ASTM F738M-02(2008)

(Specification)Standard Specification for Stainless Steel Metric Bolts, Screws, and Studs (Withdrawn 2015)

Standard Specification for Stainless Steel Metric Bolts, Screws, and Studs (Withdrawn 2015)

ABSTRACT

This specification covers the chemical and mechanical requirements for stainless steel metric bolts, screws, and studs with nominal thread diameters M1.6 through M36 and is intended for use in engineering applications requiring general corrosion resistance. Eight groups of stainless steel alloys are covered, including three austenitic (grades A1, A2, and A4), one ferritic (grade F1), three martensitic (grades C1, C3, and C4), and one precipitation hardening (grade P1). The chemical composition of the material shall conform to the requirements prescribed. Tensile strength, yield strength, elongation, and torsional strength shall be tested to meet the requirements prescribed.This specification covers the material, dimensions, and construction of 5 and 10-gal (20 and 40-L) tanks purchased to store and dispense lubricating oils. The tanks are industrial safety cans mounted on a T-bar bracket, complete with drip tray. Internal air pressure test shall be performed on the tank to meet the requirements prescribed. There should be no visible seam leakage when subjected to underwater or soap bubble test.

SCOPE

1.1 This specification covers the chemical and mechanical requirements for stainless steel metric bolts, screws, and studs with nominal thread diameters M1.6 through M36 and is intended for use in engineering applications requiring general corrosion resistance.

1.2 Eight groups of stainless steel alloys are covered, including three austenitic (Grades A1, A2, and A4), one ferritic (Grade F1), three martensitic (Grades C1, C3, and C4), and one precipitation hardening (Grade P1).

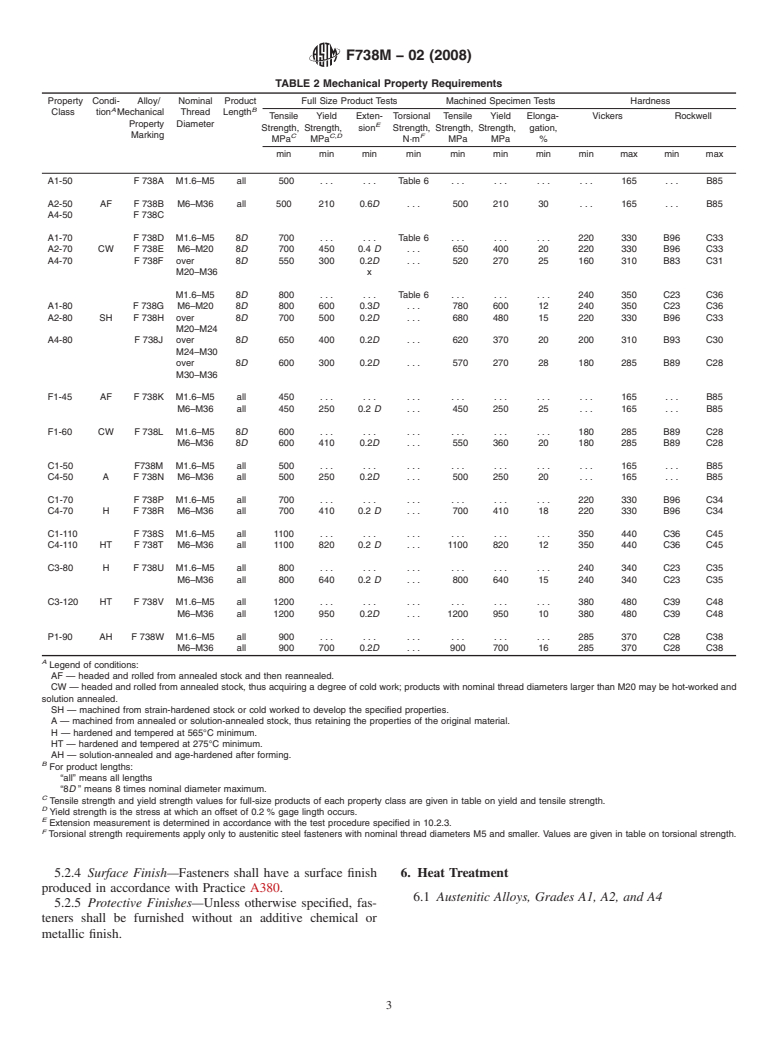

1.3 Twenty property classes are covered, including nine austenitic, two ferritic, eight martensitic, and one precipitation hardening. The property classes with the permissible alloys for each are listed in Table 1.

