ASTM B62-09

(Specification)Standard Specification for Composition Bronze or Ounce Metal Castings

Standard Specification for Composition Bronze or Ounce Metal Castings

ABSTRACT

This specification establishes requirements for an alloy having a composition of copper, tin, lead, and zinc which is used for component castings of valves, flanges, and fittings. The specimen shall have the chemical composition of major elements: copper, tin, lead zinc, nickel including cobalt. It must also be comprised of the following residual elements: iron, antimony, sulfur, phosphorus, aluminum, and silicon. Mechanical properties shall be determined from separately cast test bars. Castings shall not be repaired, plugged, welded or burned-in. Valves, flanges, and fittings shall be marked accordingly in such position as not to injure the usefulness of the casting.

SCOPE

1.1 This specification establishes requirements for an alloy having a composition of copper, tin, lead, and zinc, used for component castings of valves, flanges, and fittings. The common trade name of this alloy is 85-5-5-5; the correct identification is Copper Alloy UNS No. C83600.

1.2 The castings covered are used in products that may be manufactured in advance and supplied from stock from the manufacturer or other dealer.

1.3 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:B62 −09

StandardSpecification for

1

Composition Bronze or Ounce Metal Castings

This standard is issued under the fixed designation B62; the number immediately following the designation indicates the year of original

adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.Asuperscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope* 3. General Requirements

2

3.1 The following sections of Specification B824 form a

1.1 This specification establishes requirements for an alloy

part of this specification. In the event of a conflict between this

having a composition of copper, tin, lead, and zinc, used for

specification and Specification B824, the requirements of this

component castings of valves, flanges, and fittings. The com-

specification shall take precedence.

mon trade name of this alloy is 85-5-5-5; the correct identifi-

3

3.1.1 Terminology (Section 3),

cation is Copper Alloy UNS No. C83600.

3.1.2 Other Requirements (Section 7),

1.2 The castings covered are used in products that may be

3.1.3 Dimensions, Mass, and Permissible Variations (Sec-

manufactured in advance and supplied from stock from the

tion 8),

manufacturer or other dealer.

3.1.4 Workmanship, Finish, and Appearance (Section 9),

3.1.5 Sampling (Section 10),

1.3 The values stated in inch-pound units are to be regarded

3.1.6 Number of Tests and Retests (Sections 11 and 13),

as standard. The values given in parentheses are mathematical

3.1.7 Specimen Preparation (Section 12),

conversions to SI units that are provided for information only

3.1.8 Test Methods (Section 13),

and are not considered standard.

3.1.9 Significance of Numerical Limits (Section 14),

3.1.10 Inspection (Section 15),

2. Referenced Documents

3.1.11 Rejection and Rehearing (Section 16),

4

2.1 ASTM Standards:

3.1.12 Certification (Section 17),

B208 Practice for Preparing Tension Test Specimens for

3.1.13 Test Report (Section 18),

Copper Alloy Sand, Permanent Mold, Centrifugal, and

3.1.14 Product Marking (Section 19), and

Continuous Castings

3.1.15 Packaging and Package Marking (Section 20)

B824 Specification for General Requirements for Copper

Alloy Castings 4. Terminology

E527 Practice for Numbering Metals and Alloys in the

4.1 For definitions of terms relating to copper and copper

Unified Numbering System (UNS)

alloys, refer to Terminology B846.

2.2 MSS Standards:

SP-25 Standard Marking System for Valves, Fittings, 5. Ordering Information

5

Flanges and Unions

5.1 Include the following information when placing orders

for castings under this specification:

5.1.1 Quantity of castings required,

1

This practice is under the jurisdiction ofASTM Committee B05 on Copper and 5.1.2 Copper Alloy UNS No. (Table 1),

CopperAlloys and is the direct responsibility of Subcommittee B05.05 on Castings

5.1.3 Specification title, number, and year of issue,

and Ingots for Remelting.

5.1.4 Pattern or drawing number and condition (as-cast,

Current edition approved April 1, 2009. Published May 2009. Originally

machined),

approvedin1926.DiscontinuedJune2002andreinstatedasB62 – 02.Lastprevious

edition approved in 2002 as B62 – 02. DOI: 10.1520/B0062-09.

5.1.5 Chemical analysis of residual elements, if specified in

2

For ASME Boiler and Pressure Vessel Code applications see related Specifi-

the purchase order (Specification B824),

cation SB-61 of that Code.

5.1.6 Pressure test requirements, if specified in the purchase

3

The UNS system for copper and copper alloys (see Practice E527) is a simple

order (Specification B824),

expansion of the former standard designation system accomplished by the addition

of a prefix “C” and a suffix “00”. The suffix can be used to accommodate

5.1.7 Soundness requirements, if specified in the purchase

composition variations of the base alloy.

order (Specification B824),

4

Annual Book of ASTM Standards, Vol 02.01.

