ASTM G186-05(2011)

(Test Method)Standard Test Method for Determining Whether Gas-Leak-Detector Fluid Solutions Can Cause Stress Corrosion Cracking of Brass Alloys

Standard Test Method for Determining Whether Gas-Leak-Detector Fluid Solutions Can Cause Stress Corrosion Cracking of Brass Alloys

SCOPE

1.1 This test method covers an accelerated test method for evaluating the tendency of gas leak detection fluids (LDFs) to cause stress corrosion cracking (SCC) of brass components in compressed gas service.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and to determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: G186 − 05(Reapproved 2011)

Standard Test Method for

Determining Whether Gas-Leak-Detector Fluid Solutions

Can Cause Stress Corrosion Cracking of Brass Alloys

This standard is issued under the fixed designation G186; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3. Terminology

3.1 Definitions of Terms Specific to This Standard:

1.1 This test method covers an accelerated test method for

3.1.1 Gas Leak Detector Solutions—Also known as leak

evaluating the tendency of gas leak detection fluids (LDFs) to

detection fluids, leak detector solutions, bubble solutions, and

cause stress corrosion cracking (SCC) of brass components in

soap solutions, designated in this standard as LDFs, are fluids

compressed gas service.

used to detect leaks in pressurized gas systems by the forma-

1.2 The values stated in inch-pound units are to be regarded

tion of bubbles at the leak site.

as standard. The values given in parentheses are mathematical

3.1.2 The terminology used herein, if not specifically de-

conversions to SI units that are provided for information only

finedotherwise,shallbeinaccordancewithTerminologyG15.

and are not considered standard.

1.3 This standard does not purport to address all of the

4. Summary of Test Method

safety concerns, if any, associated with its use. It is the

4.1 This test method consists of three steps: The first step

responsibility of the user of this standard to establish appro-

consistsofrunningasampleofthetestspecimenstoverifythat

priate safety and health practices and to determine the

they are susceptible to stress corrosion cracking using Matts-

applicability of regulatory limitations prior to use.

son’sSolution(seePracticeG37).Thesecondstepistoexpose

the specimens to a solution that does not cause SCC to verify

2. Referenced Documents

thatthetestenvironmentdoesnotcontaincomponentsthatcan

cause SCC to brass. The third step is to test the LDF to

2.1 ASTM Standards:

determine if it causes SCC of the brass specimens within 15

B135Specification for Seamless Brass Tube

wetting and evaporation cycles.

B135MSpecification for Seamless Brass Tube [Metric]

D1193Specification for Reagent Water

4.2 The specimen used in this test is a C-ring stressed to

G1Practice for Preparing, Cleaning, and Evaluating Corro-

create at least 0.65% strain in the outer fibers of the specimen.

sion Test Specimens

4.3 Macroscopic examination of the specimens is carried

G15TerminologyRelatingtoCorrosionandCorrosionTest-

out after every second wetting cycle and if cracking is

ing (Withdrawn 2010)

suspected the specimen is examined at higher magnifications

G37Practice for Use of Mattsson’s Solution of pH 7.2 to

for confirmation. Metallographic sectioning through the

Evaluate the Stress-Corrosion Cracking Susceptibility of

stressed area is used to verify minor cracking at the end of the

Copper-Zinc Alloys

fifteen cycles.

G38 Practice for Making and Using C-Ring Stress-

4.4 LDFs that cause SCC in any specimens within 15

Corrosion Test Specimens

wetting cycles are considered to have failed this test and not

suitable for use in pressurized gas systems with brass compo-

nents.

This test method is under the jurisdiction of ASTM Committee G01 on

Corrosion of Metals and is the direct responsibility of Subcommittee G01.06 on

5. Significance and Use

Environmentally Assisted Cracking.

Current edition approved March 1, 2011. Published April 2011. Originally

5.1 Brass components are routinely used in compressed gas

approved in 2005. Last previous edition approved in 2005 as G186–05. DOI:

service for valves, pressure regulators, connectors and many

10.1520/G0186-05R11.

other components. Although soft brass is not susceptible to

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

ammonia SCC, work-hardened brass is susceptible if its

Standards volume information, refer to the standard’s Document Summary page on

hardnessexceedsabout54HR30T(55HRB)(Rockwellscale).

the ASTM website.