1.4 This specification is based in concept and content on ISO 3506. The chemical and mechanical requirements specified for all property classes, except as given in 1.4.1, are essentially identical with classes of the same designation in ISO 3506.

1.4.1 This specification includes all of the property classes covered in ISO 3506. Additionally, it includes property classes A1-70, A2-70, A4-70, A1-80, A2-80, and A4-80 for products with nominal thread diameters larger than M20; and four non-ISO property classes, C1-110, C4-110, C3-120; and P1-90.

1.5 Supplementary requirements of an optional nature are provided, applicable only when agreed upon between the manufacturer and the purchaser at the time of the inquiry and order.

1.6 Suitable nuts for use with bolts, screws, and studs included in this specification are covered by Specification F 836M.

1.7 Units—The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.8 The following safety hazards caveat pertains only to the test method described in this specification. This standard does not purport to address the safety problems associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

WITHDRAWN RATIONALE

This specification covers the chemical and mechanical requirements for stainless steel metric bolts, screws, and studs with nominal thread diameters M1.6 through M36 and is intended for use in engineering applications requiring general corrosion resistance.

Formerly under the jurisdiction of Committee F16 on Fasteners, this specification was withdrawn in December 2014. This standard is being withdrawn without replacement due to its limited use by industry.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:F738M −02(Reapproved 2008)

Standard Specification for

Stainless Steel Metric Bolts, Screws, and Studs

This standard is issued under the fixed designation F738M; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope 1.8 The following safety hazards caveat pertains only to

the test method described in this specification. This standard

1.1 This specification covers the chemical and mechanical

does not purport to address the safety problems associated with

requirements for stainless steel metric bolts, screws, and studs

its use. It is the responsibility of the user of this standard to

with nominal thread diameters M1.6 through M36 and is

establish appropriate safety and health practices and deter-

intended for use in engineering applications requiring general

mine the applicability of regulatory limitations prior to use.

corrosion resistance.

1.2 Eight groups of stainless steel alloys are covered,

2. Referenced Documents

includingthreeaustenitic(GradesA1,A2,andA4),oneferritic

2.1 ASTM Standards:

(GradeF1),threemartensitic(GradesC1,C3,andC4),andone

A276Specification for Stainless Steel Bars and Shapes

precipitation hardening (Grade P1).

A342/A342MTest Methods for Permeability of Weakly

1.3 Twenty property classes are covered, including nine

Magnetic Materials

austenitic, two ferritic, eight martensitic, and one precipitation

A380Practice for Cleaning, Descaling, and Passivation of

hardening.The property classes with the permissible alloys for

Stainless Steel Parts, Equipment, and Systems

each are listed in Table 1.

A484/A484MSpecification for General Requirements for

Stainless Steel Bars, Billets, and Forgings

1.4 This specification is based in concept and content on

ISO 3506. The chemical and mechanical requirements speci- A493Specification for Stainless Steel Wire and Wire Rods

for Cold Heading and Cold Forging

fied for all property classes, except as given in 1.4.1, are

essentially identical with classes of the same designation in A555/A555MSpecification for General Requirements for

Stainless Steel Wire and Wire Rods

ISO 3506.

1.4.1 This specification includes all of the property classes A564/A564M Specification for Hot-Rolled and Cold-

covered in ISO 3506.Additionally, it includes property classes Finished Age-Hardening Stainless Steel Bars and Shapes

A1-70, A2-70, A4-70, A1-80, A2-80, and A4-80 for products A582/A582MSpecification for Free-Machining Stainless

with nominal thread diameters larger than M20; and four Steel Bars

non-ISOpropertyclasses,C1-110,C4-110,C3-120;andP1-90. A751Test Methods, Practices, and Terminology for Chemi-

cal Analysis of Steel Products

1.5 Supplementary requirements of an optional nature are

D3951Practice for Commercial Packaging

provided, applicable only when agreed upon between the

E29Practice for Using Significant Digits in Test Data to

manufacturer and the purchaser at the time of the inquiry and

Determine Conformance with Specifications

order.

