ASTM D6463/D6463M-06

(Test Method)Standard Test Method for Time to Failure of Pressure Sensitive Articles Under Sustained Shear Loading

Standard Test Method for Time to Failure of Pressure Sensitive Articles Under Sustained Shear Loading

SIGNIFICANCE AND USE

This test method measures the cohesive strength of the adhesive on a pressure sensitive article. The time to failure can predict end use properties of pressure sensitive articles such as edge ooze from cold flow; trimming, slitting and die cutting quality; telescoping in tapes; ability to seal packages; and vertical holding power.

This test method is suitable for quality control, development and applications testing.

If the adhesive is not already coated, the adhesive can be coated on smooth, clear polyester (PET) film backing 0.05 mm [0.002 in.] thick. The recommended dry adhesive thickness is 0.025 mm [0.001 in.].

Humidity has a strong effect on time to failure for many pressure sensitive articles. Therefore, humidity should be controlled in accordance with 8.1.2.

SCOPE

1.1 This test method covers the ability of a pressure sensitive article (for example, tape, label, sticker, etc.) to remain adhered to a stainless steel panel under a constant load applied parallel to the bonding surface of the pressure sensitive article.

1.2 Values stated in either SI or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents, therefore, each system must be used independently without combining values in any way.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Please contact ASTM International (www.astm.org) for the latest information.

Designation:D6463/D6463M–06

Standard Test Method for

Time to Failure of Pressure Sensitive Articles Under

1

Sustained Shear Loading

This standard is issued under the fixed designation D6463/D6463M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope ASTM Test Methods

E691 Practice for Conducting an Interlaboratory Study to

1.1 This test method covers the ability of a pressure sensi-

Determine the Precision of a Test Method

tive article (for example, tape, label, sticker, etc.) to remain

adhered to a stainless steel panel under a constant load applied

3. Terminology

parallel to the bonding surface of the pressure sensitive article.

3.1 Many of the terms found in this test method are defined

1.2 Values stated in either SI or inch-pound units are to be

in Terminology D907.

regarded separately as standard. The values stated in each

system may not be exact equivalents, therefore, each system

4. Summary of Test Method

must be used independently without combining values in any

4.1 This test method consists of bonding a standard area of

way.

a pressure sensitive article to a stainless steel panel. The

1.3 This standard does not purport to address all of the

bonded construction is allowed to dwell in a constant tempera-

safety concerns, if any, associated with its use. It is the

ture and humidity environment for 30 min. The construction is

responsibility of the user of this standard to establish appro-

then mounted vertically. A standard mass of 500 g [1.1 lb] is

priate safety and health practices and determine the applica-

attached to the pressure sensitive article and allowed to act

bility of regulatory limitations prior to use.

until the construction separates or until 3000 min elapse. If

2. Referenced Documents there is no separation after 3000 min, the test is repeated on a

2 fresh specimen with a mass of 1000 g [2.2 lb] and allowed to

2.1 ASTM Standards:

act until separation occurs or until 3000 min elapse. If no

A666 Specification for Annealed or Cold-Worked Austen-

separation occurs, perform Procedure C of Test Method

itic Stainless Steel Sheet, Strip, Plate, and Flat Bar

D3654/D3654M for shear holding power to stainless steel at

D907 Terminology of Adhesives

49°C [120°F]. The test result is the time in minutes to

D3654/D3654M Test Methods for Shear Adhesion of

separation.

Pressure-Sensitive Tapes

D5750/D5750M Guide for Width and Length of Pressure-

5. Significance and Use

Sensitive Tape

5.1 This test method measures the cohesive strength of the

E171 Specification for Atmospheres for Conditioning and

adhesive on a pressure sensitive article. The time to failure can

Testing Flexible Barrier Materials

predict end use properties of pressure sensitive articles such as

E177 Practice for Use of the Terms Precision and Bias in

edge ooze from cold flow; trimming, slitting and die cutting

quality; telescoping in tapes; ability to seal packages; and

vertical holding power.

