ASTM D7214-06

(Test Method)Standard Test Method for Determination of the Oxidation of Used Lubricants by FT-IR Using Peak Area Increase Calculation

Standard Test Method for Determination of the Oxidation of Used Lubricants by FT-IR Using Peak Area Increase Calculation

SCOPE

1.1 This test method covers the determination of the oxidation of used lubricants by FT-IR (Fourier Transform Infrared Spectroscopy). It measures the concentration change of constituents containing a carbonyl function that have formed during the oxidation of the lubricant.

1.2 This test method may be used to indicate relative changes that occur in an oil under oxidizing conditions. The test method is not intended to measure an absolute oxidation property that can be used to predict performance of an oil in service.

1.3 This test method was developed for transmission oils which have been degraded either in service, or in a laboratory test, for example a bulk oxidation test. It may be used for other in-service oils, but the stated precision may not apply.

1.4 The results of this test method may be affected by the presence of other components with an absorbance band in the zone of 1600-1800 cm-1. Low PAI values may be difficult to determine in those cases. Section describes these possible interferences in more detail.

1.5 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation:D7214–06

Standard Test Method for

Determination of the Oxidation of Used Lubricants by FT-IR

Using Peak Area Increase Calculation

This standard is issued under the fixed designation D 7214; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

This test method was jointly developed with “Groupement Francais de Coordination” (GFC),

technical committee LM5 and “Coordinating European Council” (CEC) Surveillance GroupT-048 for

the purpose of monitoring the oxidation stability of artificially aged automotive transmission fluids.

This test method has been used in the CEC L-48-A-00 method as an end of test measurement

parameter.

1. Scope 2. Referenced Documents

1.1 This test method covers the determination of the oxida- 2.1 ASTM Standards:

tion of used lubricants by FT-IR (Fourier Transform Infrared D 4057 Practice for Manual Sampling of Petroleum and

Spectroscopy). It measures the concentration change of con- Petroleum Products

stituents containing a carbonyl function that have formed D 4177 Practice for Automatic Sampling of Petroleum and

during the oxidation of the lubricant. Petroleum Products

1.2 This test method may be used to indicate relative D 6299 Practice for Applying Statistical Quality Assurance

changes that occur in an oil under oxidizing conditions. The Techniques to Evaluate Analytical Measurement System

test method is not intended to measure an absolute oxidation Performance

property that can be used to predict performance of an oil in E 131 Terminology Relating to Molecular Spectroscopy

service. E 1421 Practice for Describing and Measuring Performance

1.3 This test method was developed for transmission oils of Fourier Transform Mid-Infrared (FT-MIR) Spectrom-

which have been degraded either in service, or in a laboratory eters: Level Zero and Level One Tests

test, for example a bulk oxidation test. It may be used for other E 1866 Guide for Establishing Spectrophotometer Perfor-

in-service oils, but the stated precision may not apply. mance Tests

1.4 The results of this test method may be affected by the 2.2 CEC Standard:

presence of other components with an absorbance band in the CEC L-48-A-00 Oxidation Stability of Lubricating Oils

-1 3

zone of 1600–1800 cm . Low PAI values may be difficult to Used in Automotive Transmissions by Artificial Aging

determine in those cases. Section 6 describes these possible

3. Terminology

interferences in more detail.

3.1 Definitions—For terminology relating to molecular

1.5 The values stated in SI units are to be regarded as

spectroscopic methods, refer to Terminology E 131.

standard. No other units of measurement are included in this

standard. 3.2 Definitions of Terms Specific to This Standard:

3.2.1 carbonyl region, n—region of the FT-IR spectrum

1.6 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the corresponding to the absorbance of compounds containing a

carbonyl function. Depending on the nature of the carbonyl

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

This test method is under the jurisdiction of ASTM Committee D02 on Standards volume information, refer to the standard’s Document Summary page on

Petroleum Products and Lubricants and is the direct responsibility of Subcommittee the ASTM website.