E353Test Methods for Chemical Analysis of Stainless,

1.6 Suitable nuts for use with bolts, screws, and studs

Heat-Resisting, Maraging, and Other Similar Chromium-

included in this specification are covered by Specification

Nickel-Iron Alloys

F836M.

F606MTest Methods for Determining the Mechanical Prop-

erties of Externally and Internally Threaded Fasteners,

1.7 Units—The values stated in SI units are to be regarded

Washers, and Rivets (Metric)

asstandard.Nootherunitsofmeasurementareincludedinthis

F836MSpecification for Style 1 Stainless Steel Metric Nuts

standard.

(Metric)

This specification is under the jurisdiction of ASTM Committee F16 on

Fasteners and is the direct responsibility of Subcommittee F16.04 on Nonferrous

Fasteners. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved May 1, 2008. Published August 2008. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1981. Last previous edition approved in 2002 as F738M–02. DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/F0738M-02R08. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F738M−02 (2008)

TABLE 1 Property Classes of Stainless Steel Bolts, Screws, and

Studs

Property Class Permissible Alloys

A

A1-50 304, 304L, 305

A1-70 384, 18–9LW, 302HQ

A1-80

A2-50

4. Ordering Information

A2-70 321, 347

A2-80

4.1 Orders for bolts, screws and studs under this specifica-

tion shall include the following:

A4-50

A4-70 316, 316L

4.1.1 Quantity (number of pieces of each item).

A4-80

4.1.2 Nameofitem(bolt,screw,stud,etc.;specifictypeand

B

F1-45 430 style; and reference to dimensional standard when appropri-

F1-60

ate).

4.1.3 Size (nominal diameter, thread pitch, length).

C1-50

C1-70 410 4.1.4 Property class.

C1-110

4.1.5 ASTM designation and date of issue. When date of

issue is not specified, fasteners shall be furnished to the latest

C3-80 431

C3-120

issue.

4.1.6 Supplementary requirements, if any (S1 through S5).

C4-50

4.1.7 Additional requirements, if any, to be specified on the

C4-70 416, 416Se

C4-110

purchase order:

4.1.7.1 Forming (5.2.1).

P1-90 630

4.1.7.2 Threading (5.2.2).

A

When approved by the purchaser, Alloys 303, 303Se, or XM1 may be furnished.

B

4.1.7.3 Alloy condition (5.2.3).

When approved by the purchaser, Alloy 430F may be furnished.

4.1.7.4 Protective finish (5.2.5).

4.1.7.5 Alloy selection (7.2).

4.1.7.6 Test report (9.2).

4.1.7.7 Heat number (9.1.1).

4.1.7.8 Additional testing (9.3).

F1470Practice for Fastener Sampling for Specified Me-

4.1.7.9 Inspection (11.1).

chanical Properties and Performance Inspection

4.1.7.10 Rejection (12.1).

2.2 ISO Standard:

3 4.1.7.11 Certification (13.1).

ISO3506 Corrosion-Resistant Stainless Steel Fasteners

4.1.7.12 Marking (14.1.3 and 14.1.4).

3. Classification NOTE 1—Examples:

10000 hex-cap screws, ANSI B18.2.3.1M, M12 × 1.75 × 50, Class

3.1 The designation of each property class is composed of

A2–70, furnish test report, ASTM F738, dated _____.

three parts: a letter, followed by a single digit, followed by 15000 oval-head machine screws,Type 1 recess,ANSI B18.6.7M, M3

× 0.5 × 25, Class C4-70, 416Se, Supplementary Requirement S2,ASTM

either two or three digits.

F738, dated _____.

3.1.1 The letter indicates the general composition type of

stainless steel as follows:

5. Materials and Manufacture

3.1.1.1 A for austenitic steels,

5.1 Materials:

3.1.1.2 F for ferritic steels,

5.1.1 Specifications A276, A493, A564/A564M, and A582/

3.1.1.3 C for martensitic steels, and

A582M are noted for information only as suitable sources of

3.1.1.4 P for precipitation-hardening steel.

materialforthemanufactureofbolts,hexcapscrews,andstuds

3.1.2 The first digit (1, 2, 3, or 4) indicates the alloy group.

to this specification.

