ASTM A519-06

(Specification)Standard Specification for Seamless Carbon and Alloy Steel Mechanical Tubing

Standard Specification for Seamless Carbon and Alloy Steel Mechanical Tubing

ABSTRACT

This specification covers for several grades of carbon and alloy steel mechanical tubing, either hot-finished or cold-finished. The steel used in the mechanical tubing may be cast in ingots or may be strand cast. When steel of different grades is sequentially strand cast, identification of the resultant transition material is required. The seamless tubing is a tubular product made without a welded seam. It is usually manufactured by hot working steel, and if necessary, by subsequently cold finishing the hot-worked tubular product to produce the desired shape, dimensions and properties. The tubes shall be furnished in the following shapes: round, square, rectangular and special sections. Heat analysis shall be made to determine the percentages of the elements specified. If secondary melting processes are used, the heat analysis shall be obtained from one remelted ingot or the product of one remelted ingot of each primary melt. The tubing shall be coated with a film of oil before shaping to retard rust when specified

SCOPE

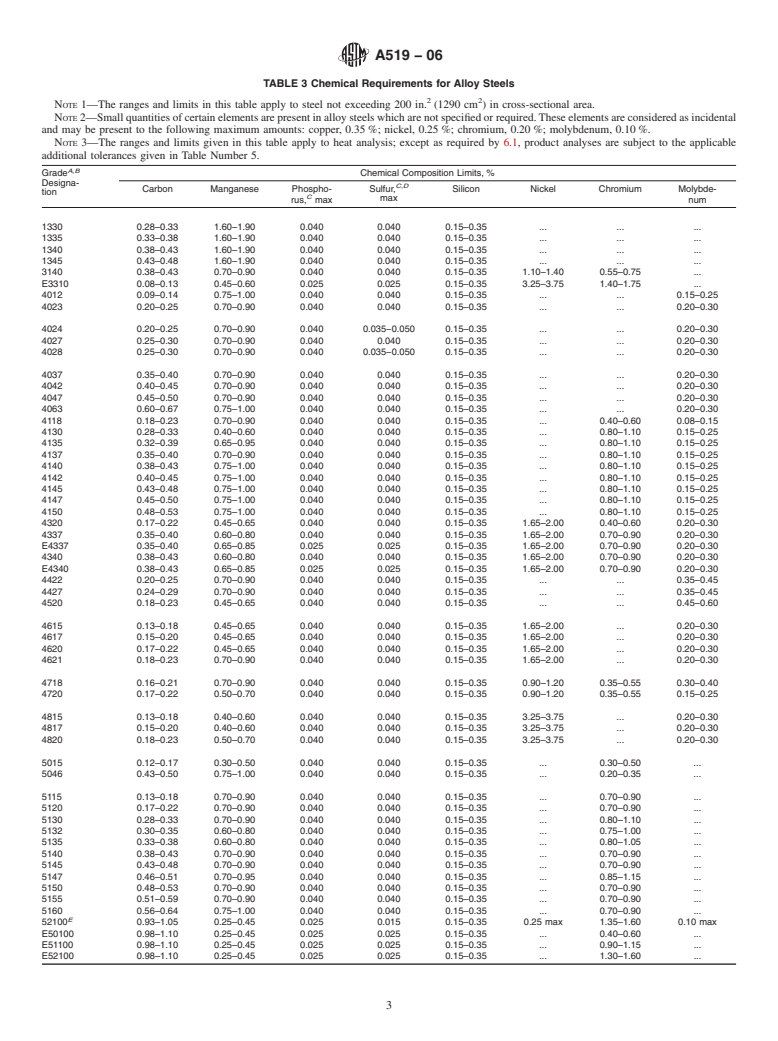

1.1 This specification covers several grades of carbon and alloy steel seamless mechanical tubing. The grades are listed in Tables 1-3. When welding is used for joining the weldable mechanical tube grades, the welding procedure shall be suitable for the grade, the condition of the components, and the intended service.

1.2 This specification covers both seamless hot-finished mechanical tubing and seamless cold-finished mechanical tubing in sizes up to and including 12 3/4 in. (323.8 mm) outside diameter for round tubes with wall thicknesses as required.

1.3 The tubes shall be furnished in the following shapes, as specified by the purchaser: round, square, rectangular, and special sections.

