ASTM B483/B483M-00

(Specification)Standard Specification for Aluminum and Aluminum-Alloy Drawn Tubes for General Purpose Applications

Standard Specification for Aluminum and Aluminum-Alloy Drawn Tubes for General Purpose Applications

SCOPE

1.1 This specification covers aluminum and aluminum-alloy drawn tubes in straight lengths and coils for general purpose applications in the alloys (Note 3), and tempers shown in Table 2. Coiled tubes are generally available only as round tubes with a wall thickness not exceeding 0.083 in. and only in non-heat-treatable alloys. Note 1-For drawn seamless tubes, see Specification B210, for tubes to be used in condensers and heat exchangers, Specification B234, and for seamless pipe, Specification B241/B241M. Note 2-Throughout this specification use of the term alloy in the general sense includes aluminum as well as aluminum alloy.

1.2 For acceptance criteria for inclusion of new aluminum and aluminum alloys in this specification, see Annex A2.

1.3 A complete metric companion to Specification B483 has been developed-B483M; therefore, no metric equivalents appear in this specification.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: B 483/B 483M – 00

Standard Specification for

Aluminum and Aluminum-Alloy Drawn Tubes for General

Purpose Applications

This standard is issued under the fixed designation B 483/B 483M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope * Cast Aluminum- and Magnesium-Alloy Products [Metric]

B 597 Practice for Heat Treatment of Aluminum Alloys

1.1 This specification covers aluminum and aluminum-alloy

B 660 Practices for Packaging/Packing of Aluminum and

drawn tubes in straight lengths and coils for general purpose

Magnesium Products

applications in the alloys (Note 2), and tempers shown in Table

B 666/B 666M Practice for Identification Marking of Alu-

1. Coiled tubes are generally available only as round tubes with

minum and Magnesium Products

a wall thickness not exceeding 0.083 in. [2.00 mm] and only in

E 29 Practice for Using Significant Digits in Test Data to

non-heat-treatable alloys.

Determine Conformance with Specifications

NOTE 1—For drawn seamless tubes, see Specifications B 210 and

E 34 Test Methods for Chemical Analysis of Aluminum and

B 210M, for tubes to be used in condensers and heat exchangers,

Aluminum-Base Alloys

Specifications B 234 and B 234M, and for seamless pipe, Specification

E 55 Practice for Sampling Wrought Nonferrous Metals and

B 241/B 241M.

Alloys for Determination of Chemical Composition

NOTE 2—Throughout this specification use of the term alloy in the

general sense includes aluminum as well as aluminum alloy. E 215 Practice for Standardizing Equipment for Electro-

magnetic Testing of Seamless Aluminum-Alloy Tube

1.2 Alloy and temper designations are in accordance with

E 227 Test Method for Optical Emission Spectrometric

ANSI H35.1 and H35.1M. The equivalent Unified Number

Analysis of Aluminum and Aluminum Alloys by the

System alloy designations are those of Table 2 preceded by A9,

Point-to-Plane Technique

for example A91060 for aluminum 1060 in accordance with

E 527 Practice for Numbering Metals and Alloys (UNS)

Practice E 527.

E 607 Test Method for Optical Emission Spectrometric

1.3 For acceptance criteria for inclusion of new aluminum

Analysis of Aluminum and Aluminum Alloys by the

and aluminum alloys in this specification, see Annex A2.

Point-to-Plane Technique, Nitrogen Atmosphere

1.4 The values stated in either inch-pound units or SI units

E 716 Practices for Sampling Aluminum and Aluminum

are to be regarded separately as standard. Within the text, the

Alloys for Spectrochemical Analysis

SI units are shown in brackets. The values stated in each

E 1251 Test Method for Optical Emission Spectrometric

system are not exact equivalents; therefore, each system shall

Analysis of Aluminum and Aluminum Alloys by the Argon

be used independently of the other. Combining values from the

Atmosphere, Point-to-Plane, Unipolar Self-Initiating Ca-

two systems may result in nonconformance with the specifi-

pacitor Discharge

cation.