The permissible alloys within each group are given in Table 1.

5.2 Manufacture:

3.1.3 The last two or three digits (50, 70, 110, etc.) indicate

5.2.1 Forming—Unless otherwise specified, fasteners shall

10% of the specified minimum tensile strength of the property

be cold-formed, hot-formed, or machined, at the option of the

class.

manufacturer.

3.1.4 For example, ClassA1-50 is an austenitic steel of any

5.2.2 Threads—Unless otherwise specified, threads shall be

one of six permitted alloys, and the manufactured fastener has

rolled or cut at the option of the manufacturer.

a minimum tensile strength of 500 MPa.

5.2.3 Condition—Fasteners shall be furnished in the condi-

tion specified for the property class in Table 2. If other

conditionsarerequired,theconditionandresultantmechanical

properties shall be as agreed upon between the manufacturer

Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

4th Floor, New York, NY 10036, http://www.ansi.org. and the purchaser.

F738M−02 (2008)

TABLE 2 Mechanical Property Requirements

Property Condi- Alloy/ Nominal Product Full Size Product Tests Machined Specimen Tests Hardness

A B

Class tion Mechanical Thread Length

Tensile Yield Exten- Torsional Tensile Yield Elonga- Vickers Rockwell

Property Diameter E

Strength, Strength, sion Strength, Strength, Strength, gation,

Marking

C C,D F

MPa MPa N·m MPa MPa %

min min min min min min min min max min max

A1-50 F 738A M1.6–M5 all 500 . . . . . . Table 6 . . . . . . . . . . . . 165 . . . B85

A2-50 AF F 738B M6–M36 all 500 210 0.6D . . . 500 210 30 . . . 165 . . . B85

A4-50 F 738C

A1-70 F 738D M1.6–M5 8D 700 . . . . . . Table 6 . . . . . . . . . 220 330 B96 C33

A2-70 CW F 738E M6–M20 8D 700 450 0.4 D . . . 650 400 20 220 330 B96 C33

A4-70 F 738F over 8D 550 300 0.2D . . . 520 270 25 160 310 B83 C31

M20–M36 x

M1.6–M5 8D 800 . . . . . . Table 6 . . . . . . . . . 240 350 C23 C36

A1-80 F 738G M6–M20 8D 800 600 0.3D . . . 780 600 12 240 350 C23 C36

A2-80 SH F 738H over 8D 700 500 0.2D . . . 680 480 15 220 330 B96 C33

M20–M24

A4-80 F 738J over 8D 650 400 0.2D . . . 620 370 20 200 310 B93 C30

M24–M30

over 8D 600 300 0.2D . . . 570 270 28 180 285 B89 C28

M30–M36

F1-45 AF F 738K M1.6–M5 all 450 . . . . . . . . . . . . . . . . . . . . . 165 . . . B85

M6–M36 all 450 250 0.2 D . . . 450 250 25 . . . 165 . . . B85

F1-60 CW F 738L M1.6–M5 8D 600 . . . . . . 180 285 B89 C28

M6–M36 8D 600 410 0.2D . . . 550 360 20 180 285 B89 C28

C1-50 F738M M1.6–M5 all 500 . . . . . . . 165 . B85

C4-50 A F 738N M6–M36 all 500 250 0.2D . 500 250 20 . 165 . B85

C1-70 F 738P M1.6–M5 all 700 . . . . . . 220 330 B96 C34

C4-70 H F 738R M6–M36 all 700 410 0.2 D . 700 410 18 220 330 B96 C34

C1-110 F 738S M1.6–M5 all 1100 . . . . . . 350 440 C36 C45

C4-110 HT F 738T M6–M36 all 1100 820 0.2 D . 1100 820 12 350 440 C36 C45

C3-80 H F 738U M1.6–M5 all 800 . . . . . . . . . . . . . . . . . . 240 340 C23 C35

M6–M36 all 800 640 0.2 D . . . 800 640 15 240 340 C23 C35

C3-120 HT F 738V M1.6–M5 all 1200 . . . . . . . . . . . . . . . . . . 380 480 C39 C48

M6–M36 all 1200 950 0.2D . . . 1200 950 10 380 480 C39 C48

P1-90 AH F 738W M1.6–M5 all 900 . . . . . . . . . . . . . . . . . . 285 370 C28 C38

M6–M36 all 900 700 0.2D . . . 900 700 16 285 370 C28 C38

A

Legend of conditions:

AF — headed and rolled from annealed stock and then reannealed.

