ASTM D731-08

(Test Method)Standard Test Method for Molding Index of Thermosetting Molding Powder

Standard Test Method for Molding Index of Thermosetting Molding Powder

SIGNIFICANCE AND USE

This test method provides a guide for evaluating the moldability of thermosetting molding powders. This test method does not necessarily denote that the molding behavior of different materials will be alike and trials may be necessary to establish the appropriate molding index for each material in question.

The sensitivity of this test diminishes when the molding pressure is decreased below 764 psi (5.3 MPa), so pressures lower than this are not ordinarily recommended. This is due to the friction of moving parts and the insensitivity of the pressure switch actuating the timer at these low pressures.

SCOPE

1.1 This test method covers the measurement of the molding index (plasticity) of thermosetting plastics ranging in flow from soft to stiff by selection of appropriate molding pressures within the range from 530 to 5300 psi (3.7 to 36.5 MPa).

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

Note 1—There is no ISO standard equivalent to this test method.

WITHDRAWN RATIONALE

This test method covered the measurement of the molding index of thermosetting plastics ranging in flow from soft to stiff by selection of appropriate molding pressures within the range from 4.1 to 31.9 MPa.

Formerly under the jurisdiction of Committee D20 on Plastics, this test method was withdrawn in August 2008 in accordance with section 10.5.3.1 of the Regulations Governing ASTM Technical Committees, which requires that standards shall be updated by the end of the eighth year since the last approval date.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information.

Designation:D731–08

Standard Test Method for

1

Molding Index of Thermosetting Molding Powder

This standard is issued under the fixed designation D731; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* 4. Summary of Test Method

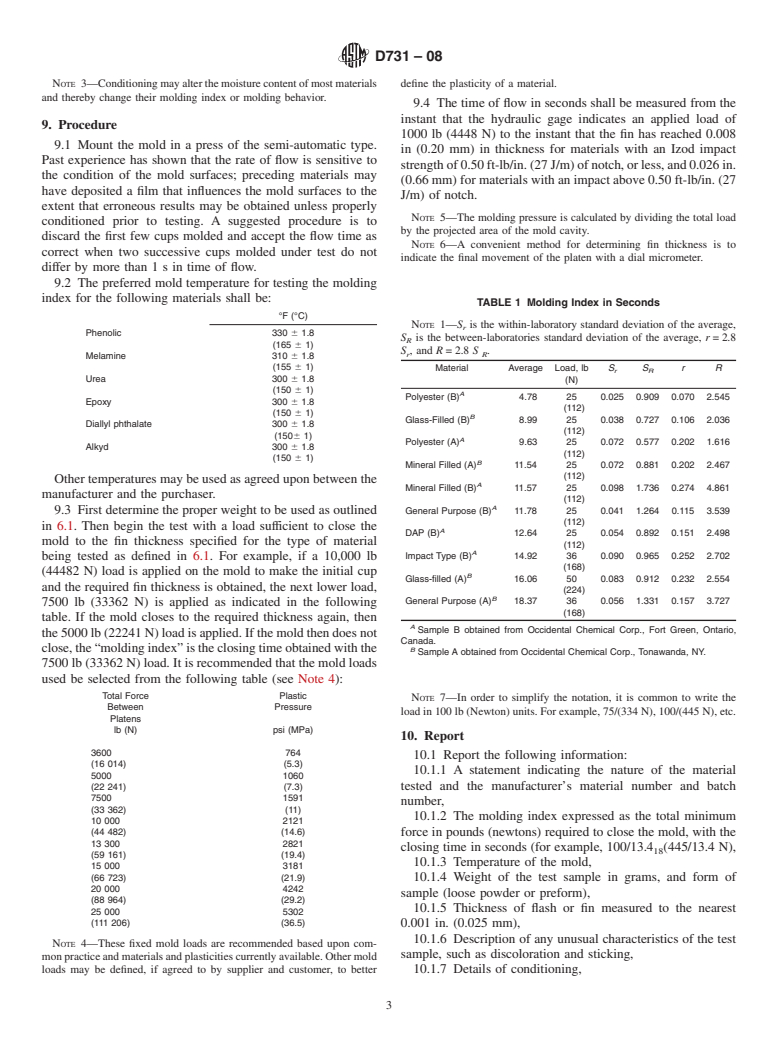

1.1 Thistestmethodcoversthemeasurementofthemolding 4.1 A cup mold is mounted in a semi-automatic type press.

index(plasticity)ofthermosettingplasticsranginginflowfrom A predetermined quantity of test sample is charged into the

soft to stiff by selection of appropriate molding pressures mold, controlled at a temperature dependent upon the test

within the range from 530 to 5300 psi (3.7 to 36.5 MPa). material. The minimum force required to mold a cup having a

1.2 The values stated in inch-pound units are to be regarded flashorfinthicknesswithinaspecifiedtoleranceisdetermined.

as standard. The values given in parentheses are mathematical This force along with the mold closing time is reported as

conversions to SI units that are provided for information only molding index.

and are not considered standard.

