ASTM D4320-93

(Test Method)Standard Test Method for Laboratory Preparation of Chemically Grouted Soil Specimens for Obtaining Design Strength Parameters

Standard Test Method for Laboratory Preparation of Chemically Grouted Soil Specimens for Obtaining Design Strength Parameters

SCOPE

1.1 This test method covers the laboratory preparation of chemically grouted soil specimens for use in laboratory tests to determine design strength parameters. Note 1-This test method may not be applicable to grout mixtures with gel times shorter than the time required to saturate the specimen with grout.

1.2 The specimens are intended for both strength and modulus determination in unconfined and confined compression testing. Note 2-Preparation methods for specimens to be used for other purposes are described in Test Methods D4219 and D5202.

1.3 This test method requires the injection of grout into soil specimens already fabricated to a desired density.

1.4 The values stated in inch-pound units are to be regarded as the standard.

1.5 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: D 4320 – 93

AMERICAN SOCIETY FOR TESTING AND MATERIALS

100 Barr Harbor Dr., West Conshohocken, PA 19428

Reprinted from the Annual Book of ASTM Standards. Copyright ASTM

Standard Test Method for

Laboratory Preparation of Chemically Grouted Soil

Specimens for Obtaining Design Strength Parameters

This standard is issued under the fixed designation D 4320; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope grouted specimens without the use of a jacking force. They

may be sized for the preparation of one or multiple specimens

1.1 This test method covers the laboratory preparation of

(Multiple specimen molds should be externally marked to

chemically grouted soil specimens for use in laboratory tests to

indicate desired ends of individual specimens, as an aid in

determine design strength parameters.

preparation). Molds shall produce specimens with a length-to-

NOTE 1—This test method may not be applicable to grout mixtures with

diameter ratio between two and three, (2.5 is recommended)

gel times shorter than the time required to saturate the specimen with

and shall have a tolerance of 60.01 in. (0.25 mm) on the

grout.

internal diameter. Molds will have top and bottom caps

1.2 The specimens are intended for both strength and

designed to prevent leakage of grout during pressure injection.