2.3 ANSI Standards:

H35.1 Alloy and Temper Designation Systems for Alumi-

2. Referenced Documents

num

2.1 The following documents of the issue in effect on date

H35.1M Alloy and Temper Designation Systems for Alu-

of order acceptance form a part of this specification to the

minum [Metric]

extent referenced herein:

H35.2 Dimensional Tolerances for Aluminum Mill Prod-

2.2 ASTM Standards:

ucts

B 557 Test Methods for Tension Testing Wrought and Cast

2 H35.2M Dimensional Tolerances for Aluminum Mill Prod-

Aluminum- and Magnesium-Alloy Products

ucts [Metric]

B 557M Test Methods for Tension Testing Wrought and

2.4 Military Standard:

This specification is under the jurisdiction of ASTM Committee B07 on Light

Metals and Alloys and is the direct responsibility of Subcommittee B07.03 on Annual Book of ASTM Standards, Vol 14.02.

Aluminum Alloy Wrought Products. Annual Book of ASTM Standards, Vol 03.05.

Current edition approved May 10, 2000. Published August 2000. Originally Annual Book of ASTM Standards, Vol 03.03.

e1 6

published as B 483–83. Last previous edition B 483–95 . Annual Book of ASTM Standards, Vol 01.01.

2 7

Annual Book of ASTM Standards, Vol 02.02. Annual Book of ASTM Standards, Vol 03.06.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

B 483/B 483M

MIL-STD-129 Marking for Shipment and Storage 4.2.8 Whether certification of the material by the producer is

2.5 Military Specification: required (Section 19).

MIL-H-6088 Heat Treatment of Aluminum Alloys

5. Manufacture

2.6 Federal Standard:

5.1 The tube may be produced by drawing tube stock

Fed. Std. No. 123 Marking for Shipment (Civil Agencies)

produced by extrusion through a bridge-type die or by die and

3. Terminology

mandrel methods, at the option of the producer, provided that

3.1 Definitions: the production method results in material that meets all

3.1.1 tube—a hollow wrought product that is long in rela-

requirements of this specification.

tion to its cross section, that is round, a regular hexagon, a 5.2 The ends of coils shall be crimped or otherwise sealed to

regular octagon, elliptical, or square or rectangular with sharp

avoid contamination during shipment.

or rounded corners, and that has uniform wall thickness except

6. Responsibility For Quality Assurance

as may be affected by corner radii.

6.1 Responsibility for Inspection and Tests—Unless other-

3.1.2 drawn tube—a tube brought to final dimensions by

wise specified in the contract or purchase order, the producer is

drawing through a die.

responsible for the performance of all inspection and test

3.1.3 producer—the primary manufacturer of the material.

requirements specified herein. Except as otherwise specified in

3.1.4 supplier—includes only the category of jobbers and

the contract or order, the producer may use his own or any

distributors as distinct from producers.

other suitable facilities for the performance of the inspection

3.2 Definition of Term Specific to This Standard:

and test requirements specified herein, unless disapproved by

3.2.1 capable of—The term capable of as used in this

the purchaser. The purchaser shall have the right to perform

specification means that the test need not be performed by the

producer of the material. However, should testing by the any of the inspections and tests set forth in this specification

where such inspections are deemed necessary to assure that

purchaser establish that the material does not meet these

requirements, the material shall be subject to rejection. material conforms to prescribed requirements.

6.2 Lot Definition—An inspection lot shall be defined as

4. Ordering Information

follows:

4.1 Orders for material to this specification shall include the

6.2.1 For heat-treated tempers, an inspection lot shall con-

following information:

sist of an identifiable quantity of material of the same alloy,

4.1.1 This specification designation (which includes the

temper, and nominal dimensions, traceable to a heat-treat lot or

number, the year, and the revision letter, if applicable),

lots, and subjected to inspection at one time.

4.1.2 Quantity in pieces or pounds,

6.2.2 For nonheat-treated tempers, an inspection lot shall

4.1.3 Alloy (7.1),

consist of an identifiable quantity of material of the same mill

4.1.4 Temper (8.1),

form, alloy, temper, and nominal dimensions subjected to

4.1.5 Cross-sectional dimensions (outside diameter and wall

inspection at one time.

thickness, or inside diameter and wall thickness for round tube;

7. Chemical Composition

for tube other than round, square, rectangular, hexagonal, or

7.1 Limits—The tubes shall conform to the composition in

octagonal with sharp corners, a drawing is required),

4.1.6 Length (straight or coiled), Table 2. Conformance shall be determined by the producer by

analyzing samples taken at the time the ingots are poured, or

4.1.7 Nominal inside diameter of coils and weight or

maximum outside diameter, if applicable, samples taken from the finished or semifinished product. If the

4.2 Additionally, orders for materials to this specification producer has determined the composition of the material

shall include the following information when required by the during the course of manufacture, he shall not be required to

purchaser: sample and analyze the finished product.

