ASTM D6139-00(2005)

(Test Method)Standard Test Method for Determining the Aerobic Aquatic Biodegradation of Lubricants or Their Components Using the Gledhill Shake Flask

Standard Test Method for Determining the Aerobic Aquatic Biodegradation of Lubricants or Their Components Using the Gledhill Shake Flask

SCOPE

1.1 This test method covers the determination of the degree of aerobic aquatic biodegradation of fully formulated lubricants or their components on exposure to an inoculum under controlled laboratory conditions. This test method is an ultimate biodegradation test that measures carbon dioxide (CO2) evolution.

1.2 This test method is intended to specifically address the difficulties associated with testing water insoluble materials and complex mixtures such as are found in many lubricants.

1.3 This test method is designed to be applicable to all non-volatile lubricants or lubricant components that are not toxic and not inhibitory at the test concentration to the organisms present in the inoculum.

1.4 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.5 This standard does not purport to address all the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and to determine the applicability of regulatory limitations prior to use. Specific hazards are discussed in Section .

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D6139–00 (Reapproved 2005)

Standard Test Method for

Determining the Aerobic Aquatic Biodegradation of

Lubricants or Their Components Using the Gledhill Shake

Flask

This standard is issued under the fixed designation D6139; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope Carbon, Hydrogen, and Nitrogen in Petroleum Products

and Lubricants

1.1 This test method covers the determination of the degree

D5864 Test Method for Determining Aerobic Aquatic Bio-

of aerobic aquatic biodegradation of fully formulated lubri-

degradation of Lubricants or Their Components

cants or their components on exposure to an inoculum under

E943 Terminology Relating to Biological Effects and Envi-

controlled laboratory conditions. This test method is an ulti-

ronmental Fate

mate biodegradation test that measures carbon dioxide (CO )

2.2 ISO Standard:

evolution.

4259:1992(E) Petroleum Products—Determination and ap-

1.2 This test method is intended to specifically address the

plication of precision data in relation to methods of test

difficulties associated with testing water insoluble materials

2.3 APHA Standards:

and complex mixtures such as are found in many lubricants.

2540B Total Solids Dried at 103–105°C

1.3 This test method is designed to be applicable to all

9215 Heterotrophic Plate Count

non-volatile lubricants or lubricant components that are not

toxic and not inhibitory at the test concentration to the

3. Terminology

organisms present in the inoculum.

3.1 Definitions:

1.4 The values stated in SI units are to be regarded as

3.1.1 Definitions of terms applicable to this test method

standard. No other units of measurement are included in this

which are not described herein, appear in the Compilation of

standard.

ASTM Standard Definitions (1990) or Terminology E943.

1.5 This standard does not purport to address all the safety

3.1.2 activated sludge, n—the precipitated solid matter,

concerns, if any, associated with its use. It is the responsibility

consisting mainly of bacteria and other aquatic microorgan-

of the user of this standard to establish appropriate safety and

isms, that is produced at a domestic wastewater treatment

health practices and to determine the applicability of regula-

plant; activated sludge is used primarily in secondary sewage

tory limitations prior to use. Specific hazards are discussed in

treatmenttomicrobiallyoxidizedissolvedorganicmatterinthe

Section 10.

effluent.

2. Referenced Documents 3.1.3 aerobic, adj.—(1) taking place in the presence of

2 oxygen; (2) living or active in the presence of oxygen.

2.1 ASTM Standards:

3.1.4 biodegradation, n—the process of chemical break-

D1129 Terminology Relating to Water

down or transformation of a test material caused by organisms

D1193 Specification for Reagent Water

or their enzymes.

D1293 Test Methods for pH of Water

3.1.4.1 Discussion—Biodegradation is only one mechanism

D4447 Guide for Disposal of Laboratory Chemicals and

by which substances are removed from the environment.

Samples

3.1.5 biomass, n—any material, excluding fossil fuels,

D5291 Test Methods for Instrumental Determination of

which is or was a living organism or component of a living

organism.

