ASTM F2459-05

(Test Method)Standard Test Method for Extracting Residue from Metallic Medical Components and Quantifying via Gravimetric Analysis

Standard Test Method for Extracting Residue from Metallic Medical Components and Quantifying via Gravimetric Analysis

SIGNIFICANCE AND USE

This test method is suitable for determination of the extractable residue in metallic medical components. Extractable residue includes aqueous and non-aqueous residue, as well as non-soluble residue.

This test method recommends the use of a sonication technique to extract residue from the medical component. Other techniques, such as solvent reflux extraction, could be used but have been shown to be less efficient in some tests, as discussed in X1.2.

This test method is not applicable for evaluating the extractable residue for the reuse of a single-use component (SUD).

SCOPE

1.1 This test method covers the quantitative assessment of the amount of residue obtained from metallic medical components when extracted with aqueous or organic solvents.

1.2 This test method does not advocate an acceptable level of cleanliness. It identifies one technique to quantify extractable residue on metallic medical components. In addition, it is recognized that this test method may not be the only method to determine and quantify extractables.

1.3 Although these methods may give the investigator a means to compare the relative levels of component cleanliness, it is recognized that some forms of component residue may not be accounted for by these methods.

1.4 The applicability of these general gravimetric methods have been demonstrated by many literature reports; however, the specific suitability for applications to all-metal medical components will be validated by an Interlaboratory Study (ILS) conducted according to Practice E 691.

1.5 This test method is not intended to evaluate the residue level in medical components that have been cleaned for reuse. This test method is also not intended to extract residue for use in biocompatibility testing.

1.6 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.7 This standard may involve hazardous or environmentally-restricted materials, operations, and equipment. This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: F2459 – 05

Standard Test Method for

Extracting Residue from Metallic Medical Components and

Quantifying via Gravimetric Analysis

This standard is issued under the fixed designation F2459; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

1.1 This test method covers the quantitative assessment of 2.1 ASTM Standards:

the amount of residue obtained from metallic medical compo- E691 Practice for Conducting an Interlaboratory Study to

nents when extracted with aqueous or organic solvents. Determine the Precision of a Test Method

1.2 This test method does not advocate an acceptable level G121 Practice for Preparation of Contaminated Test Cou-

of cleanliness. It identifies one technique to quantify extract- pons for the Evaluation of Cleaning Agents

able residue on metallic medical components. In addition, it is G131 Practice for Cleaning of Materials and Components

recognized that this test method may not be the only method to by Ultrasonic Techniques

determine and quantify extractables. G136 Practice for Determination of Soluble Residual Con-

1.3 Although these methods may give the investigator a taminants in Materials by Ultrasonic Extraction

means to compare the relative levels of component cleanliness,

3. Terminology

it is recognized that some forms of component residue may not

3.1 Definitions:

be accounted for by these methods.

1.4 The applicability of these general gravimetric methods 3.1.1 ionic compounds/water soluble residue—residue that

is soluble in water, including surfactants and salts.

have been demonstrated by many literature reports; however,

the specific suitability for applications to all-metal medical 3.1.2 non-soluble debris—residue including metals, organic

solids, inorganic solids, and ceramics.

componentswillbevalidatedbyanInterlaboratoryStudy(ILS)

conducted according to Practice E691. 3.1.3 non-water soluble residue—residue soluble in sol-

vents other than water. Inclusive in this are oils, greases,

1.5 This test method is not intended to evaluate the residue

hydrocarbons, and low molecular weight polymers. Typical

level in medical components that have been cleaned for reuse.

This test method is also not intended to extract residue for use solvents used to dissolve these residues include chlorinated or

fluorinated solvents, or low molecular weight hydrocarbons.

in biocompatibility testing.

1.6 The values stated in SI units are to be regarded as the 3.1.4 reflux system—an apparatus containing an extraction

vessel and a solvent return system. It is designed to allow

standard. The values given in parentheses are for information

only. boiling of the solvent in the extraction vessel and to return any

vaporized solvent to the extraction vessel.

