ASTM D5528-94a

(Test Method)Standard Test Method for Mode I Interlaminar Fracture Toughness of Unidirectional Fiber-Reinforced Polymer Matrix Composites

Standard Test Method for Mode I Interlaminar Fracture Toughness of Unidirectional Fiber-Reinforced Polymer Matrix Composites

SCOPE

1.1 This test method describes the determination of the opening Mode I interlaminar fracture toughness, G Ic, of continuous fiber-reinforced composite materials using the double cantilever beam (DCB) specimen (Fig. 1).

1.2 This test method is limited to use with composites consisting of unidirectional carbon fiber and glass fiber tape laminates with brittle and tough single-phase polymer matrices. This limited scope reflects the experience gained in round-robin testing. This test method may prove useful for other types and classes of composite materials; however, certain interferences have been noted (see 6.5).

1.3 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.4 This standard may involve hazardous materials, operations, and equipment.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: D 5528 – 94a

Standard Test Method for

Mode I Interlaminar Fracture Toughness of Unidirectional

Fiber-Reinforced Polymer Matrix Composites

This standard is issued under the fixed designation D 5528; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope

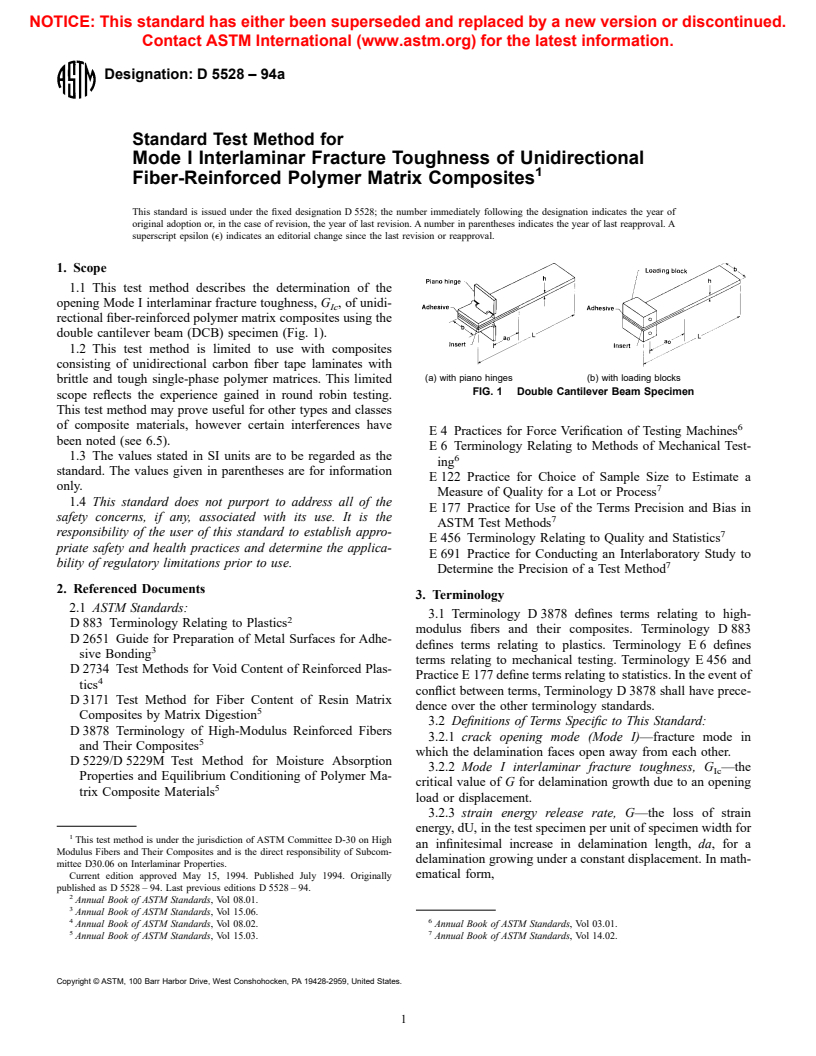

1.1 This test method describes the determination of the

opening Mode I interlaminar fracture toughness, G , of unidi-

Ic

rectional fiber-reinforced polymer matrix composites using the

double cantilever beam (DCB) specimen (Fig. 1).