D02.96 on In-Service Lubricant Testing and Condition Monitoring Services. Available from Coordinating European Council (CEC), c/o Interlynk Admin-

Current edition approved Jan. 1, 2006. Published March 2006. istrative Services, Ltd., P.O. Box 6475, Earl Shilton, Leicester, LE9 9ZB, U.K.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D7214–06

compounds, this region is usually located between approxi- 8.2 Heptane, used as cleaning solvent. Other solvents and

-1 -1

mately 1820 cm and 1650 cm . solvent mixtures may be used provided they adequately clean

3.2.2 differential spectrum, n—FT-IR absorbance spectrum the cell(s) between samples. A 50/50 mixture of cyclohexane

resulting from the subtraction of the fresh oil from the used oil. and toluene has been found to be useful in cleaning cells after

3.2.3 PAI (peak area increase), n—area of the carbonyl highly contaminated and degraded samples have been run.

region of the differential FT-IR spectrum, divided by the cell (Warning—Flammable.)

pathlength in millimetres. In this standard, PAI refers to a 8.3 PAO4, used as dilution oil (PAO4: PolyAlphaOlefin

relative measurement of the oxidation of a used lubricant by withakinematicviscosityat100°Cofapproximately4mm /s)

FT-IR.

9. Calibration and Standardization

4. Summary of Test Method

9.1 Calculation of the Cell Pathlength—Use a cell with a

4.1 FT-IR spectra of the fresh oil and of the used oil are

knownpathlengthofapproximately0.025to0.1mm.Calibrate

recorded in a transmission cell of known pathlength. Both

the infrared cell pathlength using the interference fringe

spectra are converted to absorbance and then subtracted. Using

method:

this resulting differential spectrum, a baseline is set under the

9.1.1 Acquire the background infrared spectrum. Insert the

-1

peak corresponding to the carbonyl region around 1650 cm

empty infrared cell into the infrared spectrometer sample

-1

and 1820 cm and the area created by this baseline and the

compartment and acquire the cell infrared spectrum. The final

carbonyl peak is calculated. The area of the carbonyl region is

spectrum is obtained by subtraction of the background spec-

divided by the cell pathlength in millimetres and this result is

trum from the cell spectrum.

reported as Peak Area Increase (PAI).

NOTE 1—This computation is generally an integral part of the infrared

spectrometer software.