1 3.1.6 blank, n—in biodegradability testing, a test system

This test method is under the jurisdiction of ASTM Committee D02 on

containingallsystemcomponentswiththeexceptionofthetest

PetroleumProductsandLubricants andisthedirectresponsibilityofSubcommittee

D02.12 on Environmental Standards for Lubricants.

material.

Current edition approved Nov. 1, 2005. Published November 2005. Originally

approved in 1997. Last previous edition approved in 2000 as D6139 – 00. DOI:

10.1520/D6139-00R05. Available from American National Standards Institute, 11 West 42nd St., 13th

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Floor, New York, NY 10036.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Methods from Standard Methods for the Examination of Water and Wastewa-

Standards volume information, refer to the standard’s Document Summary page on ter, latest edition.Available from theAmerican Public HealthAssoc. (APHA), 1015

the ASTM website. 18th St., N.W., Washington, D.C. 20036.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D6139–00 (2005)

3.1.7 inoculum, n—spores, bacteria, single celled organ- The evolved CO is trapped in a Ba(OH) or other alkaline

2 2

isms, or other live materials, that are introduced into a test solution and the amount of CO absorbed is determined by

medium. titrating the remaining hydroxide in solution.

3.1.8 lag phase, n—the period of diminished physiological 4.2 The carbon content of the test material is determined by

activity and cell division following the addition of microorgan- Test Methods D5291 or another appropriate method and the

isms to a new culture medium. theoretical CO is calculated from that measurement. It is

3.1.9 log phase, n—the period of growth of microorganisms necessary to directly measure the carbon content of the test

during which cells divide at a positive constant rate. material instead of calculating this number, because of the

3.1.10 mixed liquor, n—insewagetreatment,thecontentsof complexity of the mixture of compounds present in lubricants.

an aeration tank including the activated sludge mixed with 4.3 Biodegradability is expressed as a percentage of theo-

primary effluent or the raw wastewater and return sludge. retical CO production.

3.1.11 pre-adaptation, n—the incubation of an inoculum in

the presence of the test material which is done prior to the

5. Significance and Use

initiation of the test and under conditions similar to the test

5.1 Results from this CO evolution test method suggest,

conditions.

within the confines of a controlled laboratory setting, the

3.1.11.1 Discussion—The aim of pre-adaptation is to im-

degree of ultimate aerobic aquatic biodegradability of a lubri-

prove the precision of the test method by decreasing variability

cantorcomponentsofalubricant.Testmaterialswhichachieve

in the rate of biodegradation produced by the inoculum.

a high degree of biodegradation in this test method may be

Pre-adaptation may mimic the natural processes which cause

assumed to easily biodegrade in many aerobic aquatic envi-

changes in the microbial population of the inoculum leading to

ronments.

a more rapid rate of biodegradation of the test material but is

5.2 Because of the stringency of this test method, a low

not expected to change the overall extent of biodegradation of

yield of CO does not necessarily mean that the test material is

the test material.

not biodegradable under environmental conditions, but indi-

3.1.12 pre-condition, n—the pre-incubation of an inoculum

cates that further testing needs to be carried out in order to

under the conditions of the test in the absence of the test

establish biodegradability.

material.

5.3 Information on the toxicity of the test material to the

3.1.13 supernatant, n—the liquid above settled solids.

inoculum may be useful in the interpretation of low biodegra-

3.1.14 suspended solids (of activated sludge or other inocu-

dation results.

lum samples), n—solids present in activated sludge or inocu-

5.4 Activated sewage-sludge from a sewage treatment plant

lum samples that are not removed by settling under specified

that principally treats domestic waste may be used as an

conditions.

aerobic inoculum. An inoculum derived from soil or natural

3.1.15 theoretical carbon dioxide (ThCO ), n—the amount

surface waters, or any combination of the three sources, may

of CO which could theoretically be produced from the

also be used in this test method.

complete biological oxidation of all of the carbon in a test

NOTE 1—Allowance for various and multiple inoculum sources pro-

material.