1.2 This test method is limited to use with composites

consisting of unidirectional carbon fiber tape laminates with

(a) with piano hinges (b) with loading blocks

brittle and tough single-phase polymer matrices. This limited

FIG. 1 Double Cantilever Beam Specimen

scope reflects the experience gained in round robin testing.

This test method may prove useful for other types and classes

of composite materials, however certain interferences have

E 4 Practices for Force Verification of Testing Machines

been noted (see 6.5).

E 6 Terminology Relating to Methods of Mechanical Test-

1.3 The values stated in SI units are to be regarded as the

ing

standard. The values given in parentheses are for information

E 122 Practice for Choice of Sample Size to Estimate a

only.

Measure of Quality for a Lot or Process

1.4 This standard does not purport to address all of the

E 177 Practice for Use of the Terms Precision and Bias in

safety concerns, if any, associated with its use. It is the

ASTM Test Methods

responsibility of the user of this standard to establish appro- 7

E 456 Terminology Relating to Quality and Statistics

priate safety and health practices and determine the applica-

E 691 Practice for Conducting an Interlaboratory Study to

bility of regulatory limitations prior to use. 7

Determine the Precision of a Test Method

2. Referenced Documents

3. Terminology

2.1 ASTM Standards:

3.1 Terminology D 3878 defines terms relating to high-

D 883 Terminology Relating to Plastics

modulus fibers and their composites. Terminology D 883

D 2651 Guide for Preparation of Metal Surfaces for Adhe-

defines terms relating to plastics. Terminology E 6 defines

sive Bonding

terms relating to mechanical testing. Terminology E 456 and

D 2734 Test Methods for Void Content of Reinforced Plas-

Practice E 177 define terms relating to statistics. In the event of

tics

conflict between terms, Terminology D 3878 shall have prece-

D 3171 Test Method for Fiber Content of Resin Matrix

dence over the other terminology standards.

Composites by Matrix Digestion

3.2 Definitions of Terms Specific to This Standard:

D 3878 Terminology of High-Modulus Reinforced Fibers

3.2.1 crack opening mode (Mode I)—fracture mode in

and Their Composites

which the delamination faces open away from each other.

D 5229/D 5229M Test Method for Moisture Absorption

3.2.2 Mode I interlaminar fracture toughness, G —the

Ic

Properties and Equilibrium Conditioning of Polymer Ma-

critical value of G for delamination growth due to an opening

trix Composite Materials

load or displacement.

3.2.3 strain energy release rate, G—the loss of strain

energy, dU, in the test specimen per unit of specimen width for

This test method is under the jurisdiction of ASTM Committee D-30 on High

an infinitesimal increase in delamination length, da, for a

Modulus Fibers and Their Composites and is the direct responsibility of Subcom-

delamination growing under a constant displacement. In math-

mittee D30.06 on Interlaminar Properties.

ematical form,

Current edition approved May 15, 1994. Published July 1994. Originally

published as D 5528 – 94. Last previous editions D 5528 – 94.

Annual Book of ASTM Standards, Vol 08.01.

Annual Book of ASTM Standards, Vol 15.06.

4 6

Annual Book of ASTM Standards, Vol 08.02. Annual Book of ASTM Standards, Vol 03.01.

5 7

Annual Book of ASTM Standards, Vol 15.03. Annual Book of ASTM Standards, Vol 14.02.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

D 5528

1 dU

ment is recorded on an X-Y recorder, or equivalent real-time

G52 (1)

b da

plotting device or stored digitally and post processed. Instan-

taneous delamination front locations are marked on the chart at

where:

intervals of delamination growth. The Mode I interlaminar

U = total elastic strain energy in the test specimen,

fracture toughness is calculated using a modified beam theory

b = specimen width, and

or compliance calibration method.

a = delamination length.

3.3 Symbols:

5. Significance and Use

1/3

3.3.1 A —slope of plot of a/b versus C .

5.1 Susceptibility to delamination is one of the major

3.3.2 a—delamination length.

weaknesses of many advanced laminated composite structures.

3.3.3 a —initial delamination length.

