ASTM C1629/C1629M-06(2011)

(Classification)Standard Classification for Abuse-Resistant Nondecorated Interior Gypsum Panel Products and Fiber-Reinforced Cement Panels

Standard Classification for Abuse-Resistant Nondecorated Interior Gypsum Panel Products and Fiber-Reinforced Cement Panels

SIGNIFICANCE AND USE

Each abuse/impact property of abuse resistant wall panels is divided into three classification levels. The three levels of classification are: Level I, Level II, and Level III, with Level I representing the lowest rating for any given property. The test methods specified are utilized to establish the abuse-resistance classification of an abuse resistant wall panel. Each classification level requires a minimum overall specified performance. Any classified abuse resistant wall panel can be used at a classification level which is rated lower than the highest level qualified.

SCOPE

1.1 This standard establishes classifications of abuse resistance based on minimum abuse-resistance performance of nondecorated interior gypsum panel products and fiber-reinforced cement panels (abuse resistant wall panels).

1.2 The values stated in inch-pound and SI (metric) units are to be regarded separately as standard. Within the text, the SI units are shown in brackets. The values stated in each system shall be used independent of the other. Values from the two systems shall not be combined.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:C1629/C1629M −06(Reapproved 2011)

Standard Classification for

Abuse-Resistant Nondecorated Interior Gypsum Panel

Products and Fiber-Reinforced Cement Panels

This standard is issued under the fixed designation C1629/C1629M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* 3. Terminology

1.1 This standard establishes classifications of abuse resis-

3.1 Definitions of terms shall be in accordance with Termi-

tance based on minimum abuse-resistance performance of

nologies C11 and C1154.

nondecorated interior gypsum panel products and fiber-

3.2 Definitions of Terms Specific to This Standard:

reinforced cement panels (abuse resistant wall panels).

3.2.1 failure (hard body impact), n—test result constituted

1.2 Thevaluesstatedininch-poundandSI(metric)unitsare

either by the penetration of the wall cavity by the impacting

to be regarded separately as standard. Within the text, the SI

head of the impacting arm or the denting of the panel resulting

units are shown in brackets. The values stated in each system

in an indentation of a depth that exceeds the thickness of the

shall be used independent of the other. Values from the two

test panel.

systems shall not be combined.

3.2.1.1 Discussion—Depth of the indentation on the test

panel is measured from the face side.

1.3 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

3.2.2 failure (soft body impact), n—a test result constituted

responsibility of the user of this standard to establish appro-

either by the breaking of the wall cavity by the soft body

priate safety and health practices and determine the applica-

impactor or the residual deflection of any area on the test panel

bility of regulatory limitations prior to use.

that exceeds the thickness of the test panel.

3.2.2.1 Discussion—Deformation of the test panel in the

2. Referenced Documents

form of residual deflection is measured from the face side.

2.1 ASTM Standards:

3.2.2.1 deformation, n—change of shape or dimension or

C11 Terminology Relating to Gypsum and Related Building

both. ISO 6707-1

Materials and Systems

3.2.2.2 surface damage, n—pulverization of the core of the

C1154 Terminology for Non-Asbestos Fiber-Reinforced Ce-

test panel at the point of impact, which is evidenced by

ment Products

cracking, creasing, or other visible damage short of failure as

D4977 Test Method for Granule Adhesion to Mineral Sur-

defined in 3.2.2.

faced Roofing by Abrasion

D5420 Test Method for Impact Resistance of Flat, Rigid

3.2.3 residual deflection, n—permanent deformation of a

Plastic Specimen by Means of a Striker Impacted by a

building element, component, or structure after removal of

Falling Weight (Gardner Impact)

applied force.

E695 Test Method of Measuring Relative Resistance of

3.2.3.1 Discussion—Also called permanent set or residual

Wall, Floor, and Roof Construction to Impact Loading

deformation.

