ASTM C794-93

(Test Method)Standard Test Method for Adhesion-in-Peel of Elastomeric Joint Sealants

Standard Test Method for Adhesion-in-Peel of Elastomeric Joint Sealants

SCOPE

1.1 This test method covers a laboratory procedure for determining the strength and characteristics of the peel properties of a cured-in-place elastomeric joint sealant, single- or multicomponent, for use in building construction.

1.2 The values stated in metric (SI) units are to be regarded as the standard. The values given in parentheses are provided for information only.

1.3 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: C 794 – 93

Standard Test Method for

Adhesion-in-Peel of Elastomeric Joint Sealants

This standard is issued under the fixed designation C 794; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope the embedded cloth is peeled back from the substrate at 180°,

and measuring the force exerted as well as the nature of the

1.1 This test method covers a laboratory procedure for

separation of the sealant from the substrate.

determining the strength and characteristics of the peel prop-

erties of a cured-in-place elastomeric joint sealant, single- or

5. Significance and Use

multicomponent, for use in building construction.

5.1 There are differences in opinion among those concerned

1.2 The values stated in metric (SI) units are to be regarded

with sealant technology whether or not this adhesion-in-peel

as the standard. The values given in parentheses are provided

test is intended to simulate the conditions encountered by a

for information only.

sealant in normal use. Nevertheless, since it represents a test to

1.3 This standard does not purport to address all of the

destruction, the value of the test denotes the ability of the cured

safety problems, if any, associated with its use. It is the

sealant to maintain a bond to the substrate under severe

responsibility of the user of this standard to establish appro-

conditions.

priate safety and health practices and determine the applica-

5.2 Many sealant manufacturers utilize the adhesion-in-peel

bility of regulatory limitations prior to use.

test for determining the adhesive characteristics of sealant/

2. Referenced Documents primer combinations with unusual or proprietary substrates.

2.1 ASTM Standards:

6. Apparatus and Materials

C 33 Specification for Concrete Aggregates

6.1 Testing Machine with tension grips capable of pulling at

C 109 Test Method for Compressive Strength of Hydraulic

3 the rate of separation of 51 mm (2 in.)/min, and having a chart

Cement Mortars (Using 2-in. or 50-mm Cube Specimens)

indicator calibrated in 0.45-kg (1-lb) units.

C 150 Specification for Portland Cement

4 6.2 Standard Substrates:

C 717 Terminology of Building Seals and Sealants

6.2.1 Aluminum Alloy, Type 6063-T5 or 6061-T6, with a

G 23 Practice for Operating Light-Exposure Apparatus

clear anodized finish of not less than 0.0075-mm (0.3-mil)

(Carbon-Arc Type) With and Without Water for Exposure

thickness over a scale-free finish; 2 pieces, 152 by 76 by 6.3

of Nonmetallic Materials

mm (6 by 3 by ⁄4 in.).

3. Terminology 6.2.2 Mortar Slabs, prepare two cement mortar slabs, each

152 by 76 by 9.5 mm (6 by 3 by ⁄8 in.) in size, using one part

3.1 Definitions—See Terminology C 717 for applicable

of high early strength portland cement conforming to Type III

definitions of the following terms: cure, elastomeric, joint,

of Specification C 150 for Portland Cement, to two parts by

primer, sealant, and substrate.

weight of clean, uniformly graded, concrete fine aggregate

4. Summary of Test Method

(sand) conforming to Specification C 33, for Concrete Aggre-

gates. Use sufficient water to produce a flow of 100 6 5 when

4.1 This test method consists of preparing test specimens by

tested in accordance with the procedure for the determination

embedding a strip of cloth in a thin layer of the sealant being

of consistency of cement mortar described in Test Method

tested, on several substrate materials, curing these specimens

C 109. After curing 1 day in moist air and 6 days in saturated

for a certain length of time under specified conditions, then

lime water at 23 6 2°C (73 6 3°F), prepare the surface of 152

placing them in a tension-testing machine in such a way that

by 76 mm (6 by 3 in.) of each slab by wet grinding either with

a belt sander using No. 60 aluminum carbide sanding belt or

using an iron lap with No. 60 silicon carbide (or aluminum

This test method is under the jurisdiction of ASTM Committee C-24 on

oxide) grain until the aggregate is uniformly exposed. Return

Building Seals and Sealants, and is the direct responsibility of Subcommittee

C24.32 on Chemically Curing Sealants.

the slabs to saturated lime water storage until needed.

