ASTM F721-18(2022)

(Specification)Standard Specification for Gauge Piping Assemblies

Standard Specification for Gauge Piping Assemblies

ABSTRACT

This specification covers details of gage piping assemblies for pressure gages with optional provisions for additional gages, pressure switches, transmitters, and so forth, for use with steam, steam drains, feed water, condensate, fresh water, salt water, compressed air, fuel oil, and lubricating oil systems. A siphon shall be used as shown in all gage applications for steam systems to maintain a protective water seal between the gage and the steam supply.

SCOPE

1.1 This specification covers details of gauge piping assemblies for pressure gauges with optional provisions for additional gauges, pressure switches, transmitters, and so forth, for use with steam, steam drains, feed water, condensate, fresh water, salt water, compressed air, fuel oil, and lubricating oil systems.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.3 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: F721 −18 (Reapproved 2022) An American National Standard

Standard Specification for

Gauge Piping Assemblies

ThisstandardisissuedunderthefixeddesignationF721;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginal

adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.Asuperscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope A576 Specification for Steel Bars, Carbon, Hot-Wrought,

Special Quality

1.1 This specification covers details of gauge piping assem-

B16/B16M Specification for Free-Cutting Brass Rod, Bar

blies for pressure gauges with optional provisions for addi-

and Shapes for Use in Screw Machines

tional gauges, pressure switches, transmitters, and so forth, for

B61 Specification for Steam or Valve Bronze Castings

use with steam, steam drains, feed water, condensate, fresh

B62 Specification for Composition Bronze or Ounce Metal

water, salt water, compressed air, fuel oil, and lubricating oil

Castings

systems.

B75 Specification for Seamless Copper Tube (Metric)

1.2 The values stated in inch-pound units are to be regarded

B0075_B0075M

as standard. The values given in parentheses are mathematical

B124/B124M Specification for Copper and Copper Alloy

conversions to SI units that are provided for information only

Forging Rod, Bar, and Shapes

and are not considered standard.

B453/B453M Specification for Copper-Zinc-Lead Alloy

1.3 This international standard was developed in accor-

(Leaded-Brass) Rod, Bar, and Shapes

dance with internationally recognized principles on standard- B466/B466M Specification for Seamless Copper-Nickel

ization established in the Decision on Principles for the

Pipe and Tube

Development of International Standards, Guides and Recom-

2.2 ANSI Standards:

mendations issued by the World Trade Organization Technical

B16.11 Forged Steel Fittings, Socket Weld, and Threaded

Barriers to Trade (TBT) Committee.

B16.15 Cast Bronze Threaded Fittings

2.3 SAE International:

2. Referenced Documents

AMS-QQ-S-763 Steel, Corrosion Resistant, Bars, Wire,

2.1 ASTM Standards: Shapes, and Forgings

A105/A105M Specification for Carbon Steel Forgings for

3. List of Assemblies

Piping Applications

A106/A106M Specification for Seamless Carbon Steel Pipe

3.1 This specification incorporates 13 gauge piping assem-

for High-Temperature Service

blies as described in Table 1.