5. Significance and Use

1.3 This standard does not purport to address all of the

5.1 This test method provides a guide for evaluating the

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro- moldability of thermosetting molding powders. This test

method does not necessarily denote that the molding behavior

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use. of different materials will be alike and trials may be necessary

to establish the appropriate molding index for each material in

NOTE 1—There is no ISO standard equivalent to this test method.

question.

5.2 The sensitivity of this test diminishes when the molding

2. Referenced Documents

2 pressure is decreased below 764 psi (5.3 MPa), so pressures

2.1 ASTM Standards:

lower than this are not ordinarily recommended. This is due to

D256 Test Methods for Determining the Izod Pendulum

thefrictionofmovingpartsandtheinsensitivityofthepressure

Impact Resistance of Plastics

switch actuating the timer at these low pressures.

D883 Terminology Relating to Plastics

D957 Practice for Determining Surface Temperature of

6. Apparatus

Molds for Plastics

3

6.1 Mold—A cup mold of the flash type, to produce a

E691 Practice for Conducting an Interlaboratory Study to

molded cup as shown in Fig. 1, operated under controlled

Determine the Precision of a Test Method

pressure and temperatures and provided with stops so that flash

or fin thickness cannot be less than 0.0055 in. (0.14 mm). The

3. Terminology

area of the mold casting creating the molded flash shall be

3.1 Definitions are in accordance with Terminology D883,

located on top of the cup, flat, perpendicular to the axis of the

unless otherwise specified.

cup, and in the form of an annular ring 0.125 in. (3.17 mm) in

3.2 Definitions of Terms Specific to This Standard:

width.

3.3 plasticity—a measure of the resistance of a molten

6.2 Pyrometer—A calibrated pyrometer, traceable to a Na-

thermosetting material to flow under heat and pressure. A

tional Institute of Standards and Technology (NIST) standard

measure of the apparent viscosity of the material.

and accurate to 61.8°F (1°C) shall be used to determine the

temperatureofthemoldsurfaces.Forproperlymeasuringmold

1

This test method is under the jurisdiction ofASTM Committee D20 on Plastics

temperatures, reference should be made to Practice D957.

andisthedirectresponsibilityofSubcommitteeD20.30ThermalProperties(Section

6.3 Heating System—Any conventional means for heating

D20.30.08).

Current edition approved Dec. 15, 2008. Published January 2009. Originally the press platens, provided the heat source is constant enough

approved in 1950. Last previous edition approved in 1999 as D731 - 95(1999),

to maintain the molding temperature within 61.8°F (61°C) of

which was withdrawn in August 2008 and reinstated in December 2008. DOI:

the specified temperature (see 9.2).

10.1520/D0731-08.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3

Standards volume information, refer to the standard’s Document Summary page on A detailed drawing of the mold design is available from ASTM Headquarters.

the ASTM website. Order Adjunct: ADJD0731.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:D731–95 (Reapproved 1999) Designation:D731–08

Standard Test Method for

1

Molding Index of Thermosetting Molding Powder

This standard is issued under the fixed designation D 731; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

