ASTM D4871-11

(Guide)Standard Guide for Universal Oxidation/Thermal Stability Test Apparatus

Standard Guide for Universal Oxidation/Thermal Stability Test Apparatus

SIGNIFICANCE AND USE

This standard describes an apparatus that provides the versatility required to conduct oxidation or thermal stability tests on liquids using a wide variety of test conditions. It is sufficiently flexible so that new test conditions can be chosen in response to the changing demands of the marketplace.

Procedures using this apparatus are described in the following ASTM standard test methods: D5763, D5846, and D6514. Other procedures may be in use, but they have not been developed as ASTM standard test methods.

SCOPE

1.1 This guide covers an apparatus used to measure the oxidation or thermal stability of liquids by subjecting them to temperatures in the range from 50 to 375°C in the presence of air, oxygen, nitrogen, or other gases at flow rates of 1.5 to 13 L/h, or in the absence of gas flow. Stability may be measured in the presence or absence of water or soluble or insoluble catalysts. Gases evolved may be allowed to escape, condensed and collected, or condensed and returned to the test cell.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D4871 − 11

StandardGuide for

1

Universal Oxidation/Thermal Stability Test Apparatus

This standard is issued under the fixed designation D4871; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* (ASTM Color Scale)

D3339 Test Method forAcid Number of Petroleum Products

1.1 This guide covers an apparatus used to measure the

by Semi-Micro Color Indicator Titration

oxidation or thermal stability of liquids by subjecting them to

D5763 Test Method for Oxidation and Thermal Stability

temperatures in the range from 50 to 375°C in the presence of

Characteristics of Gear Oils Using Universal Glassware

air, oxygen, nitrogen, or other gases at flow rates of 1.5 to

D5770 Test Method for Semiquantitative Micro Determina-

13 L⁄h, or in the absence of gas flow. Stability may be

tion of Acid Number of Lubricating Oils During Oxida-

measured in the presence or absence of water or soluble or

tion Testing

insoluble catalysts. Gases evolved may be allowed to escape,

D5846 Test Method for Universal Oxidation Test for Hy-

condensed and collected, or condensed and returned to the test

draulic and Turbine Oils Using the Universal Oxidation

cell.

Test Apparatus

1.2 The values stated in SI units are to be regarded as

D6514 Test Method for High Temperature Universal Oxida-

standard. No other units of measurement are included in this

tion Test for Turbine Oils

standard.