4.2.1 Whether heat treatment shall be in accordance with

NOTE 3—It is standard practice in the United States aluminum industry

Practice B 597 (9.2),

to determine conformance to the composition limits prior to further

4.2.2 Whether testing for leaks is required (11.1),

processing of ingots into wrought products. Due to the continuous nature

4.2.3 Whether specified number of leaks are allowed, and

of the process, it is not practical to keep a specific ingot analysis identified

with a specific quantity of finished material.

the manner of marking leaks (11.1.3.2),

4.2.4 Whether inside cleanliness test is required on coiled

7.2 Number of Samples—The number of samples taken for

tubes (12.2), and frequency of testing required,

determination of chemical composition shall be as follows:

4.2.5 Whether inspection or witness of inspection and tests

7.2.1 When samples are taken at the time the ingots are

by the purchaser’s representative is required prior to material

poured, at least one sample shall be taken for each group of

shipment (15.1),

ingots poured simultaneously from the same source of molten

4.2.6 Whether marking for identification is required (17.1),

metal.

4.2.7 Whether Practices B 660 applies, and if so, the levels

7.2.2 When samples are taken from the finished or semifin-

of preservation, packaging, and packing required (18.3), and,

ished product, a sample shall be taken to represent each 4000

lb [2000 kg] or fraction thereof of material in the lot, except

that no more than one sample shall be required per piece.

Available from Standardization Documents Order Desk, Bldg. 4 Section D, 700

Robbins Ave., Philadelphia, PA 19111-5094, Attn: NPODS. 7.3 Methods of Sampling—Samples for determination of

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

B 483/B 483M

chemical composition shall be taken in accordance with one of 8.4 Test Methods—The tension tests shall be made in

the following methods: accordance with Test Methods B 557 and B 557M.

7.3.1 Samples for chemical analysis shall be taken from the

material by drilling, sawing, milling, turning, or clipping a

9. Heat Treatment

representative piece or pieces to obtain a prepared sample of

9.1 Unless specified in 9.2, producer or supplier heat treat-

not less than 75 g. Sampling shall be in accordance with

ment for the applicable tempers in Table 1 shall be in

Practice E 55.

accordance with MIL-H-6088.

7.3.2 Sampling for spectrochemical analysis shall be in

9.2 When specified, heat treatment of applicable tempers in

accordance with Practices E 716. Samples for other methods of

Table 1 shall be in accordance with Practice B 597.

analysis shall be suitable for the form of material being

analyzed and the type of analytical method used.

10. Heat Treatment and Reheat Treatment Capability

7.4 Methods of Analysis—The determination of chemical

composition shall be made in accordance with suitable chemi-

10.1 As-received material in the O or F temper and in alloys

cal (Test Methods E 34), or spectrochemical (Test Methods

6061 and 6063 (within the size limitations specified in Table 1

E 227, E 607, and E 1251), methods. Other methods may be

and without the imposition of cold work) shall, after proper

used only when no published ASTM method is available. In

solution heat treatment and natural aging for not less than 4

case of dispute, the methods of analysis shall be agreed upon

days at room temperature, conform to the properties specified

between the producer and purchaser.

in Table 1 for T42 temper material.