Knowledge of a laminated composite material’s resistance to

3.3.4 b—width of DCB specimen.

interlaminar fracture is useful for product development and

3.3.5 C—compliance, d/P, of DCB specimen.

material selection. Furthermore, a measurement of the Mode I

3.3.6 CV—coefficient of variation, %.

interlaminar fracture toughness, independent of specimen ge-

3.3.7 da—differential increase in delamination length.

ometry or method of load introduction, is useful for establish-

3.3.8 dU—differential increase in strain energy.

ing design allowables used in damage tolerance analyses of

3.3.9 E —modulus of elasticity in the fiber direction.

composite structures made from these materials.

3.3.10 E —modulus of elasticity in the fiber direction

1f

5.2 This test method can serve the following purposes:

measured in flexure.

5.2.1 To establish quantitatively the effect of fiber surface

3.3.11 F—large displacement correction factor.

treatment, local variations in fiber volume fraction, and pro-

3.3.12 FAW—fiber areal weight.

cessing and environmental variables on G of a particular

Ic

3.3.13 FD—fiber density.

composite material.

3.3.14 G—strain energy release rate.

5.2.2 To compare quantitatively the relative values of G

Ic

3.3.15 G —opening Mode I interlaminar fracture tough-

Ic

for composite materials with different constituents.

ness.

5.2.3 To develop delamination failure criteria for composite

3.3.16 h—thickness of DCB specimen.

damage tolerance and durability analyses.

3.3.17 L—length of DCB specimen.

3.3.18 L8—half-width of loading block.

6. Interferences

3.3.19 m—number of plies in DCB specimen.

6.1 Linear elastic behavior is assumed in the calculation of

3.3.20 N—loading block correction factor.

G used in this test method. This assumption is valid when the

3.3.21 NL—point at which the load versus opening dis-

zone of damage or nonlinear deformation at the delamination

placement curve becomes non-linear.

front, or both, is small relative to the smallest specimen

3.3.22 n—slope of plot of Log C versus Log a.

dimension, which is typically the specimen thickness for the

3.3.23 P—applied load.

DCB test.

3.3.24 P —maximum applied load during DCB test.

max

6.2 In the DCB test, as the delamination grows from the

3.3.25 SD—standard deviation.

insert, a resistance-type fracture behavior typically develops

3.3.26 t—distance from loading block pin to center line of

where the calculated G first increases monotonically, and then

Ic

top specimen arm.

stabilizes with further delamination growth. In this test method,

3.3.27 U—strain energy.

a resistance curve (R-curve) depicting G as a function of

Ic

3.3.28 VIS—point at which delamination is observed visu-

delamination length, will be generated to characterize the

ally on specimen edge.

initiation and propagation of a delamination in a unidirectional

3.3.29 V —fiber volume fraction, %.

f

specimen (Fig. 2). The principal reason for the observed

3.3.30 d—load point deflection.

3.3.31 D—effective delamination extension to correct for

rotation of DCB arms at delamination front.

3.3.32 D —incremental change in Log a.

x

3.3.33 D —incremental change in Log C.

y

4. Summary of Test Method

4.1 The DCB shown in Fig. 1 consists of a rectangular,

uniform thickness, unidirectional laminated composite speci-

men, containing a nonadhesive insert on the midplane which

serves as a delamination initiator. Opening forces are applied to

the DCB specimen by means of hinges (Fig. 1a) or loading

blocks (Fig. 1b) bonded to one end of the specimen. The ends

of the DCB are opened by controlling either the opening

displacement, or the crosshead movement, while the load and

delamination length are recorded.

FIG. 2 Delamination Resistance Curve (R-curve) From DCB

4.2 A record of the applied load versus opening displace- Test

D 5528

resistance to delamination is the development of fiber bridging adhesive interleafs between plies may be particularly sensitive

(1-3). This fiber bridging mechanism results from growing the to this phenomenon, resulting in two apparent interlaminar

delamination between two zero-degree unidirectional plies. fracture toughness values: one associated with a cohesive type

Because most delaminations that form in multi-ply laminated failure within the interleaf and one associated with an adhesive

composite structures occur between plies of dissimilar orien- type failure between the tough polymer film and the more

tation, fiber bridging does not occur. Hence, fiber bridging is brittle composite matrix.

considered to be an artifact of the DCB test on unidirectional 6.5.2 Non-unidirectional DCB configurations may experi-

materials. Therefore, the generic significance of G propaga- ence branching of the delamination away from the midplane