vides access to a greater diversity of biochemical competency and

3.1.16 ultimate biodegradation, n—degradation achieved

potentially represents more accurately the capacity for biodegradation.

when the test material is totally utilized by microorganisms

5.5 A reference or control material known to biodegrade

resultingintheproductionofCO (andpossiblymethaneinthe

under the conditions of this test method is necessary in order to

case of anaerobic biodegradation), water, inorganic com-

verify the activity of the inoculum. The test method must be

pounds, and new microbial cellular constituents (biomass and

regarded as invalid and should be repeated using a fresh

secretions).

inoculum if the reference does not demonstrate biodegradation

3.1.17 ultimate biodegradation test, n—a test which esti-

to the extent of >60 % of the theoretical CO within 28 days.

mates the extent to which the carbon in a product has been

5.6 The water solubility or dispersibility of the lubricant or

converted to CO or methane, either directly by measuring the

components may influence the results obtained and hence the

production of CO or methane, or indirectly by measuring the

procedure may be limited to comparing lubricants or compo-

consumption of O .

nents with similar solubilities.

3.1.17.1 Discussion—The measurement of new biomass is

5.7 Theratioofcarbonincorporatedintocellularmaterialto

not attempted.

carbon metabolized to CO will vary depending on the organic

4. Summary of Test Method

substrate, on the particular microorganisms carrying out the

4.1 Biodegradation of a lubricant or the component(s) of a conversion, and on the environmental conditions under which

lubricant is estimated by collecting and measuring the CO the conversion takes place. In principle, this variability com-

produced when the lubricant or component is exposed to plicates the interpretation of the results from this test method.

microorganisms under controlled aerobic aquatic conditions. 5.8 The behavior of complex mixtures may not always be

This value is then compared to the theoretical amount of CO consistent with the individual properties of the components.

whichcouldbegeneratedifallofthecarboninthetestmaterial The biodegradability of the components may be suggestive of

were converted to CO . Carbon dioxide is a product of aerobic whether a mixture containing these components (that is, a fully

microbial metabolism of carbon-containing materials and so is formulated lubricant) is biodegradable but such information

a direct measure of the test material’s ultimate biodegradation. should be used judiciously.

D6139–00 (2005)