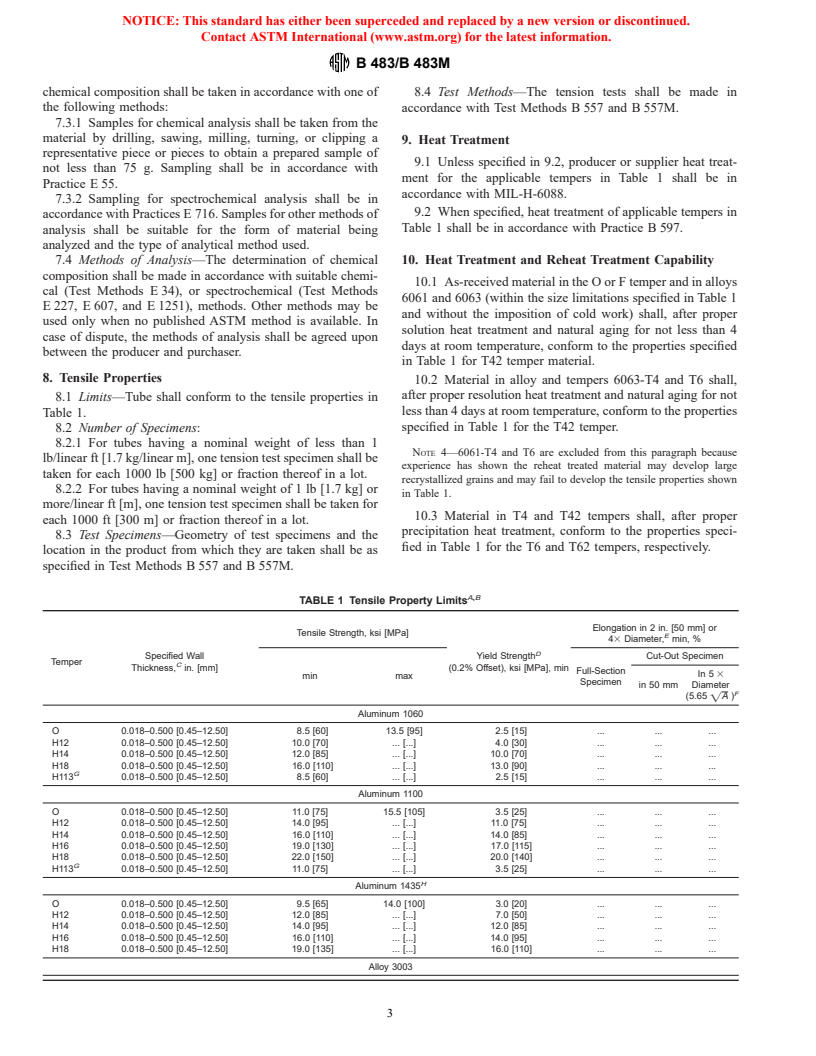

8. Tensile Properties

10.2 Material in alloy and tempers 6063-T4 and T6 shall,

after proper resolution heat treatment and natural aging for not

8.1 Limits—Tube shall conform to the tensile properties in

less than 4 days at room temperature, conform to the properties

Table 1.

specified in Table 1 for the T42 temper.

8.2 Number of Specimens:

8.2.1 For tubes having a nominal weight of less than 1

NOTE 4—6061-T4 and T6 are excluded from this paragraph because

lb/linear ft [1.7 kg/linear m], one tension test specimen shall be

experience has shown the reheat treated material may develop large

taken for each 1000 lb [500 kg] or fraction thereof in a lot.

recrystallized grains and may fail to develop the tensile properties shown

8.2.2 For tubes having a nominal weight of 1 lb [1.7 kg] or

in Table 1.

more/linear ft [m], one tension test specimen shall be taken for

10.3 Material in T4 and T42 tempers shall, after proper

each 1000 ft [300 m] or fraction thereof in a lot.

precipitation heat treatment, conform to the properties speci-

8.3 Test Specimens—Geometry of test specimens and the

fied in Table 1 for the T6 and T62 tempers, respectively.

location in the product from which they are taken shall be as

specified in Test Methods B 557 and B 557M.

A,B

TABLE 1 Tensile Property Limits

Elongation in 2 in. [50 mm] or

Tensile Strength, ksi [MPa]

E

43 Diameter, min, %

D

Specified Wall Yield Strength Cut-Out Specimen

Temper

C

Thickness, in. [mm] (0.2% Offset), ksi [MPa], min

Full-Section

In 5 3

min max

Specimen

in 50 mm Diameter

F

(5.65 A )

=

Aluminum 1060

O 0.018–0.500 [0.45–12.50] 8.5 [60] 13.5 [95] 2.5 [15] . . .

H12 0.018–0.500 [0.45–12.50] 10.0 [70] . [.] 4.0 [30] . . .

H14 0.018–0.500 [0.45–12.50] 12.0 [85] . [.] 10.0 [70] . . .

H18 0.018–0.500 [0.45–12.50] 16.0 [110] . [.] 13.0 [90] . . .

G

H113 0.018–0.500 [0.45–12.50] 8.5 [60] . [.] 2.5 [15] . . .

Aluminum 1100

O 0.018–0.500 [0.45–12.50] 11.0 [75] 15.5 [105] 3.5 [25] . . .

H12 0.018–0.500 [0.45–12.50] 14.0 [95] . [.] 11.0 [75] . . .

H14 0.018–0.500 [0.45–12.50] 16.0 [110] . [.] 14.0 [85] . . .

H16 0.018–0.500 [0.45–12.50] 19.0 [130] . [.] 17.0 [115] . . .

H18 0.018–0.500 [0.45–12.50] 22.0 [150] . [.] 20.0 [140] . . .

G

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.