5. Significance and Use

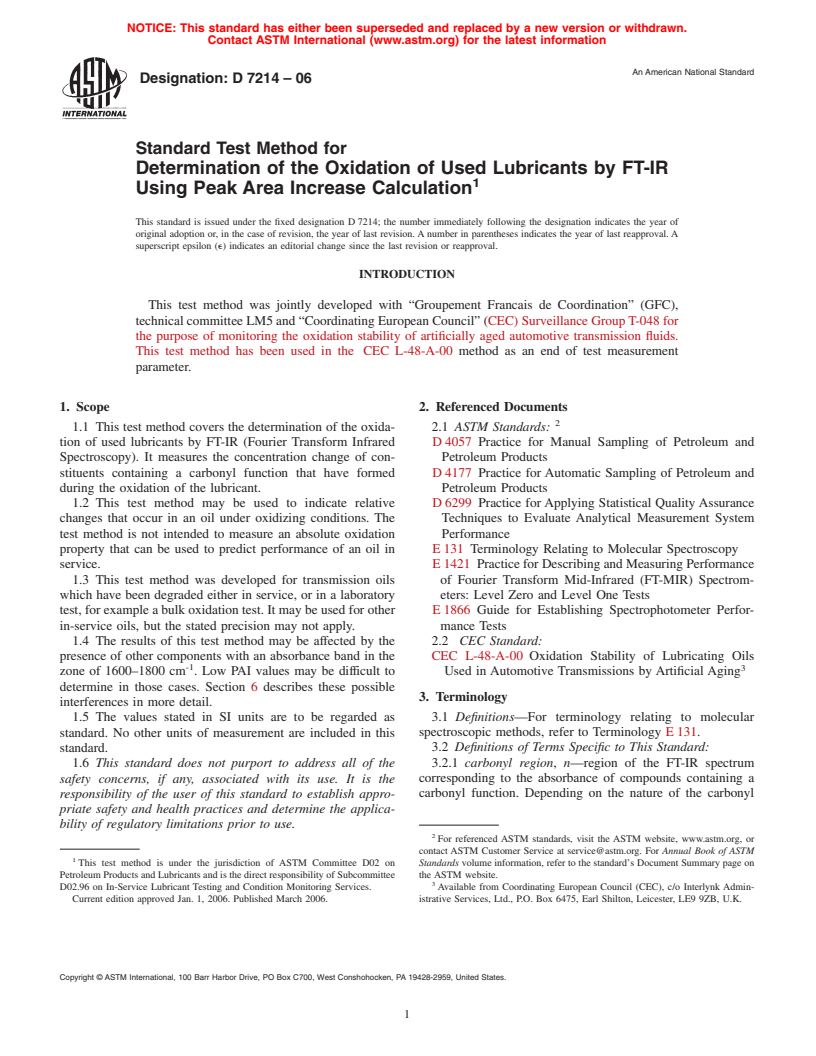

9.1.2 Choose 2 minima separated by about 20 measurable

5.1 The PAI is representative of the quantity of all the

interference fringes as shown in Fig. 1. Count the number of

compoundscontainingacarbonylfunctionthathaveformedby

interference fringes between the lower and the higher wave-

the oxidation of the lubricant (aldehydes, ketones, carboxylic

numbers, referred to as l and l .

1 2

acids, esters, anhydrides, etc.). The PAI gives representative

informationonthechemicaldegradationofthelubricantwhich NOTE 2—The spectral range may be chosen freely in an area where the

fringes are regular.

has been caused by oxidation.

5.2 This test method was developed for transmission oils

9.1.3 The cell pathlength is calculated by the formula:

and is used in the CEC L-48-A-00 test (Oxidation Stability of

5· n

Lubricating Oils Used in Automotive Transmissions by Artifi- e 5 (1)

~l 2l !

1 2

cial Aging) as a parameter for the end of test evaluation.

where:

6. Interferences

e = the pathlength in mm, and

n = the number of fringes between l and l .

6.1 Some specific cases (very viscous oil, use of ester as 1 2

9.2 Instrument Performance Checks:

base stock, high soot content) may require a dilution of the

9.2.1 Periodically, the performance of the FT-IR instrument

sample and a specific area calculation, which are described in

should be monitored using the Level 0 procedure of Practice

14.1-14.3. In those cases, the result is corrected by a dilution

E 1421. If significant change in performance is noted, then

factor, which is applied to the sample.

testing should be suspended until the cause of the performance

change is diagnosed and corrected.

7. Apparatus

9.2.2 Alternative instrument performance tests conforming

7.1 FT-IR Spectrophotometer, suitable for recording mea-

to the recommendations of Guide E 1866 may be substituted

-1 -1

surements between 1650 cm and 1820 cm and with a

-1 for the Practice E 1421 test.

resolution of 4 cm .

7.2 Transmission Cell,withwindowsofpotassiumbromide,

10. Conditioning

having a known pathlength of approximately 0.025 to 0.1 mm.

10.1 Before using the infrared cell ensure that it is clean by

7.3 Syringe, or Other Automated or Semi-Automated De-

washing through with a suitable solvent, for example, heptane.

vice, with adequate volume to fill the cell, for example, 2 mL.

Dry the cell using dry air or nitrogen, if necessary. Calibrate

8. Reagents and Materials this cell as described in Section 9.

8.1 Purity of Reagents—Reagent grade chemicals shall be

11. Preparation of Sample of Used Oil

used in all tests. Unless otherwise indicated, it is intended that

all reagents shall conform to the specifications of the commit- 11.1 Refer to Practice D 4057 (Manual Sampling) or Prac-

tee onAnalytical Reagents of theAmerican Chemical Society, tice D 4177 (Automatic Sampling) for proper sampling tech-

where such specifications are available. Other grades may be niques.

used, provided it is first ascertained that the reagent is of 11.2 When sampling used lubricants, the specimen shall be

sufficiently high purity to permit its use without lessening the representative of the system sampled and shall be free of

accuracy of the determination. contamination from external sources. As used oil can change

D7214–06

FIG. 1 Example of Interference Fringes for Cell Pathlength Calculation

appreciably in storage, test samples as soon as possible after Processing may continue if the maximum absorbance of this

removal from the lubricating system and note the dates of carbonyl region is lower than 1.5.

sampling and testing.

NOTE 4—Since the carbonyl region absorption minima (close to 1820

11.3 Ifthesampleofusedoilcontainsvisiblesediment,heat

-1 -1

cm and 1650 cm ) can vary with the type of oil sample being tested, it

to 60 6 5°C in the original container and agitate until all of the

was decided not to use fixed baseline limits for calculating the area A.

sedimentishomogeneouslysuspendedintheoil.Iftheoriginal

NOTE 5—The carbonyl band may consist of more than one peak

container is a can or if it is glass and more than three-fo

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.