ASTM G186-05(2011)

(Test Method)Standard Test Method for Determining Whether Gas-Leak-Detector Fluid Solutions Can Cause Stress Corrosion Cracking of Brass Alloys

Standard Test Method for Determining Whether Gas-Leak-Detector Fluid Solutions Can Cause Stress Corrosion Cracking of Brass Alloys

SCOPE

1.1 This test method covers an accelerated test method for evaluating the tendency of gas leak detection fluids (LDFs) to cause stress corrosion cracking (SCC) of brass components in compressed gas service.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and to determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: G186 − 05(Reapproved 2011)

Standard Test Method for

Determining Whether Gas-Leak-Detector Fluid Solutions

1

Can Cause Stress Corrosion Cracking of Brass Alloys

This standard is issued under the fixed designation G186; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3. Terminology

3.1 Definitions of Terms Specific to This Standard:

1.1 This test method covers an accelerated test method for

3.1.1 Gas Leak Detector Solutions—Also known as leak

evaluating the tendency of gas leak detection fluids (LDFs) to

detection fluids, leak detector solutions, bubble solutions, and

cause stress corrosion cracking (SCC) of brass components in

soap solutions, designated in this standard as LDFs, are fluids

compressed gas service.

used to detect leaks in pressurized gas systems by the forma-

1.2 The values stated in inch-pound units are to be regarded

tion of bubbles at the leak site.

as standard. The values given in parentheses are mathematical

3.1.2 The terminology used herein, if not specifically de-

conversions to SI units that are provided for information only

finedotherwise,shallbeinaccordancewithTerminologyG15.

and are not considered standard.

1.3 This standard does not purport to address all of the

4. Summary of Test Method

safety concerns, if any, associated with its use. It is the

4.1 This test method consists of three steps: The first step

responsibility of the user of this standard to establish appro-

consistsofrunningasampleofthetestspecimenstoverifythat

priate safety and health practices and to determine the

they are susceptible to stress corrosion cracking using Matts-

applicability of regulatory limitations prior to use.

son’sSolution(seePracticeG37).Thesecondstepistoexpose

the specimens to a solution that does not cause SCC to verify

2. Referenced Documents

thatthetestenvironmentdoesnotcontaincomponentsthatcan

2

cause SCC to brass. The third step is to test the LDF to

2.1 ASTM Standards:

determine if it causes SCC of the brass specimens within 15

B135Specification for Seamless Brass Tube

wetting and evaporation cycles.

B135MSpecification for Seamless Brass Tube [Metric]

D1193Specification for Reagent Water

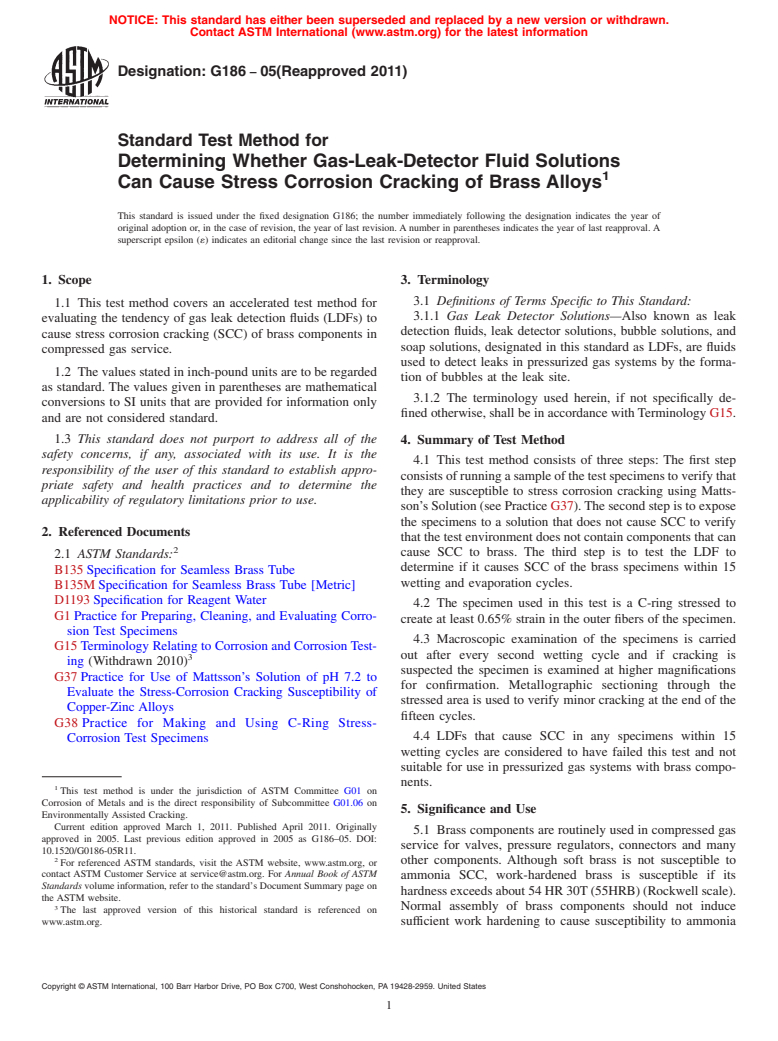

4.2 The specimen used in this test is a C-ring stressed to

G1Practice for Preparing, Cleaning, and Evaluating Corro-

create at least 0.65% strain in the outer fibers of the specimen.

sion Test Specimens

4.3 Macroscopic examination of the specimens is carried

G15TerminologyRelatingtoCorrosionandCorrosionTest-

out after every second wetting cycle and if cracking is

3

ing (Withdrawn 2010)

suspected the specimen is examined at higher magnifications

G37Practice for Use of Mattsson’s Solution of pH 7.2 to

for confirmation. Metallographic sectioning through the

Evaluate the Stress-Corrosion Cracking Susceptibility of

stressed area is used to verify minor cracking at the end of the

Copper-Zinc Alloys

fifteen cycles.

G38 Practice for Making and Using C-Ring Stress-

4.4 LDFs that cause SCC in any specimens within 15

Corrosion Test Specimens

wetting cycles are considered to have failed this test and not

suitable for use in pressurized gas systems with brass compo-

nents.

1

This test method is under the jurisdiction of ASTM Committee G01 on

Corrosion of Metals and is the direct responsibility of Subcommittee G01.06 on

5. Significance and Use

Environmentally Assisted Cracking.

Current edition approved March 1, 2011. Published April 2011. Originally

5.1 Brass components are routinely used in compressed gas

approved in 2005. Last previous edition approved in 2005 as G186–05. DOI:

service for valves, pressure regulators, connectors and many

10.1520/G0186-05R11.

2

other components. Although soft brass is not susceptible to

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

ammonia SCC, work-hardened brass is susceptible if its

Standards volume information, refer to the standard’s Document Summary page on

hardnessexceedsabout54HR30T(55HRB)(Rockwellscale).

the ASTM website.

3

Normal assembly of brass components should not induce

The last approved version of this historical standard is referenced on

www.astm.org. sufficient work hardening to cause susceptibility to ammonia

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

G186 − 05 (2011)

SCC. However, it is has been observed that over-tightening of committee on Analytical Reagents of the American Chemical

4

the components will render them suscept

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.