ASTM E140-07

(Guide)Standard Hardness Conversion Tables for Metals Relationship Among Brinell Hardness, Vickers Hardness, Rockwell Hardness, Superficial Hardness, Knoop Hardness, and Scleroscope Hardness

Standard Hardness Conversion Tables for Metals Relationship Among Brinell Hardness, Vickers Hardness, Rockwell Hardness, Superficial Hardness, Knoop Hardness, and Scleroscope Hardness

SCOPE

1.1 Conversion Table 1 presents data in the Rockwell C hardness range on the relationship among Brinell hardness, Vickers hardness, Rockwell hardness, Rockwell superficial hardness, Knoop hardness, and Scleroscope hardness of non-austenitic steels including carbon, alloy, and tool steels in the as-forged, annealed, normalized, and quenched and tempered conditions provided that they are homogeneous.

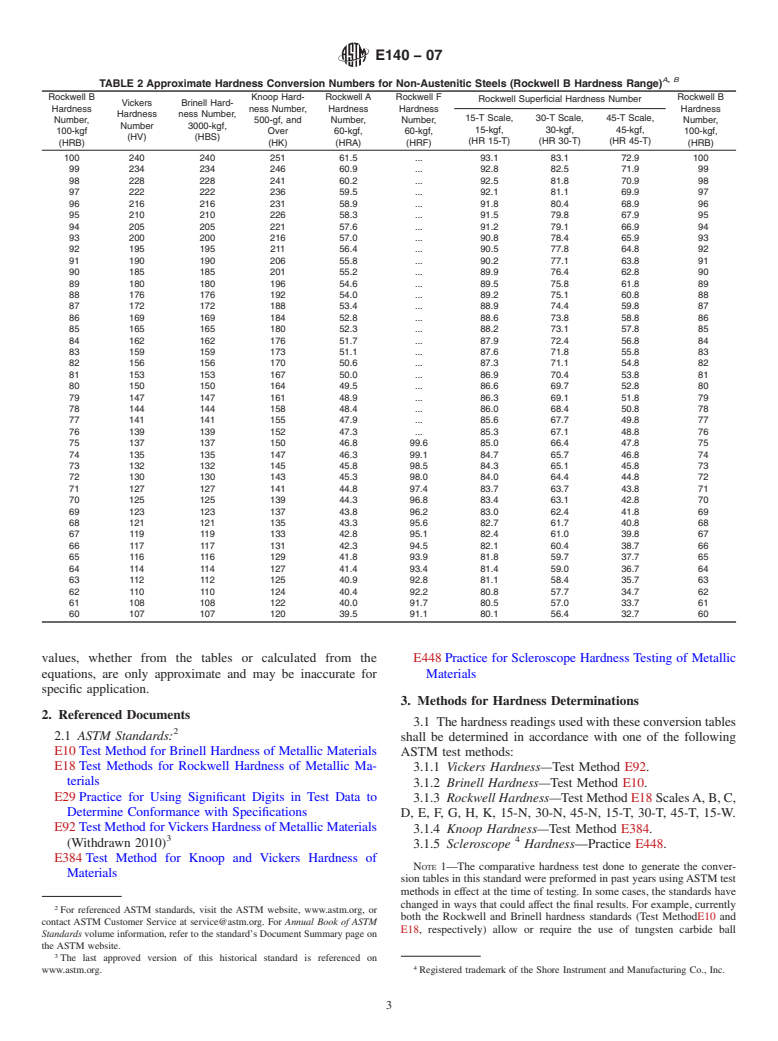

1.2 Conversion Table 2 presents data in the Rockwell B hardness range on the relationship among Brinell hardness, Vickers hardness, Rockwell hardness, Rockwell superficial hardness, Knoop hardness, and Scleroscope hardness of non-austenitic steels including carbon, alloy, and tool steels in the as-forged, annealed, normalized, and quenched and tempered conditions provided that they are homogeneous.

1.3 Conversion Table 3 presents data on the relationship among Brinell hardness, Vickers hardness, Rockwell hardness, Rockwell superficial hardness, and Knoop hardness of nickel and high-nickel alloys (nickel content over 50 %). These hardness conversion relationships are intended to apply particularly to the following: nickel-aluminum-silicon specimens finished to commercial mill standards for hardness testing, covering the entire range of these alloys from their annealed to their heavily cold-worked or age-hardened conditions, including their intermediate conditions.

1.4 Conversion Table 4 presents data on the relationship among Brinell hardness, Vickers hardness, Rockwell hardness, and Rockwell superficial hardness of cartridge brass.

1.5 Conversion Table 5presents data on the relationship between Brinell hardness and Rockwell B hardness of austenitic stainless steel plate in the annealed condition.

1.6 Conversion Table 6 presents data on the relationship between Rockwell hardness and Rockwell superficial hardness of austenitic stainless steel sheet.

1.7 Conversion Table 7presents data on the relationship among Brinell hardness, Vickers hardness, Rockwell hardness, Rockwell superficial hardness, and Knoop hardness of copper.

1.8 Conversion Table 8 presents data on the relationship among Brinell hardness, Rockwell hardness, and Vickers hardness of alloyed white iron.

1.9 Conversion Table 9 presents data on the relationship among Brinell hardness, Vickers hardness, Rockwell hardness, and Rockwell superficial hardness of wrought aluminum products.