Normal assembly of brass components should not induce

The last approved version of this historical standard is referenced on

www.astm.org. sufficient work hardening to cause susceptibility to ammonia

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

G186 − 05 (2011)

SCC. However, it is has been observed that over-tightening of committee on Analytical Reagents of the American Chemical

the components will render them susceptible to SCC, and the Society, where such specifications are applicable, shall be

problem becomes more severe in older components that have used.

been tightened many times. In this test, the specimens are

7.2 Finepurecopperpowderwithparticlesize<68µmshall

obtainedinthehardenedconditionandarestrainedbeyondthe

be used.

elastic limit to accelerate the tendency towards SCC.

7.3 Solutionsusingwatershallbepreparedusingdistilledor

5.2 It is normal practice to use LDFs to check pressurized

deionized water conforming to the purity requirements of

systems to assure that leaking is not occurring. LDFs are

Specification D1193, Type IV reagent water.

usually aqueous solutions containing surfactants that will form

7.4 Leakdetectorsolutionsshallmeetmanufacturer’sspeci-

bubbles at the site of a leak. If the LDF contains ammonia or

fications.

other agent that can cause SCC in brass, serious damage can

occur to the system that will compromise its safety and

7.5 Mattsson’s Solution shall be freshly prepared according

integrity.

to Practice G37.

5.3 It is important to test LDFs to assure that they do not

causeSCCofbrassandtoassurethattheuseoftheseproducts 8. Hazards

does not compromise the integrity of the pressure containing

8.1 Consult Material Safety Data Sheets (MSDS) for all

system.

chemicals both reagent and commercial before testing to gain

5.4 It has been found that corrosion of brass is necessary

a full understanding of any potential hazards.

before SCC can occur.The reason for this is that the corrosion

8.2 The test solutions present no undue safety hazard. It is

process results in cupric and cuprous ions accumulating in the

recommended, however, that appropriate personnel protection

electrolyte. Therefore, adding copper metal and cuprous oxide

equipment such as resistant gloves and shatterproof eyewear

(Cu O) to the aqueous solution accelerates the SCC process if

withsideshieldsbewornwhenthechemicalsorspecimensare

agents that cause SCC are present. However, adding these

handled.

components to a solution that does not cause SCC will not

8.3 The solutions contain copper and are thus considered

make stressed brass crack.

poisonous so they should not be ingested.

5.5 Repeated application of the solution to the specimen

8.4 Ammonium sulfate, (NH ) SO , in the Mattsson’s solu-

followed by a drying period causes the components in the

4 2 4

tion has been reported to be allergenic. Repeated short-time

solution to concentrate thereby further increasing the rate of

skin contact with the solution over extended periods of time

cracking. This also simulates service where a system may be

tested many times during its life. These features of the test should be avoided.

method accelerate the test and allow an answer to be obtained

8.5 The fumes given off by the Mattsson’s test solution

more rapidly.

contain ammonia. The least detectable ammonia odor corre-

5.6 This test method applies only to brasses. Successful

spondstoaconcentrationof50ppm;100ppmcanbetolerated

passage of this test does not assure that the LDF will be for several hours without serious disturbance; 700 ppm causes

acceptable for use on other alloy systems such as stainless immediate eye irritation; and greater than 5000 ppm can be

steels or aluminum alloys. lethal. The mixing and the actual testing with Mattsson’s

solution should therefore be run in a well-ventilated area.

6. Interferences

6.1 When conducting this test, it is very important that the

9. Test Solutions

air not be contaminated with ammonia vapors. Reagent bottles

9.1 Control Solution (benign water solution)—Add2.5gCu

withammoniumhydroxideorotherteststhatinvolveammonia

powder and 2.5 g Cu O to 1000 mLof H O. Then add 10 mL

2 2

or its compounds including amines must not be in the vicinity

of glycerin to solution. Shake solution vigorously to thor-

of these tests. This also includes Mattsson’s test solution.

oughly mix contents.

6.2 Cross contamination may result in false stress corrosion

9.2 Leak Detector Solutions—Add 2.5 g Cu powder and

cracking results therefore concurrent exposure tests with dif-

2.5g Cu O to 1000 mL of each manufacturer’s solution to be

ferent leak detector solutions should be conducted in such a

tested. Shake solutions vigorously to thoroughly mix contents.

way that any set of samples does not influence the results of

any of the other samples.

