ASTM D3104-14a(2018)

(Test Method)Standard Test Method for Softening Point of Pitches (Mettler Softening Point Method)

Standard Test Method for Softening Point of Pitches (Mettler Softening Point Method)

SIGNIFICANCE AND USE

4.1 Pitch does not go through a solid-liquid phase change when heated, and therefore does not have a true melting point. As the temperature is raised pitch gradually softens or becomes less viscous. For this reason, the determination of the softening point must be made by an arbitrary, but closely defined, method if the test values are to be reproducible.

4.2 This test method is useful in determining the consistency of pitches as one element in establishing the uniformity of shipments or sources of supply.

SCOPE

1.1 This test method covers the determination of the softening point of pitches having softening points in the range from 50 °C to 180 °C by this test method, and gives results comparable to those obtained by Test Method D2319 above 80 °C (176 °F).

1.2 The values stated in SI units are to be regarded as standard. The values given in parentheses after SI units are provided for information only and are not considered standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D3104 − 14a (Reapproved 2018)

Standard Test Method for

1

Softening Point of Pitches (Mettler Softening Point Method)

This standard is issued under the fixed designation D3104; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope a 6.35 mm hole in the bottom, flows downward a distance of

19 mm to interrupt a light beam, as the sample is heated at a

1.1 This test method covers the determination of the soft-

linear rate in air.

eningpointofpitcheshavingsofteningpointsintherangefrom

50 °C to 180 °C by this test method, and gives results

4. Significance and Use

comparable to those obtained by Test Method D2319 above

80 °C (176 °F). 4.1 Pitch does not go through a solid-liquid phase change

when heated, and therefore does not have a true melting point.

1.2 The values stated in SI units are to be regarded as

Asthetemperatureisraisedpitchgraduallysoftensorbecomes

standard. The values given in parentheses after SI units are

less viscous. For this reason, the determination of the softening

provided for information only and are not considered standard.

pointmustbemadebyanarbitrary,butcloselydefined,method

1.3 This standard does not purport to address all of the

if the test values are to be reproducible.

safety concerns, if any, associated with its use. It is the

4.2 This test method is useful in determining the consis-

responsibility of the user of this standard to establish appro-

tency of pitches as one element in establishing the uniformity

priate safety, health, and environmental practices and deter-

of shipments or sources of supply.

mine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accor-

5. Apparatus

dance with internationally recognized principles on standard-

3

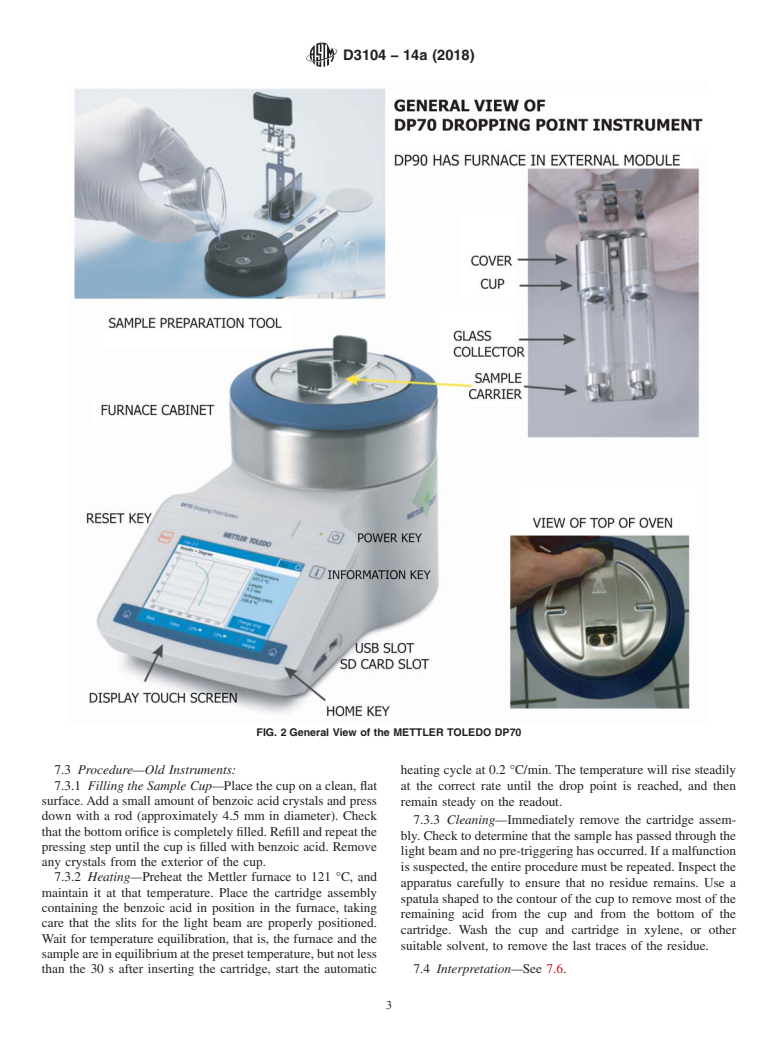

ization established in the Decision on Principles for the 5.1 A METTLER TOLEDO dropping point cell shall be

Development of International Standards, Guides and Recom- used to determine pitch softening points by this test method.

mendations issued by the World Trade Organization Technical These commercially available instruments consist of a control

Barriers to Trade (TBT) Committee. unit with a digital temperature indicator, with furnace built in

or attached, sample cartridges, and accessories. The control

unitautomaticallyregulatestheheatingrateofthefurnace.The

2. Referenced Documents

2 softening point is indicated on the readout, and the heating

2.1 ASTM Standards:

program stopped, when the sample flow triggers the softening

A314 Specification for Stainless Steel Billets and Bars for

point detection.Ageneral view of the contents of a METTLER

Forging

TOLEDO dropping point instrument is shown in Fig. 1 (old

D2319 Test Method for Softening Point of Pitch (Cube-in-

instrument) and Fig. 2 (new instrument).

Air Method)

5.1.1 IntegratedorSeparateControlUnit—The control unit

D4296 Practice for Sampling Pitch

shall provide a continuous, linear temperature increase from 25

°C to 250 °C at a rate of 2 °C/min. A digital readout shall

3. Summary of Test Method

indicate the temperature to 0.1 °C throughout.

3.1 In this test method, the softening point is defined as the

5.1.2 Integrated or Separate Furnace Unit—The furnace

temperatureatwhichpitch,suspendedinacylindricalcupwith

unit shall be capable of heating one or two sample cup

assemblies, as described in 5.1.3, at a linear rate of 2 °C 6

0.3 °C⁄min. It shall include a sensing system capable of

1 detecting the softening point with a precision of 0.1 °C.

This test method is under the jurisdiction of ASTM Committee D02 on

Petroleum Products, Liquid Fuels, and Lubricantsand is the direct responsibility of

SubcommitteeD02.05onPropertiesofFuels,PetroleumCokeandCarbonMaterial.

Current edition approved Dec. 1, 2018. Published December 2018. Originally

3

approved in 1972. Last previous edition approved in 2014 as D3104 – 14a. DOI: The sole source of supply of the apparatus known to the committee at this time

10.1520/D3104-14AR18. is available from Mettler-Toledo, LLC., 1900 Polaris Pkwy, Columbus, OH 43240,

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or www.mt.com. If you are aware of alternative suppliers, please provide this

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM information to ASTM International Headquarters. Your comments will receive

1

Standards volume information, refer to the standard’s Document Summary page on careful

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.