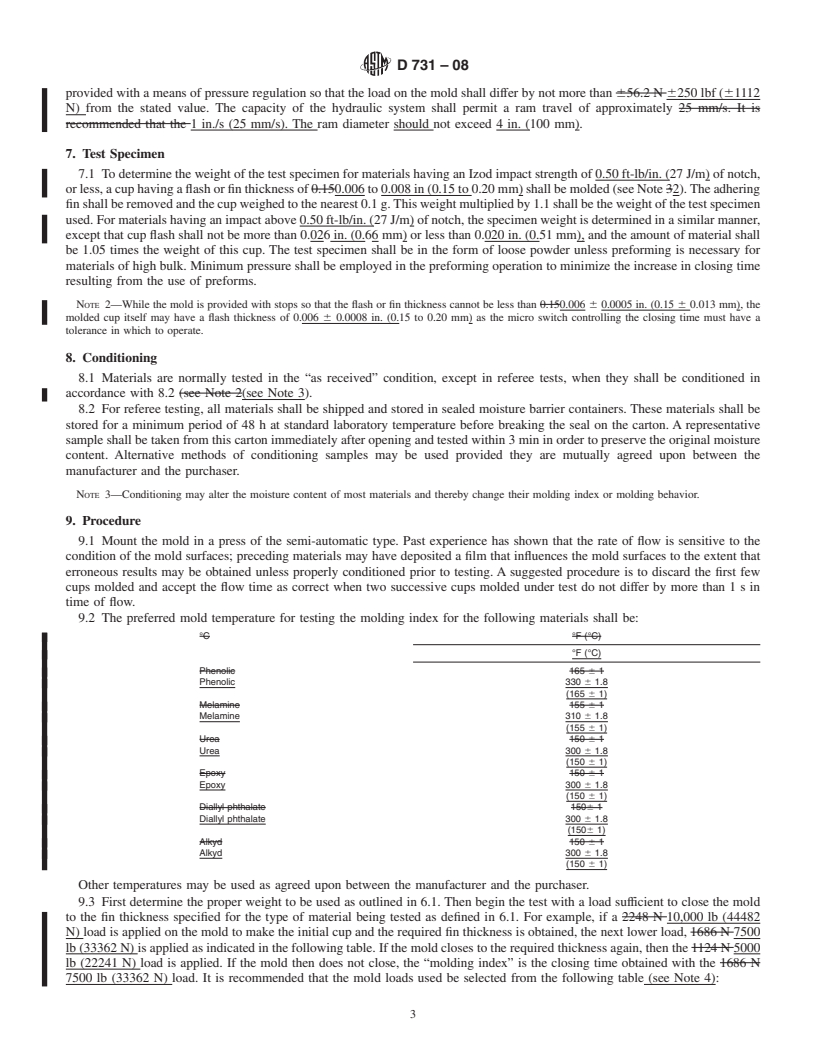

1.1This test method covers the measurement of the molding index of thermosetting plastics ranging in flow from soft to stiff by

selection of appropriate molding pressures within the range from 4.1 to 31.9 MPa.

1.2The values stated in SI units are to be regarded as standard. *

1.1 This test method covers the measurement of the molding index (plasticity) of thermosetting plastics ranging in flow from

soft to stiff by selection of appropriate molding pressures within the range from 530 to 5300 psi (3.7 to 36.5 MPa).

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

NOTE 1—There is no ISO standard equivalent to this test method.

2. Referenced Documents

2

2.1 ASTM Standards:

D 256 TestMethodsforImpactResistanceofPlasticsandElectricalInsulatingMaterialsTestMethodsforDeterminingtheIzod

Pendulum Impact Resistance of Plastics

D 883 Terminology Relating to Plastics

D 957 Practice for Determining Mold Surface Temperature of Molds for Plastics

E 691 Practice for Conducting an Interlaboratory Study to Determine the Precision of a Test Method

3. Terminology

3.1Definitions: Definitions are in accordance with Terminology D883

3.1 Definitions are in accordance with Terminology D 883, unless otherwise specified.

3.2 Definitions of Terms Specific to This Standard:

3.3 plasticity—a measure of the resistance of a molten thermosetting material to flow under heat and pressure. A measure of

the apparent viscosity of the material.

4. Summary of Test Method

4.1 A cup mold is mounted in a semi-automatic type press. A predetermined quantity of test sample is charged into the mold,

controlled at a temperature dependent upon the test material. The minimum force required to mold a cup having a flash or fin

thickness within a specified tolerance is determined. This force along with the mold closing time is reported as molding index.

5. Significance and Use

5.1 This test method provides a guide for evaluating the moldability of thermosetting molding powders. This test method does

not necessarily denote that the molding behavior of different materials will be alike and trials may be necessary to establish the

1

This test method is under the jurisdiction ofASTM Committee D-20 on Plastics and is the direct responsibility of Subcommittee D 20.30 onThermal Properties (Section

D20.30.08).

Current edition approved Feb. 15, 1995. Published April 1995. Originally published as D731-50. Last previous edition D731-90.

1

ThistestmethodisunderthejurisdictionofASTMCommitteeD20onPlasticsandisthedirectresponsibilityofSubcommitteeD20.30ThermalProperties.30onThermal

Properties (Section D20.30.08).

Current edition approved Dec. 15, 2008. Published January 2009. Originally approved in 1950. Last previous edition approved in 1999 as D 731 - 95(1999), which was

withdrawn in August 2008 and reinstated in December 2008.

2

Annual Book of ASTM Standards, Vol 08.01.

2

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D731–08

appropriate molding index for each material in question.

5.2 Thesensitivityofthistestdiminisheswhenthemoldingpressureisdecreasedbelow66MPa,764psi(5.3MPa),sopressures

lower than this are not ordinarily recommended. This is due to the friction of moving parts and

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.