Current edition approved Nov. 15, 1993. Published January 1994. Originally

6.2.2.1 Slabs may be prepared and shipped to other loca-

published as C 794 – 75. Last previous edition C 794 – 92.

2 tions for use. The slabs may be shipped dry and shall be

Annual Book of ASTM Standards, Vol 04.02.

returned to lime water storage on arrival until needed.

Annual Book of ASTM Standards, Vol 04.01.

Annual Book of ASTM Standards, Vol 04.07.

6.2.2.2 Prior to use, wet grind the previously ground surface

Annual Book of ASTM Standards, Vol 14.02.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

C 794

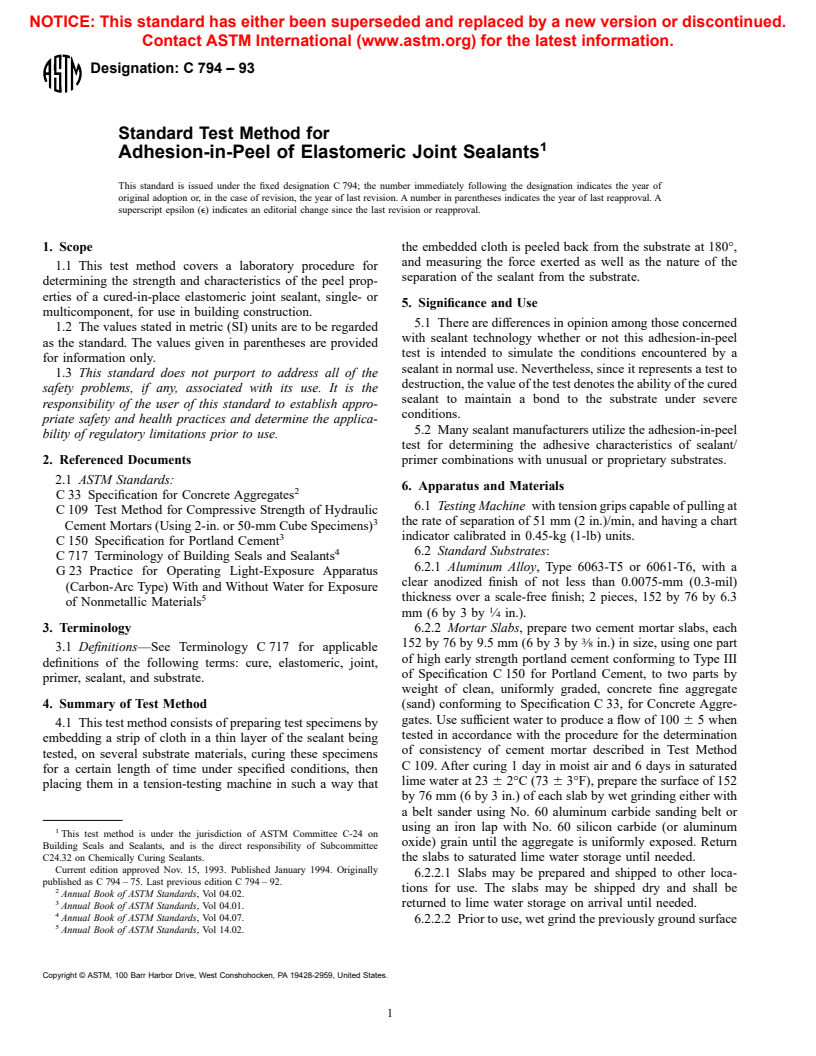

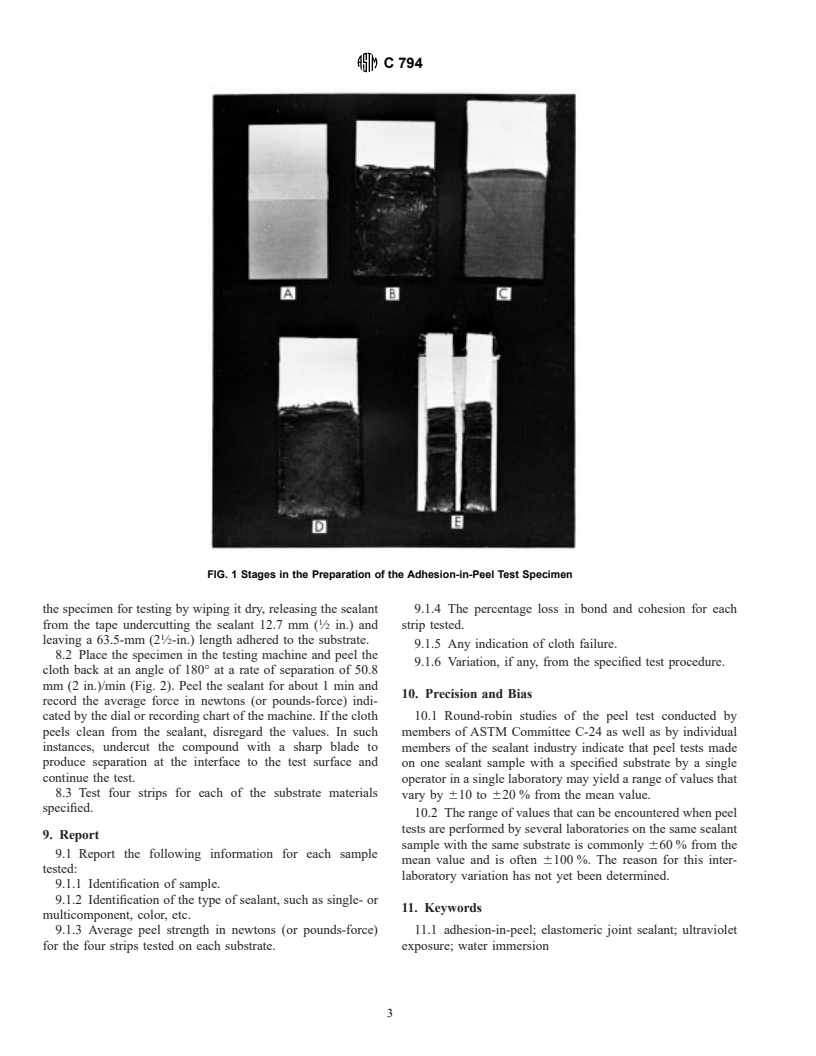

to remove any laitance, rinse thoroughly under running tap 7.1.5 Spread a portion of the conditioned compound, after

water, and dry the slabs overnight at 105 to 110°C (220 to being mixed thoroughly for 5 min (if multicomponent), over

230°F). Clean the slabs by vigorous brushing with a stiff- the 102 by 76-mm (4 by 3-in.) area, which includes the

bristled fiber brush to remove any film or powder. Condition masking tape, to a depth slightly more than 1.6 mm ( ⁄16 in.), as

the slabs at standard conditions for not less than 1 day and not shown in Fig. 1B.

more than 7 days. 7.1.6 Smear one piece of cloth with the compound at one

6.2.3 Plate Glass, polished, clear, 152 by 76 by 6.3 mm (6 end over an area of 102 by 76 mm (4 by 3 in.), forcing it into

by3by ⁄4 in.). both sides of the cloth with a putty knife until the sealant has

thoroughly penetrated the cloth.