NOTE 1—Some of the solids will settle out of the solutions in between

cycles, therefore, it is very important to shake the solutions vigorously

6.3 In this test, the susceptibility of the C-ring specimens to

prior to their use in the wetting cycle.

crack in a particular test solution can be affected by the temper

of the brass alloy; therefore, it is crucial that the C-rings be

fabricated from hard drawn temper brass tubing that meets the

Reagent Chemicals, American Chemical Society Specifications, American

minimum specified hardness requirements.

Chemical Society, Washington, DC. For Suggestions on the testing of reagents not

listed by the American Chemical Society, see Annual Standards for Laboratory

7. Reagents and Materials

Chemicals, BDH Ltd., Poole, Dorset, U.K., and the United States Pharmacopeia

7.1 Reagent grade cuprous oxide (Cu O) and USP/FCC

2 and National Formulary, U.S. Pharmacopeial Convention, Inc. (USPC), Rockville,

grade glycerin (C H O ) conforming to specifications of the MD.

3 8 3

G186 − 05 (2011)

NOTE2—Everyprecautionshallbetakentomaintaintheintegrityofthe

10. Test Specimen

surfaceafterthefinalpreparation.Avoidroughhandlingthatcouldmarthe

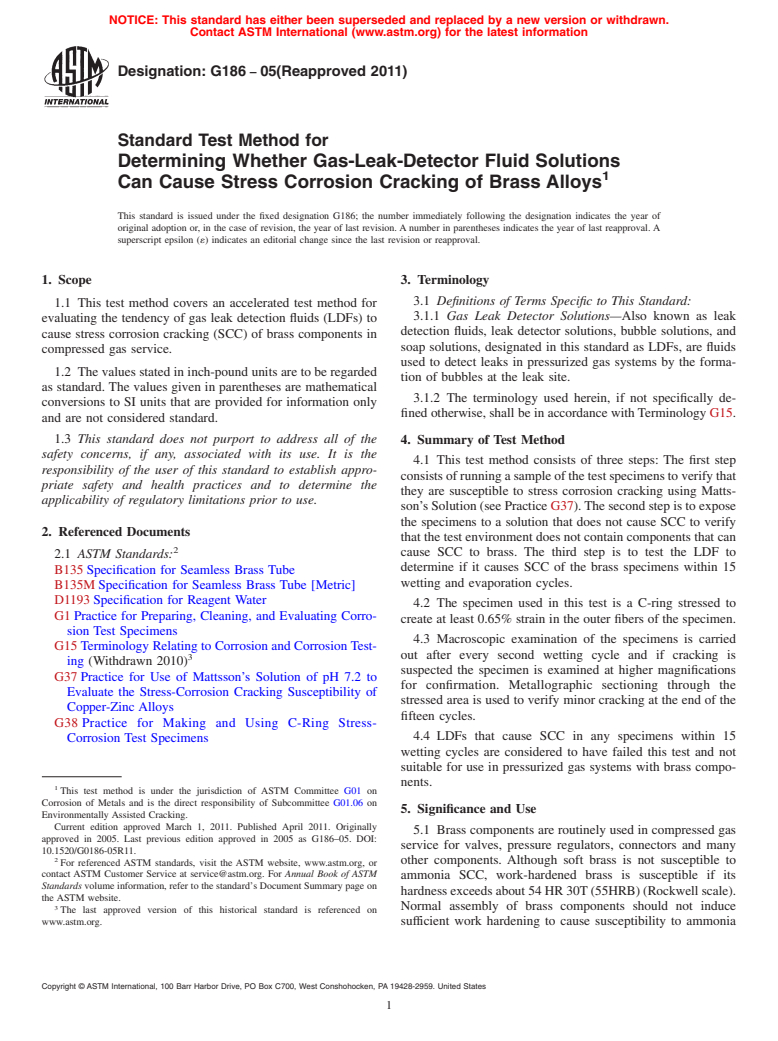

10.1 Type and Size—An unnotched C-ring in accordance

surface and handle with gloves to prevent fingerprinting and the transfer

with Practice G38 shall be used (Fig. 1). C-rings shall have an

of contaminants.

outer diameter (OD) between 1.0 to 2.0 in. (25.4 to 50.8 mm)

and thickness between 0.065 to 0.25 in. (1.65 to 6.4 mm). 11. Test Setup and Apparatus

Widths shall be fixed at 0.75 in. (19.0 mm).

