ASTM F746-04(2021)

(Test Method)Standard Test Method for Pitting or Crevice Corrosion of Metallic Surgical Implant Materials

Standard Test Method for Pitting or Crevice Corrosion of Metallic Surgical Implant Materials

SIGNIFICANCE AND USE

4.1 This test method is designed solely for determining comparative laboratory indices of performance. The results may be used for ranking alloys in order of increasing resistance to pitting and crevice corrosion under the specific conditions of this method. It should be noted that the method is intentionally designed to reach conditions that are sufficiently severe to cause breakdown of at least one alloy (Type 316 L stainless steel) currently considered acceptable for surgical implant use, and that those alloys which suffer pitting or crevice corrosion during the more severe portions of the test do not necessarily suffer localized corrosion when placed within the human body as a surgical implant.

SCOPE

1.1 This test method covers the determination of resistance to either pitting or crevice corrosion of metals and alloys from which surgical implants will be produced. It is a modified version of an established test2 and is used as a screening test to rank surgical implant alloys in order of their resistance to localized corrosion.

1.2 This test method applies only to passive metals and alloys. Nonpassive alloys (other than noble alloys) are susceptible to general corrosion and are not normally suitable for implant use.

1.3 This test method is intended for use as a laboratory screening test for metals and alloys which undergo pitting or crevice corrosion, or both.

1.4 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in nonconformance with the standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: F746 − 04 (Reapproved 2021)

Standard Test Method for

Pitting or Crevice Corrosion of Metallic Surgical Implant

1

Materials

ThisstandardisissuedunderthefixeddesignationF746;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginal

adoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

3

2.1 ASTM Standards:

1.1 This test method covers the determination of resistance

D1193Specification for Reagent Water

to either pitting or crevice corrosion of metals and alloys from

F86Practice for Surface Preparation and Marking of Metal-

which surgical implants will be produced. It is a modified

2 lic Surgical Implants

versionofanestablishedtest andisusedasascreeningtestto

F2129Test Method for Conducting Cyclic Potentiodynamic

rank surgical implant alloys in order of their resistance to

Polarization Measurements to Determine the Corrosion

localized corrosion.

Susceptibility of Small Implant Devices

1.2 This test method applies only to passive metals and G3Practice for Conventions Applicable to Electrochemical

Measurements in Corrosion Testing

alloys. Nonpassive alloys (other than noble alloys) are suscep-

G5Reference Test Method for Making Potentiodynamic

tible to general corrosion and are not normally suitable for

Anodic Polarization Measurements

implant use.

G15TerminologyRelatingtoCorrosionandCorrosionTest-

4

1.3 This test method is intended for use as a laboratory

ing (Withdrawn 2010)