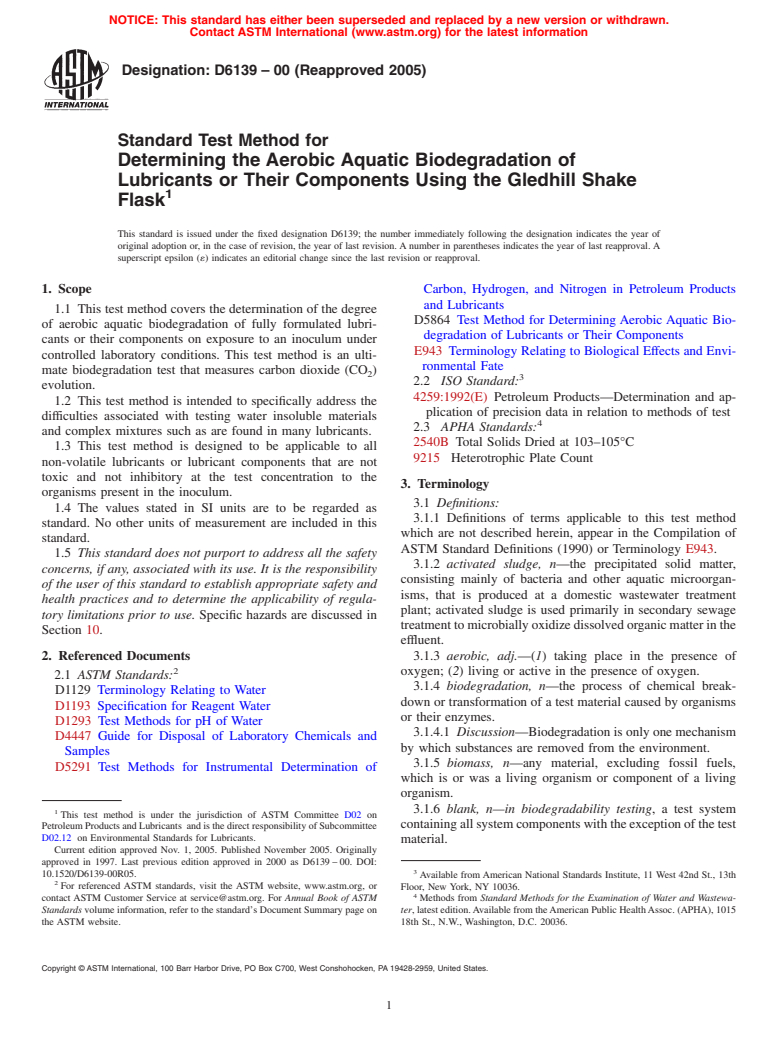

FIG. 1 NaOH Scrubber – Flask Trap Assembly for Providing CO -Free Air

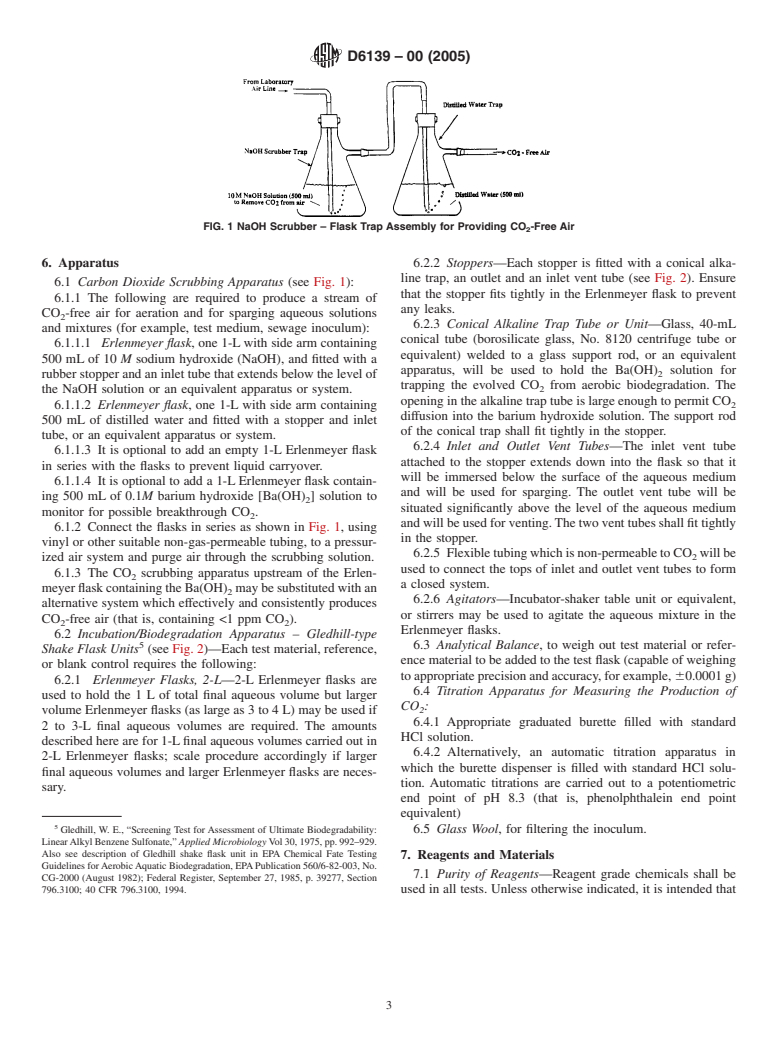

6. Apparatus 6.2.2 Stoppers—Each stopper is fitted with a conical alka-

line trap, an outlet and an inlet vent tube (see Fig. 2). Ensure

6.1 Carbon Dioxide Scrubbing Apparatus (see Fig. 1):

that the stopper fits tightly in the Erlenmeyer flask to prevent

6.1.1 The following are required to produce a stream of

any leaks.