1.10 Many of the conversion values presented herein were obtained from computer-generated curves of actual test data. Most Rockwell hardness numbers are presented to the nearest 0.1 or 0.5 hardness number to permit accurate reproduction of these curves. Since all converted hardness values must be considered approximate, however, all converted Rockwell hardness numbers shall be rounded to the nearest whole number in accordance with Practice E 29.

1.11 Appendix X1-Appendix X9 contain equations developed from the data in Table 1-9, respectively, to convert from one hardness scale to another. Since all converted hardness values must be considered approximate, however, all converted hardness numbers shall be rounded in accordance with Practice E 29.

1.12 Conversion of hardness values should be used only when it is impossible to test the material under the conditions specified, and when conversion is made it should be done with discretion and under controlled conditions. Each type of hardness test is subject to certain errors, but if precautions are carefully observed, the reliability of hardness readings made on instruments of the indentation type will be found comparable. Differences in sensitivity within the range of a given hardness scale (for example, Rockwell B) may be greater than between two different scales or types of instruments. The conversion values, whether from the tables or calculated from the equations, are only approximate and may be inaccurate for specific application.

General Information

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:E140 −07

StandardHardness Conversion Tables for

Metals Relationship Among Brinell Hardness, Vickers

Hardness, Rockwell Hardness, Superficial Hardness, Knoop

1

Hardness, and Scleroscope Hardness

This standard is issued under the fixed designation E140; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope* 1.6 Conversion Table 6 presents data on the relationship

between Rockwell hardness and Rockwell superficial hardness

1.1 Conversion Table 1 presents data in the Rockwell C

of austenitic stainless steel sheet.

hardness range on the relationship among Brinell hardness,

Vickers hardness, Rockwell hardness, Rockwell superficial

1.7 Conversion Table 7presents data on the relationship

hardness, Knoop hardness, and Scleroscope hardness of non-

among Brinell hardness, Vickers hardness, Rockwell hardness,

austenitic steels including carbon, alloy, and tool steels in the

Rockwell superficial hardness, and Knoop hardness of copper.

as-forged, annealed, normalized, and quenched and tempered

1.8 Conversion Table 8 presents data on the relationship

conditions provided that they are homogeneous.

among Brinell hardness, Rockwell hardness, and Vickers

1.2 Conversion Table 2 presents data in the Rockwell B

hardness of alloyed white iron.

hardness range on the relationship among Brinell hardness,

1.9 Conversion Table 9 presents data on the relationship

Vickers hardness, Rockwell hardness, Rockwell superficial

among Brinell hardness, Vickers hardness, Rockwell hardness,

hardness, Knoop hardness, and Scleroscope hardness of non-

and Rockwell superficial hardness of wrought aluminum prod-

austenitic steels including carbon, alloy, and tool steels in the

ucts.

as-forged, annealed, normalized, and quenched and tempered

conditions provided that they are homogeneous.

1.10 Many of the conversion values presented herein were

1.3 Conversion Table 3 presents data on the relationship

obtained from computer-generated curves of actual test data.

among Brinell hardness, Vickers hardness, Rockwell hardness, Most Rockwell hardness numbers are presented to the nearest

Rockwell superficial hardness, and Knoop hardness of nickel

0.1 or 0.5 hardness number to permit accurate reproduction of

and high-nickel alloys (nickel content over 50 %). These these curves. Since all converted hardness values must be

hardness conversion relationships are intended to apply par-

considered approximate, however, all converted Rockwell

ticularly to the following: nickel-aluminum-silicon specimens hardness numbers shall be rounded to the nearest whole

finished to commercial mill standards for hardness testing,

number in accordance with Practice E29.

covering the entire range of these alloys from their annealed to

1.11 Appendix X1-Appendix X9 contain equations devel-

their heavily cold-worked or age-hardened conditions, includ-

oped from the data in Tables 1–9, respectively, to convert from

ing their intermediate conditions.

one hardness scale to another. Since all converted hardness

1.4 Conversion Table 4 presents data on the relationship

valuesmustbeconsideredapproximate,however,allconverted

among Brinell hardness, Vickers hardness, Rockwell hardness,

hardnessnumbersshallberoundedinaccordancewithPractice

and Rockwell superficial hardness of cartridge brass.

E29.

1.5 Conversion Table 5presents data on the relationship

1.12 Conversion of hardness values should be used only

between Brinell hardness and Rockwell B hardness of auste-

when it is impossible to test the material under the conditions

nitic stainless steel plate in the annealed condition.

specified, and when conversion is made it should be done with

discretion and under controlled conditions. Each type of

hardness test is subject to certain errors, but if precautions are

1

carefullyobserved,thereliabilityofhardnessreadingsmadeon

These conversion tables are under the jurisdiction ofASTM Committee E28 on

Mechanical Testing and are the direct responsibility of Subcommittee E28.06 on

instruments of the indentation type will be found comparable.

Indentation Hardness Testing.

Differences in sensitivity within the range of a given hardness

Current edition approved Jan. 1, 2007. Published January 2007. Originally

´1

scale (for example, Rockwell B) may be greater than between

approved in 1958. Last previous edition approved in 2005 as E140 – 05 . DOI:

10.1520/E0140-07. two different scales or types of instruments. The conversion

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM Internatio

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.