ASTM D1632-06

(Practice)Standard Practice for Making and Curing Soil-Cement Compression and Flexure Test Specimens in the Laboratory

Standard Practice for Making and Curing Soil-Cement Compression and Flexure Test Specimens in the Laboratory

SIGNIFICANCE AND USE

This practice is used to prepare soil-cement specimens for compressive and flexural strength testing in accordance with Method B of Test Method D 1633, Test Method D 1634, and Test Method D 1635.

This practice does not apply to soil-cement specimens prepared in commonly available molds, which are 4.0 in. (101.6 mm) in diameter and 4.584 in. (116.4 mm) in height. For these size specimens, Methods D 559 or Methods D 560 should be used for sample preparation. Compressive strength testing should be in accordance with Method A of Test Method D 1633.

SCOPE

1.1 This practice covers the procedure for making and curing compression and flexure test specimens of soil-cement in the laboratory under accurate control of quantities of materials and test conditions.

1.2 This practice offers a set of instructions for performing one or more specific operations. This document cannot replace education or experience and should be used in conjunction with professional judgment. Not all aspects of this practice may be applicable in all circumstances. This ASTM standard is not intended to represent or replace the standard of care by which the adequacy of a given professional service must be judged, nor should this document be applied without consideration of a project's many unique aspects. The word "Standard" in the title of this document means only that the document has been approved through the ASTM consensus process.

This standard may involve hazardous materials, operations, and equipment. This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D 1632 – 06

Standard Practice for

Making and Curing Soil-Cement Compression and Flexure

1

Test Specimens in the Laboratory

This standard is issued under the fixed designation D1632; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope D560 Test Methods for Freezing and Thawing Compacted

Soil-Cement Mixtures

1.1 This practice covers the procedure for making and

D1633 Test Method for Compressive Strength of Molded

curing compression and flexure test specimens of soil-cement

Soil-Cement Cylinders

in the laboratory under accurate control of quantities of

D1634 Test Method for Compressive Strength of Soil-

materials and test conditions.

Cement Using Portions of Beams Broken in Flexure

1.2 This practice offers a set of instructions for performing

(Modified Cube Method)

one or more specific operations. This document cannot replace

D1635 Test Method for Flexural Strength of Soil-Cement

education or experience and should be used in conjunction

Using Simple Beam with Third-Point Loading

with professional judgment. Not all aspects of this practice may

D4753 Guide for Evaluating, Selecting, and Specifying

be applicable in all circumstances. This ASTM standard is not

Balances and Standard Masses for Use in Soil, Rock, and

intended to represent or replace the standard of care by which

Construction Materials Testing

the adequacy of a given professional service must be judged,

E11 Specification for Wire Cloth and Sieves for Testing

nor should this document be applied without consideration of

Purposes

a project’s many unique aspects. The word “Standard” in the

title of this document means only that the document has been

3. Significance and Use

approved through the ASTM consensus process.

3.1 This practice is used to prepare soil-cement specimens

1.3 This standard may involve hazardous materials, opera-

for compressive and flexural strength testing in accordance

tions, and equipment. This standard does not purport to

with Method B of Test Method D1633, Test Method D1634,

address all of the safety concerns, if any, associated with its

and Test Method D1635.

use. It is the responsibility of the user of this standard to

3.2 This practice does not apply to soil-cement specimens

establish appropriate safety and health practices and deter-

prepared in commonly available molds, which are 4.0 in.

mine the applicability of regulatory limitations prior to use.

(101.6 mm) in diameter and 4.584 in. (116.4 mm) in height.

2. Referenced Documents For these size specimens, Methods D559 or Methods D560

2

should be used for sample preparation. Compressive strength

2.1 ASTM Standards:

testingshouldbeinaccordancewithMethodAofTestMethod

C127 Test Method for Density, Relative Density (Specific

D1633.

Gravity), and Absorption of Coarse Aggregate

D558 Test Methods for Moisture-Density (Unit Weight)