1.7 This standard may involve hazardous or

environmentally-restricted materials, operations, and equip- 3.1.5 reuse—the repeated or multiple use of any medical

component (whether labeled SUD or reusable) with reprocess-

ment. This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the ing (cleaning, disinfection, or sterilization, or combination

thereof) between patient uses.

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica- 3.1.6 single use component (SUD)—a disposable compo-

nent; intended to be used on one patient during a single

bility of regulatory limitations prior to use.

procedure.

3.1.7 surface area—the projected surface area of a part.

This area does not include the internal porosity of parts with

This test method is under the jurisdiction ofASTM Committee F04 on Medical

cancellous, porous, or wire structure.

and Surgical Materials and Devices and is the direct responsibility of Subcommittee

F04.15 on Material Test Methods.

Current edition approved Aug. 1, 2005. Published August 2005. DOI: 10.1520/

F2459-05. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

For extraction of samples intended for the biological evaluation of devices or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

materials, refer to ISO 10993-12 Biological Evaluation—Sample Preparation and Standards volume information, refer to the standard’s Document Summary page on

Reference Materials. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

F2459 – 05

3.2 Symbols: 5. Significance and Use

5.1 This test method is suitable for determination of the

extractable residue in metallic medical components. Extract-

m = weight of extraction vessel and component before

ableresidueincludesaqueousandnon-aqueousresidue,aswell

extraction

as non-soluble residue.

m = weight of extraction vessel, component, and solvent

after extraction

5.2 This test method recommends the use of a sonication

m = mass of clean beaker used to hold removed aliquot of

3 technique to extract residue from the medical component.

extracted solution

Other techniques, such as solvent reflux extraction, could be

m = mass of beaker and aliquot of solution before drying

used but have been shown to be less efficient in some tests, as

m = mass of beaker and residue after evaporating solvent

discussed in X1.2.

m = mass of new filter

5.3 This test method is not applicable for evaluating the

m = mass of filter following filtration and drying

extractable residue for the reuse of a single-use component

m = mass of residue in removed aliquot

a

(SUD).