2.2 ISO Documents:

ISO 6707-1 Building and Civil Engineering -- Vocabulary --

4. Significance and Use

Part 1: General Terms

4.1 Each abuse/impact property of abuse resistant wall

panels is divided into three classification levels. The three

This classification is under the jurisdiction of ASTM Committee C11 on

levelsofclassificationare:LevelI,LevelII,andLevelIII,with

Gypsum and Related Building Materials and Systems and is the direct responsibility

Level I representing the lowest rating for any given property.

of Subcommittee C11.01 on Specifications and Test Methods for Gypsum Products.

The test methods specified are utilized to establish the abuse-

Current edition approved June 15, 2011. Published July 2011. Originally

resistance classification of an abuse resistant wall panel. Each

approved in 2005. Last previous edition approved in 2006 as C1629/C1629M – 06.

DOI: 10.1520/C1629_C1629M-06R11.

classification level requires a minimum overall specified per-

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

formance.Any classified abuse resistant wall panel can be used

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

at a classification level which is rated lower than the highest

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. level qualified.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

C1629/C1629M−06 (2011)

TABLE 2 Performance Requirements

5. Basis of Classification

Indentation Resistance

5.1 Abuse resistant wall panels are classified into one of

Indentation

Classification

three levels of abuse resistance based on minimum perfor-

Maximum

Level

in. [mm]

mance when tested in accordance with test methods that

evaluate surface abrasion, indentation, soft body impact, and 1 0.150 [3.8]

2 0.100 [2.5]

hard body impact as specified in 6.1 through 6.4.

3 0.050 [1.3]

5.2 Minimum requirements for each level are as shown in

Tables 1-4.

TABLE 3 Performance Requirements

6. Test Methods Soft Body Impact Test

Soft Body

6.1 Surface Abrasion Test—This test is conducted in accor-

Classification

Minimum

Level

dance with Test Method D4977 using a total load of 25.0 lb.

ft-lbf [J]

The specimen is conditioned to constant weight at 70F and

1 90 [122]

50 % relative humidity and subjected to 50 abrasion cycles. 2 195 [265]

3 300 [408]

The abrasive motion on the specimen creates measurable

surfacewearorindentationwhichismeasuredtodeterminethe

level of surface abrasion resistance.

TABLE 4 Performance Requirements

NOTE 1—It is especially important to prepare the apparatus and

Hard Body Impact

condition the brush as specified in Test Method D4977.

Hard Body

Classification

6.2 Indentation Test—This test, conducted in accordance

Minimum

Level

with Test Method D5420 (Gardner Impact), utilizes procedure ft-lbf [J]

GC, with a ⁄8 in. hemispherical head and a 72 in.-lb. [12.6 J] 1 50 [68]

2 100 [136]

impact energy. The depth of the indentation is measured to

3 150 [204]

determine the level of indentation resistance.

6.3 Soft Body Impact Test—This test, conducted in accor-

dance with Method E695, is performed with the use of the

standard leather bag filled with steel pellets to a weight of 60.0

6.3.3 Following structural failure in the initial cavity, the

lb [27.2 kg] and dropped through an angular distance until the

procedure described in 6.3.2 is repeated on the next cavity,

specimen is impacted.

beginning with a drop height of 6 in. higher than the drop

6.3.1 The specimen is mounted on nominal 2-by-4 wood

height causing structural failure in 6.3.2.

studs 16 in. [400 mm] o.c. Point of impact is midway between

6.3.3.1 If structural failure in the second cavity occurs with

studs at the mid-height of the test panel.

the first drop, the test is terminated and the level of energy

6.3.2 A single specimen is repeatedly impacted at a single

required to cause the single impact penetration or excessive

point of impact in one cavity with the drop height being

deformation is calculated to determine the soft body impact

increased by 6 in. with each successive drop until structural

resistance.

failure as defined in 3.2.2 is achieved.

6.3.3.2 If structural failure in the second cavity occurs on

6.3.2.1 Surface damage and deformation are recorded fol-

the second or subsequent drop, repeat the procedure described

lowing each impact, and the level of impact energy applied is

in 6.3.3 in the next cavity, beginning with a drop height 6 in.

calculated. The residual deflection shall be measured from the

higher than the drop height causing structural failure in the

face side of the panel.

second cavity.