NOTE 1—Because of the fact that adhesive properties of a joint sealant

7.1.7 Lay the impregnated cloth over the layer of compound

are related to the nature of the substrate, it is strongly recommended that

and place the spacer bars of proper thickness (see 6.3) on each

whenever possible the peel test be made with the substrates that are to be

used in the building under consideration in addition to or in place of the side of the specimen.

specified substrates described in 6.2.1, 6.2.2, and 6.2.3. Such substrates

7.1.8 Place a 1.6-mm ( ⁄16-in.) metal rod lengthwise on top

include brick, marble, limestone, granite, stainless steel, plastic, quarry 1

of each spacer strip and squeegee the compound to 1.6 mm ( ⁄16

tile, and others. For practical reasons the specimen dimensions may be

in.) thick by rolling the glass rod over the metal rods (starting

changed from the standard sizes provided the thickness of the sealant

from the taped end), and simultaneously pressing on the cloth

remains as specified.

and sealant beneath it. Trim off the excess amount that is

6.3 Spacer Strips, four, of hard wood, metal, or glass as

squeezed out (Fig. 1C).

follows: two 152 by 76 by 6.3 mm (6 by 3 by ⁄4 in.) for

7.1.9 Cure the specimens containing multicomponent com-

preparing the test specimens on aluminum and glass, and two

pounds 14 days at 23 6 2°C (73.4 6 3.6°F). Cure those

of the same length and width but 9.3 mm ( ⁄8 in.) thick for

containing single component compounds 21 days as follows

prepar

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.