c = concentration of residue in solution

r

c = concentration of residue in blank solutions

b

m = mass of soluble residue in the overall extract, cor- 6. Apparatus

r

rected for the blank runs

6.1 Ultrasonic Bath, for extraction. The bath must be large

m = weight of insoluble debris

i

enough to hold an extraction beaker containing the medical

m = mass of soluble and insoluble residue

t

component. This apparatus is used with the technique de-

E = extraction efficiency

scribed in 11.5. Alternatively, an ultrasonic probe can be used

4. Summary of Test Method with a bath.

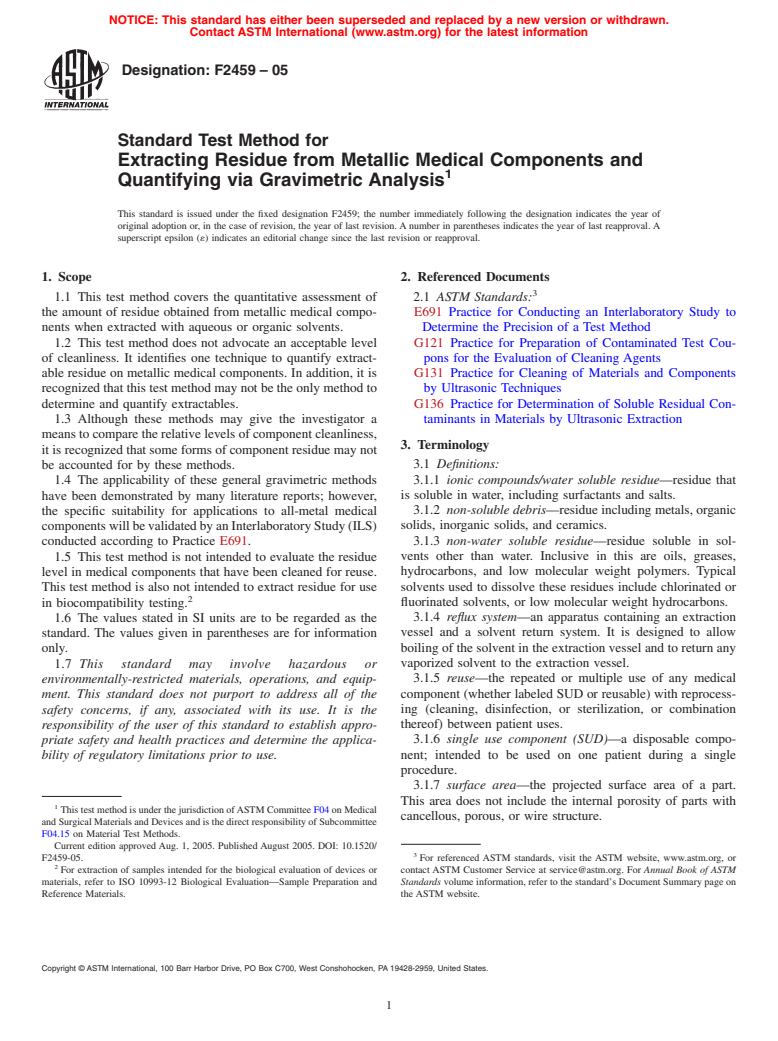

4.1 This test method describes the extraction and quantita- 6.2 Solvent Reflux Extraction Assembly, shown in Fig. 1.

Thisassemblyiscomposedofavessellargeenoughtoholdthe

tive analysis procedures used to detect and quantify extractable

residue from metallic medical components. The residues are medical component, and a water-cooled refluxing column. A

grouped into three categories: (1) water-soluble extractables; heating manifold or hotplate stirrer capable of reaching the

(2) non-water soluble extractables; and (3) non-soluble debris. boiling point of the solvent is also included. This apparatus is