screening test for metals and alloys which undergo pitting or

crevice corrosion, or both. 3. Summary of Test Method

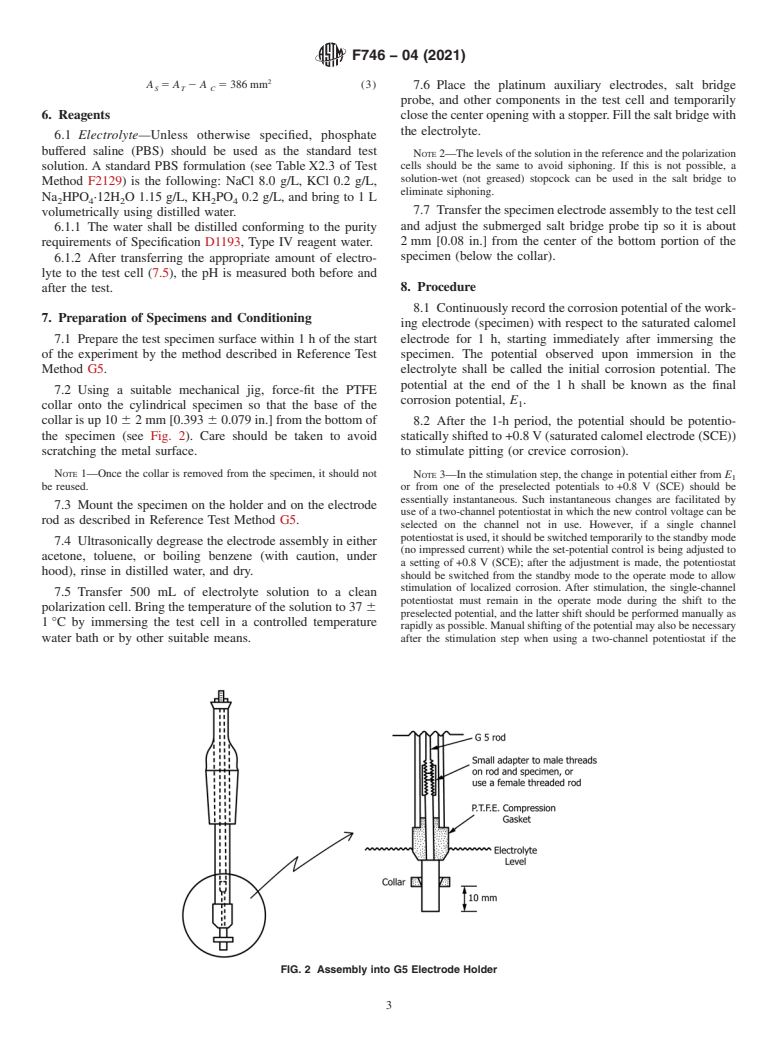

3.1 Acylindricalspecimenfittedwithaninerttaperedcollar

1.4 The values stated in either SI units or inch-pound units

is immersed in a phosphate buffered saline electrolyte at 37°C

are to be regarded separately as standard. The values stated in

for1hto establish a corrosion potential. Pitting (or crevice

each system may not be exact equivalents; therefore, each

corrosion) is then stimulated by potentiostatically polarizing

system shall be used independently of the other. Combining

thespecimentoapotentialmuchmorenoblethanthecorrosion

values from the two systems may result in nonconformance

potential. Stimulation of pitting (or crevice corrosion) will be

with the standard.

marked by a large and generally increasing polarizing current.

1.5 This standard does not purport to address all of the

3.2 Immediately after the stimulation step, the potential is

safety concerns, if any, associated with its use. It is the

decreased as rapidly as possible to one of several preselected

responsibility of the user of this standard to establish appro-

potentials at, or more noble than, the corrosion potential. If the

priate safety, health, and environmental practices and deter-

alloy is susceptible to pitting (or crevice corrosion) at the

mine the applicability of regulatory limitations prior to use.

preselected potential, the polarizing current will remain at

1.6 This international standard was developed in accor-

relatively high values and will fluctuate or increase with time.

dance with internationally recognized principles on standard-

A post-test examination of the metal specimen establishes

ization established in the Decision on Principles for the

whether localized corrosion has occurred by pitting of the

Development of International Standards, Guides and Recom-

exposed surface or by preferential attack at the crevice formed

mendations issued by the World Trade Organization Technical by the tapered collar, or both.

Barriers to Trade (TBT) Committee.

3.3 If the pit (or crevice) surface repassivates at the prese-

lectedpotentialandlocalizedcorrosionishalted,thepolarizing

1

ThistestmethodisunderthejurisdictionofASTMCommitteeF04onMedical

3

andSurgicalMaterialsandDevicesandisthedirectresponsibilityofSubcommittee For referenced ASTM standards, visit the ASTM website, www.astm.org, or

F04.15 on Material Test Methods. contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Current edition approved Aug. 1, 2021. Published August 2021. Originally Standards volume information, refer to the standard’s Document Summary page on

approved in 1981. Last previous edition approved in 2014 as F746–04 (2014). the ASTM website.

4

DOI: 10.1520/F0746-04R21. The last approved version of this historical standard is referenced on

2

Syrett, B. C., Corrosion, Vol 33, 1977, p. 221. www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.