1.3 This standard does not purport to address all of the

3. Summary of Guide

safety concerns, if any, associated with its use. It is the

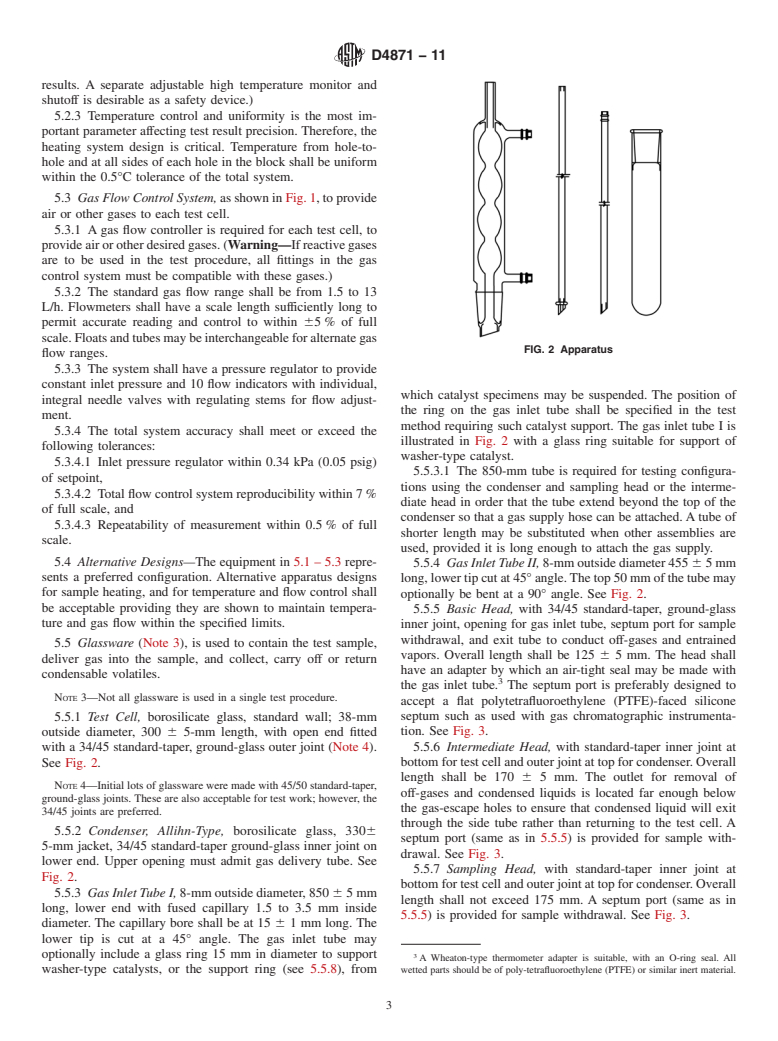

3.1 An apparatus is described in which a sample of test

responsibility of the user of this standard to establish appro-

fluid, typically from 100 ml or 100 g, is subjected to thermal or

priate safety and health practices and determine the applica-

oxidative degradation or both. Insoluble or soluble catalyst

bility of regulatory limitations prior to use.

may be added. Gas may be bubbled through the liquid to

provide agitation or to promote oxidation or both. Water or

2. Referenced Documents

water vapor may be added.At the end of the test or at intervals

2

2.1 ASTM Standards:

throughout the test, the liquid is monitored for change in

D91 Test Method for Precipitation Number of Lubricating

neutralization number, viscosity, weight loss, formation of

Oils

sludge, or for other parameters. The corrosivity of the fluid

D156 Test Method for Saybolt Color of Petroleum Products

toward any catalyst metals can be determined from the

(Saybolt Chromometer Method)

appearance and weight change of the metal test specimens, if

D445 Test Method for Kinematic Viscosity of Transparent

present, or by monitoring the oil and any sludge or water for

and Opaque Liquids (and Calculation of Dynamic Viscos-

metal content. The test is terminated after a fixed time period

ity)

or when a selected parameter reaches a condemning value.

D664 Test Method for Acid Number of Petroleum Products

NOTE 1—The volume of liquid at test temperature should be sufficient

by Potentiometric Titration

to cover the catalysts and should not extend beyond the heated portion of

D974 Test Method for Acid and Base Number by Color-

the bath.

Indicator Titration

D1500 Test Method forASTM Color of Petroleum Products

4. Significance and Use

4.1 This standard describes an apparatus that provides the

versatility required to conduct oxidation or thermal stability

1

This guide is under the jurisdiction of ASTM Committee D02 on Petroleum

tests on liquids using a wide variety of test conditions. It is

Products, Liquid Fuels, and Lubricants and is the direct responsibility of Subcom-

mittee D02.09.0D on Oxidation of Lubricants.

sufficientlyflexiblesothatnewtestconditionscanbechosenin

Current edition approved Dec. 1, 2011. Published January 2012. Originally

response to the changing demands of the marketplace.

approved in 1988. Last previous edition approved in 2006 as D4871–06. DOI:

10.1520/D4871-11.

4.2 Procedures using this apparatus are described in the

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

following ASTM standard test methods: D5763, D5846, and

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

D6514.Otherproceduresmaybeinuse,buttheyhavenotbeen

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. developed as ASTM standard test methods.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D48

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:D4871–06 Designation: D4871 – 11

Standard Guide for

1

Universal Oxidation/Thermal Stability Test Apparatus

This standard is issued under the fixed designation D4871; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*

1.1 This guide covers an apparatus used to measure the oxidation or thermal stability of liquids by subjecting them to

temperatures in the range from 50 to 375°C in the presence of air, oxygen, nitrogen, or other gases at flow rates of 1.5 to 13 L/h,

orintheabsenceofgasflow.Stabilitymaybemeasuredinthepresenceorabsenceofwaterorsolubleorinsolublecatalysts.Gases

evolved may be allowed to escape, condensed and collected, or condensed and returned to the test cell.

1.2

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

D91 Test Method for Precipitation Number of Lubricating Oils

D156 Test Method for Saybolt Color of Petroleum Products (Saybolt Chromometer Method)

D445 Test Method for Kinematic Viscosity of Transparent and Opaque Liquids (and Calculation of Dynamic Viscosity)

D664 Test Method for Acid Number of Petroleum Products by Potentiometric Titration

D974 Test Method for Acid and Base Number by Color-Indicator Titration

D1500 Test Method for ASTM Color of Petroleum Products (ASTM Color Scale)

D3339 Test Method for Acid Number of Petroleum Products by Semi-Micro Color Indicator Titration

D5763 Test Method for Oxidation and Thermal Stability Characteristics of Gear Oils Using Universal Glassware

D5770 Test Method for Semiquantitative Micro Determination of Acid Number of Lubricating Oils During Oxidation Testing