1

This test method is under the jurisdiction of ASTM Committee D14 on

5.2 This test method is suitable for quality control, devel-

Adhesives and is the direct responsibility of Subcommittee D14.50 on Hot Melts,

opment and applications testing.

Pressure Sensitives, and Archival Adhesives.

Current edition approved March 1, 2006. Published April 2006. Originally

5.3 Iftheadhesiveisnotalreadycoated,theadhesivecanbe

approved in 1999. Last previous edition approved in 1999 as D6463 – 99. DOI:

coated on smooth, clear polyester (PET) film backing 0.05 mm

10.1520/D6463_D6463M-06.

2 [0.002 in.] thick. The recommended dry adhesive thickness is

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM 0.025 mm [0.001 in.].

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

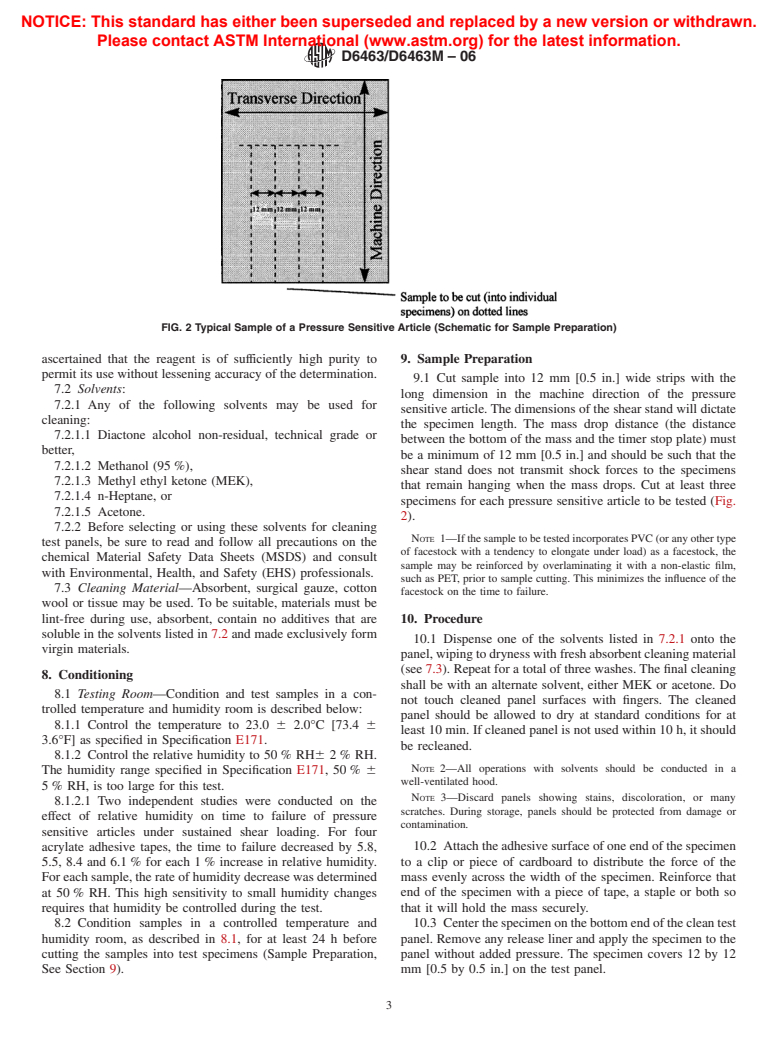

---------------------- Page: 1 ----------------------

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Please contact ASTM International (www.astm.org) for the latest information.

D6463/D6463M–06

FIG. 1 Test Panel with Specimen and Mass (Side View)

5.4 Humidity has a strong effect on time to failure for many fromameanline.Oneorbothofthepanelendsshallbeground

pressure sensitive articles. Therefore, humidity should be to form a 90° angle with the panel surface. Panels showing

controlled in accordance with 8.1.2. stains, discolorations, or numerous scratches are not accept-

able. New

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.