5

5.1.8 Certification, if specified in the purchase order (Speci-

AvailablefromManufacturersStandardizationSocietyoftheValveandFittings

Industry, 127 Park Street NE, Vienna, VA 22180-4602. fication B824),

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

B62−09

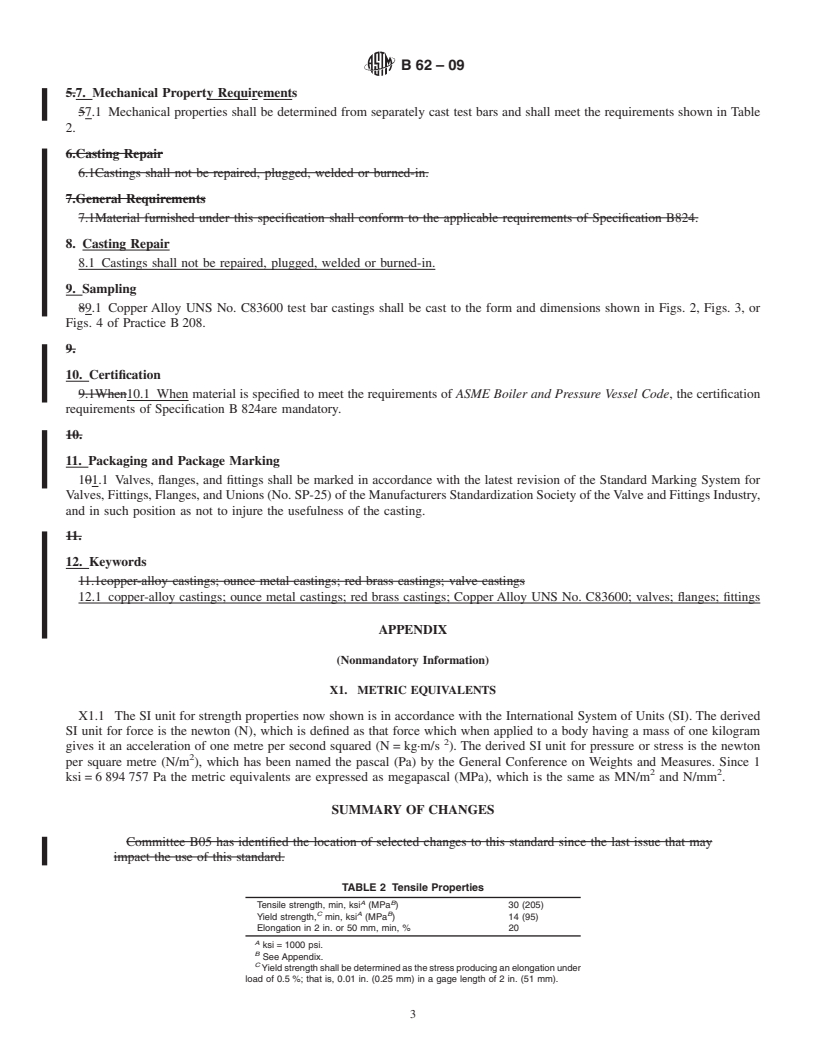

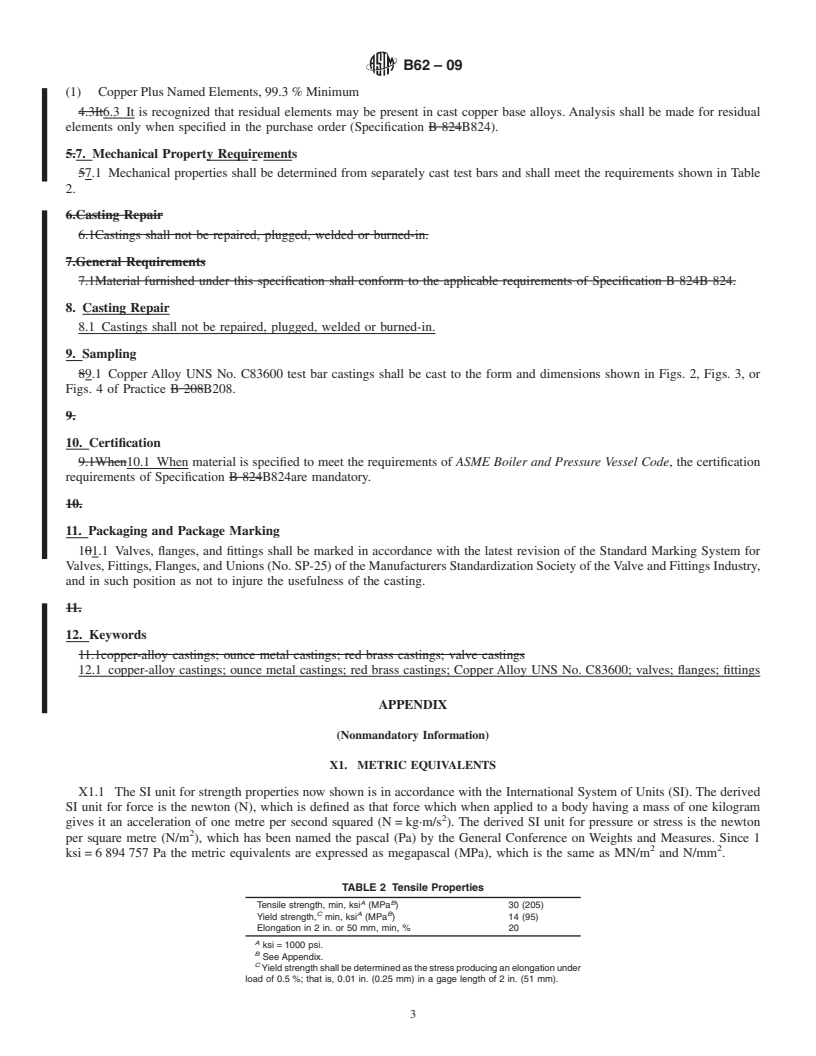

TABLE 1 Chemical Requirements Copper Alloy UNS No. C83600

6.3 It is recognized that residual elements may be present in

Composition, % max cast copper base alloys. Analysis shall be made for residual

Major Elements

(Except as Indicated)

elements only when specified in the purchase order (Specifi-

Copper 84.0–86.0

cation B824).

Tin 4.0–6.0

Lead 4.0–6.0

7. Mechanical Property Requirements

Zinc 4.0

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:B62–02 Designation: B 62 – 09

Standard Specification for

1

Composition Bronze or Ounce Metal Castings

ThisstandardisissuedunderthefixeddesignationB 62;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginal

adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.Asuperscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope*

1.1This specification

2

1.1 This specification establishes requirements for an alloy having a composition of copper, tin, lead, and zinc, used for

component castings of valves, flanges, and fittings. The common trade name of this alloy is 85-5-5-5; the correct identification is

3

Copper Alloy UNS No. C83600.

1.2 The castings covered are used in products that may be manufactured in advance and supplied from stock from the

manufacturer or other dealer.

1.3The values stated in inch-pound units are to be regarded as the standard. Metric values given in parentheses are for

information only.

1.3 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

2. Referenced Documents

2.1The following documents of the issue in effect on date of material purchase form a part of this specification to the extent

