ASTM B210/B210M-19a

(Specification)Standard Specification for Aluminum and Aluminum-Alloy Drawn Seamless Tubes

Standard Specification for Aluminum and Aluminum-Alloy Drawn Seamless Tubes

ABSTRACT

This specification covers aluminum and aluminum-alloy drawn seamless tubes in straight lengths and coils for general purpose. The tube shall be produced by drawing an extruded tube made from hollow extrusion ingot (cast in hollow form or pierced) and extruded by the use of the die and mandrel method. The tubes shall conform to the chemical composition requirements specified. The determination of chemical composition shall be made in accordance with suitable chemical (test methods E 34), or spectrochemical (test methods E 607 and E 1251), methods. The tube shall conform to the tensile property requirements specified. The tension tests shall be made in accordance with test methods B 557M. Flattening test specimens shall be flattened sidewise under a gradually applied load so as to give a uniform radius of bend until the minimum outside diameter under load is not more than F times the wall thickness of the tube as specified. The specimen shall be forced axially with steady pressure over a hardened and polished tapered steel pin having a 74° included angle, to produce a flare having the permanent expanded outside diameter specified. When specified, heat treatment of applicable tempers shall be in accordance with practice B 918. The different methods for leak testing of tubes are presented.

SCOPE

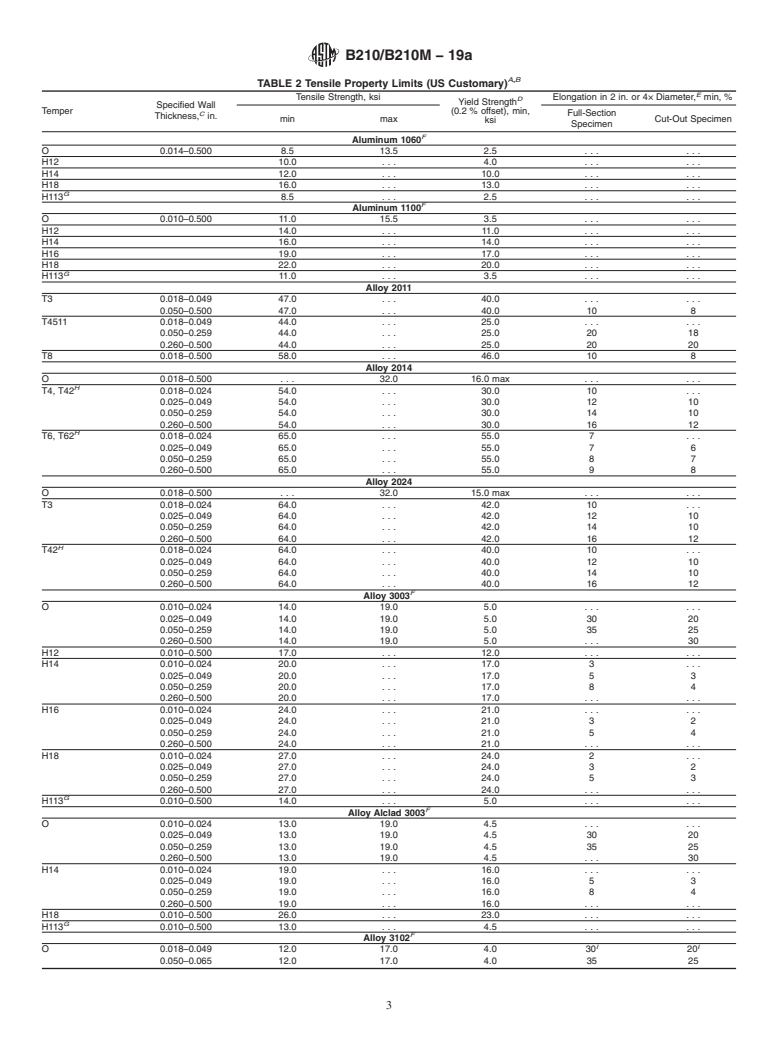

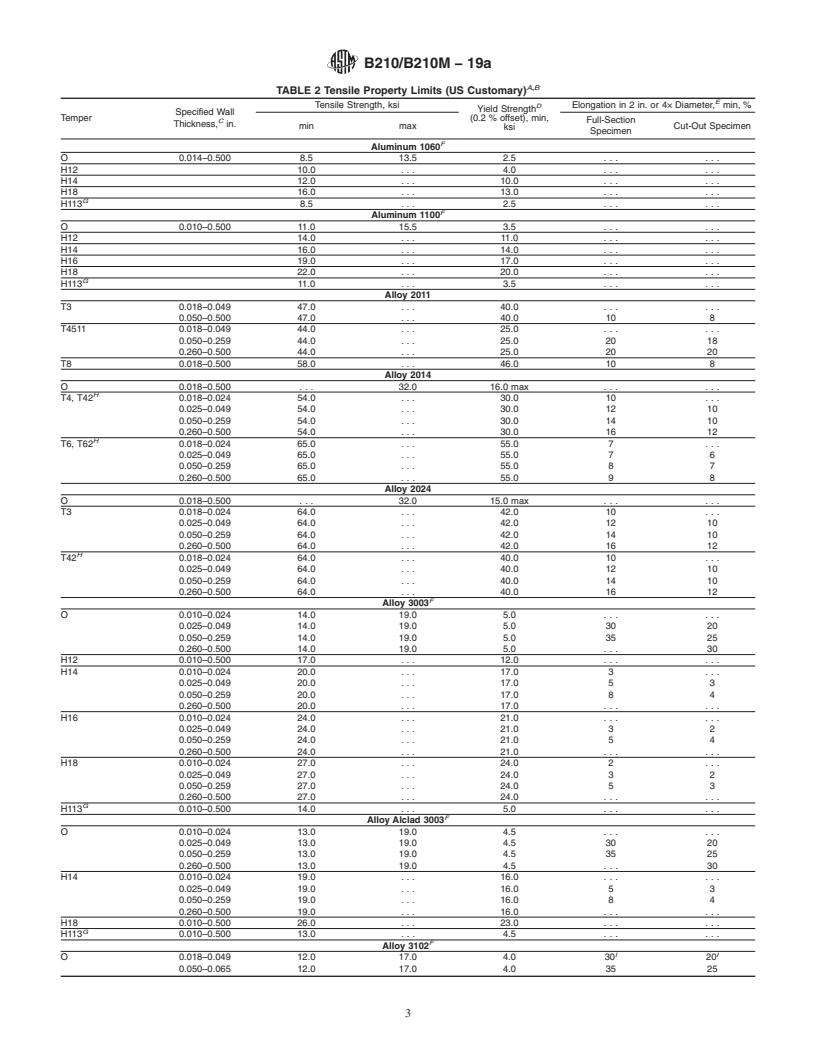

1.1 This specification2 covers aluminum and aluminum-alloy drawn seamless tubes in straight lengths and coils for general purpose and pressure applications in alloys (Note 2), tempers, and thicknesses shown in Table 2 [Table 3]. Coiled tubes are generally available only as round tubes with a wall thickness not exceeding 0.083 in. [2.00 mm] and only in non-heat-treatable alloys.

Wall Thickness, in.

[Wall Thickness, mm]

Location

up through 0.100

surface of tensile sample

[up through 2.50]

0.101 and over

sub-surface after removal of approximately 10 % of thickness

[over 2.50]

1.2 Alloy and temper designations are in accordance with ANSI H35.1/H35.1M. The equivalent Unified Numbering System alloy designations are those of Table 1 preceded by A9, for example, A91100 for aluminum designation 1100 in accordance with Practice E527.

Note 1: See Specification B483/B483M for aluminum-alloy drawn tubes for general purpose applications; Specification B234 for aluminum-alloy drawn seamless tubes for condensers and heat exchangers; and Specification B241/B241M for aluminum-alloy seamless pipe and seamless extruded tube.