CW — headed and rolled from annealed stock, thus acquiring a degree of cold work; products with nominal thread diameters larger than M20 may be hot-worked and

solution annealed.

SH — machined from strain-hardened stock or cold worked to develop the specified properties.

A — machined from annealed or solution-annealed stock, thus retaining the properties of the original material.

H — hardened and tempered at 565°C minimum.

HT — hardened and tempered at 275°C minimum.

AH — solution-annealed and age-hardened after forming.

B

For product lengths:

“all” means all lengths

“8D ” means 8 times nominal diameter maximum.

C

Tensile strength and yield strength values for full-size products of each property class are given in table on yield and tensile strength.

D

Yield strength is the stress at which an offset of 0.2 % gage lingth occurs.

E

Extension measurement is determined in accordance with the test procedure specified in 10.2.3.

F

Torsional strength requirements apply only to austenitic steel fasteners with nominal thread diameters M5 and smaller. Values are given in table on torsional strength.

5.2.4 Surface Finish—Fasteners shall have a surface finish 6. Heat Treatment

produced in accordance with Practice A380.

6.1 Austenitic Alloys, Grades A1, A2, and A4

5.2.5 Protective Finishes—Unless otherwise specified, fas-

teners shall be furnished without an additive chemical or

metallic finish.

F738M−02 (2008)

6.1.1 WhenConditionAFisspecified,thefasteners,follow- 7.3 Product analysis may be made by the purchaser from

ingmanufacture,shallbeannealedbyheatingto1040 630°C, finished fasteners representing each lot. The chemical compo-

at which time the chromium carbide will go into solution. The sition thus determined shall conform to the limits specified in

fasteners shall be held for a sufficient time and then cooled at Table 3 for the specific alloy within the product analysis

a rate sufficient to prevent precipitation of the carbide and to tolerances specified in Specification A555/A555M.

provide the properties specified in Table 2. 7.3.1 In the event of discrepancy, a referee analysis of

6.1.2 When Condition CW is specified, the austenitic alloy samples for each lot shall be made in accordance with 9.3.1.

shall be annealed as specified in 6.1.1, generally by the raw

8. Mechanical Properties

material manufacturer, and then cold-worked to develop the

8.1 Bolts, screws, and studs shall be tested in accordance

properties specified in Table 2.

with the mechanical testing requirements for the applicable

6.2 Ferritic Alloys, Grade F1

product type, property class, nominal thread diameter, length,

6.2.1 WhenConditionAFisspecified,theferriticalloyshall

and specified minimum tensile strength as specified in Table 4,

be heated to a temperature of 790 6 30°C, held for an

and shall meet the mechanical requirements specified for that

appropriate time, and then air-cooled to provide the properties

product in Tables 2-6.

specified in Table 2.

8.2 For products on which both hardness and tension tests

6.2.2 When Condition CW is specified, the ferritic alloy

are performed, acceptance based on tensile requirements shall

shall be annealed as specified in 6.2.1, generally by the raw

take precedence over low hardness readings.

material manufacturer and then cold-worked to develop the

properties specified in Table 2.

9. Number of Tests and Retests

6.3 Martensitic Alloys, Grades C1, C3, and C4

9.1 The requirements of this specification shall be met in

6.3.1 When Condition A is specified, the fasteners, follow-

continuous mass production for stock and the manufacturer

ing manufacture, shall be annealed to provide the properties

shall make sample inspections to ensure that the product

specified in Table 2.

conforms to the specified requirements. Additional tests of

6.3.2 When Condition H is specified, the fasteners shall be

individual shipments of material are not ordinarily necessary.

hardened and tempered by heating to 1010 6 30°C sufficient

9.1.1 Individual heats of steel are not identified in the

for austenitization, holding for at least ⁄2 h, rapid air- or

finished product.When specified in the p

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.