referenced herein:

2.2

4

2.1 ASTM Standards:

B 208 Practice for Preparing Tension Test Specimens for Copper-Base Alloys for Copper Alloy Sand, Permanent Mold,

Centrifugal, and Continuous Castings

B 824 Specification for General Requirements for Copper- Alloy Castings

E 527 Practice for Numbering Metals and Alloys

2.3 Practice for Numbering Metals and Alloys in the Unified Numbering System (UNS)

2.2 MSS Standards:

5

SP-25 Standard Marking System for Valves, Fittings, Flanges and Unions

3. General Requirements

3.1 The following sections of Specification B 824 form a part of this specification. In the event of a conflict between this

specification and Specification B 824, the requirements of this specification shall take precedence.

3.1.1 Terminology (Section 3),

3.1.2 Other Requirements (Section 7),

3.1.3 Dimensions, Mass, and Permissible Variations (Section 8),

3.1.4 Workmanship, Finish, and Appearance (Section 9),

3.1.5 Sampling (Section 10),

3.1.6 Number of Tests and Retests (Sections 11 and 13),

3.1.7 Specimen Preparation (Section 12),

1

This practice is under the jurisdiction ofASTM Committee B05 on Copper and CopperAlloys and is the direct responsibility of Subcommittee B05.05 on Castings and

Ingots for Remelting.

Current edition approved Dec. 10, 2002.April 1, 2009. Published February 2003.May 2009. Originally approved in 1926. Discontinued June 2002 and reinstated as

B 62 – 02. Last previous edition approved in 19932002 as B62–93.B 62 – 02.

2

For ASME Boiler and Pressure Vessel Code applications see related Specification SB-61 of that Code.

3

The UNS system for copper and copper alloys (see Practice E 527) is a simple expansion of the former standard designation system accomplished by the addition of

a prefix “C” and a suffix “00”. The suffix can be used to accommodate composition variations of the base alloy.

4

Annual Book of ASTM Standards, Vol 02.01.

5

Annual Book of ASTM Standards, Vol 01.01.

