ASTM C585-09

(Practice)Standard Practice for Inner and Outer Diameters of Thermal Insulation for Nominal Sizes of Pipe and Tubing

Standard Practice for Inner and Outer Diameters of Thermal Insulation for Nominal Sizes of Pipe and Tubing

SIGNIFICANCE AND USE

The purpose of this practice is to ensure satisfactory fit on standard sizes, to accommodate radial expansion of pipes and tubes which are heated after being insulated, and to minimize the number of insulation sizes and thicknesses to be manufactured and stocked.

While it is possible to manufacturer insulation to these recommended dimensions, exercise care in attempting to nest layers of different materials, or layers supplied by different manufacturers. Individual manufacturing processes will operate at slightly different tolerances. While the product will fit the pipe, it is possible that it will not readily nest as the outer layer between the different materials, or with a different manufacturer, and possibly the same manufacturer. Exercise care to determine these differences before specifying or ordering nesting sizes.

The wide range of outer diameter dimensional tolerances will prevent many pipe and tube insulations from nesting for staggered joints or double layered applications, or both unless specified when ordered from the manufacturer, distributor, or fabricator.

4.4 Dimensions in accordance with this practice do not necessarily permit application of one thickness of pipe insulation over another (Nesting or Simplified Dimensional System) to obtain total thicknesses greater than those manufactured as single layer, or for multilayer application when desired.

SCOPE

1.1 This practice is intended as a dimensional standard for preformed thermal insulation for pipes and tubing.

1.2 This practice covers insulation supplied in cylindrical sections and lists recommended single layer inner and outer diameters of insulation having nominal wall thicknesses from ½ to 5 in. (13 to 127 mm) to fit over standard sizes of pipe and tubing.

1.3 The values stated in inch-pound units are to be regarded as the standard. The values stated in SI units are provided for information only.

1.4 This standard does not purport to address the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information.

Designation: C585 – 09

Standard Practice for

Inner and Outer Diameters of Thermal Insulation for

1

Nominal Sizes of Pipe and Tubing

This standard is issued under the fixed designation C585; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope and tubes which are heated after being insulated, and to

minimize the number of insulation sizes and thicknesses to be

1.1 This practice is intended as a dimensional standard for

manufactured and stocked.

preformed thermal insulation for pipes and tubing.

4.2 While it is possible to manufacturer insulation to these

1.2 This practice covers insulation supplied in cylindrical

recommended dimensions, exercise care in attempting to nest

sections and lists recommended single layer inner and outer

layers of different materials, or layers supplied by different

diameters of insulation having nominal wall thicknesses from

1 manufacturers. Individual manufacturing processes will oper-

⁄2 to 5 in. (13 to 127 mm) to fit over standard sizes of pipe and

ate at slightly different tolerances.While the product will fit the

tubing.

pipe, it is possible that it will not readily nest as the outer layer

1.3 The values stated in inch-pound units are to be regarded

between the different materials, or with a different manufac-

as the standard. The values stated in SI units are provided for

turer, and possibly the same manufacturer. Exercise care to

information only.

determine these differences before specifying or ordering

1.4 This standard does not purport to address the safety

nesting sizes.

concerns, if any, associated with its use. It is the responsibility

4.3 The wide range of outer diameter dimensional toler-

of the user of this standard to establish appropriate safety and

ances will prevent many pipe and tube insulations from nesting

health practices and determine the applicability of regulatory

for staggered joints or double layered applications, or both

limitations prior to use.

unless specified when ordered from the manufacturer, distribu-

2. Referenced Documents tor, or fabricator.

2

4.4 Dimensions in accordance with this practice do not

2.1 ASTM Standards:

necessarily permit application of one thickness of pipe insula-

C168 Terminology Relating to Thermal Insulation

tion over another (Nesting or Simplified Dimensional System)

C302 Test Method for Density and Dimensions of Pre-

to obtain total thicknesses greater than those manufactured as

formed Pipe-Covering-Type Thermal Insulation

single layer, or for multilayer application when desired.