Ic

tion values calculated beyond the end of the implanted insert is through matrix cracks in off-axis plies. If the delamination

questionable, and an initiation value of G measured from the branches away from the midplane, a pure mode I fracture may

Ic

implanted insert is preferred. Because of the significance of the not be achieved due to the coupling between extension and

initiation point, the insert must be properly implanted and shear which may exist in the asymmetric sublaminates formed

inspected (8.2). as the delamination grows. In addition, non-unidirectional

6.3 Three definitions for an initiation value of G have been specimens may experience significant anti-clastic bending

Ic

evaluated during round-robin testing (4). These include G effects which result in non-uniform delamination growth along

Ic

values determined using the load and deflection measured (1) the specimen width, particularly affecting the observed initia-

at the point of deviation from linearity in the load-displacement tion values.

curve (NL), (2) at the point where delamination is visually 6.5.3 Woven composites may yield significantly greater

observed on the edge (VIS) measured with a microscope as scatter and unique R-curves associated with varying toughness

specified in 7.5, and (3) at the point where the compliance has within and away from interlaminar resin pockets as the

increased by 5 % or where the load has reached a maximum delamination grows. Composites with significant strength or

value (5 %/max) (see Section 11). The NL G value, which is toughness through the laminate thickness, such as composites

Ic

typically the lowest of the three G initiation values, is with metal matrices or 3D fiber reinforcement, may experience

Ic

recommended for generating delamination failure criteria in failures of the beam arms rather than the intended interlaminar

durability and damage tolerance analyses of laminated com- failures.

posite structures (5.2.3). All three initiation values can be used

7. Apparatus

for the other purposes cited in the scope (5.2.1 and 5.2.2).

7.1 Testing Machine—A properly calibrated test machine

However, physical evidence indicates that the initiation value

shall be used which can be operated in a displacement control

corresponding to the onset of non-linearity (NL) in the load

mode with a constant displacement rate in the range from 0.5

versus opening displacement plot corresponds to the physical

to 5.0 mm/min (0.02 to 0.20 in./min). The testing machine shall

onset of delamination from the insert in the interior of the

conform to the requirements of Practices E 4. The testing

specimen width (5). In round-robin testing of AS4/PEEK

machine shall be equipped with grips to hold the loading

thermoplastic matrix composites, NL G values were 20 %

Ic

hinges, or pins to hold the loading blocks, that are bonded to

lower than VIS and 5 %/max values (4).

the specimen.

6.4 Delamination growth may proceed in one of two ways:

7.2 Load Indicator—The testing machine load sensing de-

(1) by a slow stable extension, or (2) by a run-arrest extension,

vice shall be capable of indicating the total load carried by the

where the delamination front jumps ahead abruptly. Only the

test specimen. This device shall be essentially free from

first type of growth is of interest in this test method. An

inertia-lag at the specified rate of testing and shall indicate the

unstable jump from the insert may be an indication of a

load with an accuracy over the load range(s) of interest of

problem with the insert. For example, the insert may not be

within 61 % of the indicated value.

completely disbonded from the laminate, or may be too thick

7.3 Opening Displacement Indicator—The opening dis-

resulting in a large neat resin pocket, or may contain a tear or

placement may be estimated as the crosshead separation

fold. Furthermore, rapid delamination growth may introduce

provided the deformation of the testing machine, with the

dynamic effects in both the test specimen and in the fracture

specimen grips attached, is less than 2 % of the opening

morphology. Treatment and interpretation of these effects is

displacement of the test specimen. If not, then the opening

beyond the scope of this test method.

displacement shall be obtained from a properly calibrated

6.5 Application to Other Materials, Layups, and Architec-

external gage or transducer attached to the specimen. The

tures:

displacement indicator shall indicate the crack opening dis-

6.5.1 The DCB test has been used extensively for unidirec-

placement with an accuracy of within 61 % of the indicated

tional glass fiber reinforced tape laminates with single-phase

value once the delamination occurs.

polymer matrices, but corrections may be needed for anticlastic

7.4 Load Versus Opening Displacement Record—An X-Y

bending effects. Toughness values measured on unidirectional

plotter, or similar device, shall be used to make a permanent

composites with multiple phase matrices may vary depending

record during

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.