5

Available from Manufacturers Standardization Society of the Valve and Fittings Industry, 127 Park Street NE, Vienna, VA 22180-4602.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

B62–09

3.1.8 Test Methods (Section 13),

3.1.9 Significance of Numerical Limits (Section 14),

3.1.10 Inspection (Section 15),

3.1.11 Rejection and Rehearing (Section 16),

3.1.12 Certification (Section 17),

3.1.13 Test Report (Section 18),

3.1.14 Product Marking (Section 19), and

3.1.15 Packaging and Package Marking (Section 20)

4. Terminology

4.1 For definitions of terms relating to copper and copper alloys, refer to Terminology B 846.

5. Ordering Information

3.1Orders for castings under this specification shall include the following:

3.1.1Quantity of castings required,

3.1.2Copper Alloy UNS No. (

5.1 Include the following information when placing orders for castings under this specification:

5.1.1 Quantity of castings required,

5.1.2 Copper Alloy UNS

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:B 62–02 Designation: B62 – 09

Standard Specification for

1

Composition Bronze or Ounce Metal Castings

This standard is issued under the fixed designation B62; the number immediately following the designation indicates the year of original

adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.Asuperscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope*

1.1This specification

2

1.1 This specification establishes requirements for an alloy having a composition of copper, tin, lead, and zinc, used for

component castings of valves, flanges, and fittings. The common trade name of this alloy is 85-5-5-5; the correct identification is

3

Copper Alloy UNS No. C83600.

1.2 The castings covered are used in products that may be manufactured in advance and supplied from stock from the

manufacturer or other dealer.

1.3The values stated in inch-pound units are to be regarded as the standard. Metric values given in parentheses are for

information only.

1.3 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

2. Referenced Documents

2.1The following documents of the issue in effect on date of material purchase form a part of this specification to the extent

referenced herein:

2.2

4

2.1 ASTM Standards:

B208 Practice for Preparing Tension Test Specimens for Copper-Base Alloys for Copper Alloy Sand, Permanent Mold,

Centrifugal, and Continuous Castings

B824 Specification for General Requirements for Copper- Alloy Castings

E527 Practice for Numbering Metals and Alloys

2.3 Practice for Numbering Metals and Alloys in the Unified Numbering System (UNS)

2.2 MSS Standards:

5

SP-25 Standard Marking System for Valves, Fittings, Flanges and Unions

3. General Requirements

3.1 The following sections of Specification B824 form a part of this specification. In the event of a conflict between this

specification and Specification B824, the requirements of this specification shall take precedence.

3.1.1 Terminology (Section 3),

3.1.2 Other Requirements (Section 7),

3.1.3 Dimensions, Mass, and Permissible Variations (Section 8),

3.1.4 Workmanship, Finish, and Appearance (Section 9),

3.1.5 Sampling (Section 10),

3.1.6 Number of Tests and Retests (Sections 11 and 13),

1

This practice is under the jurisdiction ofASTM Committee B05 on Copper and CopperAlloys and is the direct responsibility of Subcommittee B05.05 on Castings and

Ingots for Remelting.

Current edition approved Dec. 10, 2002. Published February 2003. Originally approved in 1926. Discontinued June 2002 and reinstated as B 62–02. Last previous edition

approved in 1993 as B 62–93.

Current edition approved April 1, 2009. Published May 2009. Originally approved in 1926. Discontinued June 2002 and reinstated as B62 – 02. Last previous edition

approved in 2002 as B62 – 02. DOI: 10.1520/B0062-09.

2

For ASME Boiler and Pressure Vessel Code applications see related Specification SB-61 of that Code.

3

The UNS system for copper and copper alloys (see Practice E 527E527) is a simple expansion of the former standard designation system accomplished by the addition

of a prefix “C” and a suffix “00”. The suffix can be used to accommodate composition variations of the base alloy.

4

Annual Book of ASTM Standards, Vol 02.01.

5

Annual Book of ASTM Standards, Vol 01.01.

5

Available from Manufacturers Standardization Society of the Valve and Fittings Industry, 127 Park Street NE, Vienna, VA 22180-4602.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

B62–09

3.1.7 Specimen Preparation (Section 12),

3.1.8 Test Methods (Section 13),

3.1.9 Significance of Numerical Limits (Section 14),

3.1.10 Inspection (Section 15),

3.1.11 Rejection and Rehearing (Section 16),

3.1.12 Certification (Section 17),

3.1.13 Test Report (Section 18),

3.1.14 Product Marking (Section 19), and

3.1.15 Packaging and Package Marking (Section 20)

4. Terminology

4.1 For definitions of terms relating to copper and copper alloys, refer to Terminology B846.

5. Ordering Information

3.1Orders for castings under this specification shall include the following:

3.1.1Quantity of castings

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.