NOTE 2—Surface damage and deformation, which do not constitute

6.3.4 Repeat the procedures in 6.3.2 through 6.3.3.2 until

structural failure, may compound the results.

structural failure occurs on a single drop in a fresh cavity, at

which time the test is terminated and the level of energy

TABLE 1 Performance Requirements

required to cause the single impact penetration or excessive

Surface Abrasion Resistance

deformation is calculated to determine the soft body impact

Abraded Depth

Classification resistance.

Maximum

Level

in. [mm]

6.4 Hard Body Impact Test—This test is conducted in

1 0.126 [3.2]

accordance with the method described in Annex A1 or with

2 0.059 [1.5]

another apparatus equipped with an equivalent impact head

3 0.010 [0.3]

that is capable of delivering equivalent impact loads.

C1629/C1629M−06 (2011)

ANNEX

(Mandatory Information)

A1. HARD BODY IMPACT TEST

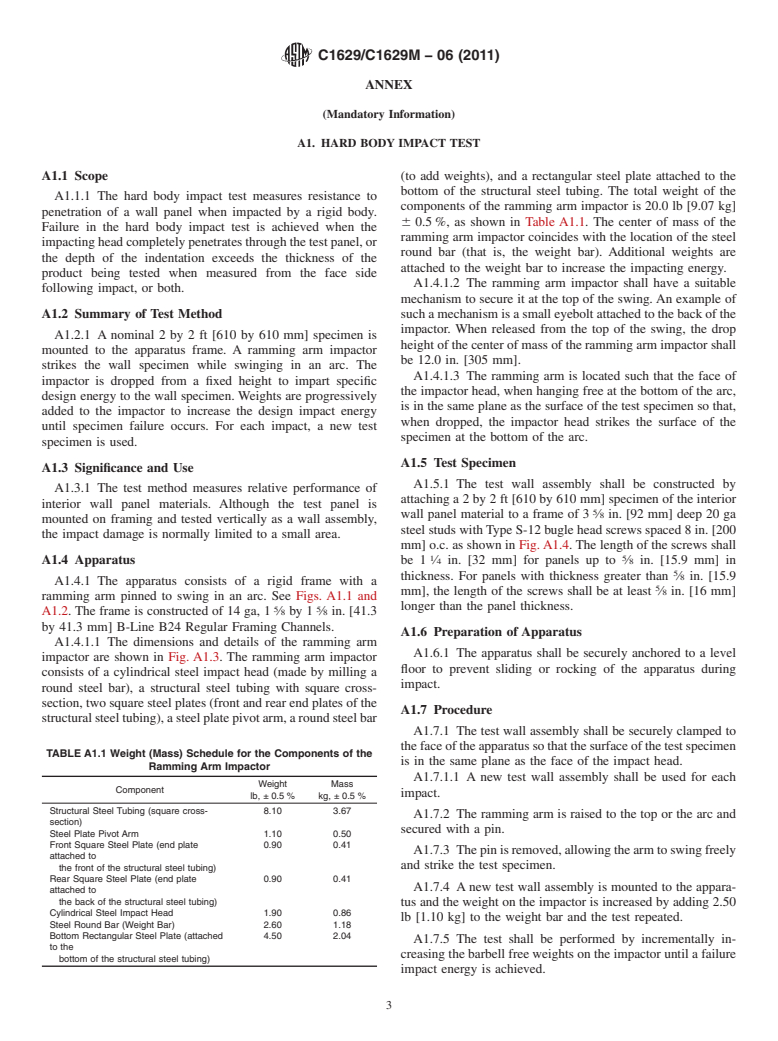

A1.1 Scope (to add weights), and a rectangular steel plate attached to the

bottom of the structural steel tubing. The total weight of the

A1.1.1 The hard body impact test measures resistance to

components of the ramming arm impactor is 20.0 lb [9.07 kg]

penetration of a wall panel when impacted b

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.