FIG. 1 Sample Solvent Reflux Extractor Assembly

F2459 – 05

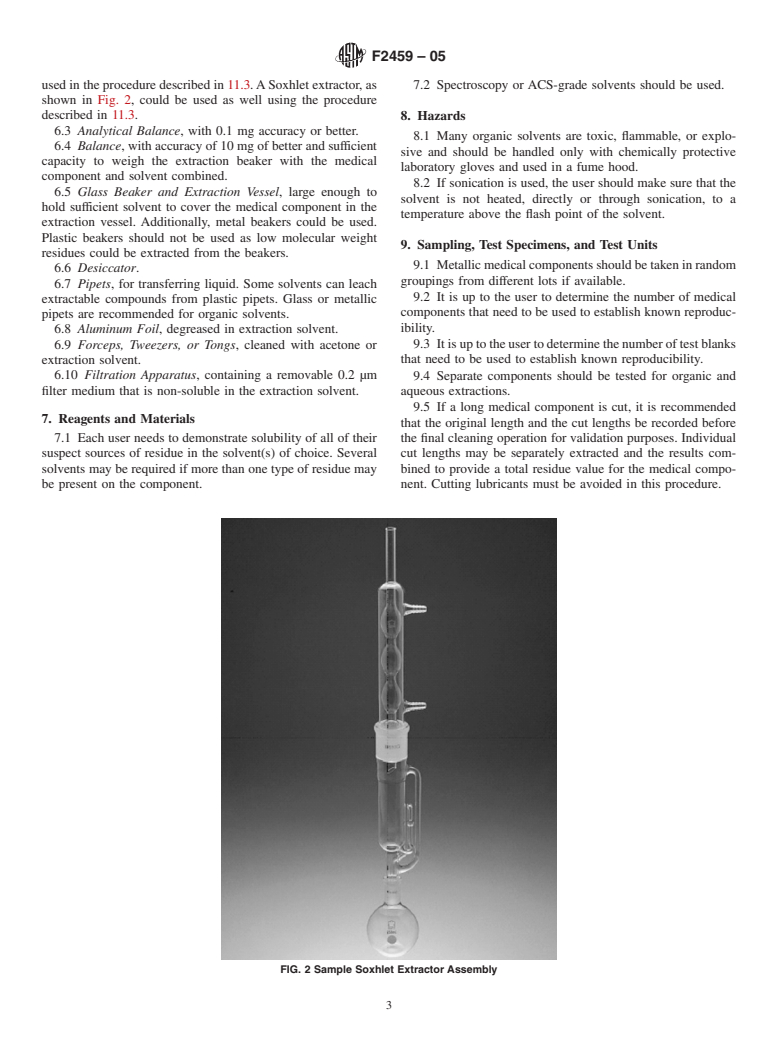

used in the procedure described in 11.3.ASoxhlet extractor, as 7.2 Spectroscopy or ACS-grade solvents should be used.

shown in Fig. 2, could be used as well using the procedure

described in 11.3.

8. Hazards

6.3 Analytical Balance, with 0.1 mg accuracy or better.

8.1 Many organic solvents are toxic, flammable, or explo-

6.4 Balance, with accuracy of 10 mg of better and sufficient

sive and should be handled only with chemically protective

capacity to weigh the extraction beaker with the medical

laboratory gloves and used in a fume hood.

component and solvent combined.

8.2 If sonication is used, the user should make sure that the

6.5 Glass Beaker and Extraction Vessel, large enough to

solvent is not heated, directly or through sonication, to a

hold sufficient solvent to cover the medical component in the

temperature above the flash point of the solvent.

extraction vessel. Additionally, metal beakers could be used.

Plastic beakers should not be used as low molecular weight

9. Sampling, Test Specimens, and Test Units

residues could be extracted from the beakers.

9.1 Metallicmedicalcomponentsshouldbetakeninrandom

6.6 Desiccator.

groupings from different lots if available.

6.7 Pipets, for transferring liquid. Some solvents can leach

9.2 It is up to the user to determine the number of medical

extractable compounds from plastic pipets. Glass or metallic

components that need to be used to establish known reproduc-

pipets are recommended for organic solvents.

ibility.

6.8 Aluminum Foil, degreased in extraction solvent.

6.9 Forceps, Tweezers, or Tongs, cleaned with acetone or 9.3 Itisuptotheusertodeterminethenumberoftestblanks

that need to be used to establish known reproducibility.

extraction solvent.

6.10 Filtration Apparatus, containing a removable 0.2 µm

9.4 Separate components should be tested for organic and

filter medium that is non-soluble in the extraction solvent. aqueous extractions.

9.5 If a long medical component is cut, it is recommended

7. Reagents and Materials

that the original length and the cut lengths be recorded before

7.1 Each user needs to demonstrate solubility of all of their the final cleaning operation for validation purposes. Individual

suspect sources of residue in the solvent(s) of choice. Several cut lengths may be separately extracted and the results com-

solvents may be required if more than one type of residue may bined to provide a total residue value for the medical compo-

be present on the component. nent. Cutting lubricants must be avoided in this procedure.

FIG. 2 Sample Soxhlet Extractor Assembly

F2459 – 05

10. Limits of Detection and Recovery Efficiency 11.3.14 Weigh an aliquot beaker large enough to hold an

aliquot of the extraction vessel along with a clean piece of foil

10.1 Standardized test coupons can be prepared according

and record the weight as m . The beaker should be weighed to

to Practice G121. Limits of detection with the two techniques 3

a resolution of at least 0.1 mg.

can be assessed by placing known amounts of residues on the

11.3.15 Allow the insoluble debris to settle in the extraction

test coupons, and performing the extraction and analyses

vessel for 1 h. Withdraw an aliquot of the extracted solution

described in Section 11.The recovery efficiency of the selected

that comprises at least 90 % of the total extracted solution and

extraction technique should be determined by doping pre-

place in the aliquot beaker as described in 11.3.14, being

cleaned medical components with known amounts of the target

carefulnottowithdrawanyinsolubledebrisfromthebottomof

residue, then extracting and quantifying the target residue. The

the extraction vessel. Weigh the solution with beaker and foil

extraction efficiency E is the ratio of the amount of recovered

and record as m .

residue to the doped amount of residue.