Note 2: Throughout this specification, use of the term alloy in the general sense includes aluminum as well as aluminum alloy.

1.3 For acceptance criteria for inclusion of new aluminum and aluminum alloys in this specification, see Annex A2.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: B210/B210M −19a Used in USNRC-NDT standards

Standard Specification for

1

Aluminum and Aluminum-Alloy Drawn Seamless Tubes

This standard is issued under the fixed designation B210/B210M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope* 2. Referenced Documents

2

2.1 The following documents of the issue in effect on date

1.1 This specification covers aluminum and aluminum-

of material purchase form a part of this specification to the

alloy drawn seamless tubes in straight lengths and coils for

extent referenced herein:

general purpose and pressure applications in alloys (Note 2),

3

tempers, and thicknesses shown in Table 2 [Table 3]. Coiled

2.2 ASTM Standards:

tubes are generally available only as round tubes with a wall

B234Specification for Aluminum and Aluminum-Alloy

thickness not exceeding 0.083 in. [2.00mm] and only in

Drawn Seamless Tubes for Surface Condensers,

non-heat-treatable alloys.

Evaporators, and Heat Exchangers

B241/B241MSpecification for Aluminum and Aluminum-

1.2 Alloy and temper designations are in accordance with

Alloy Seamless Pipe and Seamless Extruded Tube

ANSI H35.1/H35.1M. The equivalent Unified Numbering

B483/B483MSpecification for Aluminum and Aluminum-

SystemalloydesignationsarethoseofTable1precededbyA9,

Alloy Drawn Tube and Drawn Pipe for General Purpose

for example,A91100 for aluminum designation 1100 in accor-

Applications

dance with Practice E527.

B557Test Methods for Tension Testing Wrought and Cast

NOTE 1—See Specification B483/B483M for aluminum-alloy drawn

Aluminum- and Magnesium-Alloy Products

tubes for general purpose applications; Specification B234 for aluminum-

B557MTest Methods forTensionTestingWrought and Cast

alloy drawn seamless tubes for condensers and heat exchangers; and

Aluminum- and Magnesium-Alloy Products (Metric)

Specification B241/B241M for aluminum-alloy seamless pipe and seam-

less extruded tube. B660Practices for Packaging/Packing of Aluminum and

NOTE 2—Throughout this specification, use of the term alloy in the

Magnesium Products

general sense includes aluminum as well as aluminum alloy.

B666/B666MPractice for Identification Marking of Alumi-

num and Magnesium Products

1.3 For acceptance criteria for inclusion of new aluminum

B807/B807MPractice for Extrusion Press Solution Heat

and aluminum alloys in this specification, see Annex A2.

Treatment for Aluminum Alloys

1.4 This standard does not purport to address all of the

B881Terminology Relating toAluminum- and Magnesium-

safety concerns, if any, associated with its use. It is the

Alloy Products

responsibility of the user of this standard to establish appro-

B918/B918MPractice for Heat Treatment of Wrought Alu-

priate safety, health, and environmental practices and deter-

minum Alloys

mine the applicability of regulatory limitations prior to use.

B985Practice for SamplingAluminum Ingots, Billets, Cast-

1.5 This international standard was developed in accor-

ings and Finished or Semi-Finished Wrought Aluminum

dance with internationally recognized principles on standard-

Products for Compositional Analysis

ization established in the Decision on Principles for the

E29Practice for Using Significant Digits in Test Data to

Development of International Standards, Guides and Recom-

Determine Conformance with Specifications

mendations issued by the World Trade Organization Technical

E215PracticeforStandardizingEquipmentandElectromag-

Barriers to Trade (TBT) Committee.

netic Examination of Seamless Aluminum-Alloy Tube

E527Practice for Numbering Metals and Alloys in the

Unified Numbering System (UNS)

1

This specification is under the jurisdiction ofASTM Committee B07 on Light

E607 Test Method for Atomic Emission Spectrometric

Metals and Alloys and is the direct responsibility of Subcommittee B07.03 on

Aluminum Alloy Wrought Products.

