush,dependingupon 6.3.2.3 Where mortar fins and extrusions project from the

the desired test conditions. If tooling is required, tool only the specimen to the extent that they may interfere with the

joints on one face of each prism. attachment of the bond wrench, they shall be removed without

C1072–00a

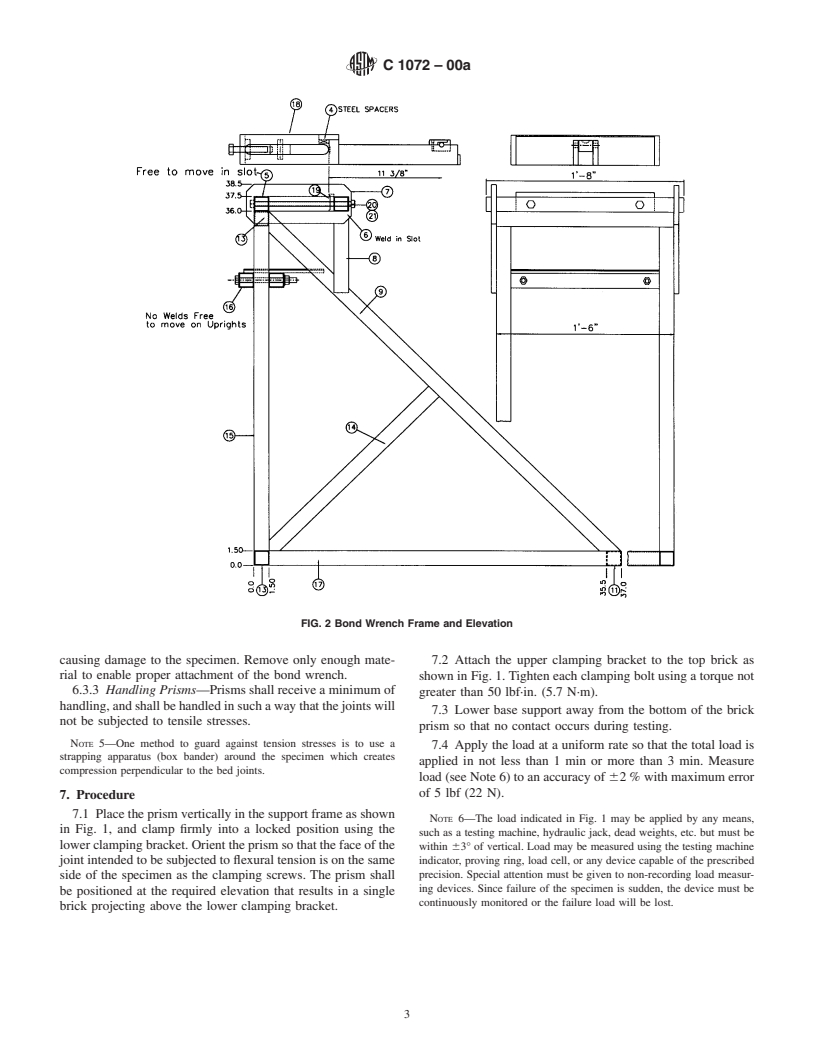

FIG. 2 Bond Wrench Frame and Elevation

causing damage to the specimen. Remove only enough mate- 7.2 Attach the upper clamping bracket to the top brick as

rial to enable proper attachment of the bond wrench. shown in Fig. 1. Tighten each clamping bolt using a torque not

6.3.3 Handling Prisms—Prisms shall receive a minimum of

greater than 50 lbf·in. (5.7 N·m).

handling,andshallbehandledinsuchawaythatthejointswill

7.3 Lower base support away from the bottom of the brick

not be subjected to tensile stresses.

prism so that no contact occurs during testing.

NOTE 5—One method to guard against tension stresses is to use a

7.4 Apply the load at a uniform rate so that the total load is

strapping apparatus (box bander) around the specimen which creates

applied in not less than 1 min or more than 3 min. Measure

compression perpendicular to the bed joints.

load (see Note 6) to an accuracy of 62 % with maximum error

of 5 lbf (22 N).

7. Procedure

7.1 Place the prism vertically in the support frame as shown

NOTE 6—The load indicated in Fig. 1 may be applied by any means,

in Fig. 1, and clamp firmly into a locked position using the

such as a testing machine, hydraulic jack, dead weights, etc. but must be

lower clamping bracket. Orient the prism so that the face of the

within 63° of vertical. Load may be measured u

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.