3. Terminology

5. Summary of Practice

3.1 Definitions—Definitions pertaining to insulation are de-

5.1 This practice provides for each pipe and tubing sizes the

fined in Terminology C168.

inner diameters with tolerances for calcium silicate, cellular

4. Significance and Use

foam plastics, cellular glass, mineral fiber, and perlite pre-

formed pipe and tubing insulation identified by Table 1 and

4.1 The purpose of this practice is to ensure satisfactory fit

Table 2.

on standard sizes, to accommodate radial expansion of pipes

5.2 This practice provides for each pipe and tubing sizes the

outer diameters for calcium silicate, cellular foam plastics,

1

This practice is under the jurisdiction of ASTM Committee C16 on Thermal

cellular glass, mineral fiber, and perlite preformed pipe and

InsulationandisthedirectresponsibilityofSubcommitteeC16.20onHomogeneous

tubing insulation identified by Table 3, Table 4, Table 5 and

Inorganic Thermal Insulations.

Current edition approved April 1, 2009. Published May 2009. Originally Table 6.

approvedin1966toreplaceC312andC521.Lastpreviouseditionapprovedin2004

5.3 This practice provides for a range of pipe and tubing

as C585 – 90 (2004). DOI: 10.1520/C0585-09.

sizes the outer diameter tolerances for calcium silicate and

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

perlite preformed pipe and tubing insulation identified byTable

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

3a, Table 4a, Table 5a, and Table 6a.