10.2 The user should adjust the extraction parameters in 11.3.15.1 Allow the solvent to completely evaporate in a

11.3.11 or 11.5.8, or select the appropriate solvent, or both, in

fume hood at room temperature. See X1.1.3 for more details.

order to achieve an extraction efficiency of E>75%.

11.3.15.2 Place the beaker, with residue, in a dessicator for

a minimum of 2 h.

11. Procedure

11.3.15.3 Weigh the beaker and foil again and record as m .

11.1 If more than one specimen is to be extracted collec-

11.3.15.4 If the volume of the aliquot beaker is smaller than

tively, record the number of specimens.

the aliquot, multiple aliquots can be removed from the extrac-

11.2 If multiple specimens are to be extracted collectively,

tionvessel,weighingeachaliquot,evaporatingthesolvent,and

they must be of the same type and size.

collecting the next aliquot. The solution weight m is the sum

11.3 Reflux Extraction:

of the aliquot weights plus the foil weight. The final beaker

11.3.1 Equipmentmayneedtobecleanedwithnitricacidor

weight m should be recorded as described in 11.3.15.3.

other appropriate means prior to solvent cleaning.

11.4 Blank Run:

11.3.2 Clean the extraction equipment by rinsing at least

11.4.1 Conduct test blank(s) using the same amount of

three times with spectroscopy-grade hexane or another suitable

solvent and rinses, but no component, for the complete

solvent. The extraction solvent may be used.

extractionandanalysisprocedure.Recordallweightsasabove.

11.3.3 Air dry all beakers and glassware at room tempera-

11.5 Sonication Extraction:

ture in a fume hood and store in a dessicator prior to use.

11.5.1 Backgroundinformationonsonicationextractioncan

11.3.4 Assemble the extraction apparatus as shown in Fig.

be found in Practices G131 and G136.

1.

11.5.2 Glassware may need to be cleaned with nitric acid or

11.3.5 Do not use any type of joint grease on the extraction

other appropriate means prior to solvent cleaning.

assembly. It can dissolve in the solvent and contaminate the

solution.Polytetrafluoroethylene(PTFE)sleevesortapecanbe 11.5.3 Clean the glassware by rinsing at least three times

used to seal the joints if necessary. with spectroscopy-grade hexane or another suitable solvent.

11.3.6 Place the sample component in the extractor vessel The extraction solvent may be used.

and add a magnetic stirring bar or PTFE boiling stones to

11.5.4 Air dry all beakers and glassware at room tempera-

reducethepotentialforboilingretardationinthesystemduring

ture in a fume hood and store in a dessicator prior to use.

reflux. The stir bar or boiling stones, or both, should be

11.5.5 Place the medical component in a beaker, cover with

carefully cleaned in a suitable solvent prior to use.

clean foil, and weigh. Record the weight as m .

11.3.7 Weigh the extractor vessel with the component on a

11.5.6 Add enough solvent to completely cover the compo-

balance and record the weight m .

nent.

11.3.8 Charge the flask with enough solvent to completely

11.5.7 Cover the beaker with the clean aluminum foil, then

cover the component(s) and assemble the reflux system.

place in a sonicator bath.The aluminum foil should not contact

11.3.9 Start flow of cooling water through the condenser.

the water in the sonicator bath.

11.3.10 Adjust the hotplate stirrer or heating manifold to

11.5.8 Startthesonicatorbath,andextractthecomponent(s)

maintain the solvent at a brisk boil with moderate constant

for a time period and temperature determined by the user

stirring.

pending internal validation of their extraction efficiency on the

11.3.11 Extract the component(s) for 4 h or for approxi-

targetresidues.Theextractiontemperatureshouldbebelowthe

mately 10 cycles if using a Soxhlet extractor. The extraction

boiling point of the solvent. More details on sonication times

time or number of

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.