4. Apparatus

Relations of Soil-Cement Mixtures

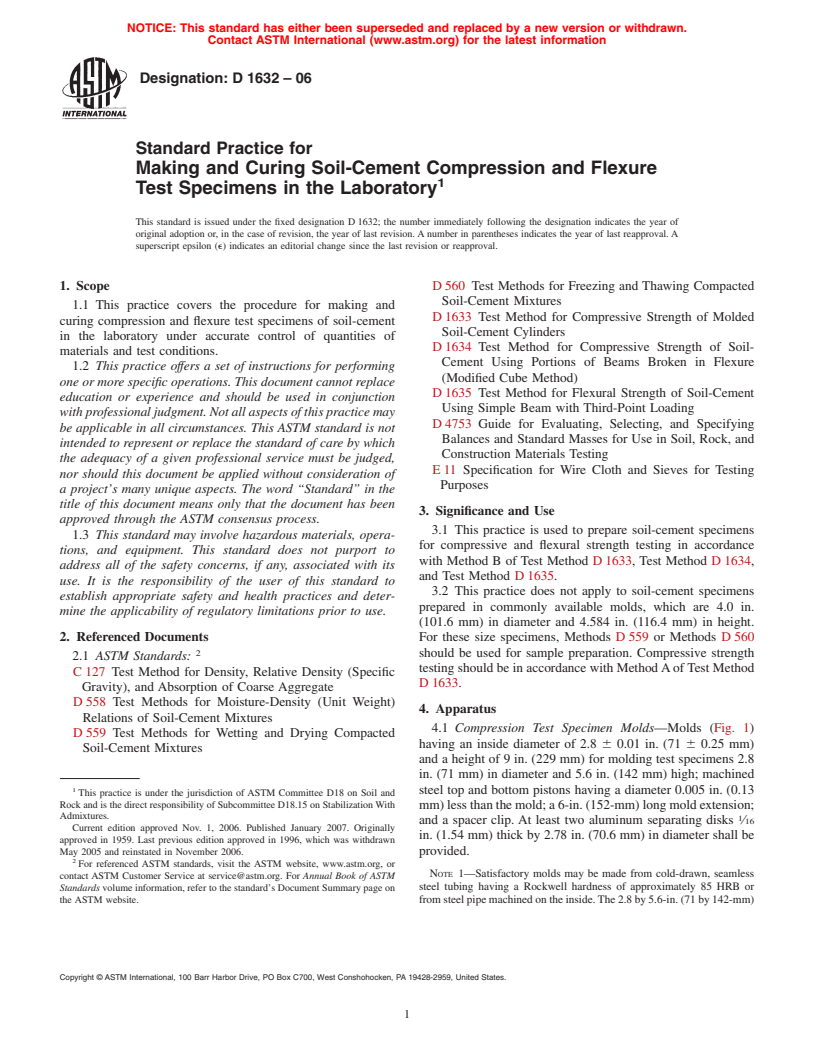

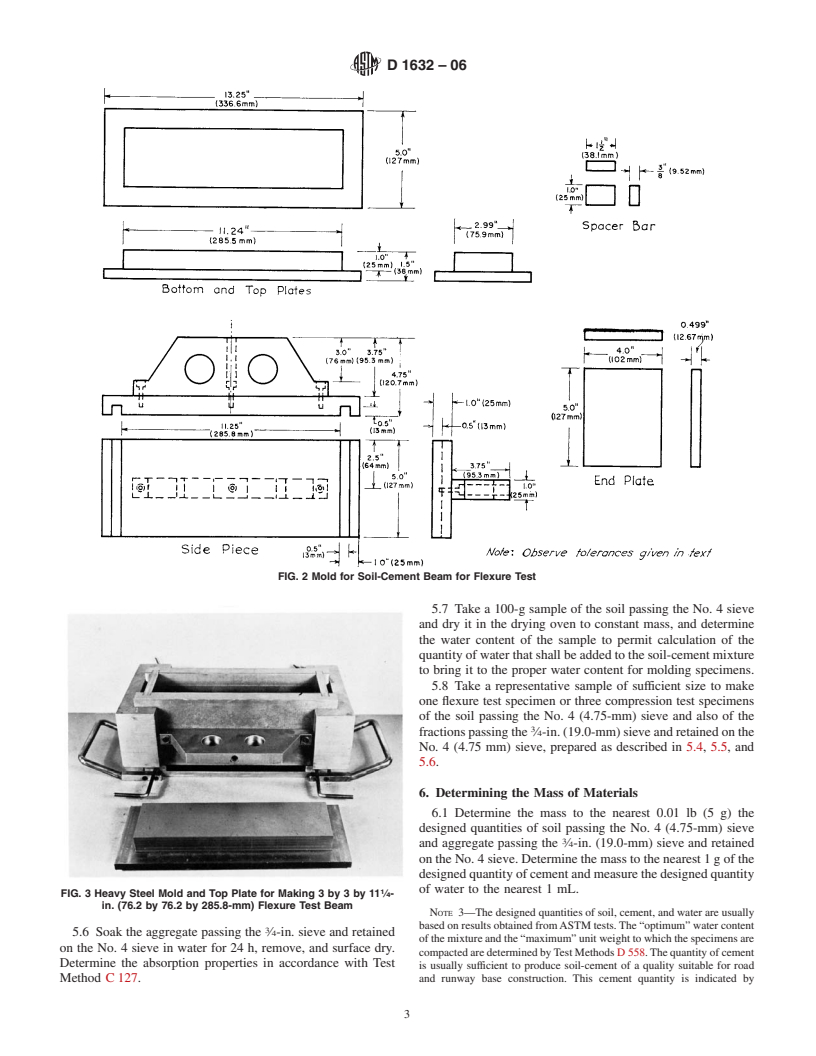

4.1 Compression Test Specimen Molds—Molds (Fig. 1)

D559 Test Methods for Wetting and Drying Compacted

having an inside diameter of 2.8 6 0.01 in. (71 6 0.25 mm)

Soil-Cement Mixtures

and a height of 9 in. (229 mm) for molding test specimens 2.8

in. (71 mm) in diameter and 5.6 in. (142 mm) high; machined

1

steel top and bottom pistons having a diameter 0.005 in. (0.13

This practice is under the jurisdiction of ASTM Committee D18 on Soil and

Rock and is the direct responsibility of Subcommittee D18.15 on StabilizationWith

mm)lessthanthemold;a6-in.(152-mm)longmoldextension;

Admixtures.

1

and a spacer clip. At least two aluminum separating disks ⁄16

Current edition approved Nov. 1, 2006. Published January 2007. Originally

in. (1.54 mm) thick by 2.78 in. (70.6 mm) in diameter shall be

approved in 1959. Last previous edition approved in 1996, which was withdrawn

May 2005 and reinstated in November 2006. provided.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

NOTE 1—Satisfactory molds may be made from cold-drawn, seamless

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

steel tubing having a Rockwell hardness of approximately 85 HRB or

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. fromsteelpipemachinedontheinside.The2.8by5.6-in.(71by142-mm)

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D1632–06

4.4 Balances—Abalance or scale of 25-lb (12-kg) capacity,

sensitive to 0.01 lb (0.0045 kg) and a balance of 1000-g

capacity, sensitive to 0.1 g, both meeting the requirements of

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.