1.4 Supplementary requirements of an optional nature are provided and when desired shall be so stated in the order.

1.5 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information only.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:A519 −06

StandardSpecification for

1

Seamless Carbon and Alloy Steel Mechanical Tubing

This standard is issued under the fixed designation A519; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope* 2.2 Military Standards:

4

MIL-STD-129 Marking for Shipment and Storage

1.1 This specification covers several grades of carbon and

MIL-STD-163 Steel Mill Products Preparation for Shipment

alloysteelseamlessmechanicaltubing.Thegradesarelistedin

4

and Storage

Tables 1-3. When welding is used for joining the weldable

mechanical tube grades, the welding procedure shall be suit- 2.3 Federal Standard:

4

able for the grade, the condition of the components, and the Fed. Std. No. 123 Marking for Shipment (Civil Agencies)

intended service.

3. Ordering Information

1.2 This specification covers both seamless hot-finished

mechanical tubing and seamless cold-finished mechanical 3.1 Orders for material under this specification should

3

tubinginsizesuptoandincluding12 ⁄4in.(323.8mm)outside

include the following, as required, to describe the desired

diameter for round tubes with wall thicknesses as required. material adequately:

3.1.1 Quantity (feet, weight, or number of pieces),

1.3 The tubes shall be furnished in the following shapes, as

3.1.2 Name of material (seamless carbon or alloy steel

specified by the purchaser: round, square, rectangular, and

mechanical tubing),

special sections.

3.1.3 Form (round, square, rectangular or special shapes,

1.4 Supplementary requirements of an optional nature are

Section 1),

provided and when desired shall be so stated in the order.

3.1.4 Dimensions (round, outside diameters and wall

1.5 The values stated in inch-pound units are to be regarded thickness, Section 8; square and rectangular, outside dimen-

as the standard. The values given in parentheses are for sions and wall thickness, Section 9; other, specify),

information only. 3.1.5 Length (specific or random, mill lengths, see 8.5 and

9.5),

2. Referenced Documents 3.1.6 Manufacture (hot finished or cold finished, 4.5 and

2 4.6),

2.1 ASTM Standards:

3.1.7 Grade (Section 5),

A370 Test Methods and Definitions for Mechanical Testing

3.1.8 Condition (sizing method and thermal treatment, Sec-

of Steel Products

tion 12),

A1040 Guide for Specifying Harmonized Standard Grade

3.1.9 Surface finish (special pickling, shot blasting, or

Compositions for Wrought Carbon, Low-Alloy, andAlloy

ground outside surface, if required),

Steels

3.1.10 Specification designation,

E59 Practice for Sampling Steel and Iron for Determination

3

3.1.11 Individual supplementary requirements, if required,

of Chemical Composition

3.1.12 End use, if known,

3.1.13 Packaging,

3.1.14 Product analysis and chemical analysis, if required

1

This specification is under the jurisdiction ofASTM Committee A01 on Steel,

(Section 6 and Section 7),

Stainless Steel and Related Alloys and is the direct responsibility of Subcommittee

3.1.15 Specific requirements, or exceptions to this

A01.09 on Carbon Steel Tubular Products.

Current edition approved Oct. 1, 2006. Published October 2006. Originally

specification,

approved in 1964. Last previous edition approved in 2003 as A519 – 03. DOI:

3.1.16 Special marking (Section 15), and

10.1520/A0519-06.

3.1.17 Special packing (Section 16).

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

3 4

Withdrawn. The last approved version of this historical standard is referenced AvailablefromStandardizationDocumentsOrderDesk,Bldg.4SectionD,700

on www.astm.org. Robbins Ave., Philadelphia, PA 19111-5094, Attn: NPODS.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

A519−06

TABLE 1 Chemical Requirements of Low-Carbon Steels

and, if necessary, by subsequently cold finishing the hot-

Grade Chemical Composition Limits, % worked tubular product to produce the desired shape, dimen-

Designation

A B B B

Carbon Manganese Phosphorus, Sulfur, sions and properties.

max max

5. Chemical Composition

MT 1010 0.05–0.15 0.30–0.60 0.040 0.050

MT 1015 0.10–0.20 0.30–0.60 0.040 0.050

5.1 The steel shall conform to the requirements as to

MT X 1015 0.10–0.20 0.60–0.90 0.040 0.050

chemical composition prescribed i

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.