CO -free air for aeration and for sparging aqueous solutions

6.2.3 Conical Alkaline Trap Tube or Unit—Glass, 40-mL

and mixtures (for example, test medium, sewage inoculum):

conical tube (borosilicate glass, No. 8120 centrifuge tube or

6.1.1.1 Erlenmeyer flask, one 1-L with side arm containing

equivalent) welded to a glass support rod, or an equivalent

500 mL of 10 M sodium hydroxide (NaOH), and fitted with a

apparatus, will be used to hold the Ba(OH) solution for

rubber stopper and an inlet tube that extends below the level of 2

trapping the evolved CO from aerobic biodegradation. The

the NaOH solution or an equivalent apparatus or system.

opening in the alkaline trap tube is large enough to permit CO

6.1.1.2 Erlenmeyer flask, one 1-L with side arm containing 2

diffusion into the barium hydroxide solution. The support rod

500 mL of distilled water and fitted with a stopper and inlet

of the conical trap shall fit tightly in the stopper.

tube, or an equivalent apparatus or system.

6.2.4 Inlet and Outlet Vent Tubes—The inlet vent tube

6.1.1.3 It is optional to add an empty 1-L Erlenmeyer flask

attached to the stopper extends down into the flask so that it

in series with the flasks to prevent liquid carryover.

will be immersed below the surface of the aqueous medium

6.1.1.4 It is optional to add a 1-L Erlenmeyer flask contain-

and will be used for sparging. The outlet vent tube will be

ing 500 mL of 0.1M barium hydroxide [Ba(OH) ] solution to

situated significantly above the level of the aqueous medium

monitor for possible breakthrough CO .

andwillbeusedforventing.Thetwoventtubesshallfittightly

6.1.2 Connect the flasks in series as shown in Fig. 1, using

in the stopper.

vinyl or other suitable non-gas-permeable tubing, to a pressur-

6.2.5 Flexibletubingwhichisnon-permeabletoCO willbe

ized air system and purge air through the scrubbing solution.

used to connect the tops of inlet and outlet vent tubes to form

6.1.3 The CO scrubbing apparatus upstream of the Erlen-

a closed system.

meyerflaskcontainingtheBa(OH) maybesubstitutedwithan

6.2.6 Agitators—Incubator-shaker table unit or equivalent,

alternative system which effectively and consistently produces

or stirrers may be used to agitate the aqueous mixture in the

CO -free air (that is, containing <1 ppm CO ).

2 2

Erlenmeyer flasks.

6.2 Incubation/Biodegradation Apparatus – Gledhill-type

6.3 Analytical Balance, to weigh out test material or refer-

Shake Flask Units (see Fig. 2)—Each test material, reference,

ence material to be added to the test flask (capable of weighing

or blank control requires the following:

toappropriateprecisionandaccuracy,forexample, 60.0001g)

6.2.1 Erlenmeyer Flasks, 2-L—2-L Erlenmeyer flasks are

6.4 Titration Apparatus for Measuring the Production of

used to hold the 1 L of total final aqueous volume but larger

CO :

volume Erlenmeyer flasks (as large as 3 to 4 L) may be used if

6.4.1 Appropriate graduated burette filled with standard

2 to 3-L final aqueous volumes are required. The amounts

HCl solution.

described here are for 1-Lfinal aqueous volumes carried out in

6.4.2 Alternatively, an automatic titration apparatus in

2-L Erlenmeyer flasks; scale procedure accordingly if larger

which the burette dispenser is filled with standard HCl solu-

final aqueous volumes and larger Erlenmeyer flasks are neces-

tion. Automatic titrations are carried out to a potentiometric

sary.

end point of pH 8.3 (that is, phenolphthalein end point

equivalent)

Gledhill, W. E., “Screening Test for Assessment of Ultimate Biodegradability: 6.5 Glass Wool, for filtering the ino

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.