Current edition approved Nov. 1, 2019. Published November 2019. Originally

3

approved in 1946. Last previous edition approved in 2019 as B210/B210M–19. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

DOI: 10.1520/B0210_B0210M-19A. contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

2

For ASME Boiler and Pressure Vessel Code applications see related Specifi- Standards volume information, refer to the standard’s Document Summary page on

cation SB-210 in Section II of that Code. the ASTM websi

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: B210/B210M − 19 B210/B210M − 19a Used in USNRC-NDT standards

Standard Specification for

1

Aluminum and Aluminum-Alloy Drawn Seamless Tubes

This standard is issued under the fixed designation B210/B210M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*

2

1.1 This specification covers aluminum and aluminum-alloy drawn seamless tubes in straight lengths and coils for general

purpose and pressure applications in alloys (Note 2), tempers, and thicknesses shown in Table 2 [Table 3]. Coiled tubes are

generally available only as round tubes with a wall thickness not exceeding 0.083 in. [2.00 mm] and only in non-heat-treatable

alloys.

1.2 Alloy and temper designations are in accordance with ANSI H35.1/H35.1M. The equivalent Unified Numbering System

alloy designations are those of Table 1 preceded by A9, for example, A91100 for aluminum designation 1100 in accordance with

Practice E527.

NOTE 1—See Specification B483/B483M for aluminum-alloy drawn tubes for general purpose applications; Specification B234 for aluminum-alloy

drawn seamless tubes for condensers and heat exchangers; and Specification B241/B241M for aluminum-alloy seamless pipe and seamless extruded tube.

NOTE 2—Throughout this specification, use of the term alloy in the general sense includes aluminum as well as aluminum alloy.

1.3 For acceptance criteria for inclusion of new aluminum and aluminum alloys in this specification, see Annex A2.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of

regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2.1 The following documents of the issue in effect on date of material purchase form a part of this specification to the extent

referenced herein:

3

2.2 ASTM Standards:

B234 Specification for Aluminum and Aluminum-Alloy Drawn Seamless Tubes for Surface Condensers, Evaporators, and Heat

Exchangers

B241/B241M Specification for Aluminum and Aluminum-Alloy Seamless Pipe and Seamless Extruded Tube

B483/B483M Specification for Aluminum and Aluminum-Alloy Drawn Tube and Drawn Pipe for General Purpose Applications

B557 Test Methods for Tension Testing Wrought and Cast Aluminum- and Magnesium-Alloy Products

B557M Test Methods for Tension Testing Wrought and Cast Aluminum- and Magnesium-Alloy Products (Metric)

B660 Practices for Packaging/Packing of Aluminum and Magnesium Products

B666/B666M Practice for Identification Marking of Aluminum and Magnesium Products

B807/B807M Practice for Extrusion Press Solution Heat Treatment for Aluminum Alloys

B881 Terminology Relating to Aluminum- and Magnesium-Alloy Products

B918/B918M Practice for Heat Treatment of Wrought Aluminum Alloys

B985 Practice for Sampling Aluminum Ingots, Billets, Castings and Finished or Semi-Finished Wrought Aluminum Products for

Compositional Analysis

1

This specification is under the jurisdiction of ASTM Committee B07 on Light Metals and Alloys and is the direct responsibility of Subcommittee B07.03 on Aluminum

Alloy Wrought Products.

Current edition approved Jan. 1, 2019Nov. 1, 2019. Published February 2019. Originally approved in 1946. Last previous edition approved in 20122019 as

B210 – 12.B210 – 19. DOI: 10.1520/B0210_B0210M-19.10.1520/B0210_B0210M-19A.

2

For ASME Boiler and Pressure Vessel Code applications see related Specification SB-210 in Section II of that Code.

3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 --------

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.