the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

C585 – 09

Fig. 1a Three Meaurement Locations

Fig. 1b Diameter and Half-Diameter Measurement Locations

FIG. 1 Inner Diameter Measurement Location

Fig. 2a Three Measurement Locations

Fig. 2b Diameter and Half-Diameter Measurement Locations

FIG. 2 Outer Diameter Measurement Location

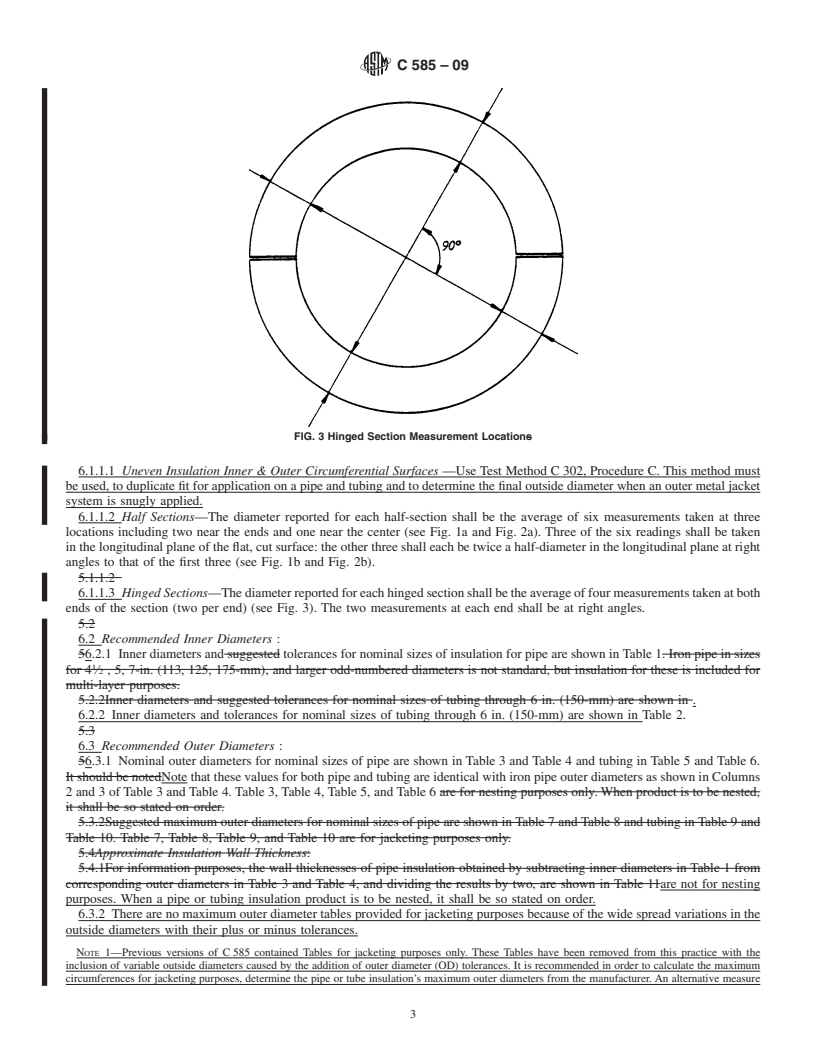

FIG. 3

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:C585–90 (Reapproved2004) Designation: C 585 – 09

Standard Practice for

Inner and Outer Diameters of Rigid Thermal Insulation for

1

Nominal Sizes of Pipe and Tubing (NPS System)

This standard is issued under the fixed designation C 585; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This practice is intended as a dimensional standard for preformed rigid thermal insulation for pipes and tubing.

1.2 This practice covers insulation supplied in cylindrical sections, usually split into half-sections, sections and lists

1

recommended single layer inner and outer diameters of insulation having nominal wall thicknesses from 1 ⁄2 to 5 in. (25(13 to 127

mm) to fit over standard sizes of pipe and tubing.

1.3 The values stated in inch-pound units are to be regarded as the standard. The values stated in SI units are provided for

information only.

1.4 This standard does not purport to address the safety concerns, if any, associated with its use. It is the responsibility of the

user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations

prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

C 168 Terminology Relating to Thermal Insulation Terminology Relating to Thermal Insulation

C 302 Test Method for Density and Dimensions of Preformed Pipe-Covering-Type Thermal Insulation

3. Terminology

3.1 Definitions—Definitions pertaining to insulation are defined in Terminology C 168.

4. Significance and Use

4.1 The purpose of this practice is to ensure satisfactory fit on standard sizes, to accommodate radial expansion of pipes and

tubes which are heated after being insulated, and to minimize the number of insulation sizes and thicknesses to be manufactured

and stocked.

4.2While insulation may be manufactured to these recommended dimensions, care should be exercised in attempting to nest

layers of different materials, or layers supplied by different manufacturers. Individual manufacturing processes may operate at

slightly different tolerances. While the product will fit the pipe, it may not readily nest as the outer layer between the different

materials or with different manufacturers. Care should be exercised to determine these differences before specifying or ordering

nesting sizes.

4.3Dimensions in accordance with this practice permit application of one thickness of pipe insulation over another (Nesting or

Simplified Dimensional System), to obtain total thicknesses greater than those manufactured as single layer, or for multilayer

application when desired.

4.2 While it is possible to manufacturer insulation to these recommended dimensions, exercise care in attempting to nest layers

of different materials, or layers supplied by different manufacturers. Individual manufacturing processes will operate at slightly

different tolerances. While the product will fit the pipe, it is possible that it will not readily nest as the outer layer between the

different materials, or with a different manufacturer, and possibly the same manufacturer. Exercise care to determine these

differences before specifying or ordering nesting sizes.

4.3 The wide range of outer diameter dimensional tolerances will prevent many pipe and tube insulations from nesting for

staggered joints or double layered applications, or both unless specified when ordered from the manufacturer, distributor, or

fabricator.

1

This practice is under the jurisdiction of ASTM Committee C16 on Thermal Insulation and is the direct responsibility of Subcommittee C16.20 on Homogeneous

Inorganic Thermal Insulations.

Current edition approved April 1, 2004.2009. Published May 2004.2009. Originally approved in 1966 to replace C 312 and C 521. Last previous edition approved in

19982004 as C 585 – 90 (1998). (2004).

2

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

C585–09

4.4 Dimensions in accordance with this practice do not necessarily permit applicat

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.