11.1 C-ring Test Assembly—Individual C-ring specimens

10.2 Alloy Composition and Temper—Test specimens shall

shall be placed apex down in a glass-fiber-wick covered dish

be fabricated from copper alloy (UNS C27200) seamless tube

(Fig. 2).

with a H80 hard-drawn temper. The hard drawn temper shall

11.2 Exposure Dish—The individual dishes shall be made

have a minimum hardness of 70 on the 30T Rockwell scale

out of a material that will not react with the chemicals being

which corresponds to minimum tensile strength of 66 ksi

used for the exposure (for example, glass, polystyrene, poly-

(455MPa). Refer to Specifications B135 and B135M for tube

carbonate). The required dish dimensions are 2.36- to 3.94-in.

information.

(60-to100-mm)diameterand0.59-to0.79-in.(15-to20-mm)

10.3 Surface Finish—Specimens shall have a 120-grit fin-

height.

ish. Grind marks shall be in the circumferential direction.

11.3 Wick Material—Borosilicateglasswickmaterialwitha

10.4 Restraining Hardware—Nuts, bolts, and flat washers

fiber diameter of about 0.3 mil (8 µm) shall be used.

shall be made from a metal resistant to the chemicals used in

this test (for example, Type 316 stainless steel, UNS S31600). 11.4 Number of Specimens—Five individual C-ring speci-

Insulationwashersshallbemadefromahardresistantmaterial men test assemblies will be used for each leak detector or

to prevent relaxation of the stressed C-ring specimen (for control solution to be tested.

example, alumina). Refer to Fig. 1.

11.5 Test Assembly Arrangement—Individual exposure

10.5 Pre-test Condition—C-rings will be unstressed prior to

dishes shall be laid out such that there is at least a 1.0 ft (305

testing.

mm) separation between groups of specimens (Fig. 3). The

control solution specimens shall always be positioned in the

10.6 Stressing Method—Constant-strain stressing method

center of the test group.

shall be used in stressing the C-rings (refer to Practice G38).

Tensile stress will be introduced on the exterior of the ring by

12. Calibration and Standardization

tightening a bolt centered on the diameter of the ring.

10.7 Surface Preparation—The specimen surface should be 12.1 When a new batch of specimens is to be used, it is

free of oil, grease, and dirt. This usually entails cleaning with necessary to first test a representative number of C-rings from

organic solvent such as acetone followed by an alcohol rinse. the batch with Mattsson’s solution.

FIG. 1 C-ring Specimen

G186 − 05 (2011)

FIG. 2 C-ring Specimen Ready for Exposure to Test Solution

FIG. 3 Arrangement and Spacing of Specimens for Multiple Solution Testing

12.2 Mattsson’s Solution test must produce cracking of the

test specimens before any further testing is carried out.

G186 − 05 (2011)

TABLE 1 Deflection for Stressing C-rings

12.3 If cracking is not produced during the predescribed

Mattsson’s solution test the following variables need to be O.D. (inch) Wall Thickness (in.)

verified before rejecting the batch of C-rings. 0.065 0.08 0.091 0.125 0.25

12.3.1 Specimen material hardness shall exceed 70 HR 30T

1 0.073 0.059 0.051 0.036 0.015

(Rockwell scale). 1

1 ⁄16 0.083 0.067 0.058 0.041 0.018

1 ⁄8 0.094 0.075 0.065 0.046 0.020

12.3.2 Strain should be checked with a strain gauge if

1 ⁄16 0.105 0.089 0.073 0.052 0.023

hardness is sufficient.

1 ⁄4 0.116 0.083 0.081 0.057 0.026

12.3.3 Mattsson’s solution should be checked to make sure

1 ⁄16 0.129 0.099 0.090 0.064 0.028

1 ⁄8 0.142 0.114 0.099 0.070 0.032

it conforms to Practice G37.

1 ⁄2 0.169 0.136 0.119 0.084 0.038

1 ⁄16 0.184 0.148 0.129 0.092 0.042

12.4 Follow steps in Annex A1 to test the C-rings in

1 ⁄8 0.199 0.160 0.140 0.100 0.046

Mattsson’s Solution.

1 ⁄4 0.232 0.187 0.163 0.116 0.054

1 ⁄8 0.267 0.215 0.188 0.134 0.062

2 0.304 0.245 0.214 0.153 0.072

13. Air Conditions

13.1 Temperature—Airtemperatureshallbemaintainedina

range of 70 to 80°F (21 to 27°C) through

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.