D5846 Test Method for Universal OxidationTest for Hydraulic andTurbine Oils Using the Universal OxidationTestApparatus

D6514 Test Method for High Temperature Universal Oxidation Test for Turbine Oils

3. Summary of Guide

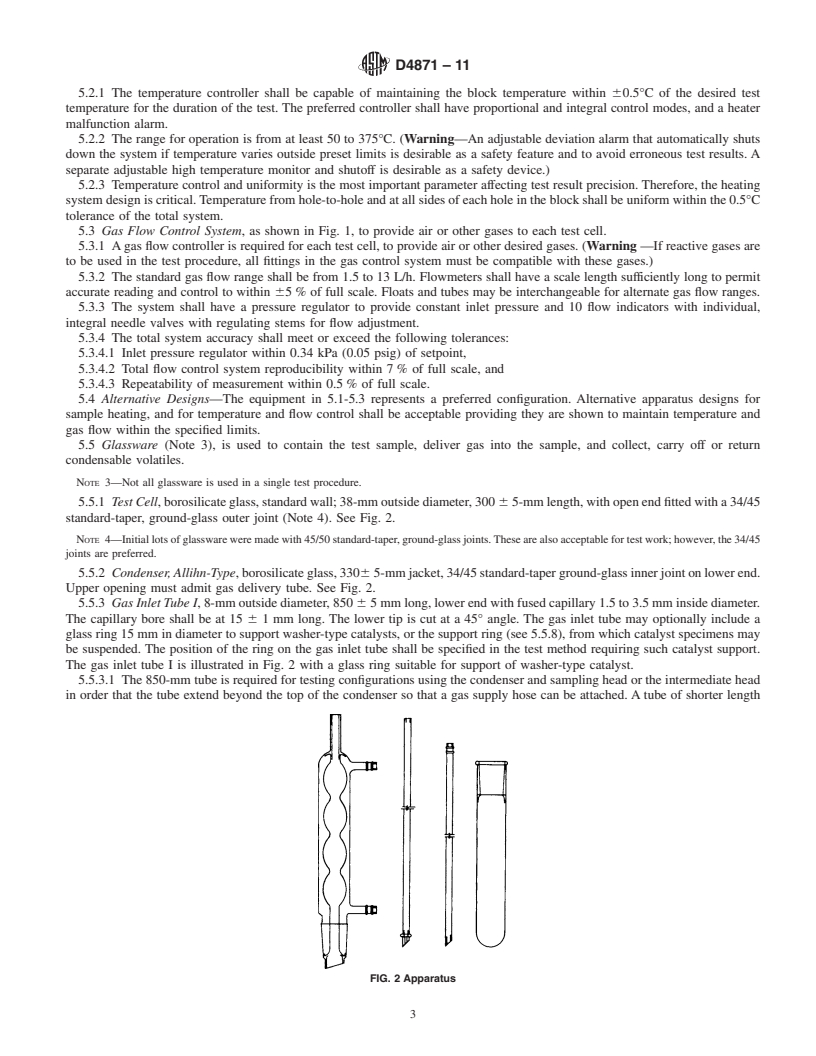

3.1 Anapparatusisdescribedinwhichasampleoftestfluid,typicallyfrom100mlor100g,issubjectedtothermaloroxidative

degradation or both. Insoluble or soluble catalyst may be added. Gas may be bubbled through the liquid to provide agitation or

to promote oxidation or both. Water or water vapor may be added. At the end of the test or at intervals throughout the test, the

liquid is monitored for change in neutralization number, viscosity, weight loss, formation of sludge, or for other parameters. The

corrosivity of the fluid toward any catalyst metals can be determined from the appearance and weight change of the metal test

specimens, if present, or by monitoring the oil and any sludge or water for metal content. The test is terminated after a fixed time

period or when a selected parameter reaches a condemning value.

NOTE 1—The volume of liquid at test temperature should be sufficient to cover the catalysts and should not extend beyond the heated portion of the

bath.

4. Significance and Use

4.1 This standard describes an apparatus that provides the versatility required to conduct oxidation or thermal stability tests on

liquids using a wide variety of test conditions. It is sufficiently flexible so that new test conditions can be chosen in response to

the changing demands of the marketplace.

1

This guide is under the jurisdiction of ASTM Committee D02 on Petroleum Products and Lubricants and is the direct responsibility of Subcommittee D02.09.0D on

Oxidation of Lubricants.

Current edition approved MayDec. 1, 2006.2011. Published May 2006.January 2012. Originally approved in 1988. Last previous edition approved in 20002006 as

D4871–00.D4871–06. DOI: 10.1520/D4871-06.10.1520/D4871-11.

2

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book ofASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, Unit

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.