A108 Specification for Steel Bar, Carbon and Alloy, Cold-

4. General Requirements and Guidelines

Finished

A182/A182M Specification for Forged or Rolled Alloy and

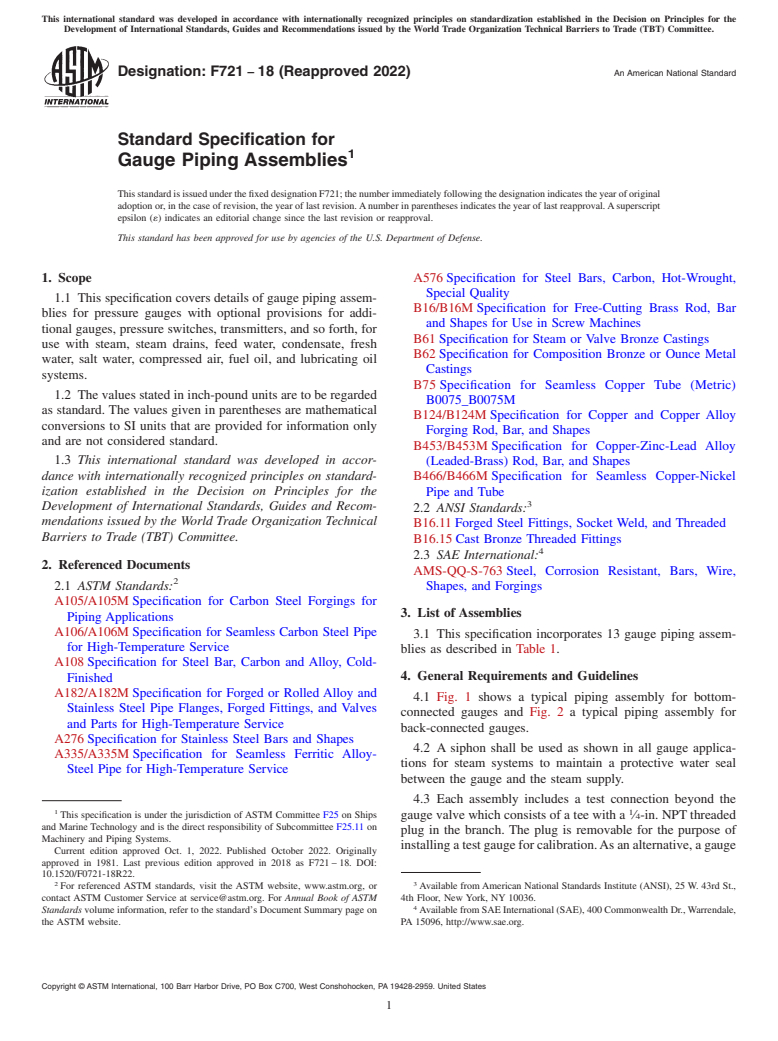

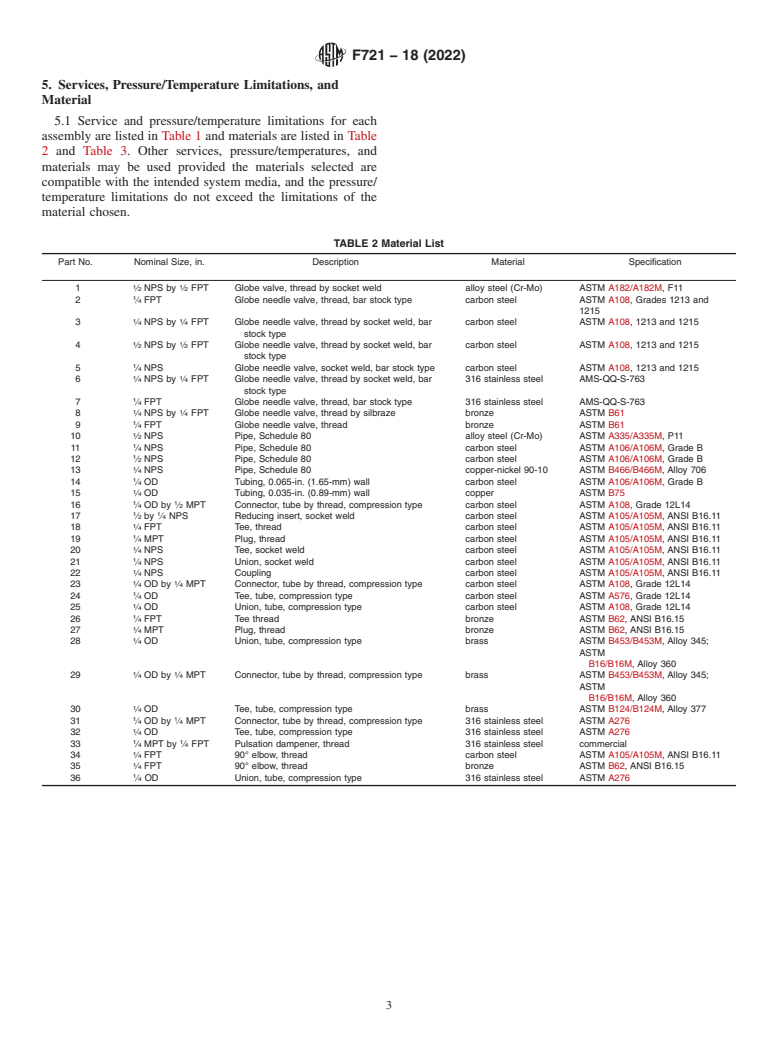

4.1 Fig. 1 shows a typical piping assembly for bottom-

Stainless Steel Pipe Flanges, Forged Fittings, and Valves

connected gauges and Fig. 2 a typical piping assembly for

and Parts for High-Temperature Service

back-connected gauges.

A276 Specification for Stainless Steel Bars and Shapes

4.2 A siphon shall be used as shown in all gauge applica-

A335/A335M Specification for Seamless Ferritic Alloy-

tions for steam systems to maintain a protective water seal

Steel Pipe for High-Temperature Service

between the gauge and the steam supply.

4.3 Each assembly includes a test connection beyond the

1 1

This specification is under the jurisdiction of ASTM Committee F25 on Ships

gauge valve which consists of a tee with a ⁄4-in. NPT threaded

and Marine Technology and is the direct responsibility of Subcommittee F25.11 on

plug in the branch. The plug is removable for the purpose of

Machinery and Piping Systems.

installingatestgaugeforcalibration.Asanalternative,agauge

Current edition approved Oct. 1, 2022. Published October 2022. Originally

approved in 1981. Last previous edition approved in 2018 as F721 – 18. DOI:

10.1520/F0721-18R22.

2 3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Available from American National Standards Institute (ANSI), 25 W. 43rd St.,

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM 4th Floor, New York, NY 10036.

Standards volume information, refer to the standard’s Document Summary page on Available from SAE International (SAE), 400 Commonwealth Dr.,Warrendale,

the ASTM website. PA 15096, http://www.sae.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F721 − 18 (2022)

A,B

TABLE 1 Gauge Piping Assemblies

Assembly Maximum Pressure, Maximum Temperature,

Service

No. psi (kPa) °F (°C)

1 Superheated steam 1125 (7757) 960 (516)

2 High-pressure desuperheated steam and high-pressure extractions 1100 (7584) 580 (304)

3 Low-pressure extractions, gland seal, auxiliary exhaust, and 150-psig (1034-MPa) 900 (6205) 563 (295)

steam

4 Low-pressure steam 125 (861) 353 (178)

5 Boiler feed discharge 1500 (10 342) 450 (232)

6 Feed suction and condensate 165 (1138) 300 (149)

7 Compressed air above 165 psi (1.14 MPa) 900 (6205) 563 (295)

8 Compressed air 165 (1138) 300 (149)

9 Fresh and potable water 200 (1379) 150 (66)

10 Main and auxiliary salt water circulating, salt water service, and wet firemain 200 (1379) 150 (66)

11 Dry firemain and deck washdown 200 (1379) 150 (66)

12 Fuel oil and lube oil 900 (6205) 250 (121)

13 Diesel oil 900 (6205) 563 (295)

A

For typical piping assemblies see Fig. 1 and Fig. 2.

B

For materials required see Table 2 and Table 3.

NOTE 1—For material identification see Table 3.

NOTE 2—Use siphon for Assemblies 1 through 4.

NOTE 3—For pulsation dampener requirements see 4.6 and Table 3.

NOTE 4—Piping through the root valve is normally detailed on the

NOTE 1—For material identification see Table 3.

piping arrangement drawings but is shown here as an aid in establishing

material requirements. NOTE 2—Use siphon for Assemblies 1 through 4.

FIG. 1 Typical Piping Assembly for Bottom-Connected Gauges

NOTE 3—For pulsation dampener requirements see 4.6 and Table 3.

NOTE 4—Piping through the root valve is normally detailed on the

piping arrangement drawings but is shown here as an aid in establishing

valve that incorporates a built-in test connection integral with

material requirements.

the valve may be substituted for the gauge valve and test tee.

FIG. 2 Typical Piping Assembly for Back-Connected Gauges

4.4 Root connections should be kept to a minimum by

connecting other instruments at the tee between the root and

gauge valves.There is no limit to the number of dead-end-type

instruments that can be served from a single root connection. 4.6 Pulsation dampeners are shown for certain assemblies

However, each instrument should have its o

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.