modulus determination in unconfined and confined compres-

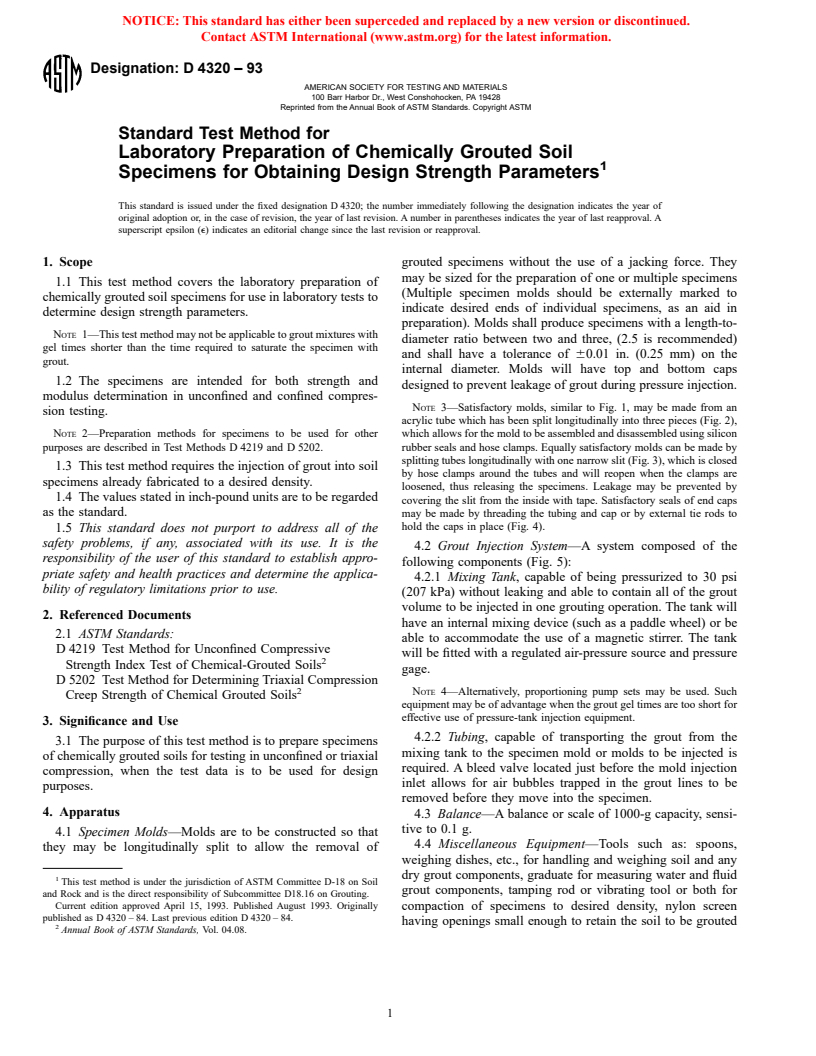

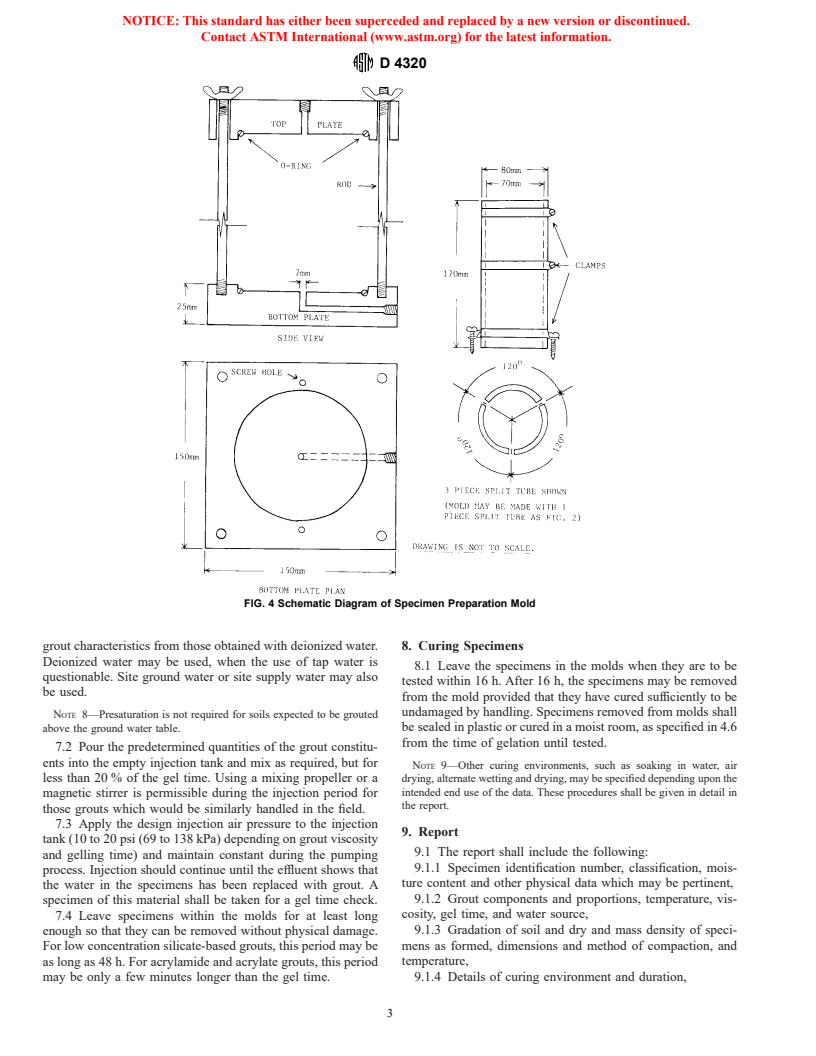

NOTE 3—Satisfactory molds, similar to Fig. 1, may be made from an

sion testing.

acrylic tube which has been split longitudinally into three pieces (Fig. 2),

NOTE 2—Preparation methods for specimens to be used for other which allows for the mold to be assembled and disassembled using silicon

purposes are described in Test Methods D 4219 and D 5202. rubber seals and hose clamps. Equally satisfactory molds can be made by

splitting tubes longitudinally with one narrow slit (Fig. 3), which is closed

1.3 This test method requires the injection of grout into soil

by hose clamps around the tubes and will reopen when the clamps are

specimens already fabricated to a desired density.

loosened, thus releasing the specimens. Leakage may be prevented by

1.4 The values stated in inch-pound units are to be regarded

covering the slit from the inside with tape. Satisfactory seals of end caps

as the standard. may be made by threading the tubing and cap or by external tie rods to

hold the caps in place (Fig. 4).

1.5 This standard does not purport to address all of the

safety problems, if any, associated with its use. It is the

4.2 Grout Injection System—A system composed of the

responsibility of the user of this standard to establish appro-

following components (Fig. 5):

priate safety and health practices and determine the applica-

4.2.1 Mixing Tank, capable of being pressurized to 30 psi

bility of regulatory limitations prior to use.

(207 kPa) without leaking and able to contain all of the grout

volume to be injected in one grouting operation. The tank will

2. Referenced Documents

have an internal mixing device (such as a paddle wheel) or be

2.1 ASTM Standards:

able to accommodate the use of a magnetic stirrer. The tank

D 4219 Test Method for Unconfined Compressive

will be fitted with a regulated air-pressure source and pressure

Strength Index Test of Chemical-Grouted Soils

gage.

D 5202 Test Method for Determining Triaxial Compression

2 NOTE 4—Alternatively, proportioning pump sets may be used. Such

Creep Strength of Chemical Grouted Soils

equipment may be of advantage when the grout gel times are too short for

effective use of pressure-tank injection equipment.

3. Significance and Use

4.2.2 Tubing, capable of transporting the grout from the

3.1 The purpose of this test method is to prepare specimens

mixing tank to the specimen mold or molds to be injected is

of chemically grouted soils for testing in unconfined or triaxial

required. A bleed valve located just before the mold injection

compression, when the test data is to be used for design

inlet allows for air bubbles trapped in the grout lines to be

purposes.

removed before they move into the specimen.

4. Apparatus

4.3 Balance—A balance or scale of 1000-g capacity, sensi-

tive to 0.1 g.

4.1 Specimen Molds—Molds are to be constructed so that

4.4 Miscellaneous Equipment—Tools such as: spoons,

they may be longitudinally split to allow the removal of

weighing dishes, etc., for handling and weighing soil and any

dry grout components, graduate for measuring water and fluid

This test method is under the jurisdiction of ASTM Committee D-18 on Soil

grout components, tamping rod or vibrating tool or both for

and Rock and is the direct responsibility of Subcommittee D18.16 on Grouting.

Current edition approved April 15, 1993. Published August 1993. Originally

compaction of specimens to desired density, nylon screen

published as D 4320 – 84. Last previous edition D 4320 – 84.

having openings small enough to retain the soil to be grouted

Annual Book of ASTM Standards, Vol. 04.08.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

D 4320

FIG. 3 Split tube multiple specimen mold

6.2 Formation of Soil Specimen—The mold to be used is

assembled (with the top cap removed) and held vertically in a

stable fashion while the soil sample is prepared using the

following procedure:

6.2.1 A small piece of screen made of inert material is

placed over the grout inlet at the bottom of the mold to retain

filter material.

NOTE 6—The term “inert” refers to a material which does not interact

in any way with the components of the specific grout being used.

6.2.2 The lower portion of the mold is filled with a layer

(approximately 0.5 to 1 in. (12.5 to 25.4 mm)) of coarse sand

or pea gravel to serve as a filter to disperse grout over the entire

area of the specimen.

6.2.3 Insert the leveling device and smooth the surface of

FIG. 1 Specimen Mold

the filter material perpendicular to the long axis of the mold.

Remove the leveling device and insert a piece of inert screen,

but otherwise as large as possible, and scissors for cutting.

having a diameter no more than 0.1 in. (2.5 mm) smaller than

4.5 Leveling Device—A leveling plate attached to a rod of

the inside of the mold. Position the screen flat on the filter

sufficient length such that the plate can be